Nomenclature

a,b |

constants |

B 0 |

magnetic field |

|

applied magnetic field |

c |

stretching sheet constant |

c f |

skin friction coefficient |

D B |

Brownian diffusion coefficient |

D T |

thermophoresis diffusion coefficient |

E 0 |

electric field factor |

E 1 |

electric field parameter |

|

applied electric field |

Ec |

Eckert number |

f´ |

dimensionless velocity |

g |

magnitude of the gravity |

Gr |

Grashof number |

|

Joule current |

k |

thermal conductivity |

k f , k p |

thermal conductivity of the base fluid andnanoparticle |

Le |

Lewis number |

M |

magnetic field parameter |

Nb |

Brownian motion parameter |

Nr |

buoyancy ratio parameter |

Nt |

thermophoresis parameter |

Nu |

local Nusselt number |

Pr |

Prandtl number |

q m |

wall mass flux |

q r |

radiative heat flux |

q w |

wall heat flux |

Rd |

radiation parameter |

Re x |

local Reynolds number |

s |

suction/injection |

s c |

solutal stratification |

s t |

thermal stratification |

Sh |

local Sherwood number |

T |

temperature of the fluid |

T W |

constant temperature at the Wall |

T ∞ |

ambient temperature |

T 0 |

Reference temperature |

u, v |

velocity component along x- and y-direction component |

|

velocity fluid |

V W |

wall mass transfer |

Greek symbols

α |

thermal diffusivity |

σ* |

Stefan-Boltzmann constant |

σ |

electrical conductivity |

β |

volume expansion coefficient |

β nf |

volumetric volume expansion coefficient the nano fluid |

ε |

heat generation/absorption parameter |

η |

dimensionless similarity variable |

μ |

dynamic viscosity of the fluid |

υ |

kinematic viscosity of the fluid |

ρ, ρ nf |

density |

ρp |

particle density |

(ρ) f |

density of the fluid |

(ρc) f |

heat capacity of the fluid |

(ρc) p |

effective heat capacity of a nanoparticle |

ψ |

stream function |

σ |

electrical conductivity |

ϕ |

concentration of the fluid |

ϕ W |

nanoparticle volume fraction at the Surface |

ϕ∞ |

ambient nanoparticle |

ϕ0 |

reference concentration |

θ |

dimensionless temperature |

φ |

dimensionless concentration |

τ |

ratio between the effective heat transfer capacityof the nanoparticle and the heat capacity of thefluid |

τ W |

surface shear stress |

λ |

mixed convection parameterγ chemical reaction parameter |

1. Introduction

Magnetohydrodynamic (MHD) nanofluid is an essentialaspect of convective heat transfer and has numerous applications in science and engineering processes ( Lin, Zheng, Zhang,Ma, & Chen, 2015). Nanofluids is a composition of nanoparticles suspended in a conventional liquid that has higher thermalconductivity in contrast with the conventional liquid (Choi, 1995). Such conventional liquid is water, oil and ethylene glycol in nature are poor in thermal conductivity, which limitsthe heat transfer performance. Due to innovation in technologyvia miniaturization of an electronic device requires the further advance of heat transfer from energy saving. To overcome thischallenges leads to a new class of fluid called nanofluid. Theapplication of magnetic field for electrical conducting nanofluidis of recent interest among different researchers (Abolbashari, Freidoonimehr, Nazari, & Rashidi, 2014; Daniel, Aziz, Ismail,& Salah, 2017a; Daniel, 2015a, 2015b, 2016, 2017; Hedayatnasab, Abnisa, & Daud, 2017; Malvandi, Hedayati, & Ganji, 2014; Sandeep & Sulochana, 2015; Waqas et al., 2016). Essential roles in sink-float separation, sealing of materials andconstruction of loudspeakers. The rate of heat transfer withapplication to the nuclear reactions and metallurgical processes is as result of its greater thermal conductivity (Shateyi & Motsa, 2011). Due to the fascinating properties possessby magnetic nanofluid of liquid and magnetic behavior (Bég, Khan, Karim, Alam, & Ferdows, 2014). Such materials haverelevance applications via magneto-optical wavelength fibers, optical switches, optical modulators, nonlinear optical materials, and optical gratings. The heat conduction has an unlimitedsignificance in numerous industrial heating or cooling equipment. Recently, the impact of magnetic field on nanofluidshas also been reported by other researchers (Daniel & Daniel, 2015; Daniel, Aziz, Ismail, & Salah, 2017b; Freidoonimehr, Rashidi, & Mahmud, 2015; Gómez-Pastora et al., 2017; Hayat &Qasim, 2011; Hayat, Waqas, Khan, & Alsaedi, 2017b; Kumar & Sood, 2017; Mabood, Khan, & Ismail, 2015; Mohammed, Gomaa, Ragab, & Zhu, 2017; Shagaiy, Aziz, Ismail, & Salah, 2017).

Stratification is a deposition (formation) of layers whichoccur as result of different fluids mixtures, temperature variation, densities difference or concentration differences whichoccur in fluids (Rehman, Malik, Salahuddin, & Naseer, 2016).Physically, heat and mass transfer analysis run concurrently, itis of great interest to explore the mechanism of double stratification (thermal and mass stratifications) on the convectivetransport in nanofluid (Hayat, Waqas, Khan, & Alsaedi, 2016d).These draw the attention of researchers such as (Hayat, Mumtaz, Shafiq, & Alsaedi, 2017a; Mehmood, Hussain, & Sagheer, 2016; Ramzan, Bilal, & Chung, 2017) due to its frequent occurrence in various industrial and engineering processes namelyheat rejection into the surrounding (environment) via rivers,lakes and seas, also thermal energy storage systems via solarponds, condenser of power plants, industrial composition, manufacturing processing and heterogeneous composition in food, atmospheric density stratification, etc. The random movementof nanosized particles within the conventional fluids is known asBrownian motion, which occurred as result of continuous collisions between the nanosized particles and the fluid molecules.Diffusion of particles sized under the influence of temperaturegradient is called thermophoresis. Thermophoresis is a remarkable significance of the Brownian motion of nanosized particlesin liquids with an externally sustained and constant temperaturegradient. Buongiorno (2006) developed a two-phase nanofluidmodel for investigating thermal energy transport, which hasbeen successfully used to address various diverse flow problems (Hayat, Muhammad, Shehzad, & Alsaedi, 2016b; Mabood & Khan, 2016) involving nanofluids the aspects of Brownianmotion and thermophoretic diffusion. The influence of radiativeheat transfer which is essential in industries at higher temperature processes subjected to isothermal and non-isothermalsurroundings (Pal & Mandal, 2016). The radiative heat transfervia nanofluid play a key role in system devices and renewableenergy sources (Hayat, Qayyum, Waqas, & Alsaedi, 2016c).In view of these technological and engineering widely applications drawn the attentions of some researchers (Bhatti, Zeeshan, Ijaz, Bég, & Kadir, 2016; Daniel, Aziz, Ismail, & Salah, 2017c; Hayat, Gull, Farooq, & Ahmad, 2015; Hayat, Waqas, Shehzad, & Alsaedi, 2016e; Hussain, 2017; Jing, Pan, & Wang, 2017; Khan, Tamoor, Hayat, & Alsaedi, 2017) to explore in thisdirection.

The aim of the current study is to investigate the combinedeffects of an electric field, magnetic field, thermal radiation, heat generation/absorption, chemical reaction, viscous dissipation, and Joule heating for unsteady mixed convection flow of electrical conducting nanofluid in the presence of thermalstratification and concentration stratifications over a permeable stretching sheet. Buongiorno nanofluid model is adoptedwhich features the novel aspects of the Brownian motion andthermophoresis. Additional, water based nanofluid (Maboodet al., 2015) is used. The boundary layer governing equations which are partial differential equations are transformedinto a set of nonlinear self-similar ordinary differential equations. Computational analysis is performed through implicitfinite difference scheme known as Keller box method (Cebeci & Bradshaw, 2012). The effects of physical sundry parameters on the velocity, temperature, nanoparticle concentrationprofiles, skin friction, and Nusselt and Sherwood numbers arepresented and discussed extensively with the aids of graphs andtables.

2. Mathematical formulation

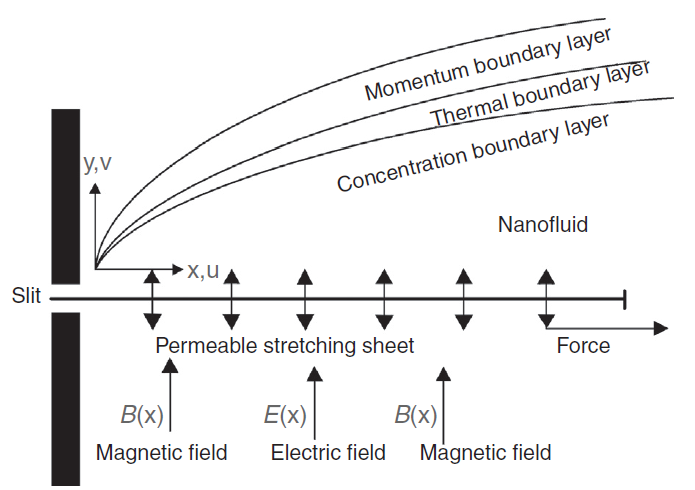

Consider the unsteady mixed convection flow of an electrical conducting nanofluid

over a permeable stretching sheetsurface in the presence of external magnetic and

electricfields, thermal radiation, heat generation/absorption, chemicalreaction,

viscous dissipation and Joule heating. The coordinate system is selected in such a

manner that the x-axis ismeasured along the stretching sheet and

the y-axis is normal to it and the flow is occupied above the

surface sheety > 0 displayed in Figure 1. Two equal and opposite forces are impulsivelyapplied along the

x-axis so that the sheet isstretched with the velocity

u

W

(x, t) along the x-axis.

As thefluid is electrical conducting so the Lorentz forcé

Continuity equation

x-Momentum equation

y-Momentum equation

Energy equation

Concentration equation

The boundary conditions at the sheet for the physical modelare presented by

Here u

W

(x,

t)=bx/(1−at) denotes the

velocity of the linearstretching sheet, where b is the stretching

rate, a is the positiveconstant with the property

(at < 1) and dimension of

a,b is T

-1.A

1, A

2, C

1, and C

2 are the dimensional constants with dimension

where σ* represent the Stefan-Boltzmann constant and k * denotethe mean absorption coefficient. Expanding T 4 by using Taylor’sseries about T ∞ and neglecting higher order terms, we have,

Using Eq. (8) into Eq. (7), we get

Use Eq. (9) in Eq. (4), we obtain

Using the order of magnitude analysis for the y-directionmomentum equation which is normal to the stretching sheet andboundary layer approximation (Daniel et al., 2017a; Ibrahim & Shankar, 2013), such as

After the analysis, the boundary layer Eqs. (1), (2), (3), (4) and (5) arereduced to the following as:

The boundary conditions at the sheet are presented by

The equations are reduced into the dimensionless form byintroducing the following dimensionless quantities defined as:

The stream function ψ can be given as:

Using Eqs. (17) and (18) into Eqs. (12), (13), (14), (15) and (16). The equations of momentum, energy and nanoparticle concentration indimensionless form become:

The boundary conditions are given by

here f´,θ and φ is the

dimensionless velocity, temperature, and concentration, respectively, δ=

a/b represent theunsteadiness parameter, λ =

Gr/Re

2 is the mixed convection parameter (Richardson number) for values of(λ

> 0) associate to heated surface and (λ < 0) corresponds to cold surface

whereas (λ=0) indicates forcedconvection flow, Gr

=gβ(1−φ∞)(T

W

−T

0)ρf∞/ν2ρf is theGrashof

number, Re=uwx/v is the Reynolds number,Nr=(ρ

f

− ρ

f∞

)(φ

W

−φ0)/βρ

f∞

(1−φ∞)(T

W

−T

0) is the buoyancy ratio parameter, Pr=v/α stand for Prandtl number,

Nb=(ρc)pDB(φw−φ∞)/(ρc)fv

is the Brownian motion parameter,Le=v/DB is the Lewis,

Nt=(ρc)pDT(Tw−T∞)/(ρc)fvT∞

is the thermophoresis parameter, M = σB0

2/bρf is the magneticfield parameter, E

1=E

0/u

W

B

0 is the electric field parameter, Ec=2

w/cp(Tw−T∞) is the Eckert number,

s

t

= A

2/A

1denotethe thermal stratification parameter, s

c

= C

2/C

1 indicate theconcentration stratification parameter,

The skin friction coefficient the local Nusselt number and thelocal Sherwood number are

where

here τ w is the shear stress in the stretching surface, q w is thesurface heat flux while q m is the surface mass flux, Re=uwx/v is the Reynolds number and k is the thermal conductivity of thenanofluid. For the local skin-friction coefficient, local Nusselt and local Sherwood numbers are presented in non-dimensionalform as

3. Results and discussion

In this paper, the transformed equations momentum, energyand concentration (19), (20) and (21) subjected to the boundary condition (22) are solved numerically by an efficient implicit finitedifference scheme known as Keller box method which is discussed comprehensively in (Cebeci & Bradshaw, 2012). Thecomputational analysis is performed with sundry parameters vizPrandtl number Pr, magnetic field M, electric field E1, unsteadiness parameter δ, mixed convection parameter λ, buoyancy ratioparameter Nr, suction/injection s, thermal radiation parameterRd, Brownian motion Nb, thermophoresis Nt, Eckert numberEc, heat generation/absorption ε, thermal stratification st, Lewisnumber Le, chemical reaction γ, and concentration stratificationsc. We have selected a step size of Δη = 0.01 to satisfy the convergence condition of 10−5. In Table 1, we see that the presentcomputational scheme from the numerical values reveals is in anexcellent agreement with the results reported by previous studiessuch as (Hayat, Imtiaz, & Alsaedi, 2016a; Ibrahim & Shankar, 2013; Khan & Azam, 2017), under limiting conditions. Table 2 displays the numerical values of local Nusselt and Sherwoodnumbers for different values of s, Le, Nt, Nb, s t , s c , Ec, E 1, M,Rd, δ, ε, γ, Nr, and λ when Pr = 6.2 are conducted. From this Table, it is examined that the values of local Nusselt number areincreased by increasing the values of s, sc, E1, δ, and λ but thesedecrease by increasing Le, Nt, Nb, st, Ec, M, Rd, ε, γ, and Nr. The values of local Sherwood numbers increase by increasingthe values of s, Le, Nt, N b , E c , E 1, M, Rd, δ, ε, γ, and λ whereasits decreases with increases in the values of st, sc, and Nr. Theresults obtained are shown through Figures 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19 and 20 for the velocity, temperature, and nanoparticle concentration profiles for sundryparameters respectively.

Table 1 Comparison with previously published works for the values of skin friction coefficient -f´´´(0) for various values of M, s, and δ when E 1=Nr=λ=0.

| M | s | δ | Khan and Azam (2017) | Ibrahim and Shankar (2013) | Hayat et al. (2016a) | Present results |

|---|---|---|---|---|---|---|

| 0.0 | 0.0 | 0.0 | - | 1.0000 | - | 1.000000 |

| 0.5 | - | 1.2808 | 1.2808 | 1.280776 | ||

| 0.5 | 0.5 | - | 1.5000 | - | 1.500000 | |

| 1.0 | 0.5 | - | 1.6861 | - | 1.686141 | |

| 1.5 | 0.5 | - | 1.8508 | - | 1.850781 | |

| 2.5 | 0.5 | - | 2.0000 | - | 2.000000 | |

| 1.0 | 0.0 | - | 1.4142 | 1.4142 | 1.414214 | |

| 5.0 | - | - | 2.4494 | 2.449490 | ||

| 0.0 | 0.0 | 1.0000 | - | - | 1.000000 | |

| 0.2 | 1.06801 | - | - | 1.068012 | ||

| 0.4 | 1.13469 | - | - | 1.134685 | ||

| 0.6 | 1.19912 | - | - | 1.199117 | ||

| 0.8 | 1.26104 | - | - | 1.261040 | ||

| 1.2 | 1.37772 | - | - | 1.377720 | ||

| 1.4 | 1.43284 | - | - | 1.432831 | ||

| 2.0 | 1.58737 | - | - | 1.587358 |

Table 2 Numerical results of local Nusselt number Nu x /Re 1/2 and local Sherwood number Sh x /Re 1/2 for various values of s, Le, Nt, Nb S t , S c , Ec, E 1, M, Rd, δ, λ, Nr, ε and γ when Pr = 6.2.

| s | Le | Nt | Nb | St | Sc | Ec | E1 | M | Rd | δ | ε | γ | Nr | λ | Nu/Re 1/2 | Sh/Re 1/2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 5.0 | 0.1 | 0.2 | 0.1 | 0.2 | 0.2 | 0.1 | 0.1 | 0.2 | 0.1 | 0.1 | 1.0 | 0.1 | 0.5 | 1.609856 | 3.277781 |

| 0.3 | 1.914229 | 3.684784 | ||||||||||||||

| 0.5 | 2.260243 | 4.104724 | ||||||||||||||

| 0.1 | 2.0 | 1.836066 | 1.696388 | |||||||||||||

| 4.0 | 1.662801 | 2.828166 | ||||||||||||||

| 7.0 | 1.533674 | 4.057326 | ||||||||||||||

| 5.0 | 0.2 | 1.424676 | 3.212881 | |||||||||||||

| 0.3 | 1.276608 | 3.214053 | ||||||||||||||

| 0.5 | 1.061147 | 3.305251 | ||||||||||||||

| 0.1 | 0.1 | 1.983094 | 2.809780 | |||||||||||||

| 0.3 | 1.308123 | 3.412765 | ||||||||||||||

| 0.5 | 0.875038 | 3.491720 | ||||||||||||||

| 0.2 | 0.2 | 1.554430 | 3.230745 | |||||||||||||

| 0.4 | 1.465419 | 3.154099 | ||||||||||||||

| 0.5 | 1.449703 | 3.138346 | ||||||||||||||

| 0.1 | 0.1 | 1.516611 | 3.451757 | |||||||||||||

| 0.4 | 1.640436 | 2.840690 | ||||||||||||||

| 0.5 | 1.683675 | 2.636516 | ||||||||||||||

| 0.2 | 0.1 | 1.616170 | 3.231450 | |||||||||||||

| 0.3 | 1.498383 | 3.264895 | ||||||||||||||

| 0.5 | 1.383440 | 3.297314 | ||||||||||||||

| 0.2 | 0.2 | 1.567688 | 3.250943 | |||||||||||||

| 0.5 | 1.589580 | 3.258948 | ||||||||||||||

| 1.0 | 1.595010 | 3.273710 | ||||||||||||||

| 0.1 | 0.2 | 1.533827 | 3.250854 | |||||||||||||

| 0.5 | 1.464559 | 3.258183 | ||||||||||||||

| 1.0 | 1.352284 | 3.270999 | ||||||||||||||

| 0.1 | 0.3 | 1.529815 | 3.250125 | |||||||||||||

| 0.5 | 1.475525 | 3.255883 | ||||||||||||||

| 0.7 | 1.423302 | 3.262969 | ||||||||||||||

| 1.0 | 0.2 | 1.400481 | 3.383713 | |||||||||||||

| 0.4 | 1.482374 | 3.588870 | ||||||||||||||

| 0.7 | 1.586703 | 3.865858 | ||||||||||||||

| 0.1 | 0.2 | 1.302533 | 3.291501 | |||||||||||||

| 0.3 | 1.255259 | 3.309122 | ||||||||||||||

| 0.5 | 1.176202 | 3.345212 | ||||||||||||||

| 0.1 | 1.5 | 1.343690 | 3.524437 | |||||||||||||

| 2.0 | 1.336748 | 3.761108 | ||||||||||||||

| 2.5 | 1.330360 | 3.984570 | ||||||||||||||

| 1.0 | 0.3 | 1.334108 | 3.267329 | |||||||||||||

| 0.5 | 1.315966 | 3.260383 | ||||||||||||||

| 1.0 | 1.263585 | 3.242419 | ||||||||||||||

| 0.1 | 1.0 | 1.430948 | 3.315061 | |||||||||||||

| 1.5 | 1.483361 | 3.356874 | ||||||||||||||

| 2.0 | 1.515111 | 3.400111 |

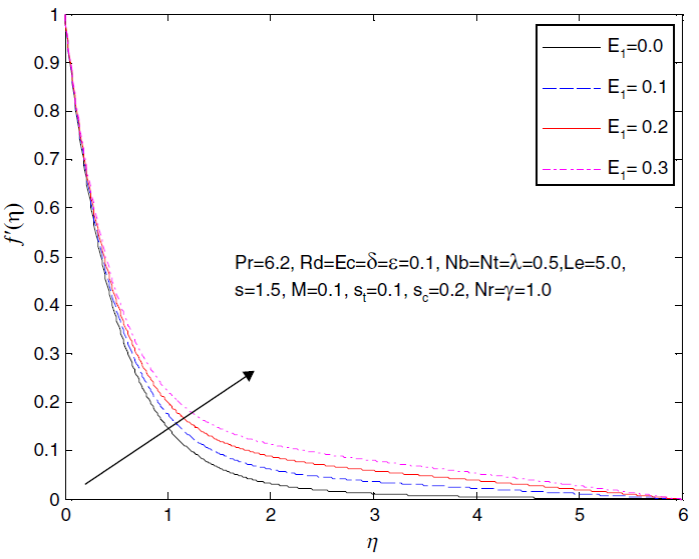

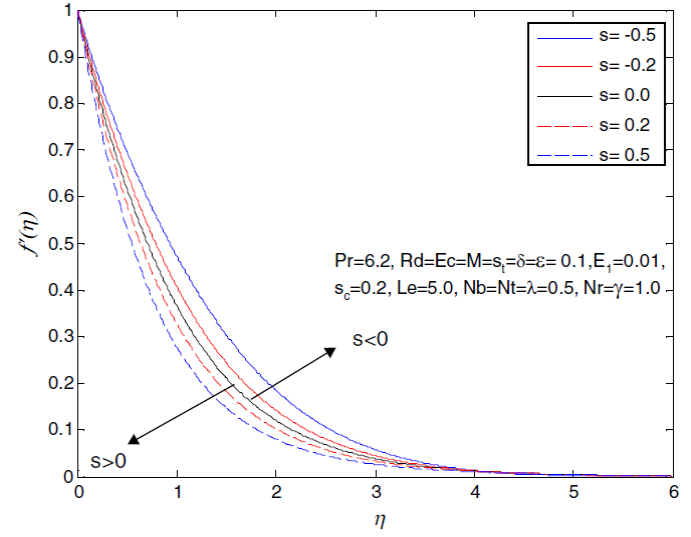

Figures 2, 3, 4, 5, 6 and 7 display the velocity profiles f´(η) for thevarious embedded parameters viz electric field, magnetic field,unsteadiness parameter, mixed convection parameter, buoyancyratio parameter, and suction/injection parameter. Figure 2 indicates that higher values of electric parameter increase thenanofluid velocity. An electric parameter acts as acceleratingforce. The higher electric parameter has the stronger Lorentzforce and the lower electric parameter associated with theweaker Lorentz force. The stronger Lorentz force creates moreenhancement and resolves sticky effect due to the nanoparticlesin the fluid that signified an increase in the convective heat transfer and momentum boundary layer thickness. The effectof magnetic field parameter M on the nanofluid velocity profileis exhibited in Figure 3. The velocity and momentum boundarylayer thickness decreased for higher values of the magneticparameter. Magnetic field results in a resistive type force knownas Lorentz flow where it opposite the flow. This leads to resists inthe fluid flow behavior that amount to a reduction in the velocityand thinner boundary layer thickness. Figure 4 demonstratesthe effect of unsteadiness parameter δ on the nanofluid velocityprofile. The behavior is due to acceleration case (δ > 0), alower rate of fluid flow and thinner momentum boundarylayer thickness. The velocity profile reduces for the higheracceleration. In Figure 5, it is noticed that the momentum boundary layer thickness for the nanofluid decreases withincreasing the values of the suction parameter(s > 0). This canbe attributed to a decrease in the fluid velocity due to increasingnanofluid suction at the stretching surface. While reverse behavior occurred for injection parameter(s < 0). The effectof mixed convection parameter λ on the nanofluid velocity ispresented in Figure 6. Corresponds to heated surface (λ > 0), higher values leads to enhancement in the fluid velocity and thicker momentum boundary layer thickness. This leads toassist the nanofluid flow in the upward direction, whereas (λ < 0) indicate cold surface opposing the nanofluid flow in thedownward direction with thinner momentum boundary layer thickness. As(λ = 0)signifies absence of the mixed convection,therefore force convection behavior due to nanofluid velocity.The effect of buoyancy ratio parameter Nr on the nanofluidvelocity is publicized in Figure 7. It is noticed that the nanofluidvelocity reduces with a high amount of buoyancy force. The buoyancy force behaves as unfavorable pressure gradient, therefore, stronger buoyancy force reduced the fluid flow dueto stretching surface in the downwind direction and thinnermomentum boundary layer thickness.

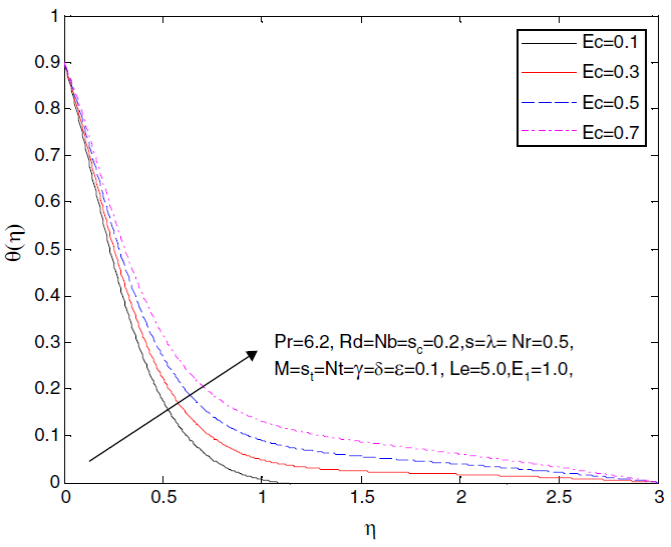

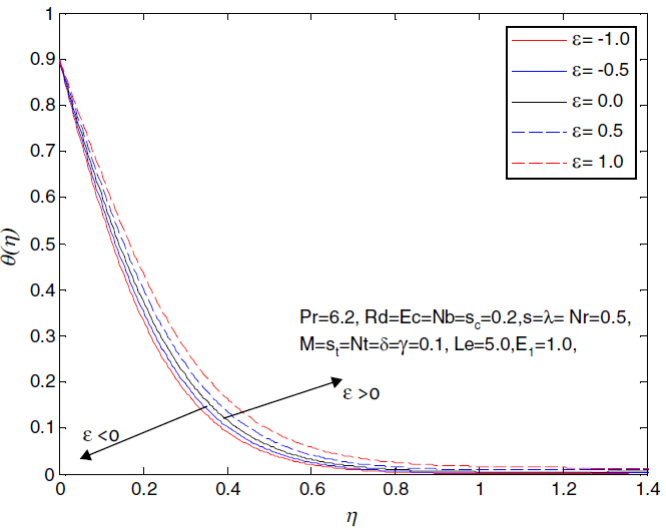

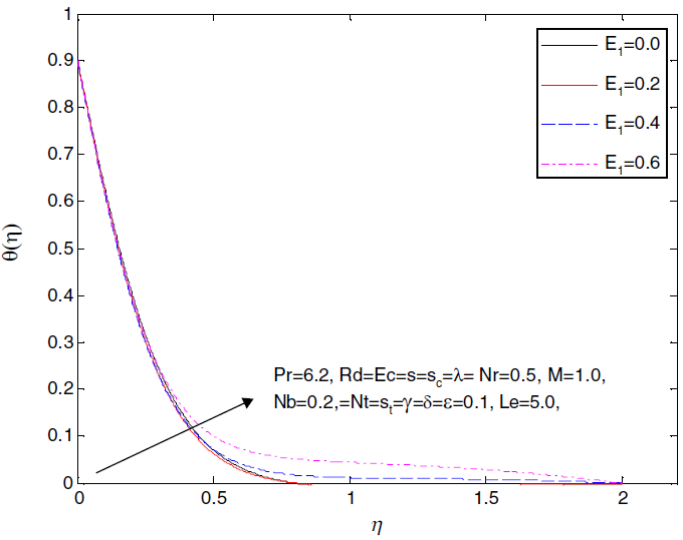

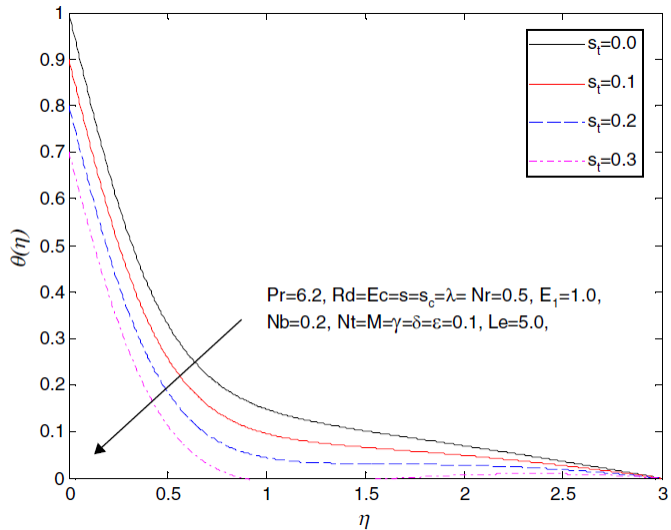

In Figures 8, 9, 10, 11, 12, 13 and 14 display the effects of thermal radiationRd, Eckert number Ec, unsteadiness parameter δ, heat generation/absorption parameter ε, magnetic field parameter M,electric field parameter E1, and thermal stratification parameter ston the temperature profiles θ(η). Figure 8 elucidates thechanges that are noticed in nanofluid temperature profiles dueto increase in the values of thermal radiation parameter Rd. It isworth noticing that the nanofluid temperature increases as thermal radiation increase due to the fact that the conduction impactof the nanofluid improves in the presence of thermal radiation.Hence higher values of radiation parameter mean higher surfaceheat flux and so, enhance the temperature within the boundarylayer region. It is also demonstrated that thermal boundary layerthickness increases with increasing the values of thermal radiation. In Figure 9, illuminates that the nanofluid temperature andthermal boundary layer thickness are enhanced due to kineticincrease rises over the energy to enthalpy with an increase in thevalues of Eckert number. The influence of unsteadiness parameter on the temperature profile in Figure 10, is similar to of thevelocity in Figure 4. The effect of heat generation/absorptionon the temperature is depicted in Figure 11. It is noted thatheat source (ε > 0)gives an increase in the temperature of thefluid and the thermal boundary layer thickness. While as theheat sink (ε < 0) provides a decrease in the temperature of thefluid and thinner thermal boundary layer thickness. For ε = 0signify the absence of heat generation/absorption. Figure 12 establishes the impact of magnetic field parameter M on thenanofluid temperature profiles. The transverse magnetic fieldhas increased the thermal boundary layer thickness. Thus, anenhancement in thermal boundary layer thickness and fluid temperature. The magnetic field performances as a strong Lorentzforce that boost on the nanofluid temperature in the boundaryregion The effect of the electric field parameter E1on the temperature profile θ(η) is revealed in Figure 13. The electric fieldbehaves as accelerating force that enhances the fluid temperature and thermal boundary layer thickness. A higher value ofan electric field is associated with thicker higher amount temperature distribution within the boundary layer region of thevicinity of the nanofluid. Figure 14 is a sketch for nanofluid temperature profile with various values of thermal stratificationparameter s t . The nanofluid temperature is reduced for highervalues of thermal stratification parameter. It is also noticed thatthe case of prescribed surface temperature is achieved whenthermal stratification is absence (s t = 0). Physically, the variationbetween the surface temperature and the ambient temperature isdiminished for a high amount of thermal stratification. Consequently, leads lower amount of fluid temperature in the boundaryregion of the nanofluid and thinner thermal boundary layerthickness.

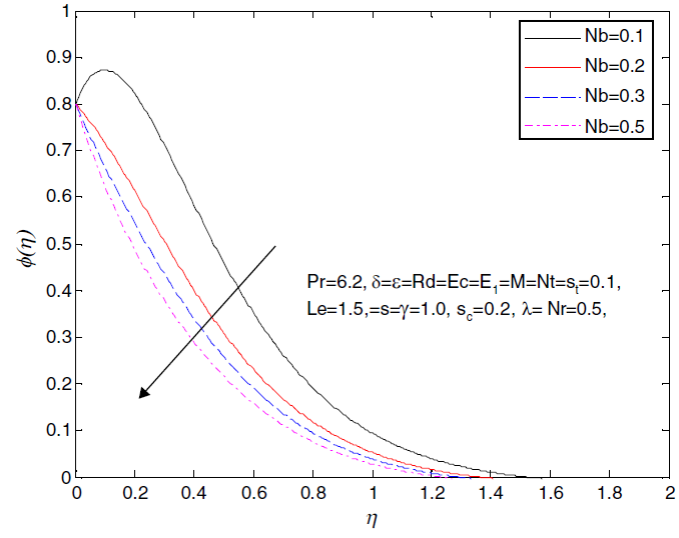

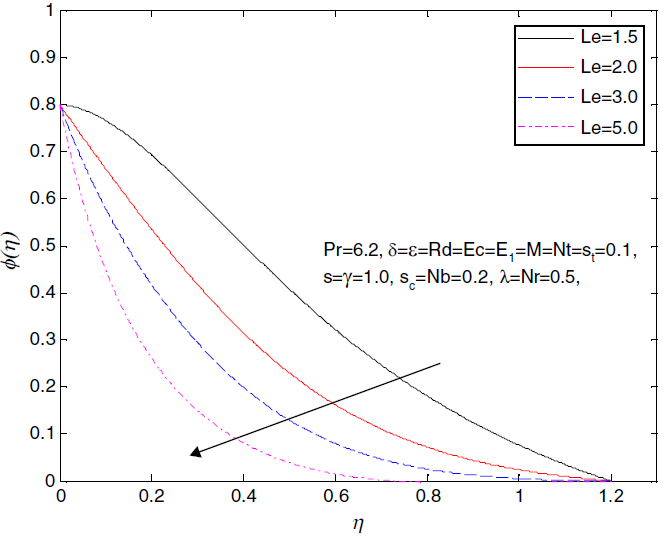

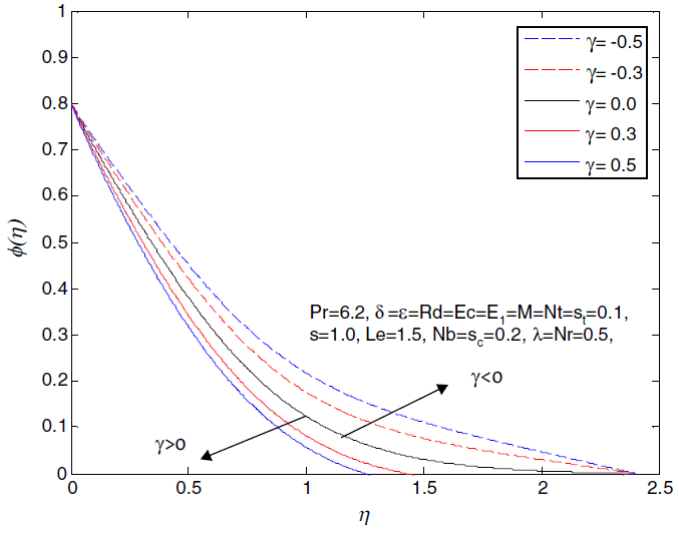

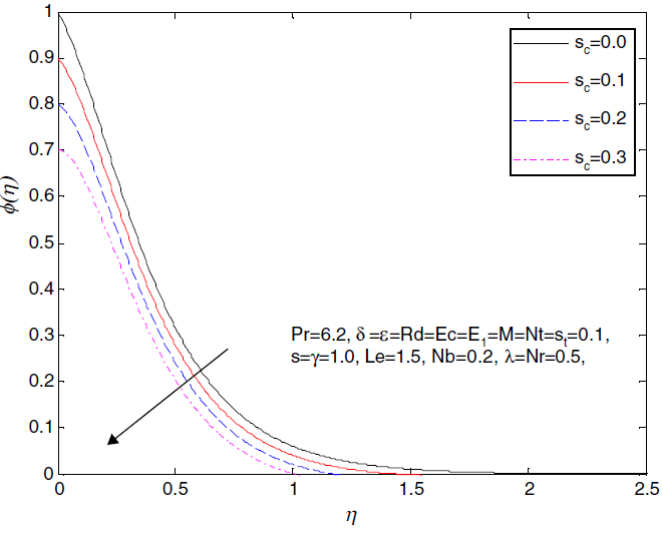

The effects of Brownian motion parameter Nb, thermophoresis parameter Nt, Lewis number Le, unsteadiness parameter δ,chemical reaction parameter γ, and concentration stratificationparameter scon the concentration profiles φ(η) are shown in Figures 15, 16, 17, 18, 19 and 20. In Figure 15 portrays the influence of Brownianmotion parameter on the nanoparticle concentration profiles. Itis noticed that the nanoparticle concentration of the nanofluidreduced with increase in Brownian motion of the nanoparticles. It is worth interesting to note that Brownian motion ofthe nanoparticles at the molecular and nanosized rates is a keynanoscale processes governing their thermal behavior with thefluid molecules. Consequently, leads to thinner solutal thermalboundary layer thickness due to Brownian motion. Figure 16 proves the effect of thermophoresis parameter on the concentration profiles φ(η). The impact of the thermophoresis parameteron the nanoparticles concentration distribution is monotonicmeaning the nanoparticles concentration is sensitive to increasesin thermophoresis parameter. The magnitude of the concentration gradient at the surface decrease for higher values ofthermophoresis parameter. Hence, due to the fact that as a thermophoresis depreciated mass transfer of nanofluids. In Figure 17 examines the influence of Lewis number on the nanoparticlesconcentration. It is worth noticeable that the nanoparticles concentration is reduced significantly for higher values of Lewisnumber. This reduction in nanoparticles concentration is due tothe change in Brownian motion coefficient. Higher values ofLewis number associated to feebler Brownian diffusion coefficient. Figure 18 demonstrates the behavior of unsteadinessparameter on the concentration profiles, which is similar tothat of Figure 10. In Figure 19 elucidates the effect of chemical reaction on the nanoparticles concentration profile. It is ofinterest to note that nanoparticles concentration enhances forhigher values of destructive chemical reaction parameter (γ < 0).Whereas reverse behavior occurred for generative chemicalreaction parameter (γ > 0). Perhaps, higher values of generativechemical reaction associated with the high rate of generativechemical reaction which generates the fluid species more efficiently and thus nanoparticles concentration rises. But oppositetrend is noticed for destructive chemical reaction parameter (γ < 0). For (γ = 0) implies absence of chemical reaction. Theinfluence of concentration stratification on the nanoparticle concentration is described in Figure 20. An increase in concentrationstratification parameter leads to a decrease in nanoparticles concentration and solutal concentration boundary layer thickness.This is as result of the fact that fluid near the plate can have a concentration lower than the ambient medium. The nanoparticlesconcentration is maximum at (s c = 0).

4. Final remarks

In this work, unsteady mixed convection with the combined effects of thermal radiation, heat generation/absorptionand chemical reaction on the electrical magnetohydrodynamic (MHD) flow of nanofluid in the presence viscous dissipation andJoule heating over a permeable stretching sheet is investigatednumerically. Buongiorno model was used to incorporate theeffects of Brownian motion and thermophoresis. The boundarylayer governing equations are converted to nonlinear ordinarydifferential equations using similarity transformations and thensolved numerically with implicit finite difference scheme. Onthe basis of findings with sundry parameters in this work, wedrew the following main conclusions:

Velocity and temperature increase with an increase in anelectric parameter.

Thermal radiation and viscous dissipation increase the temperature profiles.

Heat source increases the temperature while as reverseoccurred with a heat sink.

Destructive chemical reaction enhances the nanoparticlesconcentration while opposite behave happened in the caseof a generative chemical reaction.

Reversed behavior occurred with Brownian motion and thermophoresis parameter with nanoparticles concentration.

Thermal stratification reduced the temperature profile andconcentration stratification decreased the nanoparticles concentration profile.

Buoyancy ratio parameter decreases both Nusselt and Sherwood numbers whereas mixed convection parameter increaseboth for higher values.

The skin friction, local Nusselt and Sherwood numberare sensitive to increase in suction whereas, higher valuesunsteadiness parameter reduces the velocity, temperature, and nanoparticles concentration profile.

text new page (beta)

text new page (beta)