Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista ALCONPAT

On-line version ISSN 2007-6835

Rev. ALCONPAT vol.5 n.2 Mérida May./Aug. 2015

Articles

Carbon Nanotubes in Portland cement concrete: Influence of dispersion on mechanical properties and water absorption

1 Universidad Pontificia Católica de Paraná (PUCPR), Brasil. E-mail: ilhamarcondes@ig.com.br

2 Departamento de Construcción Civil, Universidad Federal de Paraná (UFPR), Brasil. E-mail: medeiros.ufpr@gmail.com, jmarquesfilho@gmail.com

3 Universidad de São Paulo (USP), Brasil. E-mail: paulo.helene@concretophd.com.br

Carbon nanotubes (CNTs) are carbon structures which take the shape of cylinders in nanometric scale. This work presents an evaluation in regard to the addition of CNTs in concrete made with Portland cement, focused on the importance of performing the CNTs dispersion in water ultrasound before its incorporation to the concrete mass. Therefore, three concrete mixtures were performed, one without CNT (reference series) and two with CNTs (one mixture with previous dispersion in water and additive using ultrasound and the other without dispersion). Then properties of fluidity, compressive and tensile strength and water absorption were analyzed. The amount of CNT added was 0.30% with respect to cement mass. In all cases, the previous dispersion of CNTs using ultrasound increased the effect of CNTs addition, evidencing the importance of the efficiency of such material when added to cement.

Keywords: Carbon nanotubes; concrete; strength; water absorption

Los nanotubos de carbono (NTC) son estructuras de carbono que se obtienen en forma cilíndrica a escala nanométrica. Este artículo presenta una evaluación de la adición de NTC a hormigón de cemento Portland, centrándose en la importancia de llevar a cabo la dispersión de los NTC en el agua con el uso del ultrasonido antes de su incorporación en la masa de hormigón. Para ello, se prepararon tres mezclas de hormigón sin NTC (referencia) y dos con NTC (con una serie previa de dispersión en agua y el aditivo con el uso de ondas ultrasónicas y otras sin dispersión). A continuación, se analizaron las propiedades de fluidez, resistencia a la compresión, tracción y absorción del agua. El contenido de NTC añadido fue de 0,30% con respecto a la masa de cemento. En todos los casos, la dispersión previa de NTC usando ultrasonido potenció el efecto de la adición de nanotubos de carbono, siendo importante para la eficiencia de este material cuando se añade al cemento.

Palabras clave: Nanotubo de carbono; concreto; resistencia; absorción del agua

Os nanotubos de carbono (NTCs) são estruturas de carbono que obtêm forma de cilindros em escala nanométrica. Este trabalho apresenta uma avaliação da adição dos NTCs em concreto de cimento Portland, com foco na importância da realização de dispersão dos NTCs à água com uso do ultrassom antes de sua incorporação a massa de concreto. Para isto, três traços de concreto foram preparados sendo um sem NTC (série de referência) e dois com os NTCs (uma série com dispersão prévia em água e aditivo com o uso de ultrassom e outra sem dispersão). Analisou-se então as propriedades de fluidez, resistência à compressão, tração e absorção de água. O teor de NTC adicionado foi de 0,30% em relação à massa de cimento. Em todos os casos a dispersão prévia dos NTCs usando o ultrassom potencializou o efeito da adição de NTCs, mostrando-se importante para a eficiência deste material, quando adicionado ao cimento.

Palavras chaves: Nanotubo de carbono; concreto; resistência; absorção de água

1. INTRODUCTION

Research performed in the fields of cement and nanotechnology have appointed that some nano composite cement additions allow major changes in its microstructure, which provides a more resistant production of concrete, less porous and more durable (Marcondes, 2012). Among the row of possible nanomaterials exists the carbon nanotubes (NTC), to be the focus of this work.

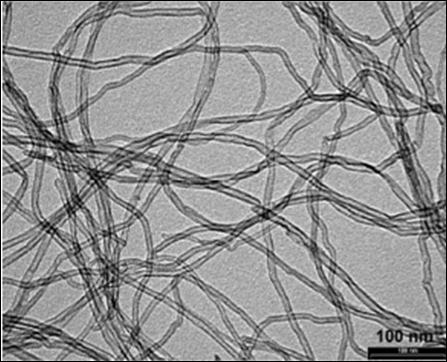

Carbon nanotubes (CNTs) are carbon structures which after synthesized, tend to form cylinders at the nanometer scale and measure approximately 3 nm in diameter and 1000 nm long (Couto, 2006).

From a structural point of view, there are two types of carbon nanotubes: the single wall, consisting of a single graphene sheet rolled on itself to form a cylindrical tube, and multi-walled, comprising an assembly of carbon coaxial nanotubes with several graphene sheets rolled into tube form wise (Zarbin, 2007). Single-walled carbon nanotubes (NTCPS) are difficult to be synthesized, which increases their cost and virtually precludes its application on a large scale (Herbst et al., 2004).

This test used the CNTs of multiple walls, due to its lower cost and availability in relation to single wall. They were purchased from a company in Belgium and added to the concrete, in order to review the effect of CNTs in water absorption, the fluidity of fresh concrete and mechanical properties of compressive and tensile strength via diametrical compression.

2. NTC IN PORTLAND CEMENT COMPOSITES

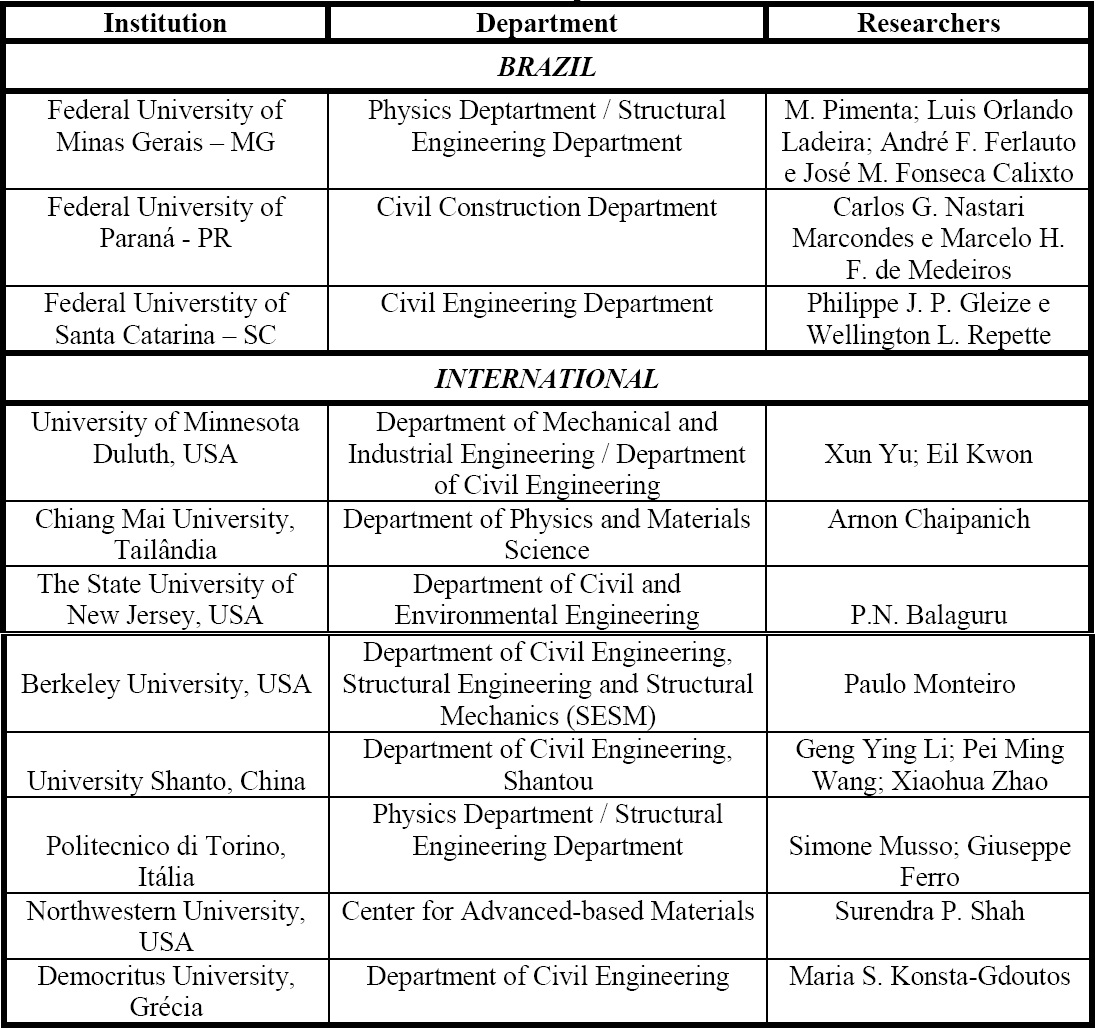

The addition of NTCs cement compounds is a topic which has been studied in several national and international universities, as showed in Table 1.

Table 1 Some of the leading universities players towards nano materials research applied to cement compounds

The reason for several researches held in this area is that in some studies [such as those by: Marcondes (2012), Batiston et al. (2010), Makar et al. (2005), Chaipanich et al. (2010), Melo et al. (2011) and Li et al. (2004)] attest the performance of nanoparticles when added to paste and Portland type cement mortars. Due to its minuscule proportions, these particles contribute to the void fill and, consequently, for the improvement of various properties of these materials. In this case, there are still some barriers to overcome. According to Batiston et al. (2010), the two major challenges to the introduction of carbon nanotubes into cementations matrices are: homogeneous distribution of the carbon nanotubes in the cement composite and to study the interaction between CNTs with compounds due to the cement hydration. This previous aspect can be interpreted as the necessity to understand the changes caused by the addition of CNTs in Portland cement composites, such as changes in microstructure, in kinetic hydration reactions, the paste/aggregate adhesion, among others.

In regard to distribution of CNTs to a cementations matrix, several methods have been used, especially the sonification and functionalization of CNTs using mixture of nitric and sulfuric acid (Li et al., 2004; Konsta-Gdoutos et al, 2010).

From the scope of researchers Koshio et al. (2001), ultrasound can be considered an effective technique in dispersing carbon nanotubes in water, oil or polymers. For these researchers, the sieving forces triggered by ultrasound had overcome the bonding forces between the nanotubes, turning out to split them. This was attested by researchers Konsta et al. (2010) who achieved an efficient dispersion by application of ultrasonic energy and the use of a surfactant. The results appointed an adequate dispersion with the application of ultrasonic energy and the multi-walled carbon nanotubes to enhance the cement matrix, to increase the amount of CSH and reduce the porosity.

Chaipanich et al. (2010) analyzed the addition of carbon nanotubes in Portland cement mortars (0.5 and 1% by mass relative to the cement). The CNTs were initially dispersed in water using ultrasound for a 10 min of timeframe. In that case, the authors rendered with fly ash cement and the compressive strength of the composites (paste and mortar) also investigated. Research has appointed the use of carbon nanotubes increased strength of composite Portland cement with 20% of fly ash. The highest strength was obtained with the addition of 1% NTC where the compressive one at 28 days indicated 51.8 MPa representing a 10% of increase in compressive strength when compared to the reference mixture without nanotube carbon, which evidenced strength of 47.2 MPa. Furthermore, according to Chaipanich et al. (2010), the analysis towards scanning electron microscopy also evidenced a good interaction between carbon nanotubes and cement with fly ash in comparison to mixture without CNTs.

3. EXPERIMENTAL PROCEDURE

The works published until now focused on the influence of CNTs into pastes and Portland cement mortars and this experimental was conducted fin this study focused in the effect of adding CNTs in Portland cement concrete. The key feature was to explore the feasibility of using conventional NTC dosing in concrete with compressive strength between 25 and 40 MPa, and measuring some effects on the mechanical strength and water transport through the concrete pore network with and without the addition of NTC.

3.1 Materials

3.1.1 Cement

The cement used was Portland cement type CPV-ARI. The cement was selected because it has no pozzolanic ash and contain higher amount of clinker in its composition. It eliminates another variable in the study, since pozzolanic materials may interact with CNTs and interfere in results (Chaipanich et al., 2010).

The physical and chemical composition of the cement are evidenced in Table 2. The specific cement average weight is 3.12 g/cm³ in accordance with the NM NBR 23/2001 (NBR NM 23, 2001).

3.1.2 Aggregates

The fine aggregate was a natural sand compound from Balsa Nova city - Paraná. The properties of fine aggregate are appointed in Table 3.

Table 3 Fine aggregate properties

| Properties | Result | Standard method |

|---|---|---|

| Maximum dimension (mm) | 4.8 | NM 248/2001 |

| Fineness Modules | 2.92 | NM 248/2001 |

| Powdery Materials (%) | 2.00 | NM 46/2003 |

| Specific gravity (g/cm³) | 2.61 | NM 52/2009 |

| Bulk Density (g/cm³) | 1.487 | NM 45/2006 |

| Absorption (%) | 0.37 | NBR 9777/1987 |

| Organic Content (ppm) | < 300 | NM 49/2001 |

| Clay Content (1%) | 0.1 | NBR 7218/1987 |

The coarse aggregate was employed for the production of concrete derived from one granite gravel crushing. The coarse aggregate is in accordance to ABNT NBR 7211 (2005).

The coarse aggregate was initially washed to remove impurities and powdery materials and, after that, was dried in an oven until mass constancy. Its characterization was conducted in accordance with national standards and is represented in Table 4.

3.1.3 Carbon nanotubes and Admixture

The CNTs used in this study were produced from Nanocyl SA Company, located in Belgium. The CNTs cost 120 euros per kilo. These are multi-walled CNTs synthesized by the chemical vapor deposition method or also called CVD - chemical vapor deposition. Commercially the product is specified by the name of NC 7000. Figure 1 shows an image of this material with the use of scanning electron microscopy (SEM).

Its properties and composition are showed in Tables 5 and 6.

Table 5 Physical properties of NTCs

| Property | Unit. | Value |

|---|---|---|

| Average diameter | Nanometer | 9.5 |

| Average Length | Mícron | 1.5 |

| Surface Area | m2/g | 250-300 |

| Average Density | g/l | 60 |

Table 6 NTCs composition

| Components | % (weight) |

|---|---|

| Synthesized graphite (NTC) | 90% |

| Cobalt Oxide | < 1% |

| Metal Oxide | 10% |

From the scope of the experiment, it was used a polycarboxylate as superplasticizer, used to set the desired consistency.

The admixture used in the experiment is a carboxylic ether polymer modified, with concentration average of 49%. It is in accordance to ASTM C 494 (2011) (Type A and F), ASTM 1017 (1998) and NBR 11768 (2011).

Polycarboxylate macromolecules are used as dispersants in cementitious compositions as high efficiency by reducing the viscosity and minimizing the amount of water used for processing (Mehta; Miller, 2008).

Some properties of admixture is showed in Table 7.

3.2 Specimens

The concrete without CNTs was called REF (without adding CNTs) and was used to compare with the concrete with the addition of CNTs. Thus, it was adopted a simply conventional concrete mix as a reference and then reproduced series adding the CNTs. The mix proportions established are appointed in Table 8. It should be noted that the CNT content relative to the cement mass was maintained at 0.3% for all composites. This settlement was made based on the studies of Melo et al. (2011) that indicated 0.30 % (in cement mass) as the optimum content.

The nomenclature used in Table 8 refers to the REF as the mark without the carbon nanotubes; the CD, such as the insertion mark with the additive and carbon nanotubes (with dispersion in water and additive ultrasound); and SD, the mark containing only the NTC added powder (without the dispersion in the additive and without application of ultrasonic energy - mixed into the cement powder using only with mixer attached to a drill).

The water/cement ratio used in this study was set at 0.55. During this work, it was noted that the addition of CNTs to the concrete caused reduction of fluidity to the SD serie, which damaged its feasibility and prevented the use of smaller ratio values water/cement ratio. On the other hand, it is considered the limit value as specified by the NBR 6118 (2007) for the purpose of application of concrete in marine environments.

Cement content is 352 kg/m3 and is in accordance to the suggested consumption established by NBR 12655 (2006), which in the case of concrete placed in class III environment indicate the lower limit of 320 kg of cement per cubic meter of concrete.

From the scope of tests, they were made in the mixer 3 mixtures, one for each mix proportion, and to prepare the solution to be used for CD feature of preparation, there was the addition of CNTs water with superplasticizer and was followed with sonification. The wave application time was 1 hour. This time was predetermined based on work done by Marcondes (2012) due to a visual analysis indicated that after 60 minutes the samples did not appoint any changes to the tonality and turbidity.

Furthermore, as of 40 minutes sonication the samples are not presented (visually) CNTs decantation elapsed time of 24 hours in the solution rest, as can be seen in Figure 2.

Figure 2 Visual analysis of samples with 40 minutes of sonification elapsed in 24h rest (MARCONDES, 2012).

The ultrasonic equipment rendered low frequency, model 0-14 C / I manufacturer Thornton INPEC Electronics SA with a nominal frequency of 40 kHz and 100W of power. The dispersed solution was used within 30 minutes after sonication.

3.3 Tests procedures

3.3.1 Compressive strength

The compressive strength is the key to evaluate mechanical properties of concrete Portland cement. The molding test specimens was performed in accordance to the NBR 5738 (2003) using cylindrical molds Ø 10 x 20 cm. Six specimens were prepared for each mix proportion, on the total of 18 specimens.

3.3.2 Tensile strength by diametrical compression

The tensile strength by diametrical compression test was carried out according to the NBR 7222 (2011). This test is focused on evaluating the tensile strength in the analyzed concrete by applying a diametrical compression load to the specimen. Similarly to the previous test, it was prepared six cylindrical specimens Ø 10 x 20 cm for each mix proportion.

The Equation 1 was used to calculate the tensile strength by diametrical compression.

Where: P = maximum applied load, kN; d = specimen diameter, mm; L = specimen height, mm.

3.3.3 Immersion water absorption

The immersion absorption test was performed based on NBR 9778 (2005) and was performed according to the following steps:

Drying of specimens until they reach constant mass (the dry out temperature was 60 °C to avoid very high temperatures, which may cause microcracks in the specimen and influence the results);

After the dry out in an oven, it was rendered the immersion of the sample in water at 23 ± 2 °C for a total of 72 h. The samples were kept immersed up to 1/3 of its volume during the first 4 h, 2/3 in the subsequent 4 h, remaining completely immersed in 64 h;

It was determined the mass of the test specimens at 24 h, 48 h and 72 h of immersion. The determinations were made after dry up the sample surface with a cloth.

The water absorption by immersion was defined by Equation 2.

Where: Msat = saturated mass of specimen; Ms = mass of oven dried specimen

3.3.4 Water absorption by pipette method

This test also renowned as pipette test or RILEM pipette test (Test Method II.4: Water absorption test tube, 2006). It was proposed by German researcher Karsten and approved by RILEM (Reunion Internationale des Laboratoires d'essais et de Recherches sur les Materiaux et les Constructions) (RILEM, 2006) for the control of water infiltration in walls.

Each specimen was cut into 5 cm thick slices. These slices were placed in an oven at a temperature of 60 °C during four days. Then, the pipettes were fixed on the circumference of the specimens with silicone as shown in Figure 3. We used four slices of each series formulated for the measurements.

With fixed pipette, they were filled with water until the zero degree (highest) and the water inlet on the substrates was monitored by the decrease in the water level on the graduated scale (Figure 3). The readings were taken at 15 minute intervals to complete 2.5 hours of testing and, after that, we proceeded with readings 24h, 48h and 72h.

In order to consider the loss of water by evaporation, a pipette was fixed on a glass plate and it was used considering the variation of water level, in this case, as the water evaporated. These were subsequently evaporating discounted values of all the tested series concrete.

4. RESULTS AND DISCUSSION

To obtain more reliability it was carried out statistical processing of results of compressive strength and tensile strength by applying analysis of variance (ANOVA) aiming 95% of reliability.

4.1 Influence on consistency

The consistency results of fresh concrete mixtures obtained by the slump test upon the determined mix proportions for this experiment are showed in Figure 4.

The test results evidenced that the form of dispersion and the presence of CNTs in the concrete have a strong influence on consistency. As it can be seen in Figure 4, the presence of CNTs Without dispersion increased the consistency of the concrete (reduced its slump), while the series with the presence of CNTs in ultrasound dispersed form presented similar results compared to the reference series. In comparison to the reference series, the powder mixture without dispersion caused the reduction of slump results from 20 cm to 7 cm.

These results highlights the difficulty in performing feasible concrete with CNTs, therefore indicating to be possible only with the use of chemical admixtures to increase the plasticity of the concrete, due to the high amount of water required for the concrete with CNTs. On the other hand, it was appointed that the prior dispersion by sonification had considerably reduced the locking effect of the fluid mass submitted by the addition of powdered CNTs.

Experience shows that the slump results reduction on the addition of powdered CNTs to be due to the large specific surface of the material (250-300 m2/g) about 650 times higher than CP-V ARI as used in this study. The high slope consumption surface evidenced a splitting towards the entire area of the particles as per CNTs addition. The improvement in the slump results with the ultrasound usage for scattering technique (CD series) led to the better distribution of the CNTs in an aqueous medium and admixture incorporation as presented on the surface of CNTs. This means, the dispersion of ultrasound as evidenced to ensure a preview area and efficient water splitting to the carbon nanotubes particles.

4.2 Compressive strength

The results of the compressive strength test at 28 days of cure may be observed in Figure 5.

The data had evidenced in both cases when CNTs were added, to estate significant improvements in compressive strength effects. To acknowledge these results it was applied the analysis of variance (ANOVA) and it appeared the averages to be significantly different, 95% of certainty. The ANOVA data can be seen in Table 9 and the difference between the averages is confirmed by the fact of F to be higher than Fcritical.

The mix proportion with higher elevation of the compressive strength was the CD series, where there was 37% of increase in compressive strength compared to the reference series. The series without dispersion (SD series) showed 19% of compressive strength increase compared to the reference series.

The results show that the dispersion with ultrasound is extremely important to maximize the benefits brought about by the addition of CNTs in Portland cement concrete.

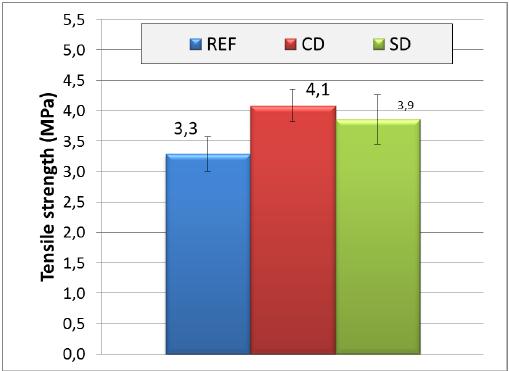

4.3 Tensile strength by diametrical compression

Figure 6 shows the results of tensile strength by diametrical compression from the concrete series screened in this study.

Figure 6 Tensile strength by diametrical compression for reference series and the two forms of NTCs addition.

These results indicate increase in tensile strength between 18 % and 24% with the NTCs addition to the concrete, as compared to the reference series. Although the SD series had resulted in a similar increase of tensile strength compared to the series with dispersion, the SD series presented the largest standard deviation among samples. This is an indication of which the addition of NTCs powder in the mixer resulted in less uniformity of distribution of NTCs in the concrete mass creating considerable variability in tensile concrete strength tests.

To obtain greater reliability in the comparison between the series of concrete studied, the ANOVA tool was used, of which indicated 95% reliability appointing significant differences between the results. This can be better detailed in Table 10, with F higher than Fcritical.

4.4 Immersion water absorption

Figure 7 evidences that samples with the NTCs there have been improvements in the immersion absorption propertie. This may be related to a better distribution of the pores, resulting in reduced macro porosity. On the other hand, to prove this it is necessary other tests, as the mercury porosimetry test to be able to better quantify the pore size.

Figure 7 Immersion absorption (%) X time (h) for reference series and the two forms of NTCs addition.

It is easy to see the trend of reduced absorption caused by addition of NTCs in concrete as reviewed in this research. However, the reduction level not to be as high as expected, presenting a decrease of 4.4% for the SD series and 3.9% for CD series.

4.5 Water absorption by pipette method

The absorption by the pipette method was performed to add more knowledge of water absorption of concrete produced with the addition of NTCs. Their results are shown in Figure 8. Note that the reference series and the SD series showed the worst results demonstrating once again the importance of employment dispersion with ultrasound, the CNTs in the additive and water before mix the concrete.

The test was conducted on the cut face and it is important to emphasize the fact that the presence of coarse aggregate in the concrete may affect the water absorption results in this method. However, the trial also showed the importance of the dispersion in the variation of water penetration results and showed reduction trend in series with CNTs pre-dispersed with ultrasound technique.

4.6 Discussion.

Chaipanich et al. (2010) showed that the addition of carbon nanotubes increased strength of cement with fly ash. In such research, the levels of 0.5% and 1% NTCs relative to the cement mass was analyzed, and the second with 20% fly ash showed a 10% increase in compressive strength. Comparing study data hereby presented with data Chaipanich et al. (2010), it appears that the first case was obtained higher level of compressive strength (increase of 19 % to 37%) and this is probably due to the use of higher levels of CNT in the work of Chaipanich et al. (2010). Due to its high specific surface, the CNT tends to make the cementitious composite less fluid and this may have been a causative point of difference between the results of two research work. However, it is not possible to compare the effect of CNTs on the fluidity in both works because the study of Chaipanich et al. (2010) was carried out on cement paste and consistency was not measured.

Melo (2009) showed an increased compressive strength and tensile strength in Portland cement products with the addition of CNTs. Melo (2009) and Nochaiya; Chaipanich (2011) in their respective studies proved a reduction of the average size of the pores caused by the incorporation of NTC in Portland cement pastes, which can increase the durability of concrete structures, since smaller diameters tend to hinder the movement of aggressive agents within the concrete. According Melo (2009), the content of 0.3% nanotubes showed the highest strength lifting capacity. According to Makar et al. (2005), an increase in the durability of concretes and mortars with addition of CNTs should the adhesion bridges that form in the mass microstructure (Figure 9). They control cracks generated in the cementitious matrix and hence promote greater strength and decrease in porosity. Li et al. (2004) also report a connecting bridge between the hydrated cement and nanomaterials on one of the reasons of increased strength mortars had the incorporation of carbon nanotubes. Other explanations cited in the work of Li et al. (2004) and Nochaiya; Chaipanich (2011) imply the fact that the nanoparticles fill the voids of the cement paste and increases the mechanical strength of the cementitious composite.

Figure 9 Micro fissure in the cement paste with addition of CNTs acting as adhesion bridges (Makar et al., 2005).

Despite being used in various fields, carbon nanotubes also have a high cost, which can be an obstacle to the use of this material in cement composites. Experience shows that with the increasing demand and the ability to synthesize CNTs in the manufacture of clinker, which is being studied at UFMG as reported by Ludving et al. (2011) and Melo et al. (2011), the material will become more accessible. Thus, although the cost of the material is a negative aspect at present, the tendency is that this drawback be overcome over time.

4. CONCLUSIONS

This study focused on the contribution to the effect of addition of carbon nanotubes in Portland cement concrete. Once upon a field of study underway of development and to be prominent and with a few initial results available in the literature. These data is applied to studies of pastes and Portland cement mortars and this test give evidence of different application of CNTs in Portland cement concrete.

The work is based on Marcondes master's dissertation (2012), developed in Federal University of Paraná and in attention to the importance of conducting dispersion of CNTs in water and additive to ultrasound prior to its use in concrete mass. The main findings in this work can be seen as below:

With 95% of significance, it had acknowledged the mechanical effects of compressive strength and tensile strength by diametrical compression, to be affected by the efficiency of the dispersion of carbon nanotubes in Portland cement concrete.

The increase of compressive and tensile strength by diametrical compression from CNTs had been found. In this research such increase in compressive strength is represented by 19 % for the SD series and 37 % for CD series, and 17 % for SD series and 19 % for CD series of increase in tensile strength by diametrical compression;

Addition of CNTs reduced to concrete fluidity of this material. In the case of adding the CNTs prior to ultrasonic dispersion, this reduction was very small, triggering the concrete frame into the same consistency range of the reference concrete, which achieved a reduction of 20 ± 3 cm. Since the addition of powdered CNTs directly into the mixer and without dispersion, caused a sharp drop in the feasibility of the concrete, decreasing its reduction to 7 cm, of which affects material applicability. In such case, this addition of water or more admixtures to adjust the consistency would be required;

Addition of CNTs reduced absorption of water by immersion in pipette test. In such case it was also found that the series of ultrasound dispersion escalated the advantages arising from the incorporation of CNTs to it.

Acknowledgements

The authors acknowledge the support of the Post-graduate degree in Construction Engineering from the Federal University of Paraná (PPGECC-UFPR) and the Pontifical Catholic University of Paraná (PUC PR) and the National Council for Scientific and Technological Development (CNPq).

REFERENCES

Marcondes, C. G. N. (2012), Adição de nanotubos de carbono em concretos de cimento portland - absorção, permeabilidade, penetração de cloretos e propriedades mecânicas Dissertação de Mestrado. Universidade Federal do Paraná, Curitiba, Brasil. [ Links ]

Couto, G. G. (2006), Nano partículas de níquel: síntese, caracterização, propriedades e estudo de sua utilização como catalisadores na obtenção de nano tubos de carbono Dissertação de Mestrado. Universidade Federal do Paraná, Curitiba, Brasil. [ Links ]

Zarbin, A. J. G. (2007), Química de nano materiais. Quimica Nova, v.30, n.6, p. 1469-1479. [ Links ]

Herbst, M. H; Macêdo, M. I. F; Rocco, A. M. (2004), Tecnologia dos nanotubos de carbono: tendências e perspectivas de uma área multidisciplinarQuímica Nova, v.27, n.6, p. 986-992. [ Links ]

Batiston, E. R., Hampinelli, D., Oliveira, R. C., Gleize, P. J. P. (2010), Funcionalização e efeito da incorporação de nano tubos de carbono na cinética de hidratação em matrizes cimentícias in: Congresso Brasileiro do Concreto, 52., Ibracon, Fortaleza (Brasil), pp. 1-12. [ Links ]

Makar, J., Margeson, J., Luh, J. (2005), "Carbon nanotube / cement composites - early results and potential applications" in: International Conference on Construction Materials: Performance, Innovations and Structural Implications, v.3., pp. 1-10. [ Links ]

Chaipanich, A., Nochaiva, T., Wongkeo, W., Torkittikul, P. (2010), Compressive strength and microstructure of carbon nanotubes-fly ash cement compositesMaterials Science and Engineering: A, v.527, n.4-5, p. 1063-1067. [ Links ]

Melo, V. S., Calixto, J. M., Ladeira, L. O., Silva, A. P., Oliveira, S. (2011), Desempenho de argamassas de cimento Portland contendo nanotubos de carbono e aditivo de melamina Revista Construindo, v.3, n.2, p. 21-26. [ Links ]

Li, H., Xiao, H. G., Ou, J. P. (2004), A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials Cement and Concrete Research, v.34, n.6, p. 435-438. [ Links ]

Konsta-Gdoutos, M. S., Zoi, S. M., Surendra, P. S. (2010), Highly dispersed carbon nanotube reinforced cement based materials Cement and Concrete Research, v.40, n.7, p. 1052-1059. [ Links ]

Koshio, A., Yudasaka, M., Zhang, M., Iijima, S. (2001), Uma maneira simples de reagir quimicamente Nanotubos de carbono de parede simples com materiais orgânicos usando a ultrasonificação Nano Letters, v.1, n.7, p. 361-363. [ Links ]

Associação Brasileira de Normas Técnicas. Cimento Portland e outros materiais em pó - Determinação da massa específica - Método de ensaio. NBR NM 23, Rio de Janeiro, 2001. [ Links ]

Associação Brasileira de Normas Técnicas. Agregados para concreto - Especificação. NBR 7211, Rio de Janeiro, 2005. [ Links ]

American Society for Testing and Materials. Standard Specification for Chemical Admixtures for Concrete. ASTM C 494 / C 494M, USA, 2011. [ Links ]

American Society for Testing and Materials. Standard Specification for Chemical Admixtures for Use in Producing Flowing Concrete. American ASTM C 1017/C 1017M, USA, 1998. [ Links ]

Associação Brasileira de Normas Técnicas. Aditivos químicos para concreto de cimento Portland - Requisitos. NBR 11768, Rio de Janeiro, 2011. [ Links ]

Mehta, P. K., Monteiro, P. (2008), Concreto - Estrutura, Propriedades e Materiais (São Paulo, Brasil: IBRACON), 3ed., p. 674. [ Links ]

Associação Brasileira de Normas Técnicas. Agregados - Determinação da composição granulométrica - Método de ensaio. NBR NM 248, Rio de Janeiro, 2001. [ Links ]

Associação Brasileira de Normas Técnicas. Agregados - Determinação do material fino que passa através da peneira 75 um, por lavagem - Método de ensaio. NBR NM 46, Rio de Janeiro, 2003. [ Links ]

Associação Brasileira de Normas Técnicas. Agregado miúdo - Determinação da massa específica e massa específica aparente - Método de ensaio. NBR NM 52, Rio de Janeiro, 2009. [ Links ]

Associação Brasileira de Normas Técnicas. Agregados - Determinação da massa unitária e do volume de vazios - Método de ensaio. NBR NM 45, Rio de Janeiro, 2006. [ Links ]

Associação Brasileira de Normas Técnicas. Agregado miúdo - Determinação da absorção de água. NBR NM 30, Rio de Janeiro, 2001. [ Links ]

Associação Brasileira de Normas Técnicas. Agregado miúdo - Determinação de impurezas orgânicas - Método de ensaio. NBR NM 49, Rio de Janeiro, 2001. [ Links ]

Associação Brasileira de Normas Técnicas. Agregados - Determinação do teor de argila em torrões e materiais friáveis - Método de ensaio. NBR 7218, Rio de Janeiro, 1987. [ Links ]

Associação Brasileira de Normas Técnicas. Projeto de estruturas de concreto - Procedimento. NBR 6118, Rio de Janeiro, 2007. [ Links ]

Associação Brasileira de Normas Técnicas. Concreto - Preparo, controle e recebimento - Requisitos. NBR 12655, Rio de Janeiro, 2006. [ Links ]

Associação Brasileira de Normas Técnicas. Concreto - Procedimento para moldagem e cura de corpos-de-prova - Procedimento. NBR 5738, Rio de Janeiro, 2003. [ Links ]

Associação Brasileira de Normas Técnicas. Concreto e argamassa - Determinação da resistência à tração por compressão diametral de corpos de prova cilíndricos - Método de ensaio. NBR 7222, Rio de Janeiro, 2011. [ Links ]

Associação Brasileira de Normas Técnicas. Argamassa e concreto endurecido - Determinação da absorção de água por imersão - Índice e vazios e massa especifica - Método de ensaio. NBR 9778, Rio de Janeiro, 2005. [ Links ]

Reunion Internationale des Lamoratoires D'Essais et de recherches sur les Materiaux et les Constructions. RILEM Test Method II.4: Water absorption tube test, 2006. [ Links ]

Melo, V. S. (2009), Nanotecnologia aplicada ao concreto: efeito da mistura física de nanotubos de carbono em matrizes de cimento Portland Dissertação de Mestrado, Universidade Federal de Minas Gerais, Belo Horizonte, Brasil. [ Links ]

Nochaiya, T., Chaipanich, A. (2011), Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials Applied Surface Science, v. 257, n. 6, p. 1941-1945. [ Links ]

Ludvig, P., Calixto, J. M., Ladeira, L. O., Gaspar, I. C. P. (2011), Using Converter Dust to Produce Low Cost Cementitious Composites by in situ Carbon Nanotube and Nanofiber Synthesis Materials, v. 4, n.3, p. 575-584. [ Links ]

Melo, V. S., Calixto, J. M. F., Ladeira, L. O., Silva, A. P. (2011), Macro- and Micro-Characterization of Mortars Produced with Carbon Nanotubes ACI Materials Journal, v. 108, n. 3, p. 327-332. [ Links ]

Received: December 27, 2014; Accepted: May 27, 2015

text in

text in