1. Introduction

Free convection in rectangular enclosures non-isothermal thermal conditions has enormous engineering applications, like cooling of electronic components, storage of food, and passive cooling in buildings. Especially in electronics cooling applications, an electronic component will not produce uniform heating over its entire surface; instead some portion will be more heated than the rest. So performance of and optimum location of such components in enclosures cannot be studied considering isothermal cases.

The most studied non-isothermal heating in enclosures are in periodic temperature profiles which are spatially variable or transient in nature (Deng & Cheng, 2008; Oztop et al., 2011). Only a few literatures are available on linear temperature profiles. It was studied about the linear temperature outline on the heated partition of a rectangular cavity using heatline visualization technique (Oztop et al., 2012). Their study was done by varying Rayleigh number and inclination of the cavity. CuO nanofluid was the working fluid and was limited to only one temperature profile. The linear temperature profiles on vertical sides of enclosures with bottom wall heated and top wall insulated were investigated (Sathiyamoorthy et al., 2007). Here the study was limited to single linear temperature profile. A study about free convection of a nanofluid with different properties in square chamber with different linear temperature distributions on partitions were conducted (Arani et al., 2014). The laminar free convection of a square chamber with an insulated arc form baffle is investigated (Tasnim & Collins, 2005). The two vertical dividers in the form of walls are retained at same but varying thermal conditions and rest walls are protected thermally and insulated. The obtained outcomes showed that the divergence of the mean Nusselt number on the hot wall enhances with the improved length of baffle arc and factors affecting shape. Also a study about transfer of heat in convection and also its fluid characteristics of nanofluid in a 2D square chamber was done (Bhuvaneswari et al., 2015). In this study many models with various compositions of nanofluids are taken and analyzed. It was clear from the study that variation among different models considered will have a vital role in knowing the trend of mean Nusselt number along the strength of nanoparticles. A study was made to know about uncertain effects connected with overall viscosity and thermal conductivity by Ho et al. (2008). This study was also done on square cavity or enclosure as in previous study. The simulation was done numerically in 2D for an even composition of solid-liquid combination. The convection here is buoyancy driven and the cavity is included with alumina-water nanofluid. Two different equations are used in this study about the viscosity enhancement as well as thermal conductivity. The study revealed that there is a major change in the increase in thermal conductivity. This is contradictory while dealing the effectiveness of transfer of heat in nanofluids. The production of entropy and transfer of heat in free convection characteristics was studied (Şahin et al., 2020). The heat is provided linearly in vertical partitions and cooling is provided in a predetermined manner from the other wall. This has been studied numerically and the variations were noted. It has been obtained from the outcome of the study that there was entropy generation at the center is enhanced which can be attributed to the linear heating. Further simulations were carried out to know the effects while the centre of heating is moved towards the top portion. While doing such a change, the results showed that the flow will be moving towards right and the strength of flow is diminished which will pave way for increase in transfer of heat. Copper-water nanofluid effects to be used for cooling purpose were numerically analyzed (Santra et al., 2008). This study was also done in free convection in a square closures. SIMPLER algorithm is used to solve Navier-Stokes equation numerically along with finite volume approach. The outcomes showed that rate of heat transfer is going down due to increase in the volume of solid fraction while keeping the Rayleigh number constant. Interestingly, it enhances while the Rayleigh number is improved at constant value of solid volume fraction. The model diameter is taken as 100 nm for all simulations.

This study aims at extending the previous works on linear temperature profile at enclosures by conducting steady state, numerical analysis on effect of four different temperature profiles at the vertical heater side of a square enclosure. Opposite vertical side is kept cold at same thermal conditions and other walls are insulated. The optimum configuration of temperature profile is found out by comparing these four cases in name of isotherms, stream lines and Nusselt number plots at different Rayleigh numbers. The results are then compared with isothermal heating condition (de Vahl Davis, 1983).

2. Problem statement

A model of the problem domain is sketched in Figure 1. A square enclosure with bottom and top wall insulated and right wall at a low temperature Tc have a non-isothermal temperature profile at the right wall. Right wall temperature varies linearly from a high temperature (T2) to a low temperature (T1). Such four cases of variations are considered as shown in Figure 1. The working fluid inside the enclosure is chosen to be air with Prandtl number of 0.71. The natural convection flow is taken to as 2D, incompressible, laminar and steady and Boussinesq approximation is sound over the selected Rayleigh number range of 103 to 106 for the study.

3. Governing equations

The governing equations for the study are given below from Equations 1 to 8.

The non-dimensional parameters used are

Local and mean Nusselt number at the heater side is defined as

Heat transfer coefficient is given by

4. Numerical methods

The Navier-Stokes equations coupled with energy equation together with the corresponding conditions at boundary are numerically resolved by FLUENT 19. The linear temperature profile is made as separate user defined function and is interpreted by the FLUENT 19 solver. The Boussinesq approximation is used to vary density of fluid. The pressure field and velocity field are combined by using SIMPLE algorithm. The terms related to energy and momentum are discretized by using the second order upwind schemes. This group of discretized equations were resolved with FLUENT solver. Also the factors for relaxation are used to make sure that the convergence of the discretized equations. The convergence criterion is chosen as 10-6 for the scaled residuals.

4.1. Validation

The validation study if numerical analysis was done by comparing the Nusselt number obtained for a differentially headed enclosure with that obtained from de Val Davis (1983). The findings are depicted in Table 1.

4.2. Mesh independent study

A mesh independence study is done by comparing average Nusselt number obtained from Case A at Ra =105. The change in values of Nusselt number was found to be very small and a mesh size of 100x100 with a suitable accuracy was chosen for further study. The study is tabulated in Table 2.

5. Results and discussions

Four cases of linearly varying heater wall temperature in a square enclosure are numerically analyzed for Rayleigh number varying in between 103 and 106 while keeping cold wall temperature constant. Air is taken as working fluid in this study. The steady state results of forecasted variables of field are depicted in terms of the isotherms, streamlines and mean Nusselt number. Average Nusselt numbers of these four cases are then compared with that of isothermal differentially heated square cavity.

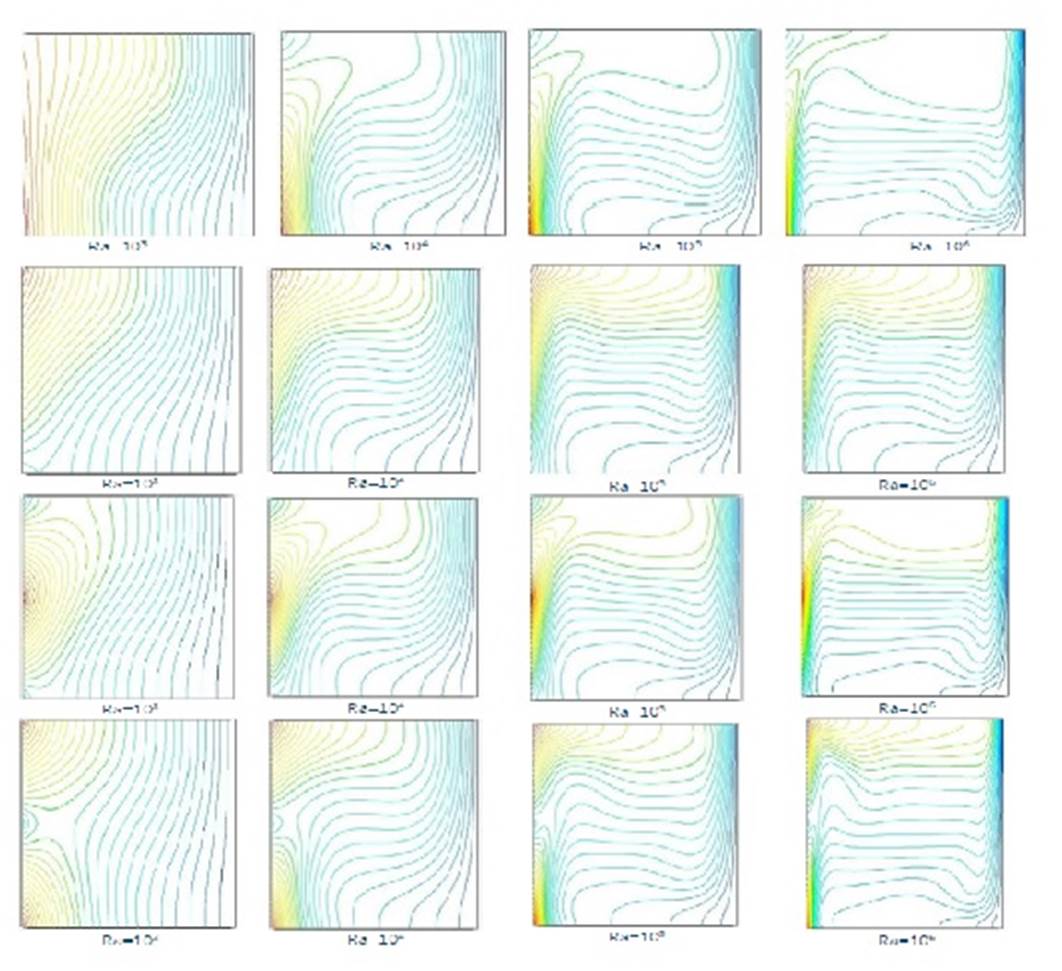

A common trend in fluid and heat transfer is observed for all the cases. Flow and heat transfer mechanism in all four cases is by clockwise-rotating vortex. Air rises up along the heater surface and cools down at the sink. At small Rayleigh number constant temperature lines are almost uniformly distributed and are parallel to the heating element and cold surface that shows dominance of conduction of heat over convection. At higher Rayleigh numbers isotherms are parallel only near heater and cold surfaces which show dominance of conduction near the boundary and convection in the bulk of fluid. Also Ψmax increases as Rayleigh number increases which implies increasing volume flow rate with increase in Rayleigh number. The following section describes peculiarities in the each cases considered in detail.

5.1. Case A

In this case heater surface temperature is maximum about bottom of the closed surface and diminishes linearly along the height. Since conduction is the predominant mechanism of transfer of heat at Rayleigh number of 103, fluid is heated all along the surface and is conducted to the colder side. At higher Rayleigh number fluid gets heated from the bottom and up to a certain height, after that the near wall fluid temperature improves rapidly than the partition wall temperature causing reversal of heat flow. This is clearly depicted in Figure 2.

Stream function contour shows that at Ra=103 (Ψmax = 1.599) and Ra=104 (Ψmax = 5.723) vortex is cantered at the middle portion of the enclosure and further enhancement in Rayleigh number will result in shifting vortex center towards the colder side of the heater and initiates secondary cell flow pattern in the bulk and at left top corner of the fluid. These two secondary cells affect the heat transfer in different ways. The former increases the heat transfer by increased fluid mixing at the core whereas latter causes the primary flow to detach from the heating surface. Since in this case heat rejection takes place at the top surface of the left wall, the detachment of fluid flow helps to reduce the reversal of heat flow. According to Türkoglu H et al. placing the high temperature region close to the bottom increases the flow rate inside the enclosure. Such an effect can be seen in Case A as Ψmax having the highest values in all Rayleigh numbers compared to other three cases.

5.2. Case B

In this case, the wall temperature increases linearly along the wall height which causes heating of the fluid all along the height of the cavity and no heat rejection from fluid at heater side. Figure 3 shows closely packed isotherms towards the top end of the wall which supports the above statement. As the Rayleigh number improves, the constant temperature lines gets compressed more near most of the thermally active sides. This case has the lowest values for Ψmax in all Rayleigh number, because fluid is heated more at the top of the enclosure and dense air is prone to stay at the top of the enclosure and thus decreasing flow rate. The flow circulation pattern is similar to Case A except that secondary cells can be found inside the primary cell only, thereby increasing the heat transfer rate. Since there are no secondary eddies at the corners, heat transfer from left wall to primary flow takes place effectively.

5.3. Case C

In this case wall temperature is highest at the middle and decreases towards top and bottom linearly. Hence isotherms are concentrated near to the centre portion of the partition. Similar to Case A, since the near wall fluid temperature is higher than the temperature of wall at the upper portion of the hot wall heat rejection takes place. Thick isotherm contour at the hot and cold surface is due to the thickening of boundary layers at high Rayleigh numbers. Also secondary cells are formed at higher Rayleigh numbers, one at the top left corner and other two inside the primary cells. Corner secondary cell in this case occurs right after the maximum temperature region also helps in controlling heat rejection to the wall.

5.4. Case D

In this case hot wall temperature is in highest value at the top and below portion and reduces linearly while moving towards middle of the wall. So heat rejection takes at middle region of the left partition unlike Cases A and C. This is evident from the isotherm plots. Flow pattern in this case is similar to Case C except that value of Ψmax is lesser and corner eddies are not formed near top left area due to the high temperature region. So heat rejection will not be controlled since it is occurring in the middle portion of the wall.

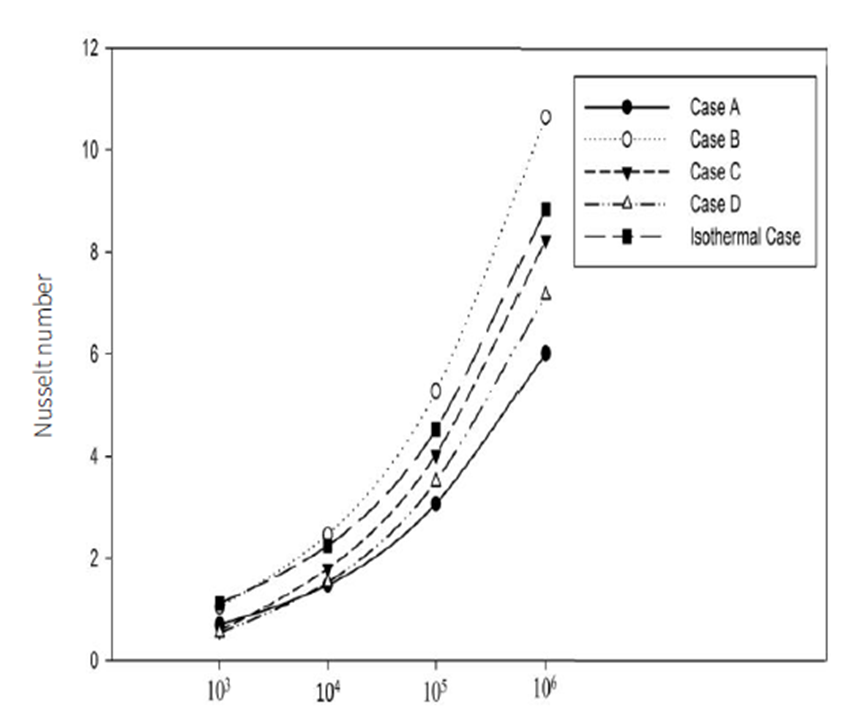

5.5. Change of Nusselt number with Rayleigh number

Mean Nusselt number is graphically analyzed against Rayleigh number from 103 to 106 for all four cases and compared with that of the constant wall temperature case in Figure 4. The results show that even though Ψmax value for Case B is lowest among other cases, the mean Nusselt number for Case B is more enhanced than that for all other cases. This is due to the fact that there is no thermal exclusion at the heated wall for Case B and absence of corner eddies. Case A has the lowest average Nusselt number. Cases A, C and D have average Nusselt number less than that of isothermal case. Case C has a slightly higher Nusselt number than Case D because of low heat rejection in Case C in contrast to Case D.

6. Conclusions

The steady state free convection in a square closure with different linear thermal profile at the heater portion is studied. From the isotherm and streamline plots it was understood that for all cases conduction dominates at lower Rayleigh numbers and convection increases with enhancement in Rayleigh number. The change of mean Nusselt number along with Rayleigh number is graphically studied. It is found that varying temperature has important repercussions on the flow of fluid and transfer of heat characteristics in enclosures. Case B with linearly increasing temperature profile along the height found to have higher Nusselt transfer than other cases. Also, Case A was found to have the lowest Nusselt number among all the cases considered. Hence, in designing electronic components with varying temperature, it is preferred to place them in an enclosure as in Case B for better heat transfers characteristics. It will not only provide higher Nusselt number but also prevent heat entering the component.

text new page (beta)

text new page (beta)