Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista ALCONPAT

On-line version ISSN 2007-6835

Rev. ALCONPAT vol.6 n.1 Mérida Jan./Apr. 2016

Applied research articles

Material and casting methodology for SCC and HPC (70 MPa) concrete foundation blocks

2Universidad de São Paulo, USP & PhD Engenharia.

The Brookfield Century Plaza Commercial Building, located in Alphaville District, in São Paulo, Brazil, was designed to be supported by two direct foundation concrete blocks. A high strength (70 MPa), self-compacting concrete SCC was developed for these two massive foundation blocks (each one measures 28.4m x 18.6m x 4.5m). A numerical model by employing a FEM software was developed to predict the thermal hydration gain of different casting procedures, to establish the most appropriate one to meet the construction and schedule requirements without cracks. Directions to control concrete production at mixing plant and placing at construction site were established as well as supervised. Finally, internal concrete temperatures were recorded to enable a better model calibration.

Keywords: high strength concrete; self-compacting concrete; concrete modelling; refrigerated concrete production

El Edificio Comercial Brookfield Century Plaza, localizado en Alphaville, São Paulo, Brasil, se proyectó apoyado por dos grandes zapatas de hormigón. Un hormigón de alta resistencia (70 MPa) y autocompactante (SCC) fue desarrollado para estas zapatas de grandes dimensiones (cada una mide 28.4m x 18.6m x 4.5m). Un modelo numérico utilizando un software FEM se desarrolló para predecir la ganancia térmica de hidratación de diferentes capas de hormigonado con el fin de establecer el procedimiento más adecuado para atender los requisitos de tiempo y de construcción, sin que aparezcan fisuras. Se establecieron y supervisaron procedimientos para controlar la producción del hormigón en la empresa productora del mismo y durante el hormigonado. Finalmente, se registró la temperatura interna del hormigón para permitir una mejor calibración del modelo.

Palabras clave: hormigón de alta resistencia; hormigón autocompactante; hormigón en masa; producción de hormigón refrigerado

O Edifício Comercial Brookfield Century Plaza, localizado em Alphaville, São Paulo, Brasil, foi projetado para ser apoiado em dois grandes blocos de concreto. Um concreto de alta resistência (70 MPa) e SCC auto adensável foi desenvolvido para estes dois blocos maciços de fundação (cada um medindo 28.4m x 18.6m por 4.5m de altura). Um modelo numérico empregando um software FEM foi desenvolvido para prever o ganho de hidratação térmica de diferentes camadas de concretagem, a fim de estabelecer o procedimento mais adequado para cumprir o cronograma e os requisitos de construção, sem fissurar. Diretrizes para controlar a produção do concreto na empresa de serviços de concretagem e procedimentos de como aplicá-lo no canteiro de obras foram estabelecidas e supervisionadas. Finalmente, as temperaturas internas do concreto foram registradas para permitir uma melhor calibração do modelo.

Palavras-chave: Concreto de alta resistência; concreto auto adensável; modelagem de concreto massa; produção de concreto refrigerado

1. INTRODUCTION

The Brookfield Century Plaza Commercial Building (Figure 1), located in Alphaville District, in São Paulo, Brazil, was designed to be supported by two direct foundation concrete blocks. Each one measures 28.4m x 18.6m by 4.5m, high (which represents about 2,400m³ or 3,000yd³ of concrete) and has 200t of reinforcing steel. The concrete compressive strength ( f ck ) at 28 days, was specified as f ck ≥ 70 MPa (10,000psi).

Figure 1. Illustrated perspective of the Brookfield Century Plaza Commercial Building (http://www.br.brookfield.com/).

The scope of this paper consisted in describing office and field procedures to achieve the best construction of these large high strength concrete blocks including: designing a concrete mix to meet the specifications, developing thermal calculations of the hydration heat, establishing concrete production and placing procedures and supervising the field execution at site.

2. CONCEPT OF MASS CONCRETE

If compared to “conventional” concrete, mass concrete is distinguished by the difficulty of dissipating the heat originated by the exothermic hydration reactions and the resultant volume variation, which requires special measures of control in order to minimize the cracking (ACI, 2005; Mehta and Monteiro, 2014; Isaia, 2011).

Portland cement hydration is an exothermic reaction, which releases thermal energy within the concrete mass after setting. The heat released to the exterior medium is influenced by the thermal characteristics of the employed materials, by environmental conditions and by the structure dimensions.

Concrete, by its thermal expansion coefficient, undergoes expansive dimensional variations when exposed to temperatures resulting from this chemical exothermic reaction. In the beginning, during first ages, it expands quickly generating compression tensions, as main exothermic reactions occur in the first ages, about 50h-120h after casting.

When concrete cools back to ambient temperature, which occurs irregularly and from the exterior to the interior creating important thermal gradients, it will be submitted to a thermal contraction. This contraction, due to natural restrictions arisen by friction or geometry constraints, produces stresses that may be higher than the concrete tensile strength, resulting into cracks on the structural members (ACI, 2005; Furnas, 2007).

In this regard, it is understood that, for the conception of structural elements involving mass concrete, such as the foundation blocks focus of this article, special care need to be taken, regarding the proportions of concrete [for example, with the least cement (clinker) content, use or not ice and cold water, use or not supplementary materials as slag, fly ash and metakaolin], efficient thermal simulation (able to inform whether or not to cast in more than one layer, as well as providing input for the preparation of a detailed plan of casting), the appropriate executive procedure (able to provide guidelines to control the maximum temperature of the concrete and other important parameters) and also the specialized technical supervision of concrete events in order to minimize potential future pathological manifestations.

3. CONCRETE MIX DESIGN

The concrete mix design for this particular task was developed with extensive studies in laboratory and field. The mix proportions were based on the guidelines of IBRACON mix design method (Tutikian and Helene, 2011), on the available inputs, the site particularities and in accordance with the requirements of the ABNT NBR 12655:2006 (ABNT, 2006) and ACI 237R-07 (ACI, 2007), as well as the specifications of the structural design, oriented by two main goals to be achieved:

As expected, a 70 MPa (10,000psi), 2,400m³ (3,000yd³) concrete block should produce quite high temperature during setting, so it was necessary to design a concrete capable of reducing hydration heat to a minimum,

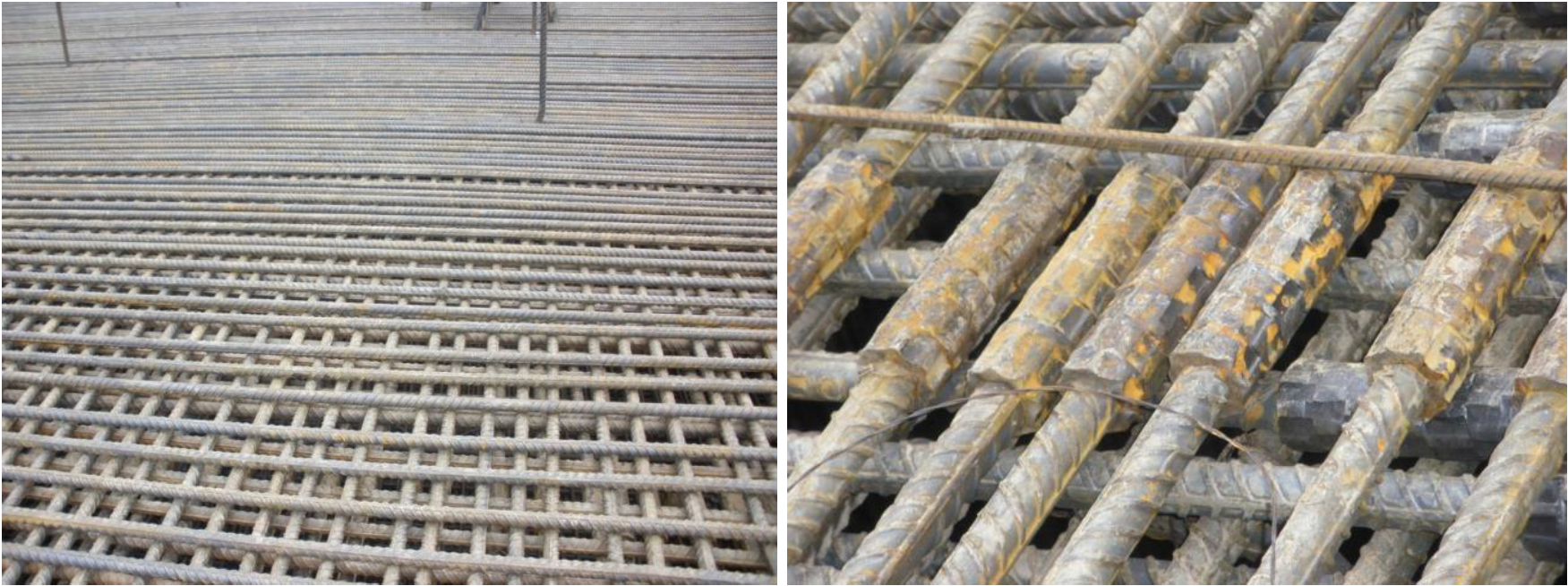

After analyzing the structural design drawings and discovering that reinforcing bars in some places were quite dense, it was necessary to choose a placing method capable of avoiding anomalies such as voids or honeycombs.

For these reasons, it was decided to replace all mixing water by ice and to use CP III 40 (50%-70% slag) and metakaolin HP in the concrete mixture (aiming to reduce hydration heat), as well as to employ self-compacting concrete, SCC, in order to speed up placing and avoid placing errors.

The concrete mix design was done at laboratory facility at São Paulo City. Different mixes were developed, with different proportions of mortar (Figure 2). For each mix, fresh concrete properties as entrapped air content, specific gravity and flow were measured, and three specimens were cast, to be tested at 3, 7 and 28 days, in order to verify their compressive strength, as shown in Figures 3 and 4, below.

The final mix that satisfied all needed characteristics was obtained with the concrete proportions shown in Table 1.

Table 1. SCC proportions for application in Brookfield Century Plaza foundation blocks.

| f ck ≥ 70 MPa (10,000psi) and water/binder ratio = 0.36 | |

|---|---|

| Cement (CP III 40 Mizú) | 447kg (313kg of slag + 134kg of clinker) |

| Metakaolin HP | 38kg |

| Artificial sand (crushed) | 481kg |

| Natural sand (river, quartz) | 321kg |

| Crushed stone 9-19mm | 194kg |

| Crushed stone 19-25mm | 777kg |

| Total water (ice + aggregates humidity) | 175L |

| Sikament 735 Plasticizer Additive(0.5% by cement mass) | 2.2L |

| Sika 5700 Superplasticizer Additive (1% by cement mass) | 4.6L |

4. THERMAL STUDY

The thermal study was done with b4cast 3.0 software, which employs the maturity method (calculated by the equation of Arrhenius) as described in ASTM C 1074-04 (ASTM, 2004). This software is based on the Finite Elements Method FEM and it is able to simulate the temperature history of the structural element to be cast and the stresses arising from temperature differences inside the element. To estimate tensile strength, the equation (1) was employed, as prescribed by Brazilian concrete standard.

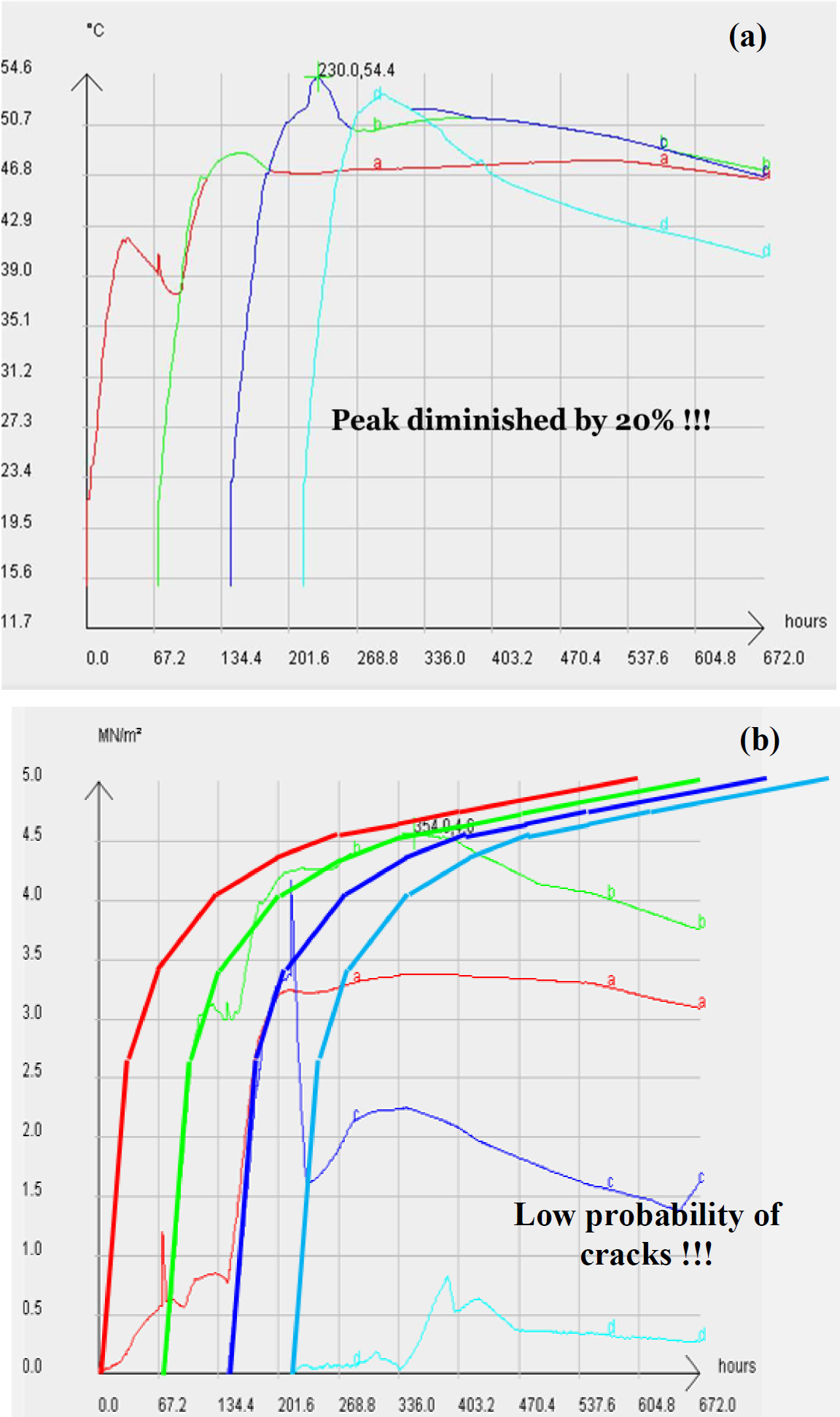

Several simulations were done exploring different casting strategies. The Contractor wanted to investigate the possibility of casting the whole block in just one or two casts, which proved to be impossible, as internal tensile stresses would be higher than actual concrete tensile strength. As a result of simulations considering one or two casts, it was decided to investigate the behavior of temperatures and stresses by casting the block into 4 layers, 1,125m high each, with a gap of 3 days between casts. The temperature peak diminished from 64,6ºC to 54,0ºC, a 20% reduction. Tensile stresses also diminished and were very close to tensile strength evolution, which implies in a low possibility of cracks due to thermal stresses (Figure 5).

5. CONCRETE PRODUCTION AND CASTING PROCEDURES

The recommended procedures for casting of the foundation blocks were based on provisions of current national standardization (ABNT, 2004; ACI, 2010) and engineering good practices (Kosmatka and Wilson, 2011; Kennedy, 2005).

In order to ensure that concrete production at batching plant and casting at site would maintain the quality standards and specified characteristics, procedures (Table 2) were designed for site casting, to be followed by the Concrete Ready-mix Company, by the Contractor team at site and by the Concrete Quality Control Laboratory.

Table 2. Concrete production and casting procedures.

| Proposed control and intervener | Procedures which should be followed |

|---|---|

| Concrete production control at Batching Plant. Responsible: Concrete Ready-mix Company and Concrete Quality Control Laboratory | Coarse aggregate should be water-sprayed; |

| Aggregates and cement temperatures should be measured, aggregates should be below 25oC and concrete below 70oC; | |

| All mixing water should be substituted by ice; | |

| Ice bags should be weighted to determine their mean weight; | |

| Sand humidity contents should be measured; | |

| Each mixer truck should be loaded with only 6m3, and additives should be already mixed at batch plant; | |

| A constant flux of mixer trucks should be established. | |

| Casting Control at site. Responsible: Concrete Quality Control Laboratory | Concrete temperature should be measured, and it should be ≤ 20oC; |

| Concrete flow should be measured; | |

| Test specimens should be cast for compressive strength and diametrical tensile tests; | |

| Temperature at defined points in each concrete layer of the foundation block should be recorded by thermocouples, at pre-established times. | |

| Casting recommendations. Responsible: Contractor | Formwork and reinforcement in place, bottom layer cleaned, water table depression in operation, storm water drains/dikes already in place; |

| Concrete pumps in place for each block(three); | |

| Preparing of concrete surface between layers to avoid “cold” joints; | |

| Concrete curing and cleansing of joint surfaces. |

It is very important to stress the fact that, in order that concrete arrives to the site at less than 20oC, a strict and periodical control of sand humidity and of the actual weight of ice that was being loaded in each mixer truck should be conducted. As in Brazil ice is normally sold in nominal 20kg bags, the mean weight of one bag should be averaged very frequently, to ensure that the stipulated water amount was effectively added to the mix.

6. TECHNICAL SUPERVISION

The concrete production and casting procedures were supervised at site, in order to ensure that the recommendations were followed and also to correct any deviation that could occur or to give technical support in specific occasions.

6.1. Supervision at the Batching Plant

At the batching plant of Concrete Ready-mix Company, situated at 20 min. drive from the site, the temperatures of cement and aggregates were checked at different hours during the day. Cement temperature never surpassed 50oC. Water was sprayed over the aggregates (Figure 6), because in the afternoon the ambient temperature raised up to 30oC. Water spraying kept aggregate temperature below 25oC (Figure 7).

Figure 7. Register of coarse aggregate’s temperature before and after the being water-sprayed at Ready-mix Company batching plant.

The number of ice bags was determined by measuring the sand humidity contents and then calculating the mean weight of ice bags. As temperature rose, ice could melt more quickly, forcing new measurements.

A movable platform was installed at the rear of the ice truck and the specified number of ice bags was loaded into the mixer truck. A technician from the Concrete Quality Control Laboratory verified the number of bags for each load.

6.2. Supervision at the site. Concrete temperature and flow

When concrete arrived at the site, its temperature was controlled. If greater than 20oC, the concrete was rejected. Mean temperature was lesser than 18oC (Figure 8).

Figure 8. Fresh concrete temperature was controlled for each mixer truck by means of an immersion digital thermometer (example: 13.2ºC).

If concrete temperature was within specification, then the concrete flow was measured. Concrete flow should be within the 600mm - 750mm range and should not be segregated, to be accepted. Flow measurements should be the mean of three different diametric measures, and were performed by the Concrete Quality Control Laboratory (Figure 9).

6.3. Supervision at the site - Temperature history of hardening concrete

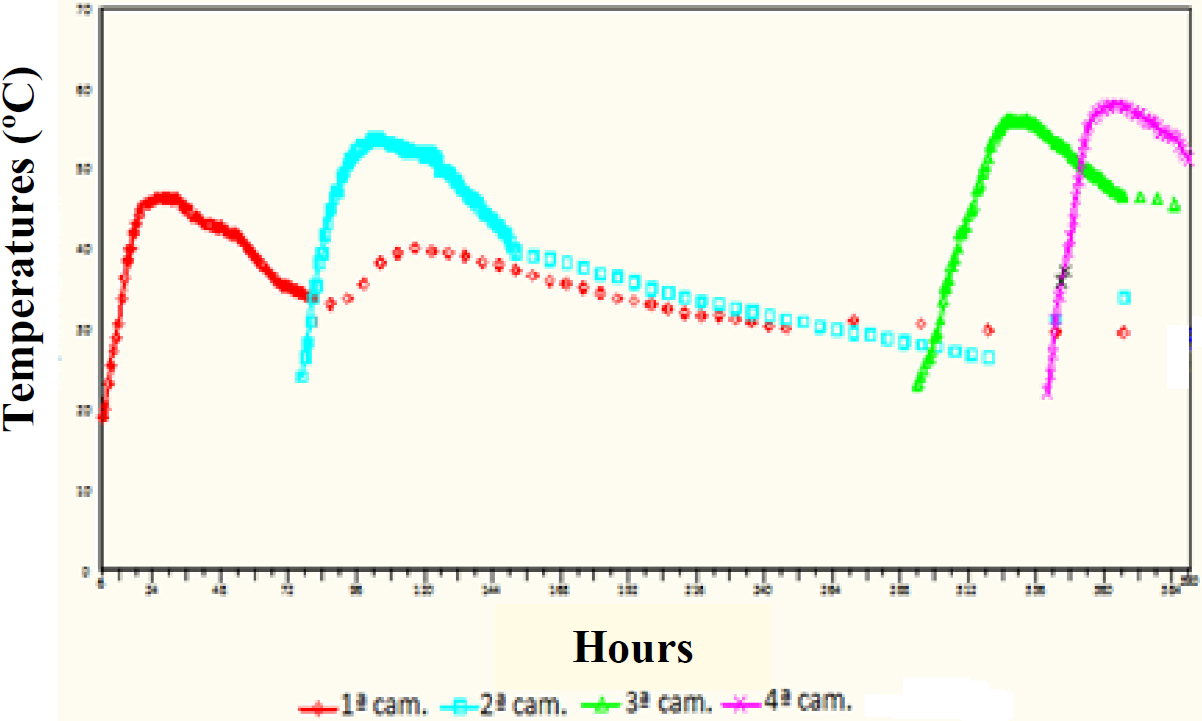

To register the temperature history of hardening concrete, 12 thermocouples were installed by the Concrete Quality Control Laboratory at three points and at the middle height of each casting layer. The time intervals when temperature data should be collected were also given. The results were recorded for posterior analysis and thermal model calibration.

6.4. Supervision at the site - Concrete pump positioning and casting procedure

The concrete pumps positioning and the casting sequence were discussed together with the Contractor technical team. Three pumps were used (Figure 10). Concrete should be deposited in uniform sub-layers, with approximately 0,3m high beginning at the entrance side with pump Nº.1 and proceeding towards the rear with pumps Nº. 2 and 3.

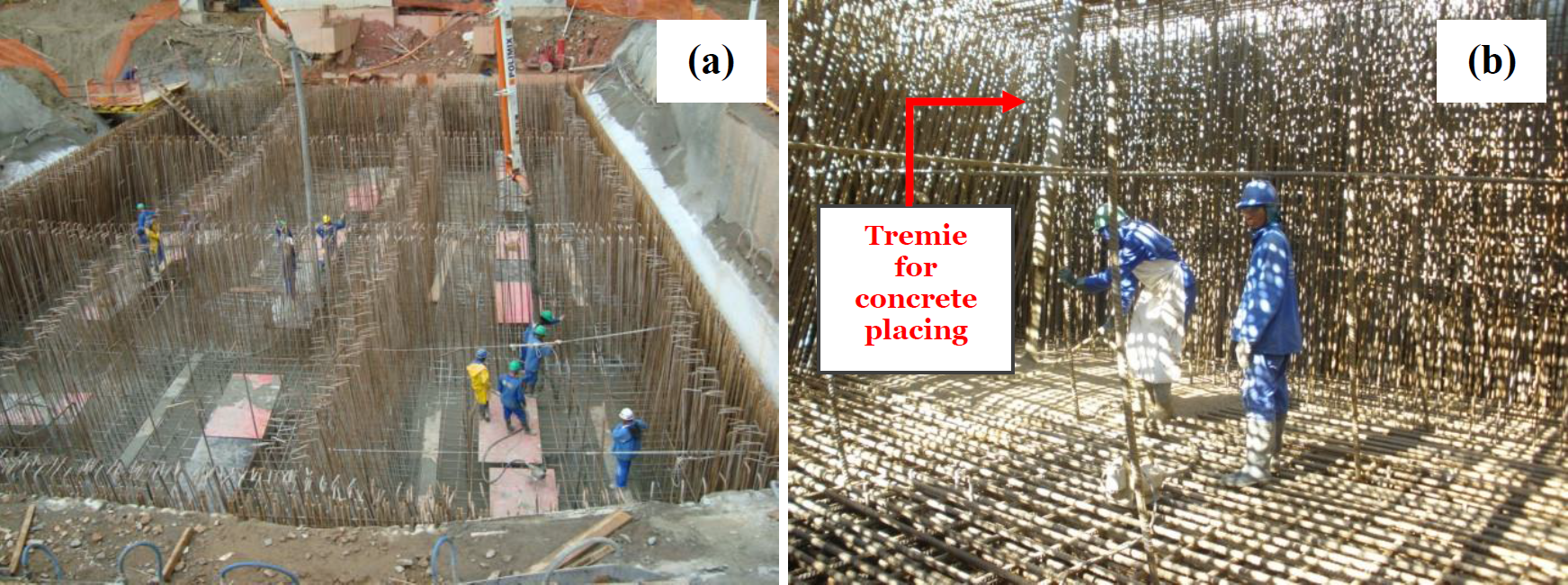

The described casting sequence was employed for all layers. The first two were cast without the superior reinforcement (Figure 11a). After finishing each cast, the surface was prepared to get the necessary roughness to promote a better adherence for the subsequent layer. Concrete curing begun immediately after, by creating a pond over the whole surface. Prior to concrete casting, the surface was drained and cleaned by water jets. Concrete was deposited on the saturated surface. After finishing the second layer, the reinforcement for columns and the superior reinforcement were placed and concrete was poured by tremies (Figures 11b and 12).

Figure 11. (a) Casting of the second layer without superior reinforcement and (b) placing of concrete after all reinforcement was put in place.

7. RESULTS

7.1 Technological control

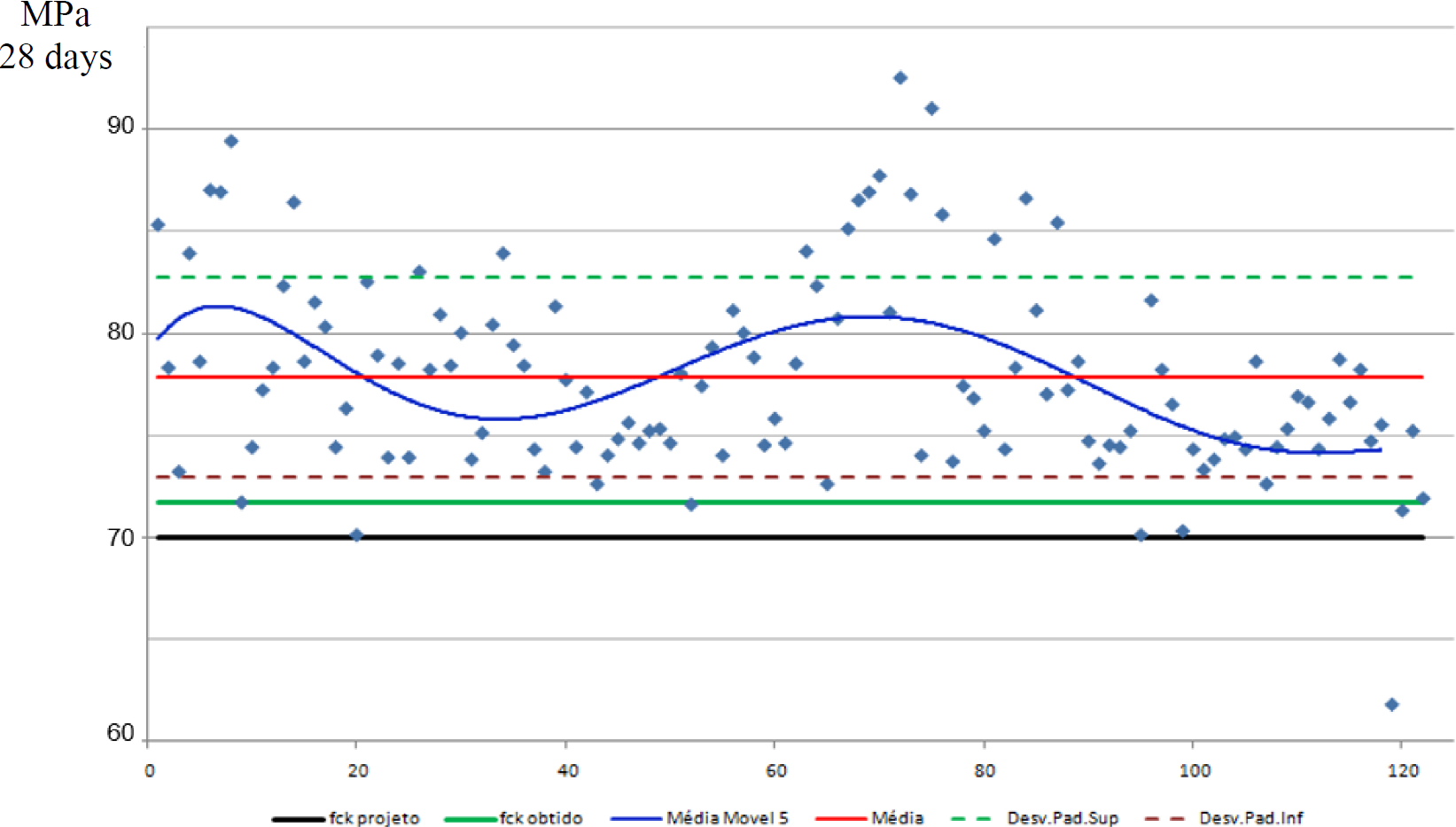

With regard to the technological control of the concrete compressive strength tests were performed on the total sample (in 100% of mixer trucks) at 7, 28 and 63days age. Most of the results met the requirements of specified compressive strength (f ck ≥ 70 MPa) and specified in the structural design. The compressive strength results corresponding to one of the concrete layers at 28days age are shown graphically in Figure 13.

Besides, self-compacting concrete proved to work very well at site, speeding up concrete casting: the mean time needed to pump a 6m³ mixer truck averages 15 minutes (including acceptance tests), and there was almost no need of vibrating.

7.2 Measured temperatures inside the foundation blocks

Actual concrete temperatures were recorded. The temperature peak, 57oC, was reached in the fourth layer after 582h. As it can be seen from the chart, time gap between castings were changed at site to better suit construction production. Instead of 3, 3, and 3 day gaps, 3, 10, and 2 were done, which lead to temperatures differing by no more than 10% (Figure 15).

8. CONCLUSIONS

This article aimed to demonstrate that the previous development of mix design laboratory studies and thermal simulations, as well as the proposition of rigorous executive procedures and, especially, the control and technical supervision of concrete events, were determining factors for promoting a structural element with integrity and in accordance with design specifications.

So, as a final mention, it was observed that the assumptions noted in this article, both theoretical (prior to the concreting) and practical (during and after concreting), made possible a satisfactory result, revealing to be powerful tools for planning and executing challenging and technically complex concrete structures, such as those involving mass concrete.

9. ACKNOWLEDGEMENTS

The authors recognize and appreciate the support and collaboration of the companies involved in this case, as follows: Brookfield S.A. (Contractor), Polimix Concreto Ltda. (Concrete Ready-mix Company), Pasqua & Graziano Consultoria, Concepção Estrutural e Projetos (Structural Designer) and Falcão Bauer (Concrete Quality Control Laboratory).

REFERENCES

American Concrete Institute (2005), “ACI 207.1R-05: Guide to Mass Concrete”, (Farmington Hills, U.S.: ACI). [ Links ]

American Concrete Institute (2007), “ACI 237R-07: Self-Consolidating Concrete”, (Farmington Hills, U.S.: ACI ). [ Links ]

American Concrete Institute (2010), “ACI 301-10: Specifications for Structural Concrete”, (Farmington Hills, U.S.: ACI ). [ Links ]

American Society for Testing and Materials (2011), “ASTM-C 1074: Standard Practice for Estimating Concrete Strength by the Maturity Method”, (West Conshohocken, U.S.: ASTM International). [ Links ]

Associação Brasileira de Normas Técnicas (2006), “NBR 12655: Concreto de cimento Portland - Preparo, controle e recebimento - Procedimento”, (Rio de Janeiro, Brazil: ABNT). [ Links ]

Associação Brasileira de Normas Técnicas (2004), “NBR 14931: Execução de estruturas de concreto - Procedimento”, (Rio de Janeiro, Brazil: ABNT ). [ Links ]

Furnas. Laboratório de Concreto; Andrade, W. P. (Ed.). (1997), “Concretos: massa, estrutural, projetado e compactado com rolo - ensaios e propriedades”, (São Paulo, Brazil: PINI). 1v. [ Links ]

Isaia, G. C. (Ed.). (2011), “Concreto: Ciência e tecnologia”, (São Paulo, Brazil: IBRACON). 2v. [ Links ]

Kennedy, Lindsay K. (Ed). (2005), “The Contractor's Guide to Quality Concrete Construction”, (St. Louis, U.S.: American Society of Concrete Contractors - ASCC). 3ed. [ Links ]

Kosmatka, Steven H.; Wilson, Michelle L. (2011), “Design and control of concrete mixtures”, (Illinois, U. S.: Portland Cement Association - PCA). 15ed. [ Links ]

Mehta, P. K; Monteiro, J. M. (2014), “Concreto: Microestrutura, Propriedades e Materiais”, (São Paulo, Brazil: IBRACON ). 2ed. [ Links ]

Tutikian, Bernardo; Helene, Paulo (2011), Dosagem dos Concretos de Cimento Portland. In: Geraldo C. Isaia. (Org.). “Concreto: Ciência e Tecnologia ”, 1 ed. São Paulo: Ibracon, v. 1, p. 415-451. [ Links ]

Received: November 30, 2015; Accepted: January 20, 2016

text in

text in