Introduction

Fruit dehydration is a widely used technique to extend shelf life, minimize waste, and preserve nutritional quality. The primary objective of food dehydration is to reduce its moisture content. This inhibits enzymatic activity and limits microbial growth in food. The key variables influencing moisture removal are exposure time, temperature, slice size, and orientation. The desired moisture level is determined by the type of final product and the food regulations of each country or customer (Monsalve, 2007). However, conventional dehydration methods frequently rely on subjective observation and decision-making, leading to inconsistent results (Madhankumar, 2023). External factors such as environmental exposure, pollution, and animal interference can further compromise product quality. Additionally, prolonged drying times pose economic challenges (Espinosa, 2023). Consequently, automated machines with specific quality control measures have been developed to mitigate these issues.

The global food market is shifting toward sustainability and health-conscious products. A significant proportion of this trend is represented by the consumption of dehydrated foods, particularly in the United States and Europe (Mordor Intelligence, n.d.). Interestingly, most dried and dehydrated products are not consumed directly but rather find their way into various indirect consumer markets (Doymaz, 2007). Dehydrated ingredients are commonly found in instant soups, sauces, teas, and various processed foods. Even frozen meals, whole-grain breakfast snacks, and trail mixes often incorporate dehydrated ingredients. Food security is a major concern worldwide, as approximately one-third of global food production (around 1.3 billion tons of food) is lost annually due to inadequate processing (Gustavsson, 2011). Food waste not only represents the loss of food itself but also the squandering of resources utilized in its production, such as land, water, energy, and labor. Furthermore, wasted food contributes to massive carbon emissions, which are a major driver of the current global warming crisis (Gustavsson, 2011). Therefore, proper food processing must be emphasized to reduce this massive loss, promote food security, mitigate global warming, and combat hunger. Drying or dehydration is a food preservation method that inhibits the growth of bacteria, yeasts, and molds through the removal of water (Gustavsson, 2011) (Sengkhamparn, 2019) (Sullivan, 2020) .

The Mexican government’s 18-24 work agenda emphasize food self-sufficiency, aiming to increase domestic production of grain (corn, beans, wheat, and rice) as well as livestock products (milk, beef, pork, chicken and fish) (Secretaría de Agricultura y Desarrollo Rural, 2024) This production includes the storage and transportation of food, so the correct dehydration can help solve this problem. A major contributor to food loss within the industrial production chain is inadequate storage and limited shelf life. Many products, particularly fruits, are not subjected to proper dehydration protocols. This results in postharvest losses of up to 28%, driving up retail costs, and negatively impacting the global economy (Anaya, 2017).

On the other hand, ANNs are emerging as a powerful predictive modeling tool within the field of food science, demonstrating increasing significance in addressing complex challenges and optimizing various processes (Florez, 2008) (Khan, 2022). Technology has made tremendous strides, and artificial intelligence (AI) has aided numerous scientific fields by tackling problems that were once considered insurmountable (Alaloul, 2020). One application of artificial intelligence leverages ANNs to estimate calculations that are often time-consuming or, as in the case of fruit drying, necessitate laborious, exhaustive, and expensive experimental setups (Benítez, 2014).

This paper focuses on presenting a straightforward methodology for utilizing artificial intelligence (AI) as a tool in the fruit dehydration process with a simple neural network model, employing relative humidity measurements in an instructive manner that is easily reproducible. The methodology encompasses data collection through model development, with the overarching goal of enabling future implementation of this model within a dehydrator to enhance product quality, facilitate automation, and potentially reduce energy consumption. Additionally, results from dehydration experiments conducted at varying temperatures and fruit thicknesses are discussed, along with their impact on organoleptic and nutritional properties.

Materials

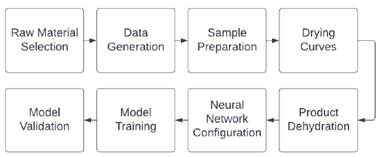

The general methodology for the treatment of tomato samples (Gómez, 2019) has the following steps:

Raw Material Selection: This process aimed to obtain tomatoes with uniform color and shape. Fresh saladette tomatoes (solanum lycopersicum), procured from a local supermarket, were selected as the raw material. The chosen tomatoes exhibited a vibrant red color, were free of surface blemishes, and displayed visual indicators of optimal ripeness. Additionally, they were visually assessed to be of uniform size. In preparation for processing, each tomato was thoroughly washed with soap and water to remove any adhering particulate matter, followed by disinfection with a bactericidal agent.

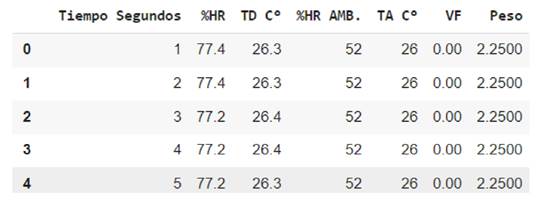

Data generation: An industrial air convection oven was rented, equipped with internal temperature sensors and a humidity sensor at the outlet. Data was transmitted to a computer, which recorded the information used for training the neural network. The temperature recorded corresponded to the interior of the oven, and the humidity was measured as relative humidity at the oven’s exit. The oven was equipped with a thermocouple with an accuracy of ±0.5°C for temperature sensing, an anemometer with an accuracy of ±0.1 m/s to measure air velocity, and a capacitive sensor with an accuracy of ±3% RH for monitoring relative humidity. The oven’s core incorporated a microcontroller that received data from these sensors and regulated both the temperature and air velocity generated by electric heaters and fans. Due to rental conditions, further technical details could not be disclosed.

Tomatoes sample preparation: Three groups of saladette tomatoes (Solanum lycopersicum), each weighing 1 kilogram (for a total of 3 kilograms), were used. Each group was dried at a different temperature: 45°C, 50°C, and 55°C. Each kilogram was then divided into three subgroups with different slice thicknesses: 0.75 mm, 1.5 mm, and 3 mm.

A digital caliper was used to verify slice thickness, and a measuring tape confirmed the dimensions of each slice. To ensure consistent and uniform slices, a mandoline with adjustable thickness was used.

Obtaining drying data.: Each of the three groups of one kilogram was dried at the three distinct temperatures mentioned above (45°C, 50°C, and 55°C). The drying process continued until the relative humidity (%RH) at the oven’s exit reached between 16% and 20%. The final dataset was then randomly partitioned into two halves, each containing input and output vectors. The first half was designated as the training dataset, while the second half served as the testing dataset. The training dataset was utilized to train the model, while the testing dataset validated the trained model by comparing predicted outputs against actual data, assessing the model's accuracy and generalization capabilities. (Please see appendix A)

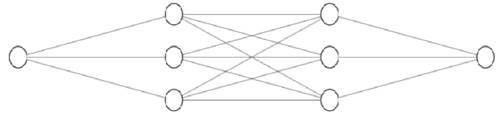

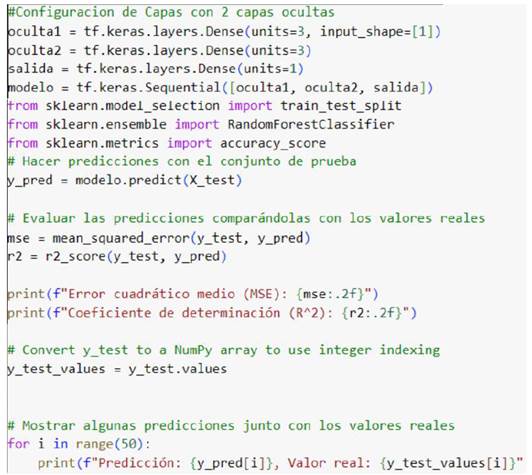

Artificial neural network configuration: The neural network architecture consisted of an input layer with a single neuron, followed by two hidden layers with three neurons each, and an output layer with a varying number of neurons, depending on the specific task (Fuentes G., 2023).

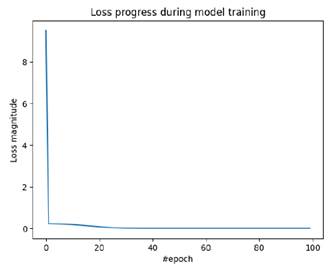

Obtaining the model through the Neural Network: The neural network training used the dataset described in the previous step, which was employed to estimate the model parameters corresponding to the underlying equation. Upon completion of training, the trend of the loss function over time was observed as the model minimized error, ultimately converging to a final loss value close to zero.

Weight Change Calculation Equation: The equation used to calculate the proportion of weight change with respect to relative humidity during the dehydration process took into account the relative humidity of the material:

As:

i. ∆w = |

proportion of weight change |

ii. w i = |

initial weight |

iii. ∆%HR = |

relative humidity percentage during a dehydration process |

iv. H d = |

desired humidity in product |

This equation assumed that weight loss was primarily due to water removal, with negligible contributions from other factors, such as the loss of volatile compounds. Additionally, it assumed a linear relationship between moisture loss and weight change (Fuentes G., 2023). While this equation did not directly calculate weight change, it effectively targeted a relative humidity level of 16% in tomatoes, a commonly used benchmark in food processing. (Fuentes G., 2023).

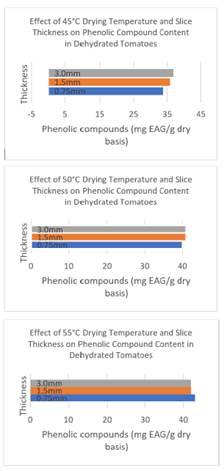

Quantification of Phenolic Compounds: To evaluate the effect of dehydration temperature and slice thickness on nutrient content, a quantification of phenolic compounds was conducted. Phenolic compounds in tomatoes encompass various phytochemicals, including flavonoids, phenolic acids, and tannins, which are vital for plant physiology and defense, as well as for human health due to their antioxidant and anti-inflammatory properties. The concentration of phenolic compounds was quantified in terms of gallic acid equivalents (mg GAE/g dry basis) using a gallic acid calibration curve. Tests were outsourced to a certified private laboratory for accuracy. Following the experimental setup described in Section 2, a total of 3 kg of tomatoes were prepared for dehydration. Each kilogram was dehydrated at different temperatures and subdivided into three groups based on slice thickness (0.75 mm, 1.5 mm, and 3 mm), as shown in Table 1.

Table 1 Process Parameters for Tomato Dehydration Trials

| Temperature (ͦ C) | Sample thickness | Time (seconds) | Time (Hours) | %Relative humidity (%HR) |

|---|---|---|---|---|

| 45 | 0.75 | 6650 | 1.84 | 20.7 |

| 45 | 1.5 | 7100 | 1.97 | 20.4 |

| 45 | 3.0 | 7873 | 2.20 | 19.6 |

| 50 | 0.75 | 6784 | 1.84 | 16.9 |

| 50 | 1.5 | 7050 | 2.00 | 16.6 |

| 50 | 3.0 | 7334 | 2.03 | 15.9 |

| 55 | 0.75 | 5650 | 1.56 | 17.5 |

| 55 | 1.5 | 6500 | 1.80 | 16.9 |

| 55 | 3.0 | 7196 | 1.90 | 16.40 |

Source: Own Elaboration

Sensory Panel Evaluation: A sensory panel was conducted to assess texture, aroma, color, and flavor. This panel consisted of five experts, all professionals with substantial experience in food-related fields, including chefs and food industry specialists.

The sensory panel followed a structured protocol in a controlled setting. Participants were seated in individual tasting booths under neutral lighting to minimize visual biases. Each expert received standardized evaluation sheets to record their perceptions, which included the following:

Hedonic Scale: Experts rated the overall acceptability on a 5-point scale (1 = ‘strong dislike’, 5 = ‘strong preference’).

Texture Profile Test: A texture profile test was conducted to evaluate key textural attributes: hardness, chewiness, and elasticity. These attributes were rated on a 5-point scale, with 1 representing "does not meet the attribute" and 5 indicating "fully meets the texture attribute."

Quantitative Descriptive Analysis (QDA): Experts assessed the intensity of key sensory attributes, including sweetness, acidity, and tomato flavor. Each attribute was rated on a 5-point numerical scale, where 1 signified "does not possess the attribute" and 5 represented "fully possesses the attribute."

Results

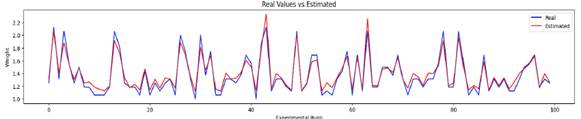

Verification of the artificial neural network training: As shown in Figure 7, the time evolution of the model's estimated data closely aligns with the real data. The mean squared error between these two datasets is 0.04.

Tomato dehydration organoleptic results: The visual outcomes of the tomato dehydration process are illustrated in Figures 8, where distinct differences in color among the three samples are evident. The images on the left correspond to samples dehydrated at lower temperatures. As reported in relevant literature, color is closely linked to the concentration of lycopene and other essential nutrients.

The panel's evaluation indicated that tomato samples dehydrated at 50°C, regardless of thickness, were the most favored. Samples dehydrated at 55°C were slightly less preferred, whereas those dehydrated at 45°C received the lowest scores. Figure 9 presents these results.

Source: Own Elaboration

Figure 9 Effect of Temperature (45, 50, 55 ͦ C) and Slice Thickness (0.75, 1.5, 3.0 mm)

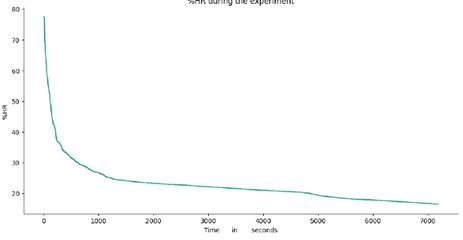

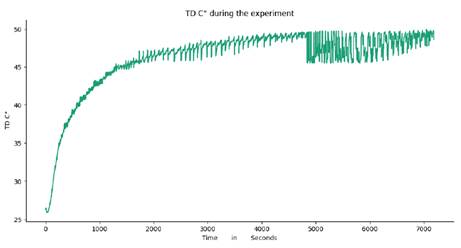

Behavior of Variables: Measurements of the variables were recorded every second. The collected data captures the temporal evolution of temperature, airflow at the oven’s outlet, and the relative humidity percentage of the product (Figures 10 -11). "TD" (Target Dryer Temperature) refers to the target temperature maintained within the dryer chamber throughout the dehydration process, measured in degrees Celsius (°C) (Figure 12).

Discussion

The primary goal of nutrition is to provide the body with the sustenance required for optimal growth and development. However, human culinary practices, driven by the pursuit of flavor and texture, often prioritize palatability over nutritional value (Degwale, 2022).

Fuentes (2023) presents a training model using the evolution of tomato weight over time. This methodology presents certain challenges, as temperature fluctuations occur during the process due to tomato weight measurements. The advantages of the present study lie in the indirect measurement of tomato humidity, ensuring compliance with the humidity and nutritional requirements demonstrated by laboratory results.

This research aims to identify the balance between nutrient content and sensory appeal, utilizing this data to train a neural network model. Studies by Degwale (2022), Yegrem (2022) and Umeohia (2024) focus on nutritional properties, exploring dehydration techniques, packaging, and other conditions to optimize nutrient retention in dehydrated tomatoes and other product. Most of this data is used to train artificial intelligence models for dehydration machines. However, no reports integrate organoleptic data into AI training to optimize its performance.

As observed in the temperature and thickness datasets, the impact on nutrient levels, though detectable, is not substantial but remains significant. This is significant as it indicates that despite variations in thickness and temperature, the nutritional composition remains relatively consistent with %HR as the principal goal, (remember that 16 % HR is the principal reference to the dehydration process). Concerning organoleptic properties, the diner's preference was to get samples at 50 degrees Celsius. With these results, the data for the artificial neural network training is selected and can be implemented in the oven and not using the weight data measurements through the process as (Fuentes G., 2023).

Future research could investigate the temporal evolution of the equipment's electric power consumption, incorporating relative humidity measurements alongside organoleptic and nutritional properties presented in this work. This multi-dimensional dataset could then be used to further refine and optimize the training process for an artificial neural network model to achieve not only the nutritional and industry requirements but also organoleptic properties, important for the diners’ consumers.

Conclusions

This research highlights the potential of artificial intelligence (AI), specifically using ANNs, to optimize the fruit dehydration process. By focusing on the critical parameter of relative humidity (%RH), the study demonstrates that it is possible to achieve consistent dehydration results while preserving nutritional content, even when varying factors such as temperature and slice thickness. The developed ANN model, trained on data collected from tomato dehydration experiments, accurately predicted the relationship between %RH and weight change, showcasing the efficacy of AI in modeling complex food processing dynamics. The findings further highlight the delicate balance between nutritional quality and sensory attributes in food processing. While higher dehydration temperatures might lead to faster processing times, they could also negatively impact nutrient levels and sensory appeal. The study's organoleptic tests revealed a preference for tomatoes dehydrated at 50°C, suggesting an optimal temperature range indicating an optimal temperature range that maintains both nutritional quality and sensory appeal. The integration of AI into food dehydration processes holds promising implications for the future. By enabling precise control over %RH and other critical parameters, AI can facilitate automation, enhance product quality, and potentially reduce energy consumption. The ability to predict and control dehydration outcomes based on real-time data can lead to significant advancements in food processing efficiency and sustainability.

Future research directions include expanding the scope of data collection to encompass the temporal evolution of dehydration equipment and incorporating measurements of %RH alongside organoleptic and nutritional properties. The resulting multi-dimensional datasets can be leveraged to refine ANN models further, enabling even more precise control and optimization of dehydration processes. The continued exploration of AI's potential in food science and technology is crucial for addressing the challenges of food security, sustainability, and nutritional quality in an ever-evolving global landscape.

Future research directions

Future research should focus on integrating artificial intelligence (AI) into embedded systems for real-time monitoring and autonomous control of the drying process, optimizing energy consumption and enhancing efficiency through microcontroller-based implementations. Additionally, expanding AI applications to the dehydration of other food products, such as mangoes, bananas, and chili peppers, will allow for comparative analyses of drying dynamics and nutrient retention across different food matrices. The incorporation of multidimensional data, including real-time measurements of temperature, humidity, color, and texture, will improve model accuracy, particularly through the use of advanced deep learning architectures such as recurrent neural networks (RNNs). Furthermore, the development of explainable AI (XAI) models will enhance interpretability and provide insights into key dehydration parameters, facilitating the implementation of hybrid approaches that combine neural networks with physical drying models. Lastly, the automation of the drying process using AI-driven control systems, coupled with computer vision for real-time quality assessment, holds significant potential to optimize both product quality and energy efficiency in industrial food processing.

nueva página del texto (beta)

nueva página del texto (beta)