1. Introduction

The experimental study of concrete structures under the action of high temperatures, requires a large amount of financial resources and a large proportions laboratory structure, which allows testing significant parts of a reinforced concrete structure with foundations, columns, beams and slabs, besides the interaction with sealing walls or structural masonry. This capacity does not exist yet worldwide neither in the scientific literature, there is only the record of the experiment carried out at the Cardington Laboratory (CHANA; PRICE, 2003).

Thus, the engineering, until today, has been content to extrapolate results obtained from test bodies and small structural elements, performed isolated and without loads many times, to with a lot of creativity create “models” that allows to predict the behavior of a structure facing a fire. Another significant difficulty is the fact that all the limited laboratory tests results, depend on a standard “fire” designed by a standard curve ISO 834 (1999) or ASTM E119 (2019), that most of times do not corresponds to a true fire.

Considering these limitations until now insurmountable, this paper, as well as others, for example the articles about Windsor Building fire in Madrid, which took place on 2005, researched por Alonso (2008) from IET (Eduardo Torroja Institute of Cement and Concrete) and Calavera Ruiz et al. (2005) from INTEMAC (Technical Institute of Materials & Constructions) and the report on the collapse of the World Trade Center Twin Towers, where studies culminated in changing the design standards of tall buildings (NIST, 2005), seek to study thoroughly the cases of true fires, in search of lessons that many times are no impossible from expensive and limited laboratory tests.

For the authors of this paper, the greatest contribution is to gather all possible information from a disastrous event like the collapse occurred in only 80 minutes of Wilton Paes de Almeida building, in order to enable a diagnosis of the incident and thus understand a little bit more about the complexity of the behavior prediction of reinforced concrete structures under fire. Therefore, the scientific contribution is well characterized in the research carried out, seeking information and data that may explain this premature collapse.

2. Historic

Started in the early of 1960s, the Wilton Paes de Almeida building was concluded in 1968 by the construction company Morse & Bierrenbach, Co., serving as the headquarters for the business conglomerate of the politician and businessman Sebastião Paes de Almeida. The building occupied an area of 6,996.54 sq. ft and its built total area was 129,166.93 sq. ft (ALETEIA, 2018).

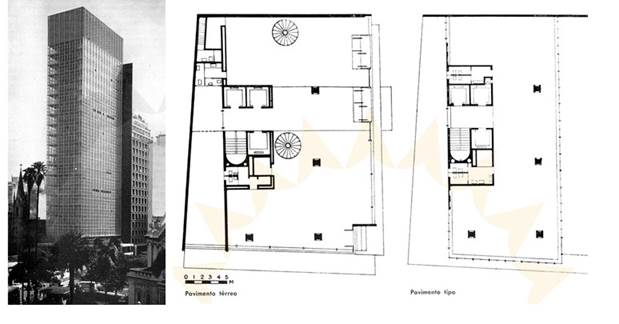

With characteristics of a typical Miesian building, it had a reinforced concrete structure, with only 04 (four) recessed columns with “H” section, supporting a ribbed concrete slab in the central region and a cantilever slab in the periphery (Figure 1). In the facade, the thin thickness of the slabs made possible to use an equally thin aluminum window frame fixing the “glass skin” blades of green glass made by the Rayban house.

(source: Revista Acrópole, 1965)

Figure 1 View of the Wilton Paes de Almeida building and ground floor and typical stories

The main company that occupied the building at its beginning was CVB (Commercial Glass Company of Brazil). After a year of activity by CVB, the building had an agency of the bank Caixa Econômica Federal on the ground floor.

Considered a development milestone because it was the first building of Brazil with a glass-skin facade, it was listed in 1992 by the Municipal Council for the Preservation of the Historical, Cultural and Environmental Heritage of the City of São Paulo (CONPRESP).

Subsequently, the building would receive a post from the Brazilian Social Security Institute (INSS) and in the early 2000s began to house the Federal Police. During this period, there are no records of significant renovations to keep the building in good conditions.

Years later, the two public agencies left Wilton Paes de Almeida so that it would be empty for sale by the Ministry of Cities' Union Heritage Secretariat (SPU) in February 2015. With the length of the process and the lack of interested in the purchase, the building was invaded by poor and homeless people (NEWS RONDÔNIA, 2018).

At dawn on the first day of May 2018, a fire caused the collapse of Wilton Paes de Almeida building. The fire started around 1:30 AM, and the flames began with a probable short circuit on the fifth floor (G1, 2018).

In a short time, due to the building's constructive characteristics, fire spread quickly through the other floors, both upwards (as expected) and downwards (unexpected), taking over the entire structure, from the ground floor to the roof. At about 2:50 AM, the entire building, still in flames, collapsed on itself (Figure 2), causing the death of seven people and many damages on the neighbor buildings as well as huge disruption to families and the traffic and free movement of people from the region.

With the collapse occurred in the Largo do Paissandu Square (Center Region of São Paulo), it is evident that the lack of maintenance and neglect with the patrimony can cause many losses and risks to the society. There were 07 people who lost their lives, about 92 families who lost the roof to the housed; 220 million of Brazilians who have lost a public property belonging to the Goverment estimated at more than US$ 7 million, and countless of other inconvenience to people who live and work in properties around the building that collapsed (Figure 3).

(source: Paulo Helene's personal collection)

Figure 3 Damage to the Lutheran Church, next to Ed. Wilton Paes de Almeida

Due the unusual collapse of this building, PMSP (City Hall of São Paulo) through Prof. Vitor Castex Aly, Secretary of Infrastructure, and Eng. Julio Timerman, President of IBRACON (Brazilian Concrete Institute), signed a technical cooperation protocol to make the case study feasible, which was under the responsibility of IBRACON's Technical Director, Prof. Paulo Helene.

3. Building fire safety

The premature collapse, around 80 minutes, of the Wilton Paes de Almeida (WPA) building surprised the engineering of concrete structures. From the conception of this building system, patented by François Hennebique in 1892, who used as a slogan of his advertising “plus d ' incendies désastreux”, in other words, never more disastrous fires, it is known that reinforced concrete has high structural strength to the action of the fire and the weather. An example of this statement can be seen in Figure 4, which shows the first building made in 1900 with structural elements in reinforced concrete, located at Rue Danton, 1, Paris - France, with the system Hennebique, which is in full use today.

(Source: Paulo Helene's personal collection).

Figure 4 World's first building designed with the system Hennebique (119 years of good service to the society)

Since 1900 there has been a great evolution of concrete and with the advent of high strength concrete, above 100 MPa, doubts about the good behavior of concrete under fire rise again. Studies by Britez (2013) with high-strength concrete columns (140 MPa) subjected to high temperatures demystified the beliefs and doubts of the time that high-strength concrete could “explode” in a fire situation, with a marked spalling effect, which could lead to the premature collapse of buildings designed with this type of concrete.

The tested columns, made of colored reinforced concrete, presented excellent performance, keeping their edges intact. The reduction in concrete compressive strength was only observed in the peripheral regions, about 1.2 inches, even with fire exposure duration of 180 minutes. The steel of the reinforcement did not lose resistance after cooling and the portlandite content present in the sample also indicated that the depth of the nefarious action of the fire was very shallow, about 1.2 inches in 3 h of an ISO standard fire.

Corroborating the claim that the concrete shows excellent performance under the action of fire, previous fires as the Andraus, Joelma and Grande Avenida buildings, all in São Paulo and built in 1960s, withstood more than 4 h of fire without collapse and are currently in normal use.

This premature collapse of the WPA must be considered a serious fact, both from the point of view of the evacuation of buildings by users, and from the point of view of the safety of firefighters in their rescue and firefighting activities, as well as the safety of the surrounding neighborhood that cannot be hit by the wreckage, in other words, buildings cannot collapse so quickly in the face of fire.

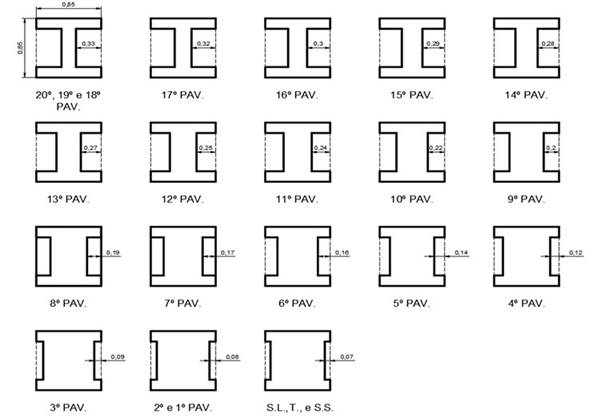

4. Reconstruction of the structure

Under a hard work of research to obtain the information and design sheets of the building, some architectural sheets describing the geometry of the columns were found in the records of FAU/USP (Faculty of Architecture of the University of São Paulo). Interestingly and surprisingly the outer section of the columns was square and constant with 85cm by side, but its sturdy cross-section with the shape of the letter H was staggered and variable from floor to floor. In addition, two opposing faces defined a “shaft” that was continuous throughout the height of the columns, from the underground floor to the rooftop, as shown in Figure 5. These “shafts” have been designed and constructed for the central air conditioner system.

(Source: executive architectural design found in the library of FAU. USP)

Figure 5 Scheduling of the columns

Many adaptations of projects and proposals made during the years of building operation that was headquarters of Federal Police, the Savings Bank and other companies were found in the archives of SPU (Union Heritage Department) together with these sheets. Engineer Leandro Coelho from SPU provided photos of his personal collection taken over the years, where it was possible to confirm, with some degree of precision, the structural typology used in the Wilton Paes de Almeida building (Figure 6).

(source: personal collection of Leandro Coelho)

Figure 6 Columns without metal coating, where it is observed the "H" which is actually a shaft of the air conditioner and l grate beam track with AJE still forms wood.

The building slabs were ribbed and were placed in situ with thickness of the topping slab of 6 cm (Figure 7). The ribs were 10 cm width and 28 cm high to the bottom of the topping slab, and were spaced every 50 cm. From the columns to the limit where it was installed the glass skin, the slab was a cantilever slab with variable cross-section (Figure 8).

Thus, the main structural system of the structure, responsible for its lateral stability, was composed of concrete columns with “H” section, forming frames in one direction with the strip beams with the same height of the slab, added to concrete shear-walls in the lift and staircase and further a large wall crosslinked to the bottom, consisting of columns, beams and masonry, making a structural frame-wall, as can be seen in the hypothetical model shown in Figure 9.

5. Properties of reinforced concrete

The following are the activities of sample collection and the test plan established to know the physical and mechanical properties of the materials present in the structure.

5 .1 Sample Collection

Two major parts of collapsed superstructure were selected for collecting samples of the building to performing characterization tests, one slab portion and one column portion (Figure 10).

5.2 Testing Plan

Regarding the concrete samples, the following activities and specific tests were established: geometric survey, core extraction, mineralogical characterization of the aggregate, petrographic appreciation of natural minerals, compressive strength, tensile strength, sclerometer test, ultrasonic test, modulus of elasticity, water absorption test, voids index, specific mass, mix reconstitution, x-ray diffraction, thermodifferential and thermogravimetry analysis, and carbonation.

Regarding the steel samples, the following activities and specific tests were established: typology of the steel employed, chemical and metallurgical composition, traction, folding, stretching and metallography.

5.3 Results - concrete

The results of tests carried out in concrete can be found full in the report made by the authors (Helene et. al., 2019) and is presented here only these analysis.

5 .3.1 Sclerometry:

The “surface hardness assessment by the reflection sclerometer” test was performed in the laboratories of Mackenzie Presbyterian University (UPM), according to ABNT NBR 7584: 2013. 224 impacts in 14 different test areas were performed, half of them on fire exposed surfaces, and the other half on cut surfaces (core), called as exposed face and core face, respectively.

It was observed that there was a significant reduction in the reflection index values obtained from the external faces in relation to the values obtained from the core. All faces were affected by the flames, there was obtained a mean value of 24% reflective index (corresponding to the cylindrical compression resistance of 16 ± 4,8 MPa), while the measurements performed on the core sample obtained an average index of 30% (that corresponds to the cylindrical compressive strength of 26 ± 6,3 MPa).

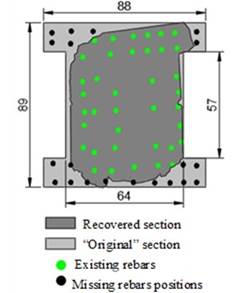

5 .3.2 Column cross section

After a diamond wire cutting in the column cross section, the layout of the rebars was evident inside the columns, being possible to make a draft with the reconstitution of column’s cross section sampled, as shown in Figure 11.

With the assessment of the cross section, arrangement of reinforcement rebars and their respective average diameters, it was possible to estimate the longitudinal reinforcement rate at approximately 3% of the gross area of the column, which is conventional for multi-story buildings.

The reinforcement cover, an important verification of the durability and fire resistance criteria, range from 1 cm to 5 cm in the collected sample, which, once again, showed a lack of control and construction care, typical and common at the date of execution of this building.

From the point of view of fire resistance, the cover (C1) that is used for the calculation of the resistance to the thermal gradient, extends from the external face of the columns to the center of the rebar reinforcement, which in this case ranged from 2.5 cm to 6.5 cm.

Still in the collected column section, it was found a column-slab intersection, and its evident reinforcement. Therefore, it was possible to determine the arrangement of the reinforcement of the strip-beam (Figure 12).

5 .3.3 Concrete Cores Obtaining:

Core tests were performed at UPM. In addition, testing of axial compressive strength and diametral tensile strength was performed, several chemical and physical analysis was dependent substantially on the availability of samples in suitable proportions for performing the same; thus, the extraction of cores for these tests was fundamental.

A total of 16 cores were performed, of which only six (06) could be used for mechanical strength, due to the large number of internal cracks, as shown in figure 13. These cracks were possibly caused by poor concrete pouring at the age of the building's construction and, most likely, by the dynamic stresses of the superstructure falling during the building's collapse as well.

5 .3.4 Compressive Strength

Tests were performed in UPM’s laboratories, following the procedure of the standard ABNT NBR NBR 5739 and 7680, checking the average compressive strength of 21.8 MPa.

The results are consistent with the concretes produced at that time, which specified resistance was around of 135 kgf/cm² (13.5 MPa) to 180 kgf / cm² (18 MPa).

For structural evaluation purposes it was assumed that the characteristic compressive strength of concrete was f ck = 15 MPa.

5 .3.5 Tensile Strength

The tensile strength test was performed at UPM’s laboratories, following the procedure of ABNT NBR 7222, checking an average value of 2,1 MPa.

The result obtained corresponds to approximately 10% of the value obtained for the compressive strength, which is totally satisfactory, coherent and expected for concretes of that time, in São Paulo.

5 .3.6 Ultrasonic test and modulus of elasticity

The test for determining the ultrasonic velocity was performed in the PhD laboratories, for determining the dynamic elastic modulus by following the procedure d ABNT NBR 8802, checking an average speed of propagation of waves of 3707 m/s.

The Dynamic Modulus of Elasticity by Impact Stimulus test was also performed by following the procedure of ASTM C215, where values of 19.6 GPa (longitudinal) and 12.3 GPa (transverse) were checked.

Based on the master's dissertation of Bilesky (2016), it was possible to estimate the conventional static modulus of elasticity, ranging from 20 GPa to 26 GPa, that is perfectly compatible for the concrete in question.

5 .3.7 Water absorption test, void indices and specific mass

The tests to determining water absorption, void index and density were performed following the procedure ABNT NBR 9778 and carried out in laboratories UPM. Samples were taken from the core of the column.

The following average results were obtained:

Water absorption (6.52%, voids index (14.75% and specific mass (2.260 kg/m³

It is concluded that the results obtained are consistent with the quality of a concrete of the order of f ck = 15 MPa.

5 .3.8 Mix Design Reconstitution

The test for Mix reconstitution was performed in the laboratory of the Brazilian Portland Cement Association (ABCP), following the procedure of internal standard ABCP PO-GT 3016.

For mass proportion calculations, a calcium oxide value of 60% was adopted. No account was taken of the possible presence of limestone materials linked to the aggregates.

The concrete mixes founded in the tests were 1: 5.9 in the columns and 1: 6.2 in the slabs, in dried mass of cement / aggregates and can be considered compatible with the age, corresponding to a cement consumption of 309 kg / m³, with a water/cement ratio of 0.65.

The results obtained are appropriate to the aggressiveness class in which the structure was inserted (class II of ABNT NBR 12655: 2015) and represent the concrete found at the time.

5 .3.9 X-ray diffractometry, thermodifferential and thermogravimetry

The x-ray diffractometry, thermodifferential analysis and thermogravimetry tests were performed in the ABCP laboratory, following the procedure of the internal standard ABCP PO-GT 5042. These tests aimed to identify the crystalline phases that make up the samples of concrete submitted to high temperatures, which were analyzed in the X-Ray diffractometer and recognized through thermograms the presence of peaks related to cement hydrated to calcium hydroxide and calcium carbonate constituents of the hydrated binder, in addition to those related to the quartz present in the aggregate. By identifying the presence or absence of certain mineralogical compounds, it becomes possible to evaluate the temperature reached by a concrete structural element at different depths in a fire episode. The results of these analyzes can be found in tables 1 and 2.

Table 1 Mineralogical compounds of concrete samples.

| Minerals | Approximate Chemism | Main interplanar distance (Å) | Relative Frequency | |||||

|---|---|---|---|---|---|---|---|---|

| (top) | b (middle) | c (base) | d (top) | e (middle) | f (base) | |||

| SlowFeldspar | (Na0,5-0,3, Ca0,5-0,7) Al (Al0,5-0,7, Si0,5-0,3) Si2O8 | 3,20 | * | * | * | ** | - | ** |

| SlowMica | KAl2(AlSi3O10) (OH)8 | 9,99 | ** | * | ** | ** | ** | *** |

| SlowQuartz | SiO2 | 3,33 | **** | ** | *** | **** | ** | *** |

| SlowCalcite | CaCO3 | 3,03 | ** | * | * | * | * | * |

| SlowPortlandite | Ca(OH)2 | 4,90 | *** | **** | **** | ** | **** | **** |

| Symbology | - = not detected | ** = uncommon | ||||||

| tr = dashes | *** = frequent | |||||||

| * = present | **** = very common | |||||||

| Note: | The semiquantitative evaluation (expressed in number of asterisks) of the phases is based on the height of the diffraction peaks, whose intensity is a function of the content, symmetry and degree of crystallinity of the constituent. | |||||||

Table 2 Results of Termodiferential and Thermogravimetry tests.

| Sample Identification | Perda de Massa (%) | ||||||

|---|---|---|---|---|---|---|---|

| 40°C to 200°C (Loss of free and / or adsorbed water and decomposition of hydrated silicates) | 200°C to 400°C (Decomposition of hydrated aluminates) | 400 ° to 500 ° C [decomposition of Ca (OH)2] | 500º a 800°C (Decarbonation of the CaCO3) | Ca(OH)2 | CaCO3 | ||

| 214424 | top | 4,59 | 2,03 | 1,32 | 10,34 | 5,4 | 23,5 |

| middle | 7,54 | 4,86 | 3,85 | 2,90 | 15,8 | 6,6 | |

| base | 8,14 | 4,81 | 4,16 | 2,97 | 17,1 | 6,8 | |

| 214425 | top | 4,35 | 2,79 | 1,46 | 11,53 | 6,0 | 26,2 |

| middle | 8,38 | 5,45 | 4,18 | 4,31 | 17,1 | 9,8 | |

| base | 6,42 | 4,00 | 2,84 | 3,81 | 11,7 | 8,7 | |

As seen in Tables 1 and 2, the samples from column surface, in the coatings region , resulted in portlandite levels three times lower than the core samples, which is consistent with the friable appearance found in coatings region in situ , being more intact in the region of the reinforcement (columns core).

In conclusion, these tests allow to estimate that the high temperature only acted on the surface of the structural concrete, about less than 1cm. This can also be one of the reasons for the mechanical integrity of the reinforcement, i.e., since it was over 1 cm, it was not affected by high temperatures (below 573º C).

5 .3.10 Petrographic assessment of aggregates

The stereoscopic microscopy of the concrete constituents of the Wilton Paes de Almeida Building was performed at the ABCP laboratory by following the procedure of ABCP standard PO-GT 3016 rev. 02.

Four (4) fractions were taken from the column sample, the fractions were taken in function of the distance from the sample to the surface. It was observed that the analyzed concrete is composed of gravel and sand aggregates from rock crushing and river sand. Analyzes suggest a good quality of aggregates. The coarse aggregate comes from igneous rock, petrographically called biotite granite. A smaller amount of mafic rock was probably present, probably coming from a shaft that cut the rock massif.

From the petrographic point of view, aggregates have good characteristics to be used in concretes and no features caused by harmful exposure to fire were observed. For example, the presence of fractured quartz crystals and fractures at their crystalline interfaces that are indicative of allotropic quartz transformations was not observed. Such allotropic transformation of the alpha quartz to beta quartz occur with increased volume when the target temperature reaches 573º C, or it can be an evidence that the concrete has not been subjected to temperatures above 570º C. This is a reasonable conclusion because the exposure time to fire was very short, on the order of 1 h.

5 .3.1 1 Carbonation measurement

The determination of carbonation depth was analyzed using a phenolphthalein - based pH chemical indicator. External faces were chosen and, therefore, hypothetical regions exposed to fire.

The measurements were performed for the carbonation layer in the most affected regions depths ranging from 2.5 cm to 3.0 cm, which corroborate the hypothesis that coated structural elements, as was the case of the columns of this building, have a longer durability, since the coating acts as another barrier against the penetration of the carbonation front and heat.

Considering that it was a structure with about 54 years of age, the depth of carbonation found demonstrate a good quality concrete and consistent with its age.

5.4 Results - steel

The results of the steel tests can be consulted in full in the document prepared by the ArcelorMittal technical team (Annex I of the report prepared by Helene et. al. 2019), and only a summary of them is presented here.

5 .4.1 Steel typology employed

The steel used in the WPA reinforcement was of two types, and they were named notched and smooth due to their surface conformation. Due to the original format, the rebars "notched" presented with depressions arranged uniformly so vary their angle of 90º, as shown in Figure 14.

After researches and contributions by Prof. Dr. Eduardo Thomaz, it is believed that steel rebars for reinforced concrete were manufactured by Peristahl S/A, at that time operating in the Brazilian market. These bars are cold hardened by bite in both normal and orthogonal directions, and in the case presented the following diameters: 8, 10, 16, 20 and 22mm.

5 .4.2 Chemical Composition

A comparison between building samples with the current parameters for each chemical element present was performed, and the limits set by the ABNT NBR 8965, which for the components present in the standard (maximum values: C = 0.29; Mn = 0, 91; Si = 0.41; P = 0.14; S = 0.07 and Ceq = 0.47) were mostly below the maximum limits (0.38, 1.56, 0.55, 0.058, 0.058 and 0.59, respectively), and are therefore suitable for the weldability, ductility and strength parameters required for use in reinforced concrete.

5 .4.3 Traction / Stretching

All samples were tested for tensile strength (f st ranging from 470MPa to 760MPa; f yk ranging from 320MPa to 640MPa; elongation ranging from 3% to 35% and all showed ductile rupture). Comparing with the current standardization of ABNT NBR 7480, it can be inferred that this reinforcement can be considered as CA-60 grade steel.

5 .4. 4 Metallography

Metallographic analyzes performed at different magnifications showed that the samples of 22, 20, and 16 mm gauge longitudinal notched bars correspond to the CA 60 steel and the 10 mm gauge smooth crossbars and the 8 gauge flat complementary bars. mm correspond to AC 37 steel. An example of metallographic analysis can be seen in Figure 15.

6. Final considerations

Based on extensive testing program carried out, in different and even contradictory sources of information available, and in the simulations of the structural model made, it can be concluded that:

Concrete had a mean compressive strength of 21,8 MPa with f ck assumed of 15 MPa and MoE of 20 GPa to 26 GPa, besides other properties and characteristics very common to the age of construction in the city of São Paulo, not being the responsible for the collapse;

The X-ray Diffractometry, the thermodifferential and thermogravimetry analysis have shown that the maximum thickness of concrete not calcined reached 1 cm and the maximum temperatures of the concrete surface did not reach 573º C;

Coating studies have shown that concrete coating was enough to keep steel below 500º C, generally considered as a tolerable limit for reinforcement;

The results of the characterization tests of the rebar reinforcement showed that it was a kind of steel available in the Brazilian market at that time and still meeting the current standards, but not being the responsible for the premature collapse as well;

The reconstruction of the structural elements, column and beam, with respective cross section and reinforcement section, has demonstrated that the structure was designed to withstand the vertical loads, however when performing lateral loads checks and lateral stability with current criteria, the structure showed to by eccentric and with great potential of torsion. It must be considered the neighborhood mitigating factor, that in a way, could be a shield of lateral wind loads for this building, that stay in service for 54 years;

The structural model associated with the calculation thermal loads effects for the temperature gradient of 250º C showed that torsional moments due the thermal expansions of the structural elements, are about 20 times higher than those due to wind loads and vertical loads. This assessment is extensive and will be the subject of another specific paper, but this fact is recorded here, because it was the best explanation for the early collapse of the WPA building.

Finally, the diagnosis showed that from a “hypothetical structural design”, because the original structural design was not found, it was possible to explain the collapse by a global torsion effect generated by the high temperatures. Being a building with asymmetric structure the thermal deformations induced torsional stress and bending moments far above the resistance of the structure.

As recommendations, it stands out:

a) In existing buildings, which are thousands in the city of São Paulo, demand through the Fire Department Active and Passive Fire Protection, with training people because in case of an uncontrollable fire, they could have a serious risk of collapse, like to WPA.

b) In existing glass facade buildings, which are also hundreds in the city of São Paulo, there would be required, through City Hall, the construction of a 1.2 m minimum partitioning between twinned buildings and between stories with insulating and incombustible material.

texto em

texto em