1. Introduction

The construction industry is an important one nowadays, the search for better building materials is not limited to stronger materials but also those that present an added value. Research has been carried on corrosion, fatigue, microstructural properties [1,2], and, little attention has been paid to thermal parameters [3]. Due to climate change, the thermal properties of building materials have become an essential factor when an energy saving balance is intended. Thermal conductivity is the primary indicator of the suitableness of the sample on the energy transfer with the environment because this property “measure of the ability of a material to conduct heat” [4]. When high thermal conductivity materials are used in construction, the energy cost can raise, due to the necessity of isolating materials or more energy need to preserve a comfortable environment, the search for isolation building materials is a hot topic among researchers [3,5,6]. In this work, the thermal properties of a building tile are studied, especially thermal diffusivity and thermal effusivity. As defined elsewhere, thermal diffusivity is “how fast heat diffuses through a material, and appears in the transient heat conduction analysis” [4], and thermal effusivity is the property that determines: “the amplitude of the temperature at a sample surface and its behavior at interfaces in the case of transient and periodical heat sources” [7]. Particularly thermal effusivity which “is the relevant parameter when the contact of human skin with a material at different temperatures” is studied [7]. A commercial tile is usually composed of three layers, therefore in this work each component was measured individually. Polyvinyl Difluoride (PVDF) and Lead Zirconate Titanate (PZT) ceramic were used as a pyroelectric sensor in the Inverse Photopyroelectric configuration (IPPE) of the experimental setup to get the thermal effusivity and thermal diffusivity of each tile layer; using the so-called open photoacoustic cell (OPC), the thermal diffusivity is obtained.

2. Methods and materials

2.1. Samples

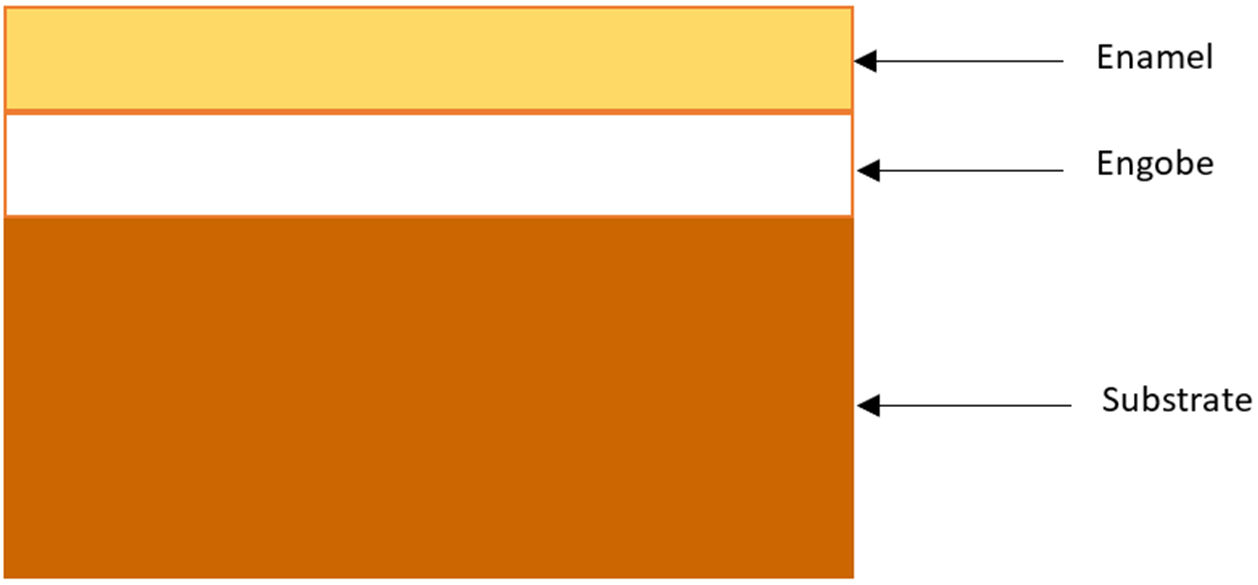

Commercial tiles can be grouped in natural stone tiles (marble, granite and terrazzo), plastic tiles as vinyl, and ceramic tiles [8]. In this work the samples were ceramic tiles presenting three layers: a substrate, a so-called engobe layer, and a color layer named enamel, a scheme of the tile configuration is shown in Fig. 1. The substrate is composed mainly by adobe and other natural components, the engobe has the function of hiding the imperfections of the substrate color -and serves as a link with the enamel. In this work each layer was measured individually. For the enamel layer, two different color layers were used (white and orange). Three different commercial tiles were used.

2.2. Inverse photopyroelectric technique

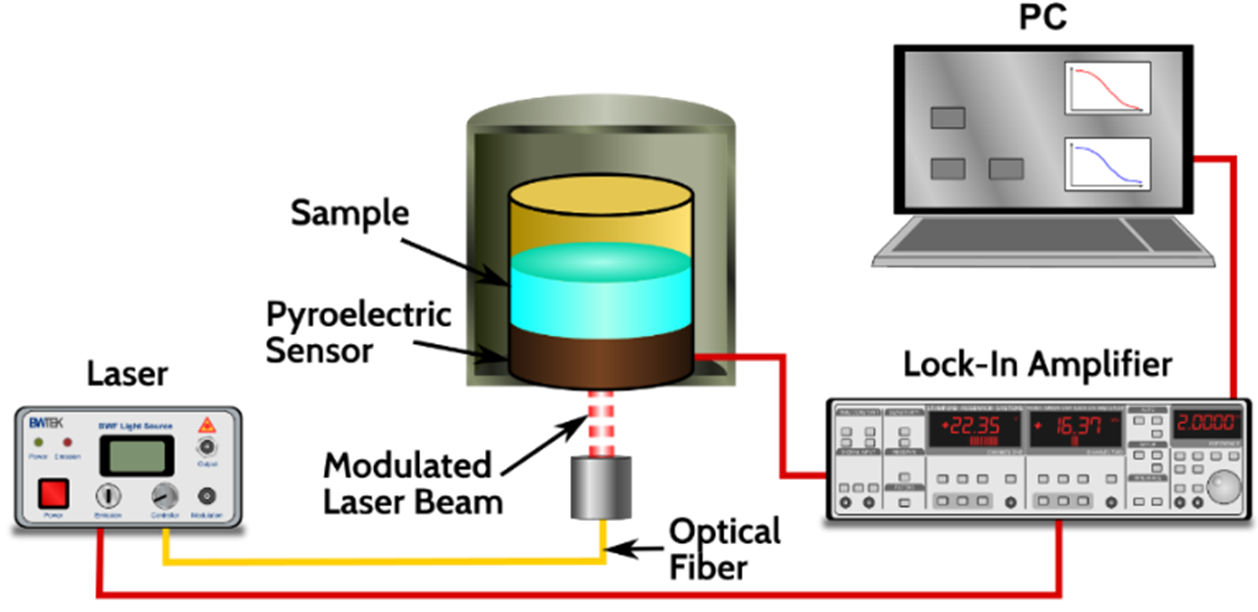

The experimental setup used to obtain the sample thermal effusivity consisted of a laser diode at 650 nm wavelength (BWTEK T55-369), modulated by a lock-in amplifier (Stanford Research Systems SR830), whose beam impinges on the pyroelectric detector. The sample was coupled to the pyroelectric sensor using a thin thermal grease layer, as shown in Fig 2. The phototpyroelectric (PPE) signal was detected using a lock-in amplifier, and the PPE signal amplitude and phase were recorded as a function of the laser beam modulation frequency (

When a thermally thick sample (i.e.,

where

2.3. Open photoacoustic cell

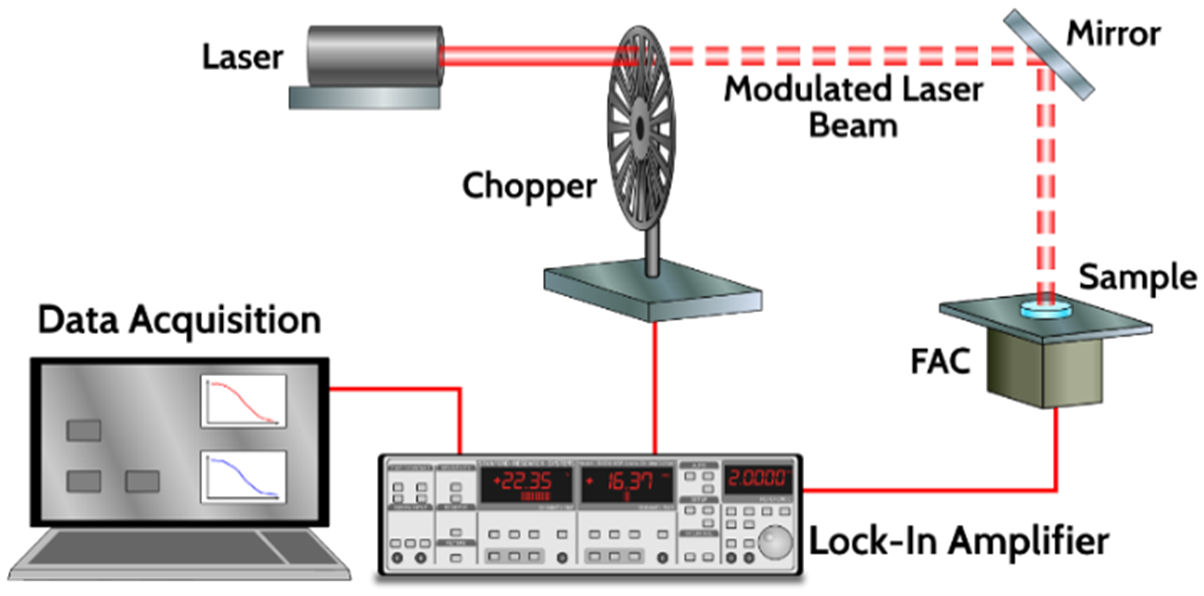

Thermal diffusivity was obtained by using the open photoacoustic cell method; the experimental setup is formed by a 150 mW Argon-ion laser (Modu-Laser Stellar-Pro), whose beam was mechanically modulated by using a mechanical chopper (Stanford Research Systems SR 540). Then the modulated light impinges in the sample under study, which is placed on the top of an electret microphone, using vacuum grease, as shown in Fig. 3. The signal amplitude and phase were monitored, as a function of the laser beam modulation frequency (

When the sample closes the microphone cavity and, assuming the sample is thermally thick and optically opaque, the microphone signal can be described by the Eq. (2) [11]:

In the above equation,

2.4. Density

Archimedes method was used to measure the density of the samples, an electronic balance (Shuler Scientific, SAS-225.R) and a calibrated Gay Lussac pycnometer of 25 ml (Kimble, 15123N-25) were used to obtain the weight and volume of the samples; all measurements were made at 25

3. Results and discussion

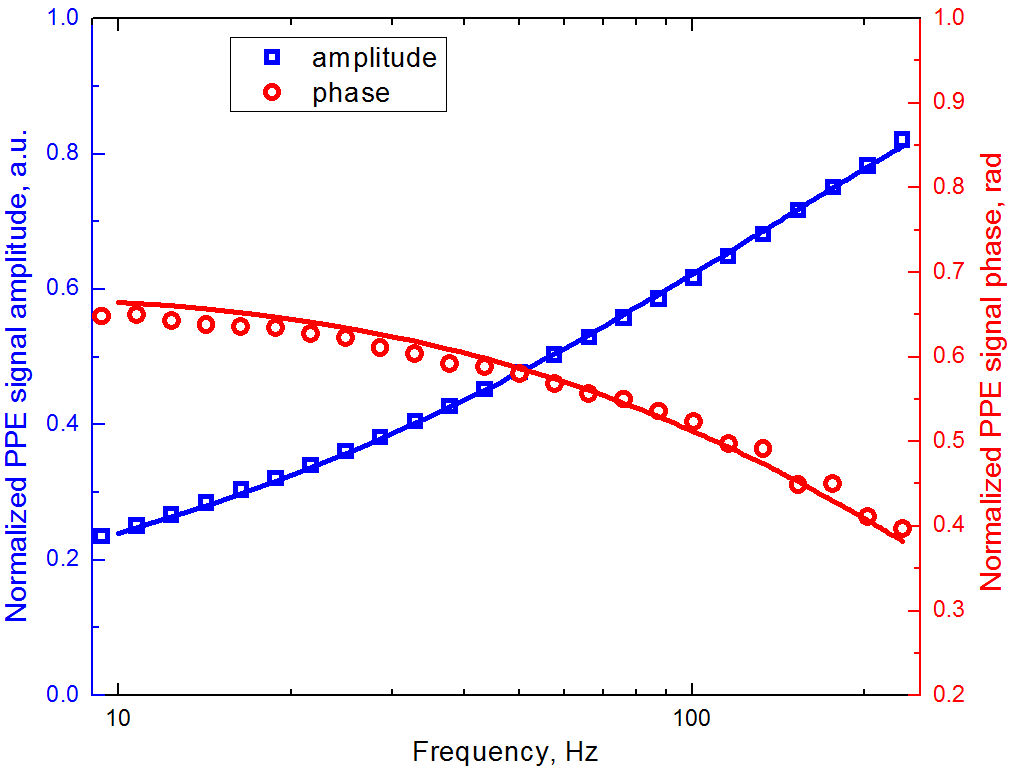

Figures 4 shows a representative plot of the normalized photopyroelectric signal amplitude and phase of the substrate sample as a function of the light modulation frequency. The squares and circles represent the experimental magnitude and phase data respectively, and solid lines are the best fit of equation 1 to this data. According to the Eq. 1, the photopyroelectric signal depends on the thermal effusivity ratio of the sample and the pyroelectric. Therefore, the thermal effusivity of the pyroelectric was determined in advanced using glycerol and water as reference samples. The thermal effusivity can be extracted either from the IPPE signal amplitude or phase using the sample thermal effusivity as the fitting parameter, the difference between obtained values from each one gives an indicator of the fitting quality.

Figure 4 Experimental IPPE signal amplitude and phase as a function of the modulation frequency for the substrate sample. the solid curve is the best fitting of the Eq. (1) to the experimental data.

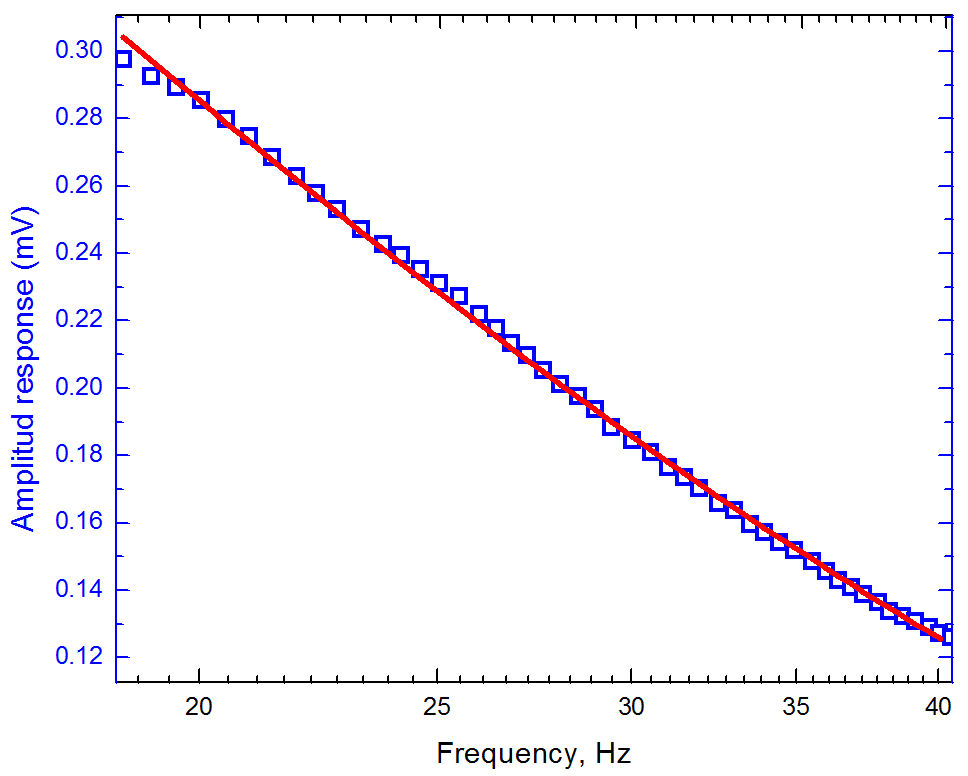

Figure 5 shows the OPC signal amplitude of the substrate, as a function of the light modulation frequency. The squares represent the experimental data, and the solid line is the best fitting of the Eq. 2 to the experimental data using the sample thermal diffusivity as the fitting parameter.

Figure 5 Substrate sample experimental OPC signal amplitude as a function of the modulation frequency. The solid line represents the best fitting of Eq. (2) to the experimental data.

Table I shows the thermal properties values for each sample obtained experimentally, at the same time the thermal conductivity values (

TABLE I Thermal properties of studied samples.

| Sample | Measured values | Literature Values3 | ||||

|---|---|---|---|---|---|---|

| Thermal effusivity | Thermal diffusivity | Thermal conductivity | Density | Thermal diffusivity | Thermal conductivity | |

|

|

|

(calculated) |

|

|

|

|

| Substrate |

|

|

|

2201 | 0.101 | 1.26 |

| Engobe |

|

|

|

1979 | ||

| White enamel |

|

|

|

2068 | ||

| Orange enamel |

|

|

|

2892 | ||

The thermal conductivity of substrate and orange enamel are close to those reported in the literature for adobe with 8 and 12 wt.% of Portland cement and limestone [12,13]. The measured values are higher than those reported for the raw materials, indicating a densification process of the main component of the substrate. The obtained values for white enamel and engobe are close to sandstone with a porosity of about 12% [14]. The calculated values are the result of the thermal process applied to the raw materials for getting the tile. The high thermal conductivity values indicate that the studied materials are suitable for radiant floor heating applications [8].

White enamel thermal conductivity can be compared with red stoneware tile [8,15]. The difference between the white and orange enamel are related not only with the pigments used for giving the color to the enamel but also with the optical absorption in the wavelength used in the thermal diffusivity.

Conclusions

Two photothermal techniques, Inverse Photopyroelectric configuration (IPPE) and Open photoacoustic cell (OPC) methods, have been used to study of thermal properties of the ceramic tiles. Thermal parameters were obtained for each layer of these samples composed of three layers, a substrate, an engobe, and an enamel layer. Thermal effusivities and diffusivities, for each segment, were obtained by IPPE and OPC techniques respectively. Also, from the obtained thermal parameters, the thermal conductivity of each layer was calculated from the relationship of these three thermal parameters. The high thermal conductivity values indicate the suitableness of this materials as serving for radiant floor heating applications. Obtained thermal parameter values of the samples are in agreement with the starting raw materials and finished tiles.

text new page (beta)

text new page (beta)