Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Agrociencia

On-line version ISSN 2521-9766Print version ISSN 1405-3195

Agrociencia vol.52 n.1 Texcoco Jan./Feb. 2018

Food Science

Effect of freeze-drying conditions on the physicochemical Properties, pectin content, and rehydration capacity of plum slices (Spondias purpurea L.)

1Instituto Tecnológico de Orizaba. Oriente 9 no. 852, Orizaba, Veracruz, México. P. O. Box 324.

2Instituto de Ciencias Básicas, Universidad Veracruzana. Apartado Postal 572. 91192. Xalapa, Veracruz, México.

3Unidad de Investigación y Desarrollo en Alimentos del Instituto Tecnológico de Veracruz. M.A. de Quevedo. 2779. 91987. Veracruz, Veracruz, México.

The Mexican plum (Spondias purpurea L.) (classified as an exotic fruit( is native to southern Mexico and Central America. It has export potential due to its nutritional content and taste. Its commercialization is limited because it highly sensitive to physical damage during postharvest. Freeze-drying is an alternative that allows the industrialization of this fruit and extends its shelf life; but the quality of lyophilized products depends on the operating conditions. The objective of this study was to evaluate the effect of freeze-drying conditions on the physicochemical properties, pectin content, and rehydration of plum slices (beetroot and yellow ecotypes). The experimental design was a factorial randomized arrangement with three replications. The experimental unit was a plum sample from each ecotype. Samples were frozen at -5 and -20 °C (Tc) and lyophilized at 0.05 and 0.1 mbar (Pr) under laboratory conditions. Pr had a significant effect on the moisture content in both ecotypes, with values lower than 0.02 g H2O g s s-1. Tc significantly affected water activity. Luminosity increased with respect to fresh fruit as Tc decreased. Freeze-drying did not have a significant effect on pectin content. The correlation between Tc, Pr, and rehydration of beetroot plum slices was not significant. Tc had a significant effect on the rehydrated samples (water at 30 °C), and weakened the structure of the solid matrix of the yellow plum. Freeze-drying is a reliable method to dehydrate plums, with high-quality rehydration, suitable for preservation and a diversified use as snacks, or as an additional ingredient for cereals, yoghurt, and bakery products.

Keywords: Spondias purpurea L.; freeze-drying; rehydration; pectin; color

La ciruela mexicana (Spondias purpurea L.) es originaria del sur de México y América Central, se clasifica como fruto exótico y es un alimento con potencial de exportación por su contenido nutricional y sabor. Su comercialización es limitada porque se daña aceleradamente en post-cosecha. La liofilización es una alternativa para industrializar este fruto y prolongar su vida de anaquel; pero, la calidad de los productos liofilizados depende de las condiciones de operación. El objetivo de este estudio fue evaluar las condiciones de liofilización en las propiedades fisicoquímicas, contenido de pectina y rehidratación de rodajas de ciruela ecotipo betabel y amarilla. El diseño experimental fue en arreglo factorial al azar con tres repeticiones. La unidad experimental fue una muestra de ciruela de cada ecotipo. Las muestras se congelaron a -5 y -20 °C (Tc) y se liofilizaron a 0.05 y 0.1 mbar (Pr) en condiciones de laboratorio. Pr tuvo efecto significativo en el contenido de humedad en ambos ecotipos, con valores menores a 0.02 g H2O g s s-1. Tc afectó significativamente la actividad de agua. La luminosidad aumentó con respecto a la fruta fresca con el decremento de Tc. La liofilización no afectó significativamente el contenido de pectina. La correlación entre Tc, Pr y rehidratación de las rodajas de ciruela betabel no fue significativa. Tc tuvo efecto significativo en las muestras rehidratadas (agua a 30 °C) en la ciruela amarilla, y debilitó la estructura de la matriz sólida. La liofilización es un método fiable para deshidratar ciruela, con calidad alta para rehidratación, adecuada para conservar y diversificar su consumo como bocadillos, agregada a cereales, yogur y productos de panadería.

Palabras clave: Spondias purpurea L.; liofilización; rehidratación; pectina; color

Introduction

The Mexican plum (Spondias purpurea L.) belongs to the Anacardiaceae family, and it is native to Central America and Mexico. This species of fruit has an ellipsoidal and oviform drupe, with a mass and size ranging between 4.0 and 43.2 g, and 2 and 5 cm, respectively (Alia-Tecajal et al., 2012). The pulp is fleshy, with a sweet-acid taste, and vivid color, which (depending on the variety( can be yellow, green, or red-violet. The plum is a source of vitamin C and minerals (such as calcium, phosphorus, and iron(, as well as phenolic compounds (which are responsible for its antioxidant activity; it has a light laxative effect, as a result of its sorbitol and soluble (mainly pectin) and insoluble fiber content (Vargas-Simón et al., 2011).

Currently, Mexican plum is grown in 22 Mexican states (SIAP, 2015), making it the most cultivated species of the Spondias genus. Like other tropical fruits, it is highly perishable and its consumption is restricted by its seasonality; its rapid deterioration is commonly caused by the invasion of microorganisms during the postharvest stage, and is partially caused by its moisture content (>78 %) (Osuna et al., 2011).

The demand for products that preserve their quality has increased. For the industry, this implies developing operations that minimize the adverse effects (Lozano-Acevedo et al., 2011). Dehydration is one of the most common unit operations used in the food industry, and dehydrated products can be consumed directly or as ingredients in processed foods (Lozano-Acevedo et al., 2011; Fijalkowska et al., 2015).

Freeze-drying is one of the most advanced methods in the food industry to dry products with high nutritional value. This method prevents undesirable contraction, produces high porosity, and preserves the nutritional qualities, flavor, aroma, and color. In addition, it enables an adequate rehydration of the product (Lombraña, 2009, Sánchez-Santillán et al., 2016). The industrial application of freeze-drying is limited, because it is an expensive method. Therefore, the industry has become increasingly interested in determining the effect of the processing conditions in the freeze-drying time, the production, and the quality of the final product (Liapis and Bruttini, 2006). The quality of lyophilized products is affected by pressure, temperature of the heating plate, quality of the raw material, and freezing speed (Hammami and René, 1997; Shishehgarha et al., 2002). Freezing prior to freeze-drying is determinant of the properties of the dry product, because it directly influences the size and shape of the pores produced after freeze-drying (Kasper and Friess, 2011). The study of sublimation kinetics and classical drying curves can be useful to determine the limiting transfer mechanisms and optimize the freeze-drying stages (Hottot et al., 2007; Adhami et al., 2013).

There are studies about freeze-drying tropical fruits, but not about Mexican plum. Plum is highly perishable; therefore, freeze-drying is an alternative for its industrialization and commercialization. Process conditions, such as freezing temperature and vacuum pressure, could affect the physicochemical properties of the plum and result in product quality loss. The objective of this research was to determine the influence of the freezing temperature and pressure in the freeze-drying kinetics of Mexican plum slices and the qualities of the final product.

Materials and Methods

Sample preparation

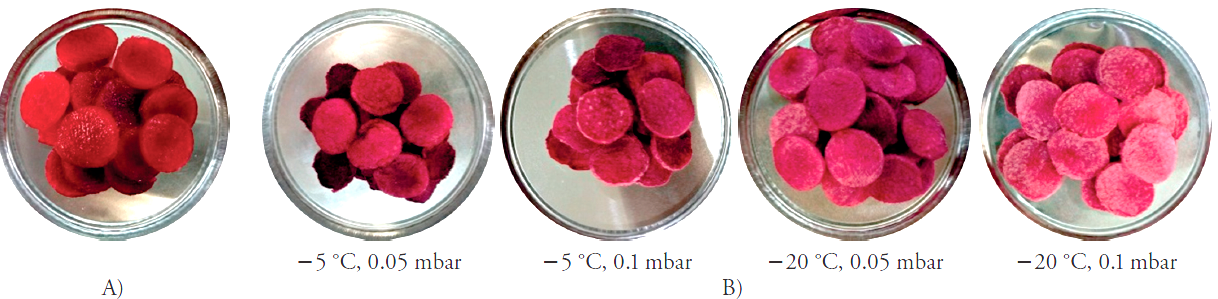

Mexican plum ecotypes (‘beetroot’ and ‘yellow”) (from the Coscomatepec, Veracruz, Mexico production area( were chosen for this study. Fruits were selected according to the color of the peel when they were cut: ‘beetroot’ ecotype showed 30 % green and 70 % red, and ‘yellow’ ecotype showed 75 % yellow. The plums were washed and cut with a stainless-steel cutter into 2.5 cm wide and 0.5 cm thick slices. The slices were cut parallel to the axial axis of the fruit. All tests were carried out in triplicate.

Freeze-drying conditions

The slices were frozen (Tc) at (20 °C, during 180 min, in an ultra-freezer (fast freezing) and -5 °C, during 2,880 min (slow freezing), in a domestic freezer (DAEWOO Mod FR-62R, Korea). The frozen samples were dehydrated during 360 min, in a laboratory freeze dryer (LABCONCO 2.5 L-Mod 742002, USA), with space for 12 flasks, which are attached to the valves of the drying chamber with stainless steel adapters and a condensed moisture collector. The drying kinetics were carried out with 0.05 and 0.1 mbar vacuum pressure (Pr) at -85 °C in the condenser. The samples were removed at specific periods, in order to evaluate moisture, water activity, and color changes.

Physical and chemical determinations

The moisture content was determined in 1 g of sample, in a Moisture Analyzer with Halogen Lamp (MB35 HALOGEN, OHAUS, Switzerland), at 65 °C; the results were expressed in terms of dry basis (g H2O g s s-1). The water activity (aw) of the plum slices during freeze-drying was determined at 25±1 °C using a water activity meter (Aqualab, series 3 TE, DECAGON; Washington, USA).

The optical properties of fresh and lyophilized plums were analyzed based on their reflectance, using a colorimeter (HunterLab, model MiniScan XE plus; Hunter Associates Laboratory Retson, VA, USA). The colorimeter was calibrated using black and white standards. Parameters L* (luminosity) and chromaticity a* (green-red) and b* (blue-yellow) were measured using the Hunter scale. Based on these parameters, Hue (hue angle), Chroma (color saturation), and ΔE (total color difference) were calculated. According to Guiné and Barroca (2012), the mathematical expressions for these parameters are as follows:

where: L* , a* , b* are the values of the lyophilized plum sample in different times, and

Degree of rehydration

Between 0.5 and 0.6 g of dehydrated product were submerged in 150 mL of distilled water, at 10 and 30 °C, for 60 min. Sample rehydration was evaluated at 2, 4, 6, 10, 15, 20, 25, 30, 35, 40, 50, and 60 min (Reyes et al., 2008), recording their weight, after removing the liquid from the surface with absorbent paper. Rehydration was also evaluated in whole milk, taking into account that dehydrated plums may be mixed with cereals. Whole and pasteurized milk were obtained in a local supermarket. The equation used to calculate rehydration was:

where: m1 is the dry sample mass (g) and m2 is the rehydrated slice mass (g) (Zhang et al., 2015).

Pectin content

Pectin was extracted from the plum slices using the method described by Kliemann et al. (2009), with some modifications. One-hundred mL of distilled water were added to 5±0.01 g of sample crushed in mortar; citric acid was added to achieve a 2.5 pH; finally, the sample was heated for 1 h at 90 °C, with continuous stirring. The heated extract was filtered through a cheesecloth. An equal volume of ethanol was added to the filtered sample and let stand for 2 h. The flocculated pectin was separated by filtration and was dehydrated in an oven, until its constant weight was obtained. The pectin yield was obtained using the following equation:

where: Ypec is the yield of pectin extract (in percentage), P is the amount of pectin extract in g, and Bi is the initial amount of sample in g.

Experimental design and statistical analysis

The experimental design was factorial, with two factors and two levels: freezing temperature (-5 and -20 °C) and pressure (0.05 and 0.1 mbar); it was completely random and included three repetitions. The experimental unit was a sample of each plum ecotype. The results are presented as means of the variables and their standard deviation. The results were analyzed using ANOVA and were considered significant when p≤0.05. All the analysis were carried out with Minitab Realese 6.

Results and Discussion

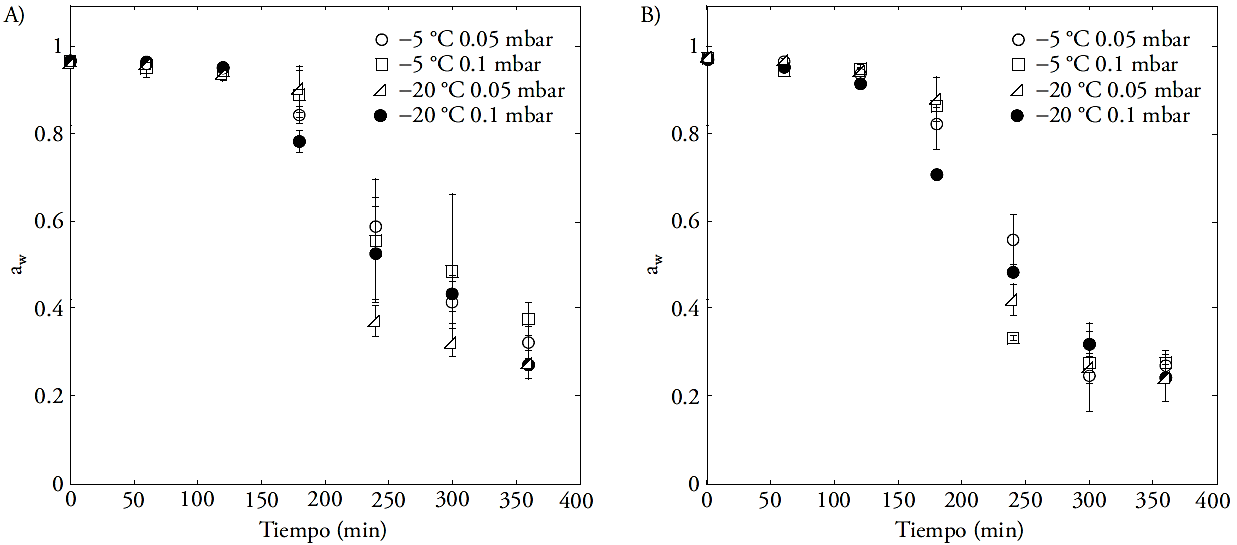

Moisture change curves

The initial moisture of beetroot and yellow ecotypes was 78 and 85 %, respectively. The drying curves showed that freeze-drying pressure had a significant effect (p≤0.05) in both ecotypes. At the end of the process, moisture was lower or equal to 0.0206 g H2O g s s-1, with 0.1 mbar. Moisture values were statistically lower than 0.05 mbar (Figure 1).

Figure 1 Moisture change in plum slices (Spondias purpurea L.): A) beetroot and B) yellow, during freeze-drying.

The slices of beetroot plums frozen at -5 °C and lyophilized with 0.05 and 0.1 mbar showed the greatest loss of moisture, at 60 and 120 minutes, respectively. In slices frozen at -20 °C and lyophilized at 0.1 and 0.05 mbar, the moisture decreased in the first 60 min and 180 min, respectively; nevertheless, the moisture in all treatments stabilized at 300 min (Figure 1A).

Moisture decreased in yellow plum (Figure 1B) after 60 min, under all conditions evaluated; however, with 0.1 mbar and freezing at -5 °C, moisture stabilized at 240 min; finally, at 300 min, it stabilized in the other treatments. In all the treatments, there were two acceleration and deceleration periods of moisture loss. Pei et al. (2014) noted that the acceleration period may be attributed to the greater sublimation area during the first stage of drying, and that it is gradually reduced as the process continues, because it increases the mass-transfer resistance. The effect of freezing temperature in the final moisture of the slices was not significant. However, slow freezing caused rapid sublimation of yellow plums, probably because the ice crystals were larger compared to fast freezing. These results are similar to those reported by Reyes et al. (2011) and Ceballos et al. (2012) in apple and soursop slices, respectively. These authors found that small pores generated narrow roads with greater resistance to water flow.

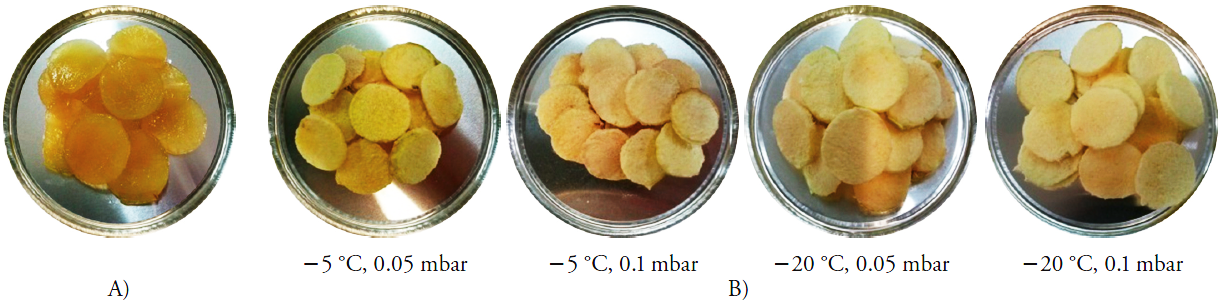

Water activity change curves

The aw of the beetroot plum slices (Figure 2A), lyophilized with both pressures, decreased significantly from 180 min, and was lower when the tissue was frozen at -20 °C. In contrast, the aw of the yellow plum decreased (Dunnett’s test p=0.05) after 120 min, with pressures and freezing at -5 ° C; also, with freezing at -20 °C, the decrease started from 60 and 180 min, with the lower and higher pressure, respectively (Figure 2B).

Figure 2 Water activity of plum slices (Spondias purpurea L.): A) beetroot and B) yellow, during freeze-drying.

All plum slices were lower than 0.5 aw from 300 min. This indicated that microbial growth is unlikely. The aw balance values in lyophilized beetroot plum slices ranged between 0.275 and 0.381, and those of yellow plum, between 0.249 and 0.275. In this way, aw balance decreased significantly as the freezing temperature fell for both plum types (p=0.05). In the case of drugs, during slow freezing, as freezing advances, the solute concentrates and it forms a glassy (almost waterproof) layer on the material’s surface; this obstructs the flow of steam water through the pores (Kasper and Friess, 2011). Marques et al. (2007) observed that the decrease of aw in the freeze-drying of acerola depended on the freezing process, which produces different porous structures.

Analysis of color

Beetroot fresh plum showed 16.24 L* and this value did not change in lyophilized samples, after freezing at -5 °C. In contrast, freezing at -20 °C increased luminosity (Table 1). L* is defined as the flux of light in a given direction, and depends on the number and orientation of the surfaces that reflect light. Therefore, the freezing speed affects the luminosity of lyophilized samples. Fast freezing generates small randomly-positioned crystals; therefore, the luminosity of quickly frozen products is higher than that of slowly frozen products (Ceballos et al., 2012).

Table 1 Color of beetroot plum (Spondias purpurea L.) slices, before and after freeze-drying.

| Tc (°C) | Pr (mbar) | L* | Chroma | Hue | ΔE | ||

| Ciruela betabel |

fresca | 16.24a | 17.41a | 16.58a | - | ||

| liofilizadas | -5 | 0.05 | 19.98ab | 20.17a | 17.87a | 4.67a | |

| -5 | 0.1 | 22.26ab | 20.23a | 17.70a | 6.66ab | ||

| -20 | 0.05 | 26.02b | 23.72a | 12.17a | 11.74b | ||

| -20 | 0.1 | 26.3b | 23.54a | 15.22a | 11.79b |

a,b Treatments with a different letter in the same column are statistically different (p≤0.05).

The Chroma and Hue angle values of lyophilized beetroot plum did not show significant differences regarding fresh slices. This indicates that anthocyanins -pigments related to the red color of fruits- are stable. Beaudry et al. (2004) and Franceschinis et al. (2015) lyophilized cranberries and cherries, and observed that those berries still possessed an intense red shade, because their anthocyanins were preserved, while thermal treatments brown them and dull their color. The overall color difference (ΔE) in the slices was significant (p≤0.05) with regard to the beetroot plum unprocessed slices (Figure 3). Since the freeze-drying increased the luminosity of the sample, the value of ΔE was affected.

L* of lyophilized yellow plum increased significantly in comparison with fresh fruit; lower freezing temperature produced a greater increase (Table 2). These results are similar to those obtained with carrots and asparagus (Reyes et al., 2008; Jokic et al., 2009).

Table 2 Color of yellow plum (Spondias purpurea L.) slices, before and after their processing.

| Tc (°C) | Pr (mbar) | L* | Chroma | Hue | ΔE | ||

| Ciruela amarilla |

fresca | 19.95a | 7.89a | 101.41a | - | ||

| liofilizada | -5 | 0.05 | 53.53b | 18.83b | 85.00b | 35.49a | |

| -5 | 0.1 | 55.01b | 21.57b | 86.81b | 37.78b | ||

| -20 | 0.05 | 52.84b | 17.51b | 91.90ab | 34.32c | ||

| -20 | 0.1 | 58.45c | 20.63b | 87.14b | 40.68d |

a,b,c,d Treatments with a different letter in a column are statistically different (p≤0.05).

Chroma increased with freeze-drying. This shows that carotenoids were concentrated in the tissue. Results are similar to those observed in mashed mango, in which β-carotenes increased with freezedrying, compared to samples dried with convective heat transfer (Caparino et al., 2012). The initial Hue angle value in yellow plum was 101.41°; this is found in the yellow/green region (90-180° Hue). However, the shade of the slices decreased (Hue angle (90°). This was due to the negative-to-positive variation of the a* parameter, possibly as a result of the enzymatic browning caused by mechanical damage when the fruit was cut.

ΔE showed significant differences (p<0.05) between yellow plum treatments. This was due to the high luminosity of the samples and a slight shift of Hue towards the red shades (Figure 4).

Pectin content

There were no significant differences (p>0.05) in pectin content (ypec) between treatments: the freezing temperature or vacuum pressure did not affect the polysaccharide content of the samples (Table 3).

Table 3 Pectin content in lyophilized plum slices (Spondias purpurea L.).

| Ciruela liofilizada | Tc (°C) | Pr (mbar) | ypec (% b.s.) |

| betabel | -5 | 0.05 | 2.60a |

| -5 | 0.10 | 2.89a | |

| -20 | 0.05 | 1.95a | |

| -20 | 0.10 | 3.81a | |

| amarilla | -5 | 0.05 | 2.20a |

| -5 | 0.10 | 3.23a | |

| -20 | 0.05 | 2.13a | |

| -20 | 0.10 | 3.73a | |

Treatments with a different letter in a column are statistically different (p≤0.05).

High pressures can compress the raw material and modify its surface; as a result, the following actions take place: the chemicals reactions are balanced, while the solvent penetration is accelerated, and its diffusion in the food is sped up. The results were similar to those reported by Guo et al. (2012) and Naghshineh et al. (2013) who applied high vacuum to lime and orange peels. The use of high vacuum to obtain ingredients from medicinal herbs and the food matrix increases the extraction of bioactive compounds (Xi, 2009; Huang et al., 2013).

Rehydration of lyophilized Mexican plum

The rehydration ratio (RR) measures the structural damage and the reconstitution properties of fruits and vegetables that have undergone a drying process. The RR of lyophilized beetroot plum was not affected by the conditions of the process (Table 4).

Table 4 Degree of rehydration of lyophilized plum slices (Spondias purpurea L.).

| Ciruela liofilizada | Tc (°C) | Pr (mbar) | Grado de rehidratación (g g-1) | |||

| Agua | Leche | |||||

| 10 °C | 30 °C | 10 °C | 30 °C | |||

| betabel | -5 | 0.05 | 3.46a | 3.89a | 2.66a | 2.52a |

| -5 | 0.1 | 3.99a | 3.32a | 2.94a | 2.71a | |

| -20 | 0.05 | 3.43a | 3.88a | 2.82a | 2.84a | |

| -20 | 0.1 | 3.17a | 3.32a | 2.68a | 2.42a | |

| amarilla | -5 | 0.05 | 3.62a | 3.76a | 2.40a | 2.85a |

| -5 | 0.1 | 2.17a | 2.82ab | 1.82a | 1.61a | |

| -20 | 0.05 | 3.56a | 1.88b | 2.51a | 2.62a | |

| -20 | 0.1 | 2.53a | 3.09ab | 2.38a | 2.04a | |

a,b Treatments with a different letter in the same column are statistically different (p≤0.05).

Beetroot plum slices kept the structure required to recover their original size during rehydration. The rehydrating medium seems to have spread properly in the uniform and porous structure, as well as in the cell walls, without damaging the slice. The RR was greater in water than in milk, probably as a result of the higher viscosity of the latter, although it can be a source of solids whose nutritional importance can be transported to the rehydrated product (Marín et al., 2006). However, the RR values in milk (2.42-2.94 g g-1) of the beetroot plum slices were greater than those reported by Shih et al. (2008) in strawberry slices (less than 2 g g-1).

The lyophilized slices of yellow plum shed off material shortly after rehydration starts. In the samples that were frozen at -5 °C, the rehydration took 6 min, and in the ones frozen at -20 °C, 15 min. This difference is the result of long-term freezing, which creates bigger pores and weakens the structure. These results are similar to those obtained in the rehydration of lyophilized avocado (Arriola-Guevara et al., 2006). The freezing temperature had a significant effect on RR in water at 30 °C, and freezing at -5 °C increased the value of RR. Similarly, the RR of the yellow plum was lower in milk (less than 3 g g-1). In the case of fruits combined with cereals or used as snacks, RR should be low.

Conclusions

Freeze-drying reduces moisture and aw of Mexican plum slices, therefore reducing the probability of microbiological contamination. The freeze-drying process alters the color, the luminosity, and the pigment retention of the Mexican plum slices. The freezing temperature and the vacuum pressure do not modify the pectin content. The lyophilized slices have high rehydration capacity, although the yellow plum sheds off small portions of material during rehydration.

Literatura Citada

Adhami, S., A. Rahimi, and M. S. Hatamipour. 2013. Freeze drying of quince (Cydonia oblonga): Modelling of drying kinetics and characteristics. Korean J. Chem. Eng. 30: 1201-1206. [ Links ]

Alia-Tecajal, I., Y. I. Astudillo-Maldonado, C. A. Núñez-Colín, L. A. Valdez-Aguilar, S. Bautista-Baños, E. García-Vázquez, R. Ariza-Flores, y F. Rivera-Cabrera. 2012. Caracterización de frutos de ciruela mexicana (Spondias purpurea L.) del sur de México. Rev. Fitotec. Mex. 35: 21-26. [ Links ]

Arriola-Guevara, E., T. García-Herrera, G. M. Guatemala-Morales, J. Nungaray-Arellano, O. González-Reynoso, y J.C. Ruíz-Gómez. 2006. Comportamiento del aguacate has liofilizado durante la operación de rehidratación. Rev. Mex. Ing. Quim. 5: 51-56. [ Links ]

Beaudry, C., G. S. V. Raghavan, C. Ratti, and T. J. Rennie. 2004. Effect of four drying methods on the quality of osmotically dehydrated cranberries. Dry. Technol. 21: 1797-1810. [ Links ]

Caparino, O. A., J. Tang, C. I. Nindo, S. S. Sablani, J. R. Powers, and J. K. Fellman. 2012. Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. J. Food Eng. 111: 35-148. [ Links ]

Ceballos, A. M., G. I. Giraldo, and C. E. Orrego. 2012. Effect of freezing rate on quality parameters of freeze dried soursop fruit pulp. J. Food Eng. 111: 360-365. [ Links ]

Fijalkowska, A., M. Nowacka, A. Wiktor, M. Sledz, and D. Witrowa‐Rajchert. 2015. Ultrasound as a pretreatment method to improve drying kinetics and sensory properties of dried apple. J. Food Process Eng. 39: 256-265. [ Links ]

Franceschinis, L., P. Sette, C. Schebor, and D. Salvatori. 2015. Color and bioactive compounds characteristics on dehydrated sweet cherry products. Food Bioprocess Technol. 8: 1716-1729. [ Links ]

Guiné, R. P., and M. J. Barroca. 2012. Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod. Process. 90: 58-63. [ Links ]

Guo, X., D. Han, H. Xi, L. Rao, X. Liao, X. Hu, and J. Wu. 2012. Extraction of pectin from navel orange peel assisted by ultra-high pressure, microwave or traditional heating: a comparison. Carbohydr. Polym. 88: 441-448. [ Links ]

Hammami, C., and F. René. 1997. Determination of freeze-drying process variables for strawberries. J. Food Eng. 32: 133-154. [ Links ]

Hottot, A., J. Andrieu, and S. Vessot. 2007. Sublimation kinetics during freeze-drying of pharmaceutical protein formulation. Dry. Technol. 25: 753-758. [ Links ]

Huang, H. W., C. P. Hsu, B. B. Yang, and C. Y. Wang. 2013. Advances in the extraction of natural ingredients by high pressure extraction technology. Trends Food Sci. Technol. 33: 54-62. [ Links ]

Jokic, S., I. Mujic, M. Martinov, D. Velic, M. Bilic, and J. Lukinac. 2009. Influence of drying procedure on colour and rehydration characteristic of wild asparagus. Czech J. Food Sci. 27: 171-177. [ Links ]

Kasper, J. C., and W. Friess. 2011. The freezing step in lyophilization physico-chemical fundamentals, freezing methods and consequences on process performance and quality attributes of biopharmaceuticals. Eur. J. Pharm. Biopharm. 78: 248-263. [ Links ]

Kliemann, E., K. Nunes de Simas, E. R. Amante, E. P. Schwiden, R. F. Teófilo, M. M. C. Ferreira, and R. D. M. C. Amboni. 2009. Optimization of pectin acid extraction from passion fruit peel (Passiflora edulis flavicarpa) using response surface methodology. Int. J. Food Tech. 44: 476-483. [ Links ]

Liapis, A. I., and R. Bruttini. 2006. Freeze drying. In: Mujundar, A. (ed). Handbook of Industrial Drying. CRC Press, Boca Raton. pp: 257-281. [ Links ]

Lombraña, J. I. 2009. Fundamentals and tendencies in freezedrying of foods. In: Ratti, C. (ed). Advances in Food Dehydration. CRC Press. Boca Raton, US. pp: 209-213. [ Links ]

Lozano-Acevedo, A., M. Jiménez-Fernández, A. Ragazzo-Sánchez, G. R.Urrea-Garcia, and G. Luna-Solano. 2011. Fluidized bed drying process of thinly sliced potato (Solanum tuberosum). Am. J. Pot. Res. 88: 360-366. [ Links ]

Marín, B. E., M. R. Lemus, M. V. Flores, y G. A. Vega. 2006. La rehidratación de alimentos deshidratados. Rev. Chil. Nutr. 33: 527-538. [ Links ]

Marques, L. G., M. C. Ferreira, and J. T. Freire, 2007. Freeze-drying of acerola (Malpighia glabra L.) Chem. Eng. Process. 46: 451-457. [ Links ]

Naghshineh, M., K. Olsen, and C. A. Georgiou. 2013. Sustainable production of pectin from lime peel by high hydrostatic pressure treatment. Food Chem. 136: 472-478. [ Links ]

Osuna, G. J. A., B. M. H. Pérez, V. V. Vázquez, y J. R. Gómez. 2011. Aplicación de 1-metilciclopropeno (1-MCP) y su efecto en ciruela mexicana (Spondias purpurea L.) Rev. Fitotec. Mex. 34: 197-204. [ Links ]

Pei, F., Y. Shi, A.M. Mariga, W. J. Yang, X.Z. Tang, L. Y. Zhao, X. X. An, and Q. H. Hu. 2014. Comparison of freeze-drying and freeze-drying combined with microwave vacuum drying methods on drying kinetics and rehydration characteristics of button mushroom (Agaricus bisporus) slices. Food Bioprocess Technol. 7: 1629-1639. [ Links ]

Reyes, A., R. Vega, R. Bustos, and C. Araneda. 2008. Effect of processing conditions on drying kinetics and particle microstructure of carrot. Dry. Technol. 26: 1272-1285. [ Links ]

Reyes, A., A. Mahn, and P. Huenulaf. 2011. Drying of apple slices in atmospheric and vacuum freeze dryer. Dry. Technol. 29: 1076-1089. [ Links ]

Sánchez-Santillán, P., M. A. Cobos-Peralta, D. Hernández-Sánchez, A. Álvarado-Iglesias, D. Espinosa-Victoria, y J. G. Herrera-Haro. 2016. Uso de carbón activado para conservar bacterias celulolíticas liofilizadas. Agrociencia 50: 575-582. [ Links ]

Shih, C., Z. Pan, T. McHugh, D. Wood, and E. Hirschberg. 2008. Sequential infrared radiation and freeze-drying method for producing crispy strawberries. Transactions ASABE. 51: 205-216. [ Links ]

Shishehgarha, F., J. Makhlouf, andC. Ratti. 2002. Freeze-drying characteristics of strawberries. Dry. Technol. 20: 131-145. [ Links ]

SIAP (Servicio de información agroalimentaria y pesquera). Ciclos: Cíclicos y perennes 2015. www.siap.gob.mx (Consulta: mayo 2016). [ Links ]

Vargas-Simón, G., R. Hernández-Cupil, y E. Moguel-Ordoñez. 2011. Caracterización morfológica de ciruela (Spondias purpurea L.) en tres municipios del estado de Tabasco, México. Bioagro 23: 141-149. [ Links ]

Xi, J. 2009. Caffeine extraction from green tea leaves assisted by high pressure processing. J. Food Eng. 94: 105-109. [ Links ]

Zhang, L., T. Liu, Y. Xue, C. Liu, H. Ru, M. Dong, and Z. Yu. 2015. Effects of drying methods on the aroma components and quality of Capsella Bursa‐Pastoris L. J. Food Process Eng. 39: 107-120. [ Links ]

Received: November 2016; Accepted: August 2017

text in

text in