Introduction

Barley (Hordeum vulgare) is produced almost everywhere in the world, with 70 % of its production going to the malting industry and the remaining 30 % to cattle feed (Akar, Avci, & Dusunceli, 2004). The barley used for brewing must have high starch percentages (60 to 80%), as it is the compound that gives rise to the fermentable extract; in addition, the type of barley is one of the most important factors in the development of flavor. During malting, cereal grains undergo a series of chemical and structural changes, which lead both to the release of fermentable carbohydrates and to the production of precursors related to the organoleptic properties (color, aroma and flavor) desired for beer production (Chandra, Proudlove, & Baxter, 1999). The malt produced during this process provides saccharides, proteins, free amino nitrogen and enzymes, which favor fermentation (Bokulich & Bamforth, 2013; Fox, 2009).

Depending on the roasting applied to the grains, different types of malt can be obtained, such as base, crystal or caramel, special, amber, chocolate and black malts. The main difference between the first three is color, since in base malts, such as Ale and Lager, some enzymes tolerate the drying process because it is carried out under low temperature conditions, which minimizes color formation (Briggs, Boulton, Brookes, & Stevens, 2004). On the contrary, in the making of special malts, the high temperature promotes the formation of free sugars and amino acids; the interaction of these and other substances form melanoidins by Maillard reaction ( Therefore, special malts, such as Chocolate and Café, are rich in melanoidins (Čechovská, Konecny, & Valisek, 2012), which also impart aroma to beers. Roasted malts generate products such as methylpyrazines, furfural, pyrrole, 5-methyl furfural, benzaldehydes and maltol. In clear malts, such as Crystal, compounds such as isomaltol, 2-furanmetanol and 2-hydroxy-2-cyclopenten-1-one are produced that provide specific characteristics to beer (Yahya, Linforth, & Cook, 2014).

The brewing industry has shown high growth, mainly in the craft beer brewing market, where the process must be more careful due to the little technology used in making it. However, the characteristics of this type of beer vary compared to a commercial beer. Some important variation factors are the care and dedication of the master brewer during production (Bernáldez-Camiruaga, 2013), gasification and barley quality, the last affecting both physical and chemical characteristics. Therefore, barley must have enough starch, and enzymes to hydrolyze it, to leave simple sugars available for fermentation; however, not all barleys have these characteristics.

The demand for barley for beer production has increased the production of this cereal, mainly in rainfed agricultural areas, which has led to the need to obtain varieties with higher yields, tolerance to major diseases, and malting and brewing quality. The new varieties are an alternative with higher yields and greater tolerance to foliar diseases (Zamora-Díaz et al., 2008). In this sense, the Doña Josefa variety was obtained as an alternative to improve yields, as well as the agricultural conditions for planting in the rainy season. Currently there are few data on the production of different malts from this variety, so the conditions for its use in brewing craft beer are unknown. Due to the above, the aim of this work was to evaluate the potential of the Doña Josefa barley variety to produce gourmet-type beer with different flavor notes according to the type of malt.

Materials and methods

Raw material

Doña Josefa barley variety from the Coatlaco area, belonging to the municipality of Almoloya, Hidalgo, Mexico (19° 42’ 12’’ NL, 98° 24’ 12’’ WL, and between 2 600 and 3 300 masl), was used. The barley was obtained from a simple random sampling. All determinations were made in triplicate.

To obtain the malt, the barley grains were soaked for 24 h at 20 °C, then placed in an automatic germinator (developed by the Centro de Investigación en Ciencia Aplicada y Tecnología Avanzada of the Instituto Politécnico Nacional) for 48 h at 20 °C, and finally dried and roasted in a stove (model 6957, Thermo Scientific™, USA) according to the type of malt to be obtained (Table 1).

Malt extract

Once the different types of malt had been obtained, the extract was obtained in accordance with method 4.5.1 of the European Brewery Convention (EBC, 2003). First, 90 mL of water were added to 12.5 g of ground malt at 65 ± 0.5 °C, maintaining this thermal condition for 90 min. Subsequently, the temperature was raised to 70 °C and 100 mL of water were added.

Malt analysis

Total sugars (TS; g·100 g-1 of sample). This determination was made in accordance with the method described by Dubois, Gilles, Hamilton, and Rebers (1956). First, 1 mL of malt extract, previously diluted with distilled water (1:100), and 1 mL of 5 % phenol (J.T. Baker) were placed in a test tube, where the mixture was stirred. Subsequently, 5 mL of concentrated sulfuric acid (J.T. Baker) were added, stirred and left to cool for 15 min. Absorbance was measured at 490 nm in a UV-vis spectrophotometer (Genesys, Thermo Scientific™, USA).

Reducing sugars (RS; g·100 g-1 of sample). They were obtained using the 3,5-dinitrosalicylic (DNS) technique (Sigma Aldrich) (Miller, 1959). First, 1 mL of malt extract, previously diluted with distilled water (1:10), and 3 mL of DNS were placed in a test tube. Subsequently, the tube was immersed in a vessel with boiling water for 3 min, it was removed and 6 mL of distilled water were added, and then it was stirred and allowed to stand for 10 min. Absorbance was measured at 550 nm in the UV-vis spectrophotometer.

β-glucans (%). This compound was determined using enzymatic methods 3.10.1 and 4.16.1 (EBC, 2003). The malt was milled, sieved with a mesh size of 0.5 mm and 120 mg were placed in a test tube. The sample was moistened with 0.2 mL of 50 % ethanol (J.T. Baker), 4 mL of sodium phosphate buffer (20 mM, pH 6.5) were added and then it was immediately placed in water at 100 °C for 60 s. Subsequently, the tube was vortexed and incubated for 2 min in water at 50 °C. It was removed from the water bath, 0.2 mL of lichenase were added, vigorously stirred and incubated for 1 h at 50 °C, with stirring every 15 min. After this time, 5 mL of sodium acetate buffer (200 mM, pH 4) were added and vortexed. The sample was allowed to stand for 15 min and subsequently centrifuged for 10 min at 1000 rpm. Three aliquots of 0.1 mL each were taken from the supernatant and placed separately in three 12 mL tubes. Then 0.1 mL of sodium acetate buffer (50 mM, pH 4) was added to tube 1 (blank), and 0.1 mL of β-glucosidase (previously prepared with 50 mM sodium acetate buffer) was added to tubes 2 and 3. The tubes were closed and incubated for 10 min at 50 °C. After this time, 3 mL of glucose oxidase/peroxidase (GOPOD) reagent were added to each tube and incubated at 50 °C for 20 min. Finally, absorbance was measured at 510 nm. The results were expressed according to the following equation:

where ΔA is the absorbance of the sample minus the absorbance of the blank, F is the conversion factor for the values in the D-glucose standard solution (100 μg of glucose/absorbance of 100 μg glucose) and W is the moisture of the sample. The latter was determined with a thermobalance (MB45, Ohaus®, USA) at 105 °C.

Diastatic power (WK). It was estimated using method 4.12 (EBC, 2003). This analysis consists of extracting the α and β amylase enzymes from the malt with water at 40 °C. A standard solution of starch was then hydrolyzed with these enzymes and the amount of reducing sugars formed by the iodometric method was estimated. For the extraction, 2 g of ground malt were placed with 48 mL of water at 40 °C for 1 h. The sample was then cooled and filtered with Whatman paper no. 40. From this extract, 0.5 mL were taken and added to 10 mL of a starch solution (20 g·L-1 at pH 4.3). Hydrolysis was performed for 30 min at 20 °C and stopped with 0.4 mL of NaOH (1 M) (J.T. Baker), using thymophthalein as the indicator (pale blue color). Subsequently, an aliquot of 0.5 mL was taken and 2.5 mL of iodine (0.1 M) (J.T. Baker) and 0.3 mL of NaOH (J.T. Baker) were added; this mixture was maintained for 15 min. Finally, 0.45 mL of sulfuric acid (H2SO4) (0.5 M) (J.T. Baker) were added, titrating the solution with sodium thiosulfate (NaS2O3) (0.1 M) (J.T. Baker). The results were obtained from the following equations:

where DP1 is the diastatic power of the sample (WK), DP2 is the diastatic power in malts (WK), V b is the titration value of iodine that did not react with the blank, V T is the titration value of iodine that did not react with the sample, F is the correction factor and M is the moisture of the malt (%) determined with a thermobalance (MB45, Ohaus®, USA) at 105 °C.

Making of beer worts

The malts were mixed with water at a controlled temperature of 60 ºC and different beer worts were made, with Pilsen malt as a base, at a ratio of 80:20 (80 % Pilsen malt and 20 % other malt): Pilsen-Chocolate (PCH), Pilsen-Café (PC), Pilsen-Viena, (PV) and Pilsen-Melano (PM) (Table 2).

Brewing

Yeast propagation. First, 0.2 g of yeast (Sacharomyces cerevisiae), previously hydrated with 10 mL of wort, were weighed and placed in 100 mL of sterile Pilsen wort. The inoculated wort was placed in an incubator (Max Q 4000, Thermo Scientific™, USA) at 25 °C for 12 h with constant stirring at 200 rpm.

Wort cooking and hopping. The prepared worts (Table 2) were kept under stirring for 90 min at 60 ± 5 °C. They were then allowed to cool to room temperature and filtered with Whatman paper no. 41. The filtered worts were boiled for 30 min; half of the hops were added at the first 5 minutes to make the beer bitter, and the rest of the hops were added at the first 25 minutes of boiling. At the end of the boiling time, the worts were removed, allowed to cool, filtered and sterilized at 121 °C for 15 min.

Wort inoculation. The activated yeast was inoculated into the sterile worts by taking 5 % of the culture and placing it in 250 mL of sterile wort.

Fermentation and maturation. The inoculated wort was left to ferment in an incubator (Ambi-Hi-Lo Chambers, Cole Parmer®, USA) for 5 days at 15 °C. Once the fermentation process was completed, the sample was filtered and transferred to sterile amber bottles. The hermetically sealed bottles were kept refrigerated for 15 days at 5 °C, and finally sterilized in an autoclave at 121 °C for 15 min.

Determination of beer quality. In each of the beers brewed, the pH (EBC method 1.5, 2003), ethanol (EBC methods 9.3 and 9.2, 2003) and color were measured at a wavelength of 430 nm (EBC method 8.5, 2003), and finally a sensory analysis was performed by means of an affective test to determine the level of liking of the beer. A five-point hedonic scale with 100 panelists was used.

Statistical analysis

An analysis of variance and Tukey’s mean comparison tests (P ≤ 0.05) were performed using MiniTab 17 (Granato, de Araújo-Calado, & Jarvis, 2014). The data were expressed as the mean plus the standard deviation of the replicas (three for each analysis).

Results and discussion

Malt analysis

Moisture and diastatic power. The moisture of the malts after roasting varied between 1.94 and 4.42 % (Table 3). All malts were significantly different (P < 0.05) because the drying and roasting process was different for each. The moisture content present in the malts is important because it ensures stability during storage. The processed malts are special, since they are oriented to obtain a specific color and aroma, according to the type of roasting applied. The degree of enzymatic inactivation depends on the thermal stability of each malt, so it is necessary to control the baking or roasting processes to produce a wort with the desired composition (Varman & Sutherland, 1994).

Table 3 Drying temperature, moisture content and diastatic power of the processed malts.

| Malt | Final drying temperature (°C) | Moisture before roasting (%) | Moisture after roasting (%) | Diastatic power (WK) |

|---|---|---|---|---|

| Viena | 50-60 | 42.9 | 2.78 ± 0.02 cz | 342.09 ± 0.001 b |

| Pilsen | 80-85 | 43.03 | 4.42 ± 0.02 a | 455.02 ± 39.51 a |

| Melano | 50-60 | 46.03 | 2.91 ± 0.02 b | 454.95 ± 39.50 a |

| Café | 50-60 | 44.12 | 2.46 ± 0.01 d | 432.14 ± 39.5 ab |

| Chocolate | 50-60 | 45.29 | 1.94 ± 0.03 e | 440.60 ± 40.38 a |

Average values ± standard deviation. zMeans with the same letters within each column do not differ statistically (Tukey, P ≤ 0.05).

The diastatic power was 342 to 455 WK (Table 3), and only the Vienna malt showed significant difference (P < 0.05). Similar results could be related to germination time, which was the same for all malts, so enzymatic activity was similar in all samples. Farzaneh, Ghodsvali, Bakhshabadi, Zare, and Carvalho (2017) mention that when germination time increases, diastatic power increases, as it represents the activity of all starch bioconversion factors, including α and β-amylase, α-glucosidase and limit dextrinase enzymes. On the other hand, Nielsen and Munck (2003) found lower concentrations than those in this study (from 254.7 to 292.5 WK). EBC (2003) indicates that a diastatic power between 200 and 600 WK ensures the obtaining of sugars necessary for fermentation. In this sense, all the malts produced complied with the suggested levels; therefore, the malts obtained from Doña Josefa barley are suitable for fermentation.

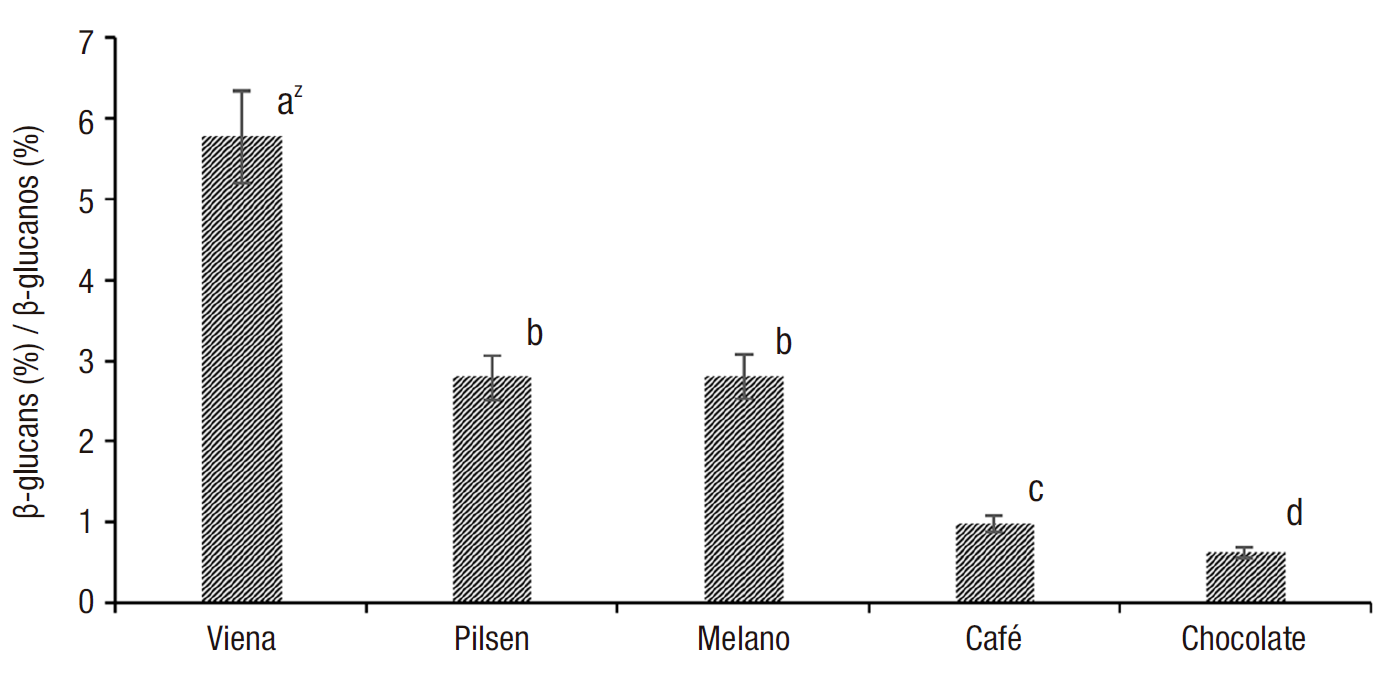

β-glucans. The Viena malt presented a β-glucans percentage of 5.76 %, being the highest percentage and statistically different (Figure 1). Pilsen malt (base) obtained 2.79 % and Melano 2.8 %, which does not represent a significant difference (P > 0.05) between them, while the Café and Chocolate malts had values of 0.98 and 0.62 %, respectively. This could be caused by the depolymerization of the β-glucans during the different roasting temperatures. Boulton and Quian (2001) mention that during the malting process the average percentage of β-glucans in malts is 4, and it is possible that they may decrease during the wort boiling process due to the β-glucanase enzyme. Farzaneh et al. (2017) report concentrations of 1.4 % in 3-day germination malts and 0.7 % in 7-day malts. Nielsen and Munck (2003) obtained concentrations of 3.48 to 4.05 % in malts made from spring barley and 3.09 to 3.60 % in those made from winter barley.

Figure 1 Percentage of β-glucans in Doña Josefa barley malts. zMeans with the same letters between columns do not differ statistically (Tukey, P ≤ 0.05). Bars indicate standard deviation.

Café and Chocolate malts had values below those reported in the literature, which is favorable due to the problems that can be generated in the filtrate, such as the increase in the viscosity of the worts and, possibly, the precipitation of a gel during maturation in the bottle (Huerta-Zurita, Zamora-Díaz, Solano-Hernández, & López-Cano, 2014; Varman & Sutherland, 1994).

Total and reducing sugars. The TS represent the amount of starch degraded during maceration as a function of time and temperature, which are used for fermentation (Olsen, 2008). Figure 2 shows that the content of TS was higher in the Pilsen (67.09 g·100 g-1) and Chocolate (61.23 g·100 g-1) malts, which is related to the drying and roasting conditions because Pilsen had the highest temperature in the drying process (80 to 85 °C) and Chocolate the highest temperature in the roasting process (230 °C), which can facilitate the hydrolysis of starch into simpler sugars (Farzaneh et al., 2017). The Café (27.81 g·100 g-1) and Melano (24 g·100 g-1) malts had the lowest TS values, which were significantly different (P < 0.05) from the rest of the malts. This could be mainly due to the low starch degradation during maceration.

Pilsen malt can be used as a base for brewing due to its high total sugar content and neutral color. The Café and Chocolate malts presented dark color and flavor with bitter notes, which can provide special characteristics to the beer.

Figure 2 Total sugar content present in different Doña Josefa barley malts. zMeans with the same letters between columns do not differ statistically (Tukey, P ≤ 0.05). Bars indicate standard deviation.

Pilsen and Café malts had the highest RS values (35.76 and 37.08 g·100 g-1, respectively), and Melano had the lowest values (13.26 g·100 g-1) (Figure 3). The roasting time and temperature of the grain are the main factors that affected the amount of sugars present. The Café and Chocolate malts were only used as adjuncts to give sensory characteristics to the beer, because they provide aroma, flavor and specific color due to the Maillard reactions generated in the roasting.

Beer analysis

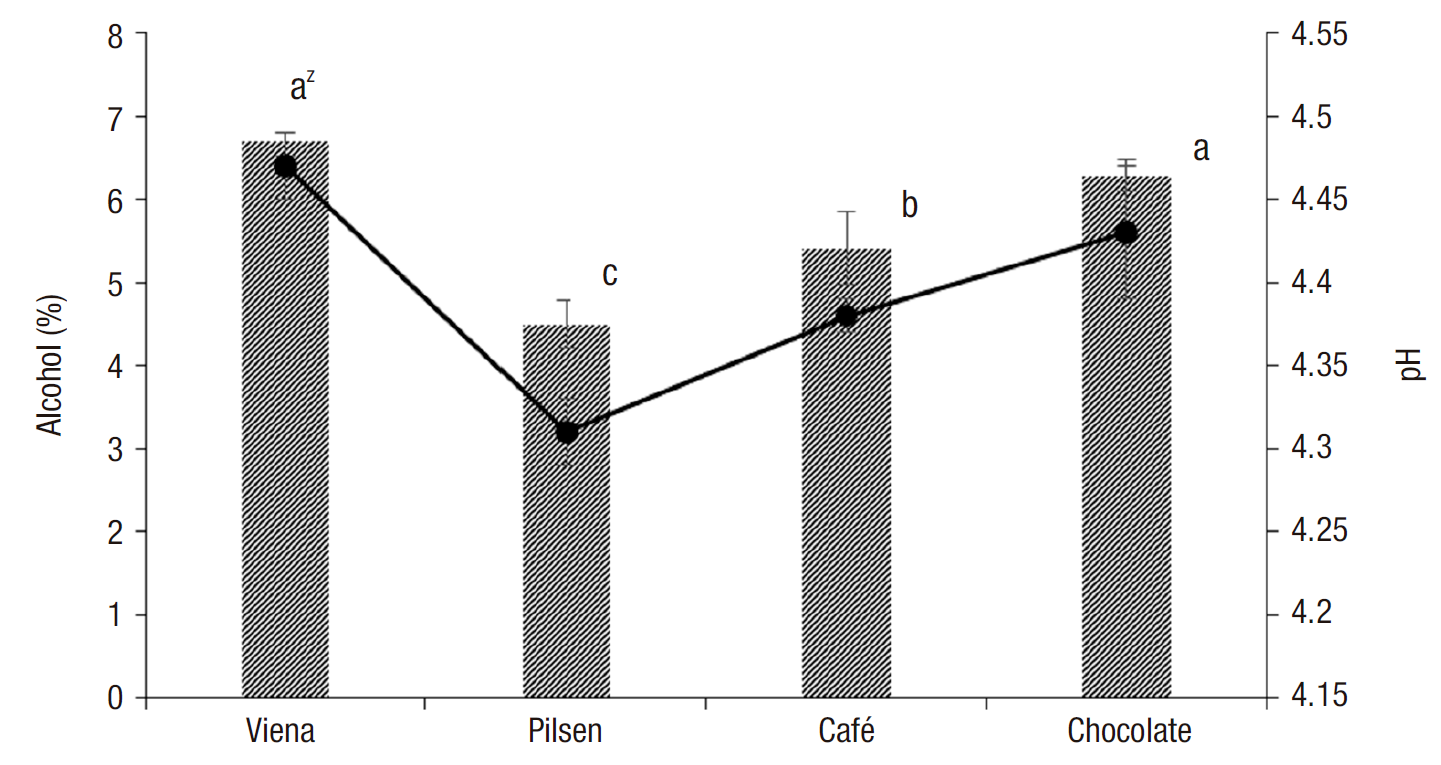

pH. This parameter is of great importance for the fermentation and flavor of beer. The pH values of the beers oscillated between 4.31 and 4.47 (Figure 4), which agree with the findings reported by Madrid (1994), who indicates that the beer should have a pH between 4 and 5. The control and monitoring of this parameter is necessary because the increase of the pH in the beer can cause problems in reactions such as saccharification, since it causes deficiency in the enzymatic activity, which limits the availability of sugars and intensifies bitterness. The increase in pH can be caused by autolysis and ammonia production, which occur with old yeast (Ros, 1980). Briggs et al. (2004) report average values of 4.3 for pale beers and 4.46 for dark beers. Di Ghionno, Sileoni, Marconi, de Francesco, and Perretti (2017) found similar pH values in teff beers (4.23).

Figure 4 Percentages of alcohol and pH values in craft beers brewed from Doña Josefa barley. zMeans with the same letters between columns do not differ statistically (Tukey, P ≤ 0.05). Bars indicate standard deviation.

Alcohol. The percentage of alcohol in the brewed beers ranged from 4.3 to 6.73 % (Figure 4). The beers with the highest percentage were Vienna and Chocolate (6.73 and 6.29 %, respectively), followed by Café and Melano; the latter presented the lowest value (4.5 %) and was significantly different (P < 0.05) to the others. The beers with the highest percentage of alcohol were the same ones that had the highest amount of TS, this associated with the time and temperature of drying and roasting. The tendency of the percentage of alcohol was similar to that of the pH, which is directly related to the activity of the yeast. It has been reported that the ideal pH of Saccharomyces cerevisiae is 4 to 5.5 (Narendranath & Power, 2005; Salari & Salari, 2017), which agrees with the values obtained.

On the other hand, the level of hydrolysis of sugars caused by temperatures during roasting may have influenced the variation in alcohol content (Kunze, 1996). Briggs et al. (2004) mention that beers can have an alcohol percentage of up to 8.4, while Di Ghionno et al. (2017) reported values of 4.68. Despite the differences between the alcohol content of the beers, all comply with the percentage established in the NOM-142-SSA1/SCFI-2013 standard for alcoholic beverages (from 2 to 20 %), and within that reported for beers (6.2 % in dark beers and 4.5 % in pale beers).

Color. Café beer presented a darker color, significantly different (P < 0.05) to the others (Table 4), and according to its value (35.62) it can be classified as a Dark Lager. Vienna and Melano beers had very similar colors, without significant difference (P > 0.05) between them (15.88 and 16.26, respectively). The values of these beers were the lowest, which places them as Weissbier-type beers. Finally, the Chocolate presented an intermediate color (27.73) with a copper tonality, classifying it as a Double IPA beer.

The difference in color intensity between beers is associated with roasting temperatures, since when a malt has been subjected for a long time to the roasting temperature it generates a dark color in the beer (Kunze & Manger, 2006). In addition, during boiling, when sugars are combined with amino acids (most of which come from malt and a small amount from hops), a reaction takes place that forms melanoidins and darkens the wort. The different roasting conditions, in addition to the color, allowed different aromas and flavor profiles to be given to the beers.

Table 4 Color of Doña Josefa barley beers according to the European Brewery Convention (EBC, 2003).

| Beer | EBC |

|---|---|

| Viena | 15.88 ± 0.47 cz |

| Melano | 16.26 ± 0.19 c |

| Café | 35.62 ± 0.24 a |

| Chocolate | 27.73 ± 0.79 b |

Average values ± standard deviation. zMeans with the same letters do not differ statistically (Tukey, P ≤ 0.05).

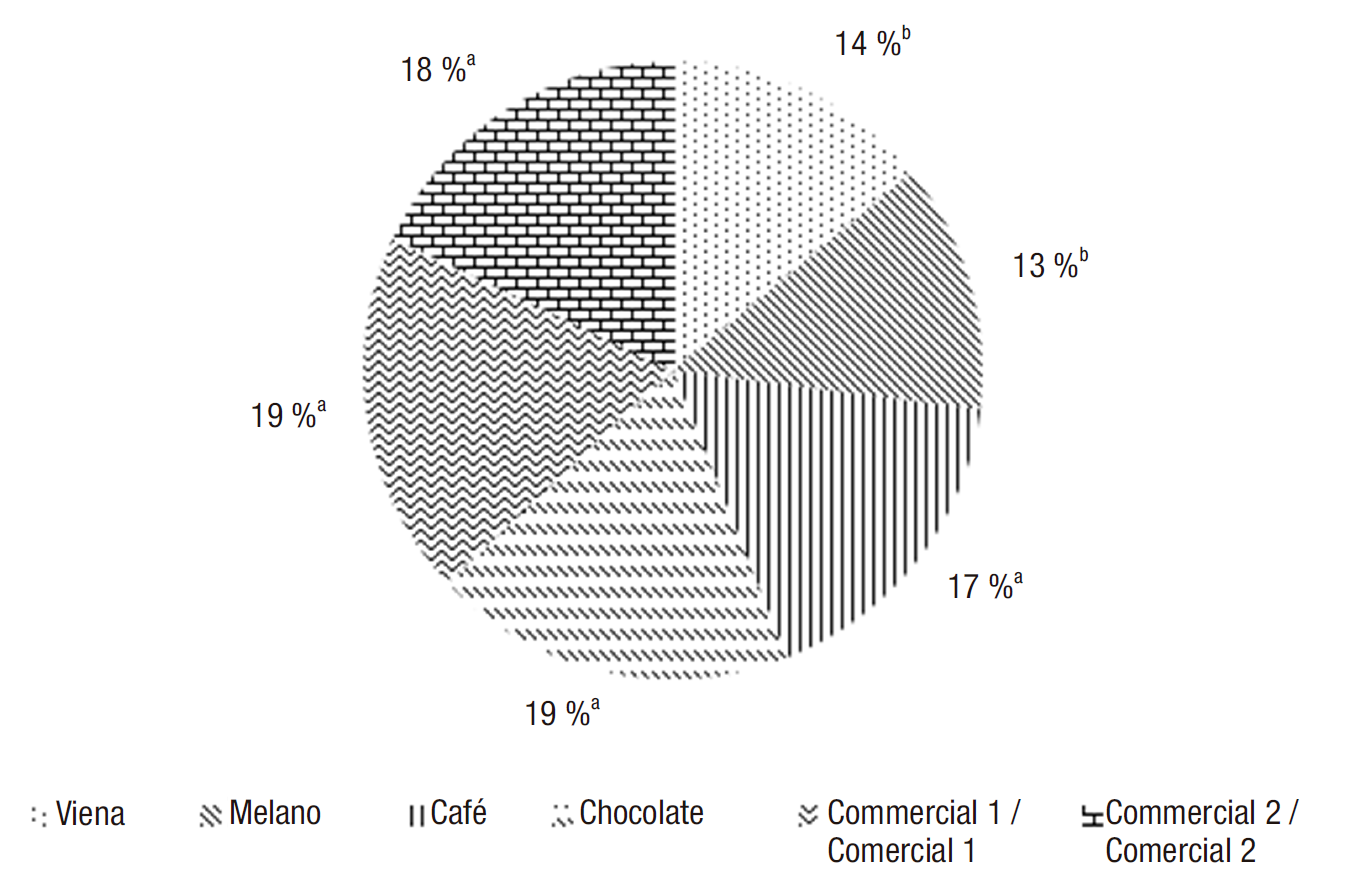

Sensory analysis. A sensory analysis was performed by means of an affective test of liking with a five-point hedonic scale. First, the four craft beers were evaluated and then compared with two commercial beers of the same style as those brewed (Figures 5 and 6). According to the results obtained, the judges preferred the Café and Chocolate beers in terms of color, flavor and aroma, with 56 % preference over the Vienna and Melano beers (23 and 21 %, respectively) (Figure 5). In addition, it was observed that the Café and Chocolate beers were statistically different (P < 0.05) to the other two.

The judges' comments focused mainly on two factors: the first referred to the lack of foam in the beers and the second to the bitter taste. The first could be due to the lack of CO2 generated during fermentation (Kunze & Manger, 2006), or to the characteristics of the container, due to a possible release of CO2. The second factor could be due to the fact that they are dark malts and thus give a characteristic flavor to the beer, which is caused by the chemical reactions generated in the roasting, since there is degradation of phenolic compounds, Maillard reactions, caramelization and presence of furaneol, maltose and isomaltol (Bamforth, Russell, & Stewart, 2009; Kunze & Manger, 2006). However, their aroma and color were acceptable to the judges.

Figure 5 Sensory analysis of Doña Josefa barley beers. Means with the same letters do not differ statistically (Tukey, P ≤ 0.05).

On the other hand, the craft beers were compared with commercial beers, one of the same style as the Vienna and Melano beers, denoted as beer 1, and the other one of the Café and Chocolate style, denoted as beer 2 (Figure 6). The Chocolate beer had a similar percentage in the level of liking as commercial beer 2 with 18 %, although the Chocolate beer’s lack of effervescence could affect its level of preference. For its part, the Café beer scored 17 % in terms of level of liking, which is below the commercial beers. The Vienna and Melano beers were statistically different (14 and 13 % acceptance, respectively) to the rest of beers, and did not have the same preference as commercial beer 1, which obtained 19 % acceptance by the judges. Among the main factors that affected the craft beers was the lack of effervescence, which could be due to the filtration processes, stabilization and low CO2 levels. It must be taken into account that the gasification of craft beers occurs naturally during fermentation in the bottle, while the industrial ones are injected with carbon dioxide. This is one of the main drawbacks of craft beers; however, they were accepted by the judges.

Conclusions

All the malts made from Doña Josefa barley were suitable for fermentation. The diastatic power values of the malts obtained ranged between 342 and 455 WK. The content of β-glucans in the malts indicated that the malting process was adequate, which avoided problems during brewing. The Pilsen malt was used as a base for the different beer-making mixtures, and the other malts were ideal for giving the beers greater color and aroma. The alcohol content was highest in Vienna, followed by Chocolate, Café and Melano, and all met the NOM-142-SSA1/SCFI-2013 standard. The color was associated with the roasting temperatures, which allowed the style of the beer to be determined. The Café was typified as a Dark Lager beer, Vienna and Melano as Weissbier beers, and Chocolate was identified as a Double IPA beer.

Regarding sensory analysis, the judges preferred the beers in the following order: Chocolate, Café, Vienna and Melano. On the other hand, when comparing craft beers with commercial ones, Chocolate had an acceptance percentage equal to that of commercial beer 2. In general, the objective was achieved by generating malts with different flavor notes and, in addition, it was proven that the new variety Doña Josefa has the potential to be used in the brewing of gourmet-type beer.

text in

text in