1 Introduction

In the modern world, the role of railway network is an essential for the people around the world. The railway system consists of infrastructure, development and maintenance. The infrastructure of the railway network is the planning and construction of the rail tracks and establishing their contacts in railway junction. The development of the railway network is used to extent the tracks to the rural and interior areas of the village. The rail tracks are maintained by maintenance division of the railway network system. The rail tracks are severely affected by corrosion due to the air and floods during rainy season. They make cracks on the rail track which leads the accident of the trains. The quality of the rail track is important to prevent such defects in rail track and these cracks must be frequently checked to avoid accidents.

In this paper, cracks in railway track are detected using neural network classification approach. The proposed method contains the following stages as preprocessing, Gabor transform, feature extraction, classification and segmentation. In preprocessing stage, the rail track image is enhanced using adaptive histogram equalization technique. This technique enhances the rail track image to detect the cracks more effectively with respect to any environmental conditions. Then, spatial domain preprocessed image is transformed into multi resolution image using Gabor transform. This multi resolution image exhibits frequency, time and orientation.

Further, GLCM and LBP texture feature are extracted from the Gabor transformed multi resolution image, which helps to differentiate the crack image from non-crack image. Now, Neural Network classifier is trained and classified using the extracted feature set. This classifier classifies the rail track image into either crack image or non-crack image based on the feature set. Finally, morphological operations are applied on the classified rail track crack image in order to detect and segment the cracks in image.

The rail track recording or capturing equipment consists of light source and line camera. This recording equipment is slowly moved over the rail track. At this time, the light source generates the light which is passed over the rail track. This light is passed over both the tracks of rail. The line camera which is placed at the rear of the image capturing equipment captures the images of the rail tracks. The specifications of the line camera are illustrated in Table 1.

Table 1 Line Camera

| Specifications | Parameter values |

|---|---|

| Sensor in Camera | Charge Coupled Device (CCD) linear type |

| Pixel size | 10*10 µm |

| Pixel distance | 10 µm |

| Camera frequency | 50 MHz |

The cracks in rail track are formed due to the overloading, corruption by environmental parameters such as wind, flood, and noises. These cracks lead to the train accidents when the train passes on the cracked track. Figure 2(a) shows the normal rail track which does not contain any cracks on it and Figure 2(b) shows the rail track which contains cracks on it. It is very clear from Fig. 2 (b), the cracks are redundant portion in rail track and they are developed due to the continuous passage of train on it.

The detection of rail crack in track is achieved by railway operators and lot of conventional techniques was proposed to detect the cracks in railway track. In concentional methods, Echo image display device or semi conduction magnetism sensor devices are used to detect these defects.

It has several limitations as slow processing and it is not suitable for low-resolution rail track images. These limitations are overcome by proposing an automated defect detection system using classification approach in this paper. The methodology proposed in this paper uses neural network classifier, which detects the cracks in rail track image using the features of the cracked and non-cracked samples of the rail track images.

This paper is organized as, Section 2 discusses various conventional techniques to detect the defects in rail tracks, Section 3 proposes an efficient technique to detect the cracks in rail track using classifiers, Section 4 discusses the experimental results and Section 5 concludes the paper.

2 Literature Survey

Marino et al. [1] used hexagonal technique and two multilayer perceptron neural classifiers to inspect the bolt system in real time rail track image. The authors achieved 95% of accuracy for the detection and classification of bolts, which connected tracks in continuous rail. Thomas et al. [2] detected rolling contact fatigue type of cracks or defects in running rail tracks. The authors constructed non-destructive rail inspection methodology to detect the cracks and defects in the obtained image from video sequences. Qingyong Li et al. [3] proposed a methodology to detect the surface defect of the rail track using visual inspection system. The authors developed projection profile model to detect the defects based on transversal projection profile technique and they applied different contrast enhancement approaches on the rail track images. The authors achieved 80.41% of Recall rate to analyze the defects in real time track image using their proposed model.

Maria Molodova et al. [4] proposed a fully automated method for the detection and segmentation of squats in rail system. The authors constructed an efficient method for the railway system by incorporating the automation technique in it. Ze Liu et al. [5] applied the basic principles of Electromagnetic Tomography on rail track image to detect the crack in their running path. The linear back projection algorithm was constructed to classify the given test source rail track image into either normal or cracked. Based on this classification of rail track, Tikhonov regularization algorithm was applied to validate the experimental results. Yong Shi et al. [6] developed an efficient rail crack detection system using random forest classification technique.

The authors extracted integral channel features from real time rail track image and these extracted features were used to detect the crack or defect in rail track images. The topological error of the proposed method was analyzed using the crack detection method. Zhu Qingbo [7] used Pavement Crack Detection Algorithm to detect and segment the crack in railway track through image processing techniques. The noises and other interferences were detected and removed before the segmentation of cracks in rail track to enhance the performance of the crack detection system. Rubel Biswas et al. [11] proposed Harris - Stephen feature detection based Support Vector Machine (SVM) classification approach for the detection of missing fasteners in rail track images. The authors achieved 81.25% of classification accuracy for their proposed missing fastener detection algorithm. Jiajia Liu et al. [12] used SVM classification method to classify the test rail track image into either tack with fastener or track without fasteners. The authors achieved recall rate of 87.3% for detecting the missing fasteners in rail track images.

The following points are observed from the conventional methods and they are stated below as:

− The segmentation accuracy of the crack detection system in rail track is low.

− The conventional methods detected the crack only on high-resolution rail track images.

The classifier based rail track detection technique is proposed in this paper to overcome the limitations of the conventional methods.

The methodology proposed in this paper detects the crack in both low and high-resolution rail track images.

3 Proposed Methodology

The flow of crack detection and segmentation methodology is depicted in Figure 3.

3.1 Preprocessing

It is used to enhance the track image to detect the crack in track.

The captured track image is converted into grey scale image. Adaptive histogram Equalization technique [5, 7] is applied on the track image to enhance the crack regions in track. It enhances the contrast of the track image which transforms the image value into its intensity value.

3.2 Gabor Transform

The multi resolution transform is used to convert the spatial domain image into multi resolution image, which is in the form of amplitude, frequency and phase. Conventional multi resolution transforms such as Discrete Wavelet Transform (DWT), Contourlet and Curvelet converted the spatial domain image into multi resolution image with low accuracy. In order to overcome such limitations of the conventional classifiers, Gabor transform is used in this paper to obtain the multi resolution image from the spatial domain rail track image.

In this paper, the Gabor kernels are designed with five scales 𝛾 ={1,2,3,4,} and four orientations θ={45°, 90°, 120°, 180°}.The Gabor kernel (g(x,y)) is defined as:

Table 2 shows the extracted GLCM features from the Gabor magnitude rail track image for the case of normal and cracked rail track images for the sample images.

Table 2 GLCM features for normal and cracked rail track test image samples

| GLCM features | Cracked | Non-cracked |

|---|---|---|

| Contrast | 8.17×103 | 2.19×104 |

| Correlation | -0.0072 | 0.02 |

| Energy | 3.21×10-5 | 2.38×10-5 |

| Homogeneity | 0.092 | 0.012 |

Where as, 𝛾 is the scaling factor which ranges from 1 to 4, 𝜑 is the orientation of the pixel and 𝜆 is the adjustable parameter, varies between 0 and 1. The coordinates of each pixel is represented by x and y, σ is the standard deviation.

The Gabor magnitude image and its phase or orientation image are shown in Figure 5(a) and Figure 5(b), respectively.

3.3 Feature Extraction

Features are extracted from the Gabor magnitude image and these are used to differentiate the cracked track image from the non-cracked track image by means of its energy characteristics. In this paper, Grey Level Co-occurrence Matrix (GLCM) features are extracted from the Gabor magnitude image for crack image classifications.

3.3.1 GLCM Features

The GLCM features are extracted from the GLCM matrix, which can be constructed directly from the Gabor magnitude image at different directions of the pixels such as 0°, 45°, 90° and 135° in the image. In this paper, the GLCM matrix is constructed at the pixel orientations of 45°. The maxima pixel value in the Gabor magnitude image is chosen as the number of rows and columns in the GLCM matrix. Then, the values in GLCM table are obtained by making 45° orientations at each pixel value in the Gabor orientation image.

The following GLCM feature are obtained from the GLCM matrix as:

Here ‘i’ and ‘j’ relates the row and column of the GLCM matrix and p(i,j) represents the corresponding values in GLCM matrix.′ 𝜎′ Depicts the variance of the GLCM matrix. 𝜎𝑖 is the variance of the GLCM matrix with respect to index i and 𝜎𝑗 is the variance of the GLCM matrix with respect to index j.µi and µj are the mean of the GLCM matrix with respect to row index i and column index j.

3.3.2 LBP Features

This feature correlates the center pixel with its surrounding pixels. Each surrounding pixel is compared with center pixel in order to produce the binary patterns. Surrounding pixel is greater than the center pixel, it will produce binary 1 and surrounding pixel is less than the center pixel, it will produce binary 0. These eight binary bits generates the single decimal value as binary pattern. The extraction procedure of LBP feature for the center pixel in 3*3 windows is given as:

Here gp is surrounding pixels in 3*3 window, gc is the center pixel in 3*3 window and P is the number of surrounding pixels for center pixel in 3*3 window.

The function‘s’ is given as:

The extracted LBP feature from the Gabor transformed rail track image is given as input pattern for neural network classifier.

3.4 Neural Network Classifier

Classifier is used to detect the running rail track image into either crack free or cracked image. Conventional classifiers such as SVM, Principal Component Analysis (PCA), classified the rail track image for defect detection with low classification accuracy. In this paper, Neural Network (NN) classifier is used for the classification of rail track image into either crack free or cracked image. The NN classifier has two types as Radial neural network and Feed Forward Back Propagation (FFBP) neural networks.

This paper uses (FFBP) neural networks for the detection of track images which can be operated in training and testing modes. In training mode of this classifier, the extracted features from both cracked and crack free rail track images are trained which produces trained pattern.

In testing mode of this classifier, the extracted features from the running rail track image is classified with respect to the trained pattern and its produces either low or high value. The low value of this classifier indicates the test image is crack free and high value of this classifier indicates the test image is cracked. Further, the cracks in the classifier image are detected using morphological operations.

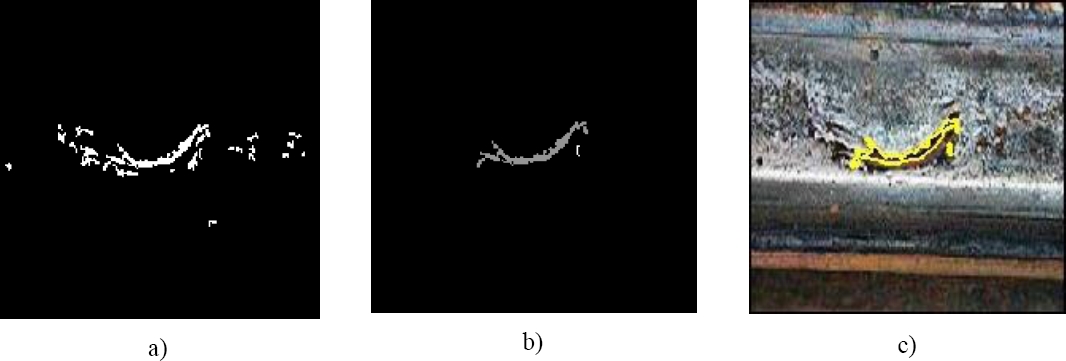

It produces dilation and erosion images, which subtracts the eroded image (Figure 6(b)) from the dilated image (Figure 6(a)) to obtain the cracked regions in the classified image (Figure 6(c)).

Table 5, shows the performance comparisons of proposed method with conventional methods interms features. In this paper, GLCM integrated with LBP features are extracted for rail track image classifications. This proposed method achieved 91.87% of sensitivity, 99.19% specificity and 98.65% of accuracy

Table 3 Performance analysis

| Parameters | Experimental Results (%) |

|---|---|

| Sensitivity | 89.99 |

| Specificity | 98.96 |

| Accuracy | 94.9 |

Table 4 Performance comparisons of proposed method with conventional methods in terms of sensitivity, specificity and accuracy

Table 5 Performance comparisons of proposed method with conventional methods in terms of features

| Methodology | Features | Sensitivity (%) | Specificity (%) | Accuracy (%) |

|---|---|---|---|---|

| Proposed Method | GLCM+LBP | 89.99 | 98.96 | 94.9 |

| Arivazhagan et al. (2015) | Fractal texture features | 81.27 | 91.28 | 87.75 |

| Liu et al. (2015) | Haar-like features | 78.93 | 94.96 | 87.98 |

4 Results and Discussion

The proposed rail track crack detection system using feed forward neural network classifier is simulated using MATLAB 2014 version with 1GB RAM in Intel Pentium Core-2-Duo processor. The performance of the proposed crack detection system is analyzed in terms of sensitivity, specificity and accuracy with respect to ground truth images. The performance evaluation parameters are given as:

Here TP is True Positive, which is the number of correctly segmented crack pixels, TN, is the True Negative which is the number of correctly segmented non-crack pixels, FP is False Positive which is the number of wrongly segmented crack pixels and FN is the False Negative which is the number of wrongly segmented non-crack pixels in rail track. Table 3 shows the performance analysis of the proposed rail crack detection system. The proposed system stated in this paper achieves 89.99% of sensitivity, 98.96% of specificity and 94.9% of accuracy. The proposed method is tested on 100 rail track images and the proposed method correctly classifies 95 images. The classification accuracy of the proposed system is 95%.

Table 4 shows the performance comparisons of the proposed rail crack detection system with conventional techniques as L. Qingyong et al. [3], L. Ze et al. [5] and Q. Zhu et al. [7]. The conventional methods Q. Zhu et al. [7] achieved 81.27% of sensitivity, 91.28% of specificity and 87.75% of accuracy; Ze Liu et al.5 achieved 78.93% of sensitivity, 94.96% of specificity and 87.98% of accuracy. L. Qingyong et al. [3] achieved 82.18% of sensitivity, 95.37% specificity and 89.71% of accuracy. The reason behind the low accuracy which was obtained by the conventional methods is its low clarity.

Another main criteria is that the present conventional methods detected and segmented the rail track crack in high resolution images only. The proposed method for the detection of cracks in rail track works on both low and high resolution rail track images. Q. Zhu et al. [7] method used Pavement Crack Detection Algorithm (PCDA) for the detection of cracks in rail tracks. This method detected only outlier edges of the cracks in rail tracks which degraded the performance of their proposed method. Hence, the accuracy rate of this method was low when compared with the methodology stated in this paper. The proposed methodology stated in this paper detects interior and outlier edges of the cracks in rail tracks which improves the accuracy rate. L. Ze et al. [5] and L. Qingyong et al. [3] detected the cracks in rail tracks in an automated manner. Still, these methods are suitable for the detection of cracks in high resolution images. These methods produced unsatisfactory results in low resolution images. These limitations are overcome by the methodology proposed in this paper, which is suitable for both low and high-resolution rail images.

5 Conclusion

In this paper, feed forward neural network classifier based crack detection in rail track is proposed to detect and segment the cracks or defects in rail track images. The proposed method enhances the track image using adaptive histogram equalization technique and further feature are extracted from the enhanced rail track image.

These extracted features are trained and classified using neural network classifier which classifies the rail track image into either cracked or non-cracked image. The proposed system stated in this paper achieves 89.99% of sensitivity, 98.96% of specificity and 94.9% of accuracy. In future, this work can be extended for the detection of cracks in video images. The methodology presented in this paper can also be extended to detect the missing fastener in rail tracks.

text new page (beta)

text new page (beta)