Research

Magnetohydrodynamic Jeffrey nanoliquid flow with thermally radiative

Newtonian heat and mass species

aDepartment of Mathematics, COMSATS

University Islamabad, Sahiwal 57000, Pakistan.

Abastract

This study characterizes the properties of Newtonian heat and mass species

conditions in three-dimensional Jeffrey nanoliquid flow generated by the

movement of thermally radiative surface. The liquid flow is electrically

conducting through the consideration of magnetic field. The aspects of heat

absorption, generation, and thermal radiation are considered in the equation of

energy conservation. The boundary layer phenomenon is employed to obtain the

mathematical expressions of considered physical model. These equations are

solved via homotopic scheme. The convergence of homotopic solutions is validated

by the numerical data. The importance of physical constraints on temperature,

and nanoparticle concentration of liquid is visualized by the graphical

results.

Keywords: Three-dimensional flow; Jeffrey liquid; nanoparticles; Newtonian conditions; bidirectional surface

PACS: 65.80.-g; 82.60.Qr

1. Introduction

Complex liquids have common nature of viscoelasticity. Some examples of complex

viscoelastic liquids include suspensions of colloidal, polymer solutions, and

polymer melts. Such fluids are generally involved in blow, and injection molding,

extrusions, lab on a chip, inkjet printers, and many others. Viscoelastic behavior

of liquids may affect the different aspects of flows like transport, and energy

dissipation, hydraulic resistance, flow stability and mixing performance [1]. Intra and inter molecules reactions of

polymer chains may generate the viscoelasticity. Analysis and modeling of

viscoelastic fluid flows have technical and scientific interests. Researchers of

modern world have paid full attention to elaborate the mechanism of viscoelastic

materials for better quality in industrial manufacturing of products. Many complex

rheological expressions of viscoelastic materials had been developed in the past. A

very fabulous model of viscoelastic liquids is known as Jeffrey fluid. This model

has the features of stress retardation, and relaxation. Various investigators have

adopted this model to discuss the different problems of fluid flows under multiple

situations. For example, Turkyilmazoglu and Pop [2] modeled the flow of Jeffrey fluid due to shrinking or stretching of

surface and express the exact behavior of govern mathematical expressions. Das

et al.[3] disclosed the

nature of thermal magnetic field in stretched Jeffrey liquid flow with transport of

melting heat. Gravitational aspects on Jeffrey liquid flow with solutal and thermal

stratification have been reported by Abbasi et al.[4]. Hayat et al.[5] addressed the convective heating effects in

hydromagnetic stagnant flow of Jeffrey fluid. Qayyum et al. [6] discussed the reactive Jeffrey fluid flow

over variable thickness surface.

Nanofluids have achieved special attention due to their broad applications in modern

science, and technology like glass fiber, electronic chips, micro-computers, wire

drawing, renewable energy sources, engine oils, vehicles, systems of thermal energy

storage, and many others. Some common base liquids such as oil, grease, water, and

ethylene glycol are poor conductors and have lesser thermal efficiency. Researchers

have developed modern technique to augment the thermal performance of such liquids

with insertion of nanoparticles. The involvement of solid particles may alter the

density, viscosity, thermal conductivity, and heat capacity of such liquids. In

nanofluids mechanisms, there are various slip factors include thermophoretic, and

Brownian movement aspects which are responsible to motion of nanoparticles in base

liquids. Concentration of nanoparticles may not be constant due to presence of

velocity slip factor of nanoliquids. Investigators of the modern era have proven

that nanoparticles have an ability of transport energy, and also alter the

thermophysical features. Buongiorno [7] was

the first who explored the forces which have impacts on nanoparticles velocity. He

reported that Brownian movement and thermophoretic are the forces which generate

drift-flux in nanoparticles. After that, different attempts have been made by using

the Buongiorno model to explore the mechanism of such factors under various

circumstances and conditions [8-20].

Here our attention is to discuss the nature of Newtonian heat and mass transportation

in three-dimensional magnetohydrodynamic flow of Jeffrey nanoliquid induced by the

bidirectional movement of surface. In the past, the investigators discuss the

various fluid flows problems by only considering the Newtonian heating aspects. They

ignored the Newtonian mass transport effects. In practical situations, heat and mass

transport occur simultaneously and if Newtonian heat phenomenon takes place, then

the importance of Newtonian mass cannot be ignored. Here we considered both

Newtonian heat and mass conditions because the problems of modern industrial

processes. This phenomenon is more realistic,and practical. We also considered the

solar radiation term in energy expression. All the governing equations are tackled

by homotopic procedure [21-26]. The results are plotted for different

values of physical constraints.

2. Governing problems

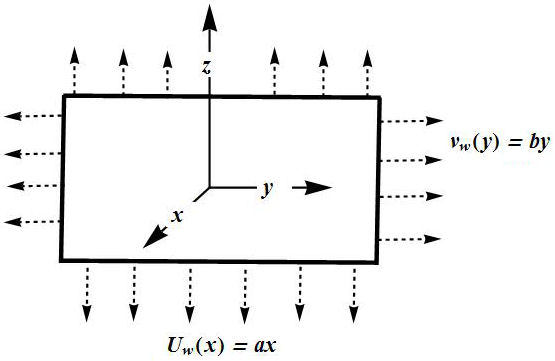

We assumed the three-dimensional steady-state flow of Jeffrey liquid induced by the

movement of thermally radiative surface (Fig.

1). The impacts of heat absorption, generation, and thermal radiation are

accounted in the expressions of energy. The Newtonian heat and mass species

conditions are imposed at boundary of surface. The equations of considered flow

phenomenon through boundary layer theory are

∂u∂x+∂v∂y+∂w∂z=0,

(1)

u∂u∂x+v∂u∂y+w∂w∂z=υ1+δ1(∂2u∂z2+δ2×(∂u∂z∂2v∂x∂z+∂v∂z∂2v∂y∂z+∂w∂z∂2v∂z2+u∂3u∂x∂z2+v∂3u∂y∂z2+w∂3u∂z3))-σB02ρfu,

(2)

u∂u∂x+v∂u∂y+w∂w∂z=υ1+δ1(∂2v∂z2+δ2×(∂u∂z∂2v∂x∂z+∂v∂z∂2v∂y∂z+∂w∂z∂2v∂z2+u∂3u∂x∂z2+v∂3u∂y∂z2+w∂3u∂z3))-σB02ρfv,

(3)

u∂T∂x+v∂T∂y+w∂T∂z=∂2T∂z2+τ(DB∂C∂z∂T∂z+DTT∞(∂T∂z)2)+1(ρc)f16σ*T∞33k*∂2T∂z2+Q(T-T∞),

(4)

u∂C∂x+v∂C∂y+w∂C∂z=DB∂2C∂z2+DTT∞∂2T∂z2

(5)

where the respective velocity components in the x-, y- and z- directions are denoted by u,

v and w, δ1 the ratio of relaxation to retardation times, δ2 the retardation time, T the fluid temperature, υ=(μ/ρ) the kinematic viscosity, μ the dynamic viscosity of fluid, ρf the density of fluid, σ the electrical conductivity, α the thermal diffusivity, Q>0 the heat generation parameter, and Q<0 represents the heat absorption parameter, τ=((ρc)p/(ρc)f) the ratio of nanoparticle heat capacity, and the base fluid heat

capacity, σ* the Stefan-Boltzmann constant, k* the mean absorption coefficient, DB the Brownian diffusion coefficient, and DT the thermophoretic diffusion coefficient.

The boundary conditions can be written in the following forms:

u=Uw(x)=ax,v=Vw(y)=by,w=0,∂T∂z=-htT,∂C∂z=-hcC,atz=0

(6)

u→0,v→0,T→T∞,C→C∞,asz→∞,

(7)

where a and b are the constants of dimension time inverse, ht conjugate coefficient of heat transport, and hc conjugate coefficient of mass transport.

By employing the following variables

u=dxf'(ξ),v=dyg'(ξ),w=-dv(f'(ξ)+g(ξ)),ξ=zdυ,θ(ξ)=T-T∞T∞,ϕ(ξ)=C-C∞C∞,

(8)

Eq. (1) is satisfied automatically, and Eqs. (2)-(7) can be converted in the

following forms:

f‴+(1+δ1)((f+g)f″-f'2)+De1(f″2-(f+g)f⁗-g'f‴)-(1+λ1)Mf'=0,

(9)

g‴+(1+δ1)((f+g)g″-g'2)+De1(g″2-(f+g)g⁗-f'g‴)-(1+λ1)Mg'=0,

(10)

(1+43TR)θ″+Pr(f+g)θ'+NBθ'φ'+NTθ'2+PrSθ=0,

(11)

φ″+PrLe(f+g)φ'+(NT/NB)θ″=0,

(12)

f=0,g=0,f'=1,g'=δ,θ'=-NH(1-θ(0)),ϕ'=-NC(1-ϕ(0))atη=0,

(13)

f'→0,g'→0,θ→0,ϕ→0asη→∞,

(14)

where De=δ2d is the Deborah number, Mg=(σB02/dρf) the magnetic parameter, α=b/a is a ratio parameter, Pr=υ/α is the Prandtl number, TR=4σT∞3/kk* is the thermal radiation parameter, S=Q/dρcp is the internal heat generation parameter, NB=(τDB/υ) is the Brownian motion parameter, NT=(τDT/υT∞) is the thermophoresis parameter, NH=htυ/d and NC=hCυ/d are the Biot numbers, Le=α/DB is the Lewis number, and prime shows the differentiation with respect to ξ. The local Nusselt number NuRex-1/2 and Sherwood number ShRex-1/2 in dimensionless forms can be described as follows:

NuRex-1/2=NH(1+43TR)(1+1θ(0)),ShRex-1/2=NC(1+1φ(0)),

(15)

in which Rex=uw(x)x/υ is the local Reynolds number.

3. Series solutions

The initial guesses and auxiliary linear operators for present case can be selected

in the forms:

f0(ξ)=1-exp(-ξ),g0(ξ)=δ(1-exp(-ξ)),

(16)

θ0(ξ)=NHexp(-ξ)1+NH,φ(ξ)=NCexp(-ξ)1+NC,

(17)

Lf=f‴-f',Lg=g‴-g',Lθ=θ‴-θ,Lφ=φ‴-φ.

(18)

We observe that the auxiliary linear operators may satisfy the following

expressions

L(f)(E1+E2eξ+E3e-ξ)=0,L(g)(E1+E2eξ+E3e-ξ)=0,L(θ)(E7eξ+E8e-ξ)=0,L(φ)(E9eξ+E10e-ξ)=0,

where Ei(i=1-10) are the arbitrary constants.

4. Analysis of convergence and results

An analytical technique namely homotopy analysis scheme has been implemented to

obtain the solutions of governing mathematical expressions. It is a well-established

fact that convergence of homotopic solutions greatly depends on the proper choice of

auxiliary parameters. We plotted curves at 15th order of deformations to

select the reasonable values of auxiliary parameters ℏf, ℏg, ℏθ and ℏφ. For the presentproblem, the solutions should be convergent in the range

of -0.85≤ℏf≤-0.15, -0.90≤ℏg≤-0.20, -1.20≤ℏθ≤-0.15 and -1.00≤ℏφ≤-0.25 (see Fig. 2). Table I executes that the present solutions

converge from order of deformations. This Table is computed by choosing ℏf=ℏg=ℏθ=ℏφ=-65/100, De=0.4, δ1=0.3, Mg=0.7, Pr=1.5=Le, NB=0.1=NT, NH=0.2=NC, S=0.1, TR=0.3, and δ=0.5. Here we analyzed that the magnitude values of f″(0) are larger in comparison to g″(0), θ'(0) and φ(0).

Table I Convergence of series solutions for different order of approximations

when De=0.4,δ1=0.3,Mg=0.7,Pr=1.5=Le,NB=0.1=NT,NH=0.2=NC,S=0.1,TR=0.3,δ=0.5,and ℏf=ℏg=ℏθ=ℏφ=-65/100

| Order of HAM approximations |

-f″(0)

|

-g″(0)

|

-θ'(0)

|

-φ'(0)

|

| 01 |

1.26661 |

0.64143 |

0.26625 |

0.26777 |

| 07 |

1.26718 |

0.68497 |

0.28911 |

0.27261 |

| 12 |

1.26722 |

0.68482 |

0.29060 |

0.27274 |

| 18 |

1.26727 |

0.68480 |

0.29080 |

0.27279 |

| 23 |

1.26726 |

0.68489 |

0.29082 |

0.27278 |

| 28 |

1.26732 |

0.68504 |

0.29081 |

0.27277 |

| 35 |

1.26732 |

0.68504 |

0.29081 |

0.27277 |

| 40 |

1.26732 |

0.68504 |

0.29081 |

0.27277 |

Figures 3-10

are produced to elaborate the nature of emerging physical constraints on

temperature θ(ξ) and nano-

particle concentration φ(ξ). Figure 3 clearly describes that an

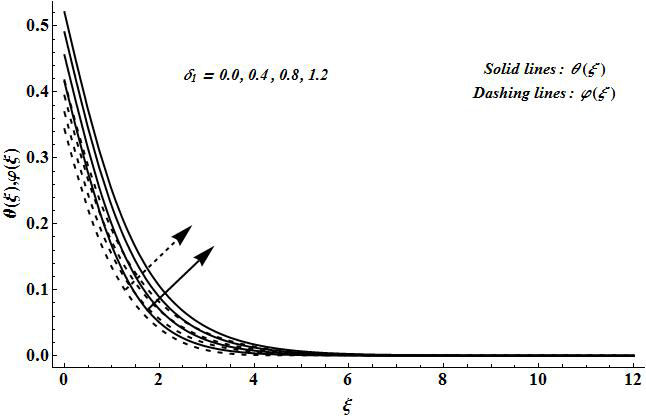

increment in Deborah number De leads to smaller profiles of θ(ξ), and φ(ξ) Here De directly depends on stress retardation δ2. The stress retardation is stronger with an enhancement in De. Such stronger stress retardation creates a reduction in the profiles θ(ξ), and φ(ξ). The results in the case of fluid liquid can be achieved when De=0, and δ1=0. The features of ratio stress relaxation and stress retardation δ1 on θ(ξ) and φ(ξ) are investigated in Fig. 4. The

curves of θ(ξ) and φ(ξ) are boost up when we use the larger δ1. From physical concept, the higher δ1 implies to larger stress relaxation in comparison to stress retardation.

This fact leads to stronger temperature and nanoparticles concentration against the

larger δ1. Figure 5 incorporates the impacts

of magnetic parameter Mg on θ(ξ), and φ(ξ). This figure clearly executes that an increment in Mg give rise to the profiles of θ(ξ) and φ(ξ). Here the Lorentz force exists due to electrically conducting liquid.

This Lorentz force becomes stronger for larger Mg that resists the flow of liquid. Such resistance in liquid flow leads to

higher temperature, and nanoparticle concentration. Further, the hydrodynamic flow

situation can be created by setting Mg=0. In case of hydrodynamic flow, the profiles of θ(ξ), and φ(ξ) are minimum position.

From Fig. 6, we evaluated the nature of Prandtl

number Pr on θ(ξ), and φ(ξ). The increasing values of Pr correspond to weaker profiles of

temperature, and nanoparticle concentration. The conductivity of liquid is lesser

for higher Pr, and stronger for smaller Pr due to fact the profiles of θ(ξ), and φ(ξ) decay. The proper choice of Pr in manufacturing processes of industry is

very essential because the suitable values of Pr are utilized to provide the best

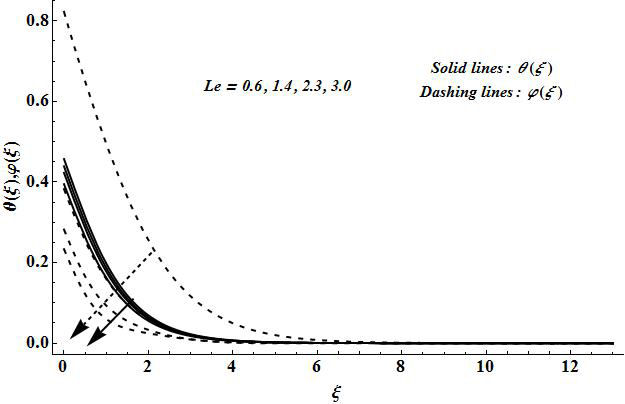

heat transport rate to achieve the highest quality product. The execution of Lewis

number Le on θ(ξ), and φ(ξ) is presented in Fig. 7. This figure

clearly elucidates that the variations in θ(ξ) are very lesser in comparison to φ(ξ) as we use the larger Le. Moreover, the curves of θ(ξ), and φ(ξ) are decreased for the increasing values of Le. The coefficient of Brownian diffusion becomes weaker for higher Le because it is inversely related to it. Such weaker Brownian coefficient

factor leads to decrement in the profiles of θ(ξ), and φ(ξ).

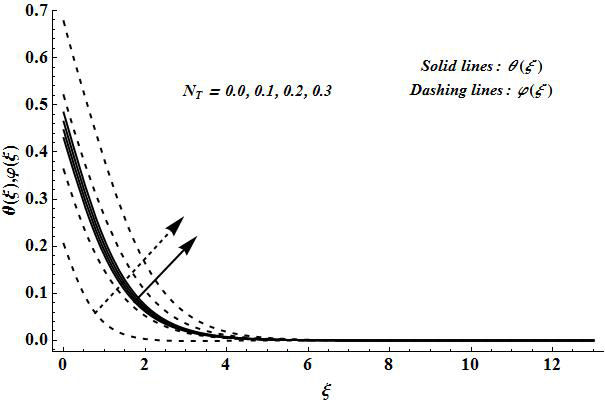

The impact of parameter of thermophoretic Nt on θ(ξ), and φ(ξ) is discussed through Fig. 8. Figure 8 clearly depicts that profiles of both θ(ξ), and φ(ξ) are risen due to rising values of NT. The stronger NT corresponds to an enhancement in thermal conductivity of liquid due to

consideration of nanoparticles. This higher thermal conductivity factor leads to

higher θ(ξ), and φ(ξ). The change in θ(ξ) for various values of NT are significant as compared to φ(ξ). The increasing values of parameter of Brownian movement NB give risen to the profiles of θ(ξ), and φ(ξ) (see Fig. 9). The liquid

temperature θ(ξ) is boost up by an increment in NB while the curves of φ(ξ) are retarded. In fact, NB is appeared in form of (1/NB) that corresponds to weaker nanoparticle concentration. The nature of

parameter of thermal radiation TR on liquid temperature, and nanoparticle concentration is described in

Fig. 10. Here we investigated that the

presence of TR give risen to θ(ξ), and φ(ξ). The case of absence of radiative effect can be discussed when TR=0. The radiation factor gives more heat to liquid due to which temperature

and concentration are enhanced.

5. Conclusions

This research work executes the features of Newtonian conditions in three-dimensional

Jeffrey liquid flow under the impact of magnetic field, thermal radiation, and

suspension of nanoparticles. We employed the boundary layer concept to govern the

expressions of physical phenomenon. The convergent solutions are developed and

plotted. We observed that the ratio of stress relaxation and stress retardation δ1, and Deborah number De have totally reverse influences on liquid temperature θ(ξ), and nanoparticle concentration ϕ(ξ). An increment in magnetic parameter Mg give risen to the profiles of θ(ξ), and φ(ξ). This phenomenon occurs due to involvement of Lorentz force. The change

in profiles of θ(ξ) for various Pr is significant as compared to profile of temperature in

case of various Le. The liquid temperature, and nanoparticle concentration enhanced by

increasing the values of thermophoretic factor NT. An increase in factor of Brownian movement lead to higher temperature

curves but lower curves of nanoparticle concentration. The involvement of radiation

factor gradually enhanced the temperature of liquid.

References

1 R. Comminal, J.H. Hattel, M.A. Alves, and J. Spangenberg,

Journal of Non-Newtonian Fluid Mechanics 237 (2016)

1-15.

[ Links ]

2 M. Turkyilmazoglu, and I. Pop, International Journal of

Heat and Mass Transfer 57 (2013) 82-88.

[ Links ]

3 K. Das, N. Acharya, and P.K. Kundu, Alexandria Engineering

Journal 54 (2015) 815-821.

[ Links ]

4 F.M. Abbasi, S.A. Shehzad, T. Hayat, and M.S. Alhuthali,

Journal of Hydrodynamics Series B 28 (2016)

840-849.

[ Links ]

5 T. Hayat , S. Asad, M. Mustafa, and A. Alsaedi, Computers

and Fluids 108 (2015) 179-185.

[ Links ]

6 Qayyum, S. Hayat, T. Alsaedi, A. and Ahmad, B.

International Journal of Mechanical Sciences 134 (2017)

306-314.

[ Links ]

7 J. Buongiorno, Journal of Heat Transfer-Transactions of

ASME 128 (2006) 240-250.

[ Links ]

8 M. Turkyilmazoglu , European Journal of

Mechanics-B/Fluids 53 (2015) 272-277.

[ Links ]

9 J. Li, L. Liu, L. Zheng, and B. Bin-Mohsin, Journal of the

Taiwan Institute of Chemical Engineers 67 (2016)

226-234.

[ Links ]

10 M. Sheikholeslami, D.D. Ganji, and M.M. Rashidi, Journal

of Magnetism and Magnetic Materials 416 (2016)

164-173.

[ Links ]

11 B. Li, W. Zhang, L. Zhu, andL. Zheng , Powder

Technology 310 (2017) 351-358.

[ Links ]

12 A. Rauf, S.A. Shehzad , T. Mushtaq, andT. Hayat , Journal

of Nanofluids 6 (2017) 1134-1142.

[ Links ]

13 K. Hsiao, Energy 130 (2017)

486-499.

[ Links ]

14 M.I. Khan, A. Alsaedi , S.A. Shehzad , andT. Hayat ,

Results in Physics 7 (2017) 2255-2260.

[ Links ]

15 M. Sheikholeslami , A.J. Chamkha, P. Rana, and R. Moradi,

Chinese Journal of Physics 55 (2017)

2356-2370.

[ Links ]

16 K. Hsiao , International Journal of Heat and Mass

Transfer 112 (2017) 983-990.

[ Links ]

17 T. Hayat , S. Qayyum, S.A. Shehzad , andA. Alsaedi ,

Journal of Molecular Liquids 230 (2017)

641-651.

[ Links ]

18 F.A. Soomro, R. Haq, Z.H. Khan, and Q. Zhang, Chinese

Journal of Physics 55 (2017) 1561-1568

[ Links ]

19 X. Xiong, S. Chen, and B. Yang, Applied Mathematics and

Mechanics 38 (2017) 585-602.

[ Links ]

20 Nagendramma, V. Raju, C.S.K. Mallikarjun, B. Shehzad, S.A. and

Leelarathnam, A. Applied Mathematics and Mechanics-English

(Edition 2018) in press.

[ Links ]

21 S. J. Liao , Homotopy analysis method in nonlinear

differential equations. Springer & Higher Education Press,

(Heidelberg 2012).

[ Links ]

22 M. Turkyilmazoglu , Communications in Nonlinear Science

and Numerical Simulation 17 (2012) 4097-4103.

[ Links ]

23 S. Han, L. Zheng , C. Li, and X. Zhang, Applied

Mathematics Letters 38 (2014) 87-93

[ Links ]

24 S.A. Shehzad , F.M. Abbasi , T. Hayat , and B. Ahmad,

Applied Mathematics and Mechanics

-English Edition 37 (2016) 761-768.

[ Links ]

25 M.A. Meraj, S.A. Shehzad , T. Hayat , F.M. Abbasi , andA. Alsaedi

, Applied Mathematics and Mechanics 38 (2017)

557-566

[ Links ]

26 M. Waqas, T. Hayat , S.A. Shehzad , and A. Alseadi,

Physica B: Condensed Matter 529 (2018)

33-40

[ Links ]

text new page (beta)

text new page (beta)