Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista ALCONPAT

On-line version ISSN 2007-6835

Rev. ALCONPAT vol.7 n.1 Mérida Jan./Apr. 2017

https://doi.org/10.21041/ra.v7i1.174

Applied research articles

Ageing of old and modern concrete structures - Observations and research

1Section of Materials and Environment, Faculty of Civil Engineering and Geosciences, Delft University of Technology, The Netherlands.

Ageing is an inherent feature of nature. Yet it seems to be a rather new topic in both science and engineering. The main reason for increasing attention for ageing as a topic is the growing awareness that, particularly in industrialized countries, ageing of our assets is a financial burden for the society and affects the overall sustainability of our planet. In this contribution, the urgency and challenges of ageing of concrete structures are addressed. The complexity of ageing problems will be illustrated by looking in more detail to the evolution in concrete mix design and the consequences thereof for the long-term performance of concrete structures. Emphasis will be on ageing of concrete infrastructure and justification of research on ageing phenomena.

Keywords: infrastructure; sustainability; ageing; mix design; autogenous shrinkage; codes

El envejecimiento es una característica inherente de la naturaleza. Sin embargo, parece ser un tema bastante nuevo en la ciencia y la ingeniería. La principal razón para aumentar la atención por el envejecimiento como tema es la creciente conciencia de que, en particular en los países industrializados, el envejecimiento de nuestros activos es una carga financiera para la sociedad y afecta la sostenibilidad global de nuestro planeta. En esta contribución se abordan la urgencia y los desafíos del envejecimiento de las estructuras de concreto. La complejidad de los problemas de envejecimiento se ilustra examinando con más detalle la evolución del diseño de la mezcla de concreto y sus consecuencias para el rendimiento a largo plazo de las estructuras de concreto. Se hace hincapié en el envejecimiento de las infraestructuras de concreto y en la justificación de la investigación sobre fenómenos de envejecimiento.

Palabras clave: infraestructura; sostenibilidad; envejecimiento; diseño de mezcla; contracción autógena; códigos

Envelhecimento é uma característica inerente da natureza. No entanto, parece ser um tópico bastante novo tanto na ciência quanto na engenharia. A principal razão para aumentar a atenção para o envelhecimento como tema é a consciência crescente de que, particularmente nos países industrializados, o envelhecimento de nossos bens é um fardo financeiro para a sociedade e afeta a sustentabilidade global do nosso planeta. Nesta contribuição, são abordados a urgência e os desafios do envelhecimento das estruturas de concreto. A complexidade dos problemas de envelhecimento será ilustrada por uma análise mais detalhada da evolução da concepção da mistura de concreto e suas consequências para o desempenho em longo prazo das estruturas de concreto. A ênfase será no envelhecimento da infraestrutura de concreto e na justificativa da investigação sobre fenômenos de envelhecimento.

Palavras-chave: infraestrutura; sustentabilidade; envelhecimento; estudo de dosagem; retração autógena; normas

1. INTRODUCTION

Ageing is everywhere around us. Huge mountains seem to keep their shape for ever. But at a closer look we see that the surface of rocks gradually changes. Changes in temperature and moisture conditions, wear, wind and light are sufficiently powerful to crumble even the strongest rock. Mountains age! Earthquakes may split mountains, causing changes in the state of stress in the newly formed parts of the mountain. Fresh fracture surfaces become exposed to climatic conditions and another cycle of ageing starts.

Like rocks, also man-made structures are exposed to ambient climate conditions. While exposed to environmental loads, structures must carry life loads and deadweight in a safe way during their entire service life. Roads and railways need continuous maintenance. If planned correctly, the trouble maintenance works often cause can be kept to a minimum. If maintenance comes too late, expensive repair is needed and may cause time and money consuming traffic jams, delays or even accidents. The direct costs of failing infrastructure can be huge, but the indirect costs are generally many times higher.

Proper functioning of our infrastructure is vital for the country’s mobility and economy. The same holds for our energy infrastructure. Power plants for generating electricity and energy distribution grids must function reliably for 24 hours per day, the whole year round. Failing components may cause expensive process interruptions and may even constitute a risk for life and limb. Pro-active replacement of vital components of systems and structures is considered a safe strategy to prevent catastrophic failures. But do we really know how close we were to a catastrophic failure at the moment these components were replaced? Was the society really at risk or did we spoil a lot of still perfectly operating components without improving safety substantially? In other words: how accurately can we predict the progress of ageing processes from which our assets are suffering?

Ageing is everywhere and unavoidable. Yet it is not easy to find a clear an unambiguous definition of ageing. The term ageing is used for changes in performance with time of materials, structures, systems, organisations, societies, governments, software, economic systems, living organisms, etc. These changes in performance can be observed at different scales. But what are the real driving forces behind these changes? Before starting an attempt to explain what we mean by ageing, we first give an impression of the societal relevance of ageing of our fixed assets, with a focus on ageing of our infrastructure.

2. AGEING INFRASTRUCTURE AND SOCIETY

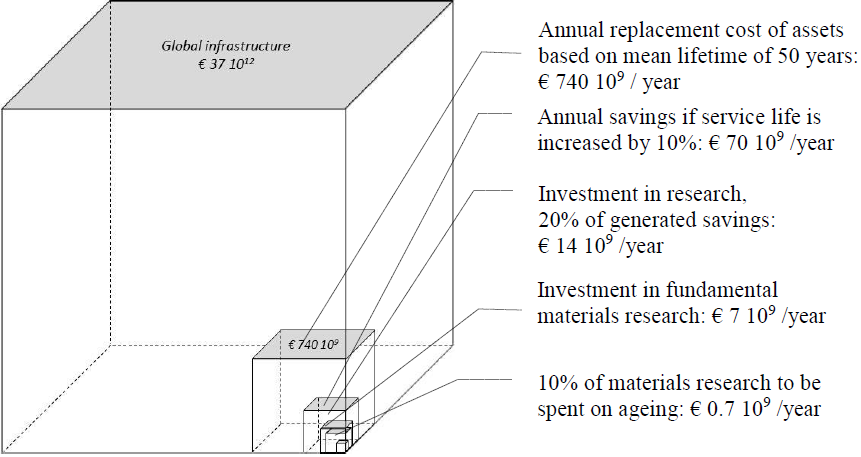

In modern industrial countries, the infrastructure makes out over 50% of the nation’s national wealth (Long, 2007). This infrastructure consists of roads and railway systems, water works, airports, power stations and electricity grids. Based on an inventory in twelve countries, the value of infrastructure stock averages around 70% of the global gross domestic product (GDP). For a global GDP of € 53 trillion in 2012, this makes € 37 trillion.

Economic growth is inconceivable without growth of a country’s infrastructure. To catch up with global economic growth the McKinsey report (Dobbs et.al., 2013) estimates a required investment in the infrastructure of € 42 trillion between 2013 and 2030. This means an annual investment of € 2.3 trillion, which is about 4.5% of the global GDP. The investment of € 42 trillion is needed for roads and railways, ports, airports, power stations, water works and telecommunication. Table 1 gives the breakdown of investments over these categories. These figures are (in part) based on an extrapolation from data provided by 84 countries.

Table 1 Estimated needs for global infrastructure in different categories. Period 2013-2030 (Dobbs et.al., 2013)

1) Organisation for Economic Co-operation and Development

2) International Energy Agency

3) Global Water Intelligence

These countries are responsible for 90% of the global GDP and are considered today’s best possible basis for estimating the extra investments needed for our infrastructure in the period from 2013 to 2030.

3.AGEING AND SCIENCE

3.1 Change of performance with time.

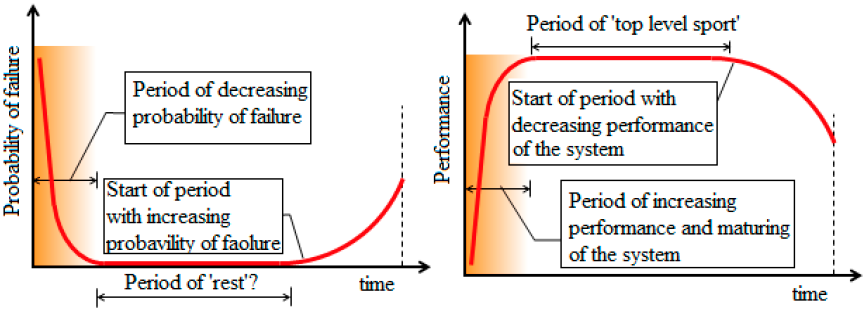

The early lifetime of made-made materials, structures and systems is often characterized by a high probability of failure. It takes some time to overcome inevitable teething problems and to reach the required level of maturity and stability. Once that point is reached a ‘quiet’ period follows until we arrive again at a period of increasing probability of failure. Exceeding a certain predefined probability of failure then marks the end of the service life of a structure or system. The high probability of failure in the beginning, the subsequent period of ‘rest’ and the subsequent period of increasing probability of failure can be presented with the bathtub curve (Figure 1a).

Figure 1 Evolution of the probability of failure (bath tube curve; left) and of performance (right) of complex systems (after Van Breugel, 2014)

In essence the bathtub curve also applies to our fixed assets, even though it has not very often been used for infrastructure. The length of the period in which the probability of failure is low is of crucial importance for the economic performance of these assets. The bathtub curve suggests that this period is a period during which ‘nothing happens’. It is a period of ‘rest’, or ‘dormant’ period. Assuming that in the period of low probability of failure nothing happens, however, is misleading. If there would really be ‘rest’, what could then be the driving force behind the increase of probability of failure with elapse of time? To illustrate the foregoing reasoning, it may help to put the bathtub curve of Figure 1a upside down, as shown in Figure 1b. On the vertical axis we now put ‘Performance’ instead of the ‘Probability of failure’. After a short period of teething problems the material, structure or system has reached the required (high) level of performance. That is the level at which the material should demonstrate its capacity to meet safety and functional criteria, if possible without intervention for maintenance or repair. It is the period of ‘top-level sport’ for all the basic building blocks, i.e. atoms, molecules and interfaces, from which a material or structure is made. When these basic building blocks give up and leave their position, the period of decay begins. Then ageing has started! These first tiny steps of decay will most probably not be observed at the macroscale immediately.

The moment that the first basic building blocks give up can only be captured with comprehensive and appropriate material models at subsequent levels of observation. Here chemistry, physics, electrochemistry, mechanics and mathematics meet each other and need each other for developing tools for describing and predicting ageing processes at a fundamental level.

3.2 Driving forces behind ageing - A closer look.

Ageing has been defined is a change of performance of a material, structure or system with time. How time per se can result in a change of performance is not easy to understand at first sight. How can a material ‘at rest’ change its performance with time? A closer look at any piece of matter ‘at rest’ tells us that the status of rest only applies to a certain length scale. Going down to the atomic scale the world is in motion all the time! Fundamental entities, i.e. basic building blocks, are continuously moving with a certain probability to leave their position for one that fits them better. This phenomenon takes place in the time domain. It is an inherent feature of matter and lies at the basis of ageing of materials. On top of this inherent feature we see, at different scales, a number of gradients, which may cause the basic building blocks of matter to start moving. Gradients are the driving forces causing changes in the material with elapse of time. Note that at the boundary of any piece of material with its environment gradients do exist. These gradients concern, for example, temperature, humidity and radiation and they may cause changes at the surface of the material.

The foregoing illustrates that a material ‘at rest’ is hardly conceivable. Al lower scales there is motion all the time and a variety of gradients cause the basic building blocks of matter to change their position. In essence, this holds for all materials and systems. Basic building blocks strive for a position (energy level), where they feel more comfortable. By designing materials in a smart way, i.e. by minimizing internal gradients and concentrations of stresses and strains, there will be less reason for basic building blocks to leave their position. Hence, the ageing process will slow down and the service life of materials, structures and systems will increase.

4. PERFORMANCE OF CONCRETE STRUCTURES

4.1 Performance of bridge decks - An inventory.

In March 2001, the results of a most interesting study were published by Mehta (Mehta and Burrows, 2001). He analysed the performance of bridge decks of bridges built in four subsequent periods in the twentieth century. The first period was the period before 1930, the second between 1930 and 1950, the third from 1950 to 1980 and the fourth from 1980 to present. The concrete mixtures used for the bridge decks were characterized by the chemical composition and the fineness of the cement. The cements used in the first period, before 1930, had a C3S content less the 30% and a Blaine surface of 180 m2/kg. Consequently, the rate of hydration was low. The performance of many of the bridge decks made with these cements was quite good.

The cements used in the second period were ground to a Blaine fineness between 180 and 300 m2/kg. The construction and building technology used for the bridge decks was similar to those used in the first period. The authors report that the bridge decks built in the second period were less durable than those built before 1930.

The structures that were built between 1950 and 1980 appeared to have more durability problems than those built before 1950. The cements used in this period had a fineness up to 400 m2/kg and a C3S content beyond 60%. With the aim to get a denser and more durable concrete the w/c ratio was lower than in the first two periods. The higher C3S content and the higher fineness of the cement had increased the early strength of these mixtures. This made it possible to build faster. This, however, had resulted in a higher probability of early-age thermal cracking and, on top of that, higher autogenous shrinkage of the low water-cement ratio mixtures. The higher proneness to early-age (micro)cracking was the most plausible reason for durability problems at later ages.

In the fourth period the tendency to go for higher strengths continued. Generally, this was realized by using mixtures with a low w/b ratio. The use of low w/b mixtures further increased the risk of cracking. For bridge decks, moderate strengths between 30 and 45 MPa were found. Among 29 bridge decks the cracking in 44 MPa bridge decks was twice that in 31 MPa bridge decks.

4.2 Mix design and proneness to ageing.

Mehta’s study of the performance of bridge decks illustrates how the pressure from the market to build faster has created a demand for mixtures with a high early strength. This was possible by using finer cements with a higher C3S content. The price of this, however, was a higher probability of early-age cracking of the bridge decks.

For realizing slenderer and more elegant structures a higher final strength is required. High strength is attainable by reducing the w/b ratio. The use of (super) plasticizers has made it possible to reduce the w/b ratio of concrete mixtures to values even below 0.2. With these low w/b mixtures dense concretes are obtained with low permeability. This is considered good for the concrete’s durability. At the same time, however, we see an increase in the concrete’s proneness to (micro)cracking, mainly because of increased autogenous shrinkage.

Another reason for a higher cracking risk of high strength and ultra-high strength concretes are the high temperatures that occur because of high cement contents. By optimizing the particle packing of the aggregate fractions the amount of cement, and hence the peak temperatures, can be reduced. A low cement content is also considered positive from the sustainability point of view (lower carbon footprint of the fresh concrete mixture). A low cement content, however, also has a drawback. A low cement content reduces the inherent self-healing capacity of the concrete. From the self-healing point of view a not too low cement content and the use of ‘old’, coarsely ground cement is favorable. This partly explains the outcome of Mehta’s study that old bridge decks performed better than newer ones. In the terminology of this paper we would say that the old concrete mixtures with coarse cements with a low C3S content were less prone to ageing than modern mixtures with finely ground cements with a high C3S content.

5. AUTOGENOUS SHRINKAGE - A CLOSER LOOK

For understanding ageing of traditional and modern concrete mixtures we need a clear picture of the processes that cause internal stresses in the material. As discussed in section 3 these internal stresses are among the driving forces of ageing. One of the causes of internal stresses is autogenous shrinkage of hardening concrete. In this section, experimental results of autogenous shrinkage of traditional and high strength concrete mixtures are presented, as well as technological measures to mitigate autogenous shrinkage. The measured autogenous shrinkage will be compared with values given by currently used design codes.

5.1 Shrinkage - Influencing factors.

Several mechanisms have been proposed as possible causes of autogenous shrinkage and/or contributing factors. The most commonly reported mechanisms are capillary tension (in the range of high internal relative humidity), changes in the disjoining presses (in medium range relative humidity) and changes of surface tension of the solid gel particles. A common parameter in all these mechanisms is the internal relative humidity. With progress of the hydration process the water in the mixture is gradually consumed and the relative humidity drops. This so-called ‘internal drying’ goes along with an increase in the capillary pressure in the pore water and, when the relative humidity decreases further, changes in the disjoining pressure. Consequently, the volume of the cement paste decreases, which is known as autogenous shrinkage.

Shrinkage of the drying paste is restrained by the aggregate particles in the mixture. Whether the restraint of autogenous shrinkage strains will cause (micro)cracking depends on the size and stiffness of the aggregate particles and on the time dependent properties (creep, relaxation) of the hardening paste. How internal curing of concrete mixtures can be used to prevent a drop of the relative humidity, and hence of autogenous shrinkage, will be discussed in the next section.

The fact that the evolution of autogenous shrinkage appears to be strongly correlated with a drop in the internal relative humidity does not mean that the magnitude of autogenous shrinkage can be related directly to the relative humidity. The type of cement has turned out to be an important parameter as well (Tazawa and Miyazawa, 1997). In the very early stage of hydration some types of cement exhibit swelling. This observation is of utmost importance if it comes to the interpretation of shrinkage measurements. Researchers should be aware of the fact that, particularly in the early stage of the hydration process, measured shrinkage strains are the net result of simultaneous expansion and shrinkage mechanisms. In those cases, attributing measured shrinkage strains to one single mechanism will lead to completely wrong conclusions about the underlying mechanisms and, consequently, to wrong measures to prevent or mitigate autogenous shrinkage.

From this brief overview, we learn that a number of parameters affect the magnitude of autogenous shrinkage. By manipulating these parameters, the consequences of autogenous shrinkage can be mitigated and hence the susceptibility of concrete mixtures to ageing. In the next sections emphasis will be on autogenous shrinkage and internal curing of HPC and how internal curing reduces autogenous shrinkage.

5.2 Autogenous shrinkage in C55/65 mixtures and internal curing.

As indicated in the previous section, autogenous shrinkage of low w/c mixtures can be reduced by internal curing. Internal curing can be accomplished by adding water-saturated lightweight aggregate (LWA) particles to the concrete (Zhutovsky et.al., 2001). When the internal RH drops, the water stored in the LWA particles is released to the drying matrix, thus maintaining the RH at a relatively high level. A similar effect can be achieved with mixed-in super absorbing polymers (SAP), a technology promoted by Jensen (2013) and subject of the RILEM committee 225-SAP (Mechtcherine and Reinhardt, 2012).

In the following results of studies on autogenous shrinkage of concrete and the effect of internal curing will be presented. First test results on autogenous shrinkage of concrete mixtures C55/65 are discussed, followed by results obtained with mixtures C28/35 and C35/45.

5.2.1 Background of the study. In the eighties and nineties of the past century the use of High Performance Concrete (HPC) with target strength C55/65 was considered for several concrete bridges in The Netherlands. The prevailing Dutch design code did not require designers to consider autogenous shrinkage of those mixtures. However, the owner of the bridges, the Dutch Ministry of Transportation, required a check of the overall performance of the mixtures, including a check of the autogenous shrinkage and the effectiveness of internal curing for mitigating the risk of early-age cracking.

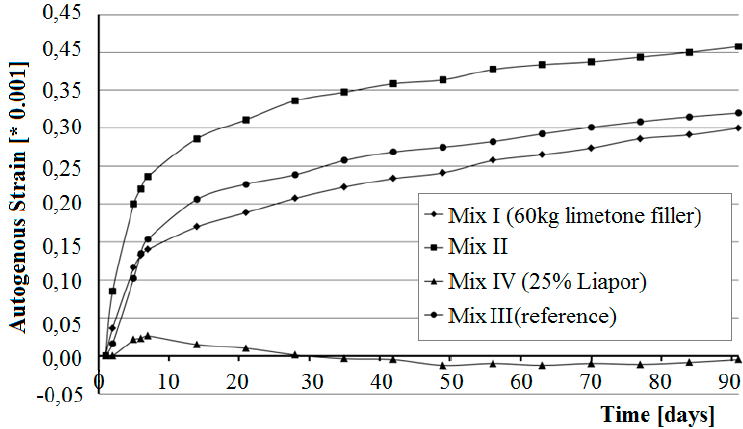

5.2.2 Mixture design and test specimen. Four mixtures were tested with w/b ranging from 0.34 to 0.39. The mix compositions are given in Table 2. In mixture I, 60 kg limestone powder was used, while the amount of cement was reduced by the same amount. In mixture IV, 25% of the coarse aggregate was replaced by water-saturated lightweight aggregate, Liapor F10. The autogenous shrinkage was measured on sealed specimens, 100×100×400 mm3.

5.2.3 Measured autogenous deformation and evaluation.

The autogenous deformations of the mixtures are presented in Figure 2. The measurements started after 1 day. This implies that the very first part of the autogenous deformation was not recorded. This was not considered a problem, since the aim of the test series was to quantify how autogenous deformation would affect drying shrinkage. In the practice drying shrinkage will generally not start during the first day after casting. For the purpose of this study it was appropriate, therefore, to measure only the autogenous deformation after 1 day.

Figure 2 Autogenous deformation mixture I to IV. 20ºC. Measurements starting after 1 day (Van Breugel et.al., 2000)

The shrinkage curves of the mixtures I, II and III show that a greater part of autogenous shrinkage occurs in the first few days after mixing. But even after 28 days autogenous shrinkage still continues. From 28 to 91 days the autogenous shrinkage of the mixtures I, II and III varies from 70 to 90 (m/m. Replacing 25% of the dense aggregate by water-saturated lightweight aggregate particles was sufficient to eliminate autogenous shrinkage of this paste. Obviously, the internal curing by using saturated lightweight aggregate particles (Liapor F10, 4-8 mm) is very effective.

5.3 Autogenous shrinkage of traditional concrete mixtures C28/35 and C35/45.

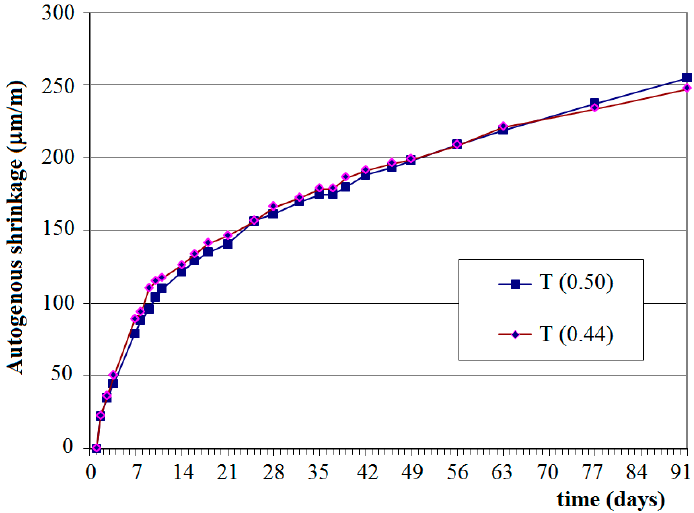

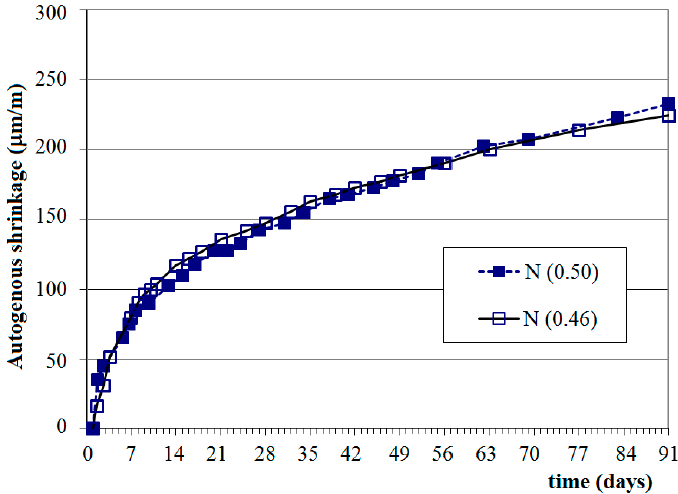

The high autogenous shrinkage of mixture C55/65, much higher than expected, was reason enough to start an investigation on the autogenous shrinkage of traditional concrete mixtures with w/b ratios between 0.44 and 0.50, strength classes C35/45 and C28/35. In a preliminary study on autogenous shrinkage of concrete mixtures with w/c ≈ 0.45 Van Cappellen (2009) found that particularly at early ages the autogenous shrinkage of concrete mixtures made with blast-furnace slag cement developed faster than that of OPC-mixtures. At 200 days the difference was not very large anymore. Van Cappelle’s study was continued by Mors (2011) for mixtures made with two types of aggregate, i.e. limestone and quartz. The mixture compositions are given in Table 3. Figures 3 and 4 show the autogenous shrinkage of the traditional mixtures T (0.50) and T (0.44) made with quartz aggregate and the mixtures N (0.50) and N (0.46) made with limestone aggregate. The shrinkage curves convincingly show that also mixtures with w/b in the range from 0.44 to 0.5 exhibit substantial autogenous shrinkage. More importantly, also these mixtures exhibit ongoing autogenous shrinkage at ages beyond 28 days, the age at which the concrete is generally assumed to have reached a high degree of maturity already!

Table 3 Mixture compositions of concrete mixtures C28/35 and C35/45 (Mors, 2011)

T = Traditional mixture (quartz aggregate); N = Mixtures made with natural limestone as aggregate

Figure 3 Autogenous shrinkage of traditional mixtures T(0.50) and T(0.44). Quartz aggregate. w/c = 0.5 and 0.44 (Mors, 2011; Van Breugel et.al., 2013)

Figure 4 Autogenous shrinkage of mixtures N(0.50) and N(0.46). Limestone aggregate. w/c = 0.46 and 0.50 (after Mors, 2011; Van Breugel et.al., 2013)

5.4 Autogenous Shrinkage, Drying Shrinkage and Design Codes.

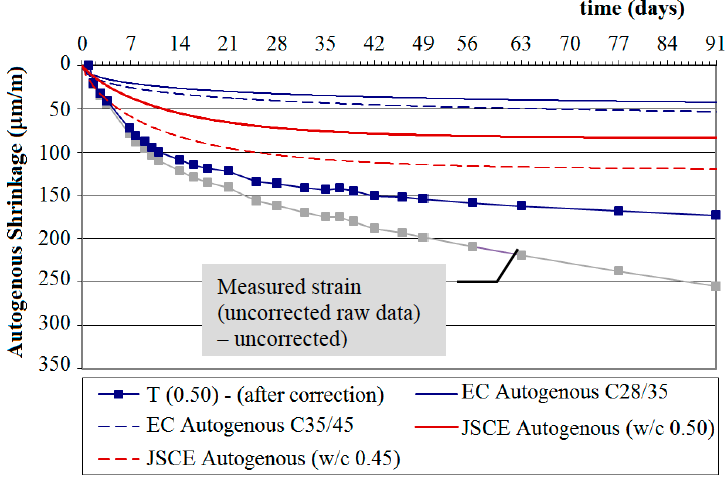

In the past experimental studies on drying shrinkage of concrete have often been carried out on 28 days old specimens and the measured shrinkage strains were mostly interpreted as drying shrinkage. From the autogenous shrinkage curves presented in the previous sections we have to conclude, however, that after 28 days autogenous shrinkage cannot be ignored, also not for mixtures with water-cement ratios higher than 0.4. For those mixtures, the contribution of autogenous shrinkage to the measured shrinkage strains in drying specimens has often been neglected. This means that in the past many drying shrinkage tests might have been misinterpreted. A substantial part of the strains measured on drying specimens should have been attributed to autogenous shrinkage. In recent updates of design codes autogenous shrinkage is now explicitly mentioned, also for traditional mixtures with w/b > 0.4. In the new EuroCode 2 and the Japanese code autogenous shrinkage is considered also for mixtures in strength classes < C55/65. For mixtures with w/b 0.44 - 0.50, however, these codes still underestimated the autogenous shrinkage, at least for the tested mixtures and cement types considered in the previous sections. Figure 5 shows autogenous shrinkage according to both the EuroCode 2 and the JSCE-Code, together with the measured autogenous shrinkage of normal strength concretes C28/35 (T(0.50)). Both the measured autogenous shrinkage and the curve after correction for small moisture loss through the sealant are presented. The autogenous shrinkage according to EuroCode 2 is presented for C28/35 and C35/45 mixtures, i.e. mixtures with strengths similar to the measured strength of the mixtures considered in this paper. In both cases the autogenous shrinkage according to EuroCode 2 is about 30% of the measured autogenous shrinkage. Underestimation of autogenous shrinkage by EuroCode 2 was also observed by Darquennes et al. (2012). The predictions with the Japanese code are closer to the measured values, but still underestimate the measured autogenous shrinkage.

Figure 5 Comparison of measured autogenous shrinkage with predictions with the EuroCode 2 and the Japanese Code (after Mors, 2011).

5.5 Shrinkage and Ageing.

Autogenous and drying shrinkage go along with the evolution of internal stresses. In both cases the cement paste is the shrinking component. All shrinkage-induced stresses are subject to relaxation. Relaxation of stresses, however, is not ‘for free’. It requires the re-structuring of smallest building blocks of matter. In other words: the material ages! As far as autogenous shrinkage strains are concerned it has been proposed that the observed long-term deformations might be creep strains following the elastic shrinkage strains exerted by the capillary forces in the pore water. Also, these creep deformations are not ‘for free’, but require re-structuring of the material’s elementary building blocks: The material ages! For quantitative analysis of creep and relaxation Wittmann (1977) has applied the activation energy concept, which is considered the most appropriate approach for fundamental research of ageing phenomena of cement-based materials.

6. COPING WITH AGEING

6.1 Materials design.

Ageing is an inherent feature of materials. Solutions for ageing problems require, therefore, interventions at fundamental materials level. For coping with ageing problems, two approaches are conceivable, i.e. the preventive approach and the reactive approach.

In the preventive approach the focus is on designing homogenous materials with as few as possible internal gradients, stress concentrations and interfaces. For heterogeneous materials, like concrete, this is a big challenge. When going through the subsequent length scales, from (sub-) nano to meso level, concrete behaves as a complex system. To state it differently, concrete is a ‘product of the mind’ (McCarter, 2009), of which the properties are determined by the properties of the individual components and of the interfaces between them. Some of these components - in fact all! - change with time, and so do the properties of the interfaces. This makes heterogeneous materials susceptible to ageing.

In the reactive approach the heterogeneity of the material, and hence the internal concentrations of stresses and strains and the occurrence of internal damage and ageing, are considered a matter of fact. If ageing is unavoidable indeed, self-healing could be a solution for ageing problems. When dealing with concrete the presence of still unhydrated cement particles provides an inherent self-healing capacity. In this respect concrete made with a coarse cement is considered favourable to concrete made with a fine cement. Mehta’s (2001) observation that old bridge decks, built with coarse cement, have performed better than the younger ones built with finer cements, could be explained, at least in part, by the role of self-healing in the older structures. The modern trend to, firstly, use finer cement to speed up the rate of strength gain and, secondly, reduce the amount of cement to reduce the CO2 footprint of concrete, may work out negative on the material’s resistance against ageing! In these cases, a comprehensive life cycle analysis is needed for weighing all the pros and cons of modern trends in concrete mix design.

6.2 Ageing and design codes.

For designing and realizing concrete structures design codes are indispensable. From the numerous buildings and fascinating construction works realised in the past a high degree of maturity of these codes can be inferred. In section 5.4 we have seen, however, that currently used prescriptive codes fall short in describing long-term performance, i.e. shrinkage, of concrete structures. In this respect, it is interesting to reflect on the recent tendency to switch from prescriptive codes to performance-based codes. The question is whether it is to be expected that with this switch ageing issues will be considered more appropriately and will become part of an integral design approach for concrete structures. Strictly speaking the change from prescriptive to performance-based codes is a return to the origin of the building profession. In the ancient past the whole building process was in the hands one person: the builder. The builder had the integral responsibility to meet all the safety and functional criteria set by the owner. How the builder managed to meet the owner’s criteria was not prescribed in detail. This was all considered the builder’s expertise and responsibility. In his classical book on building technology Vitruvius (85-20 BC) stated that ideally the whole building process should be in the hands of one person. When Vitruvius wrote his book, a few years BC, he noticed already that this ideal situation was no longer tenable. The building process became too complicated and one single person could not be an expert in all areas of the building process. Gradually the builder had to share his responsibility with others. This situation started the emerge of certificates etc., and, later on, prescriptive codes. The user of these documents could be held responsible for a correct interpretation of and compliance with the codes, but not for the content of the codes.

Prescriptive codes can be judged as the ultimate consequence of a process of increasing fragmentation of the building process and, more importantly, of the vision that everything, including quality, is engineerable. The huge sustainability problems we face today, however, illustrates that this vision has lost most of its convincing power. Prescriptive codes, even the most detailed ones, are necessary, but insufficient for guaranteeing quality and/or sustainability. Prescriptive codes deal with materials properties with the primary goal to provide the designer with data needed for designing safe structures. Any change of performance of the materials with time is considered a time dependent property without addressing the cause of these changes.

With performance-based codes the building process has been given back to the builder, including the challenge to accomplish (long-term) quality criteria and sustainability goals. The builder’s freedom to decide how to meet these criteria and goals may stimulate the builder to invest in fundamental research of traditional and new building materials and in innovative design concepts. Furthermore, performance-based codes, in combination with new DBFM (Design-Built-Finance-Maintenance) contracts, will also force the builder to focus on both the short-term and long-term performance, i.e. ageing, of materials and structures. For that purpose, the builder will need reliable predictive models, including models for quantifying the rate of ageing processes and the consequences thereof.

7. REQUIRED INVESTMENT FOR GENERATING SAVINGS

In section 2 it has been explained that ageing of the nation’s fixed capital goods is a huge financial burden for the society. A way to reduce this burden is by reducing the maintenance costs and extending the life time of our infrastructure. This will result in savings in annual replacement costs of obsolete structures. But for realizing these savings we first must invest! Potential savings justify, and require, investments in ageing research. Some key figures may help us to get an indicative picture of the required investment for realizing a certain level of savings. In section 2 the global value of the infrastructure stock has been estimated at € 37 trillion. Let us assume an average lifetime of these infrastructure assets of 50 years. Each year € 740 billion has then to be spent on replacement of obsolete assets. Let us further assume that through dedicated research the average lifetime can be increased by 10%, i.e. from 50 to 55 years. The yearly replacement costs would then decrease to from € 740 to € 670 billion. This is a reduction of € 70 billion per year. Let us assume that for saving these € 70 billion we must invest 20% of this amount in research, i.e. € 14 billion per year. Let us further assume that 50% of the required research money, i.e. € 7 billion, must be spent on management-oriented research and the other 50% on science-oriented research on materials and structures. A part of this science-oriented research must be spent on ageing research. A reasonable, though conservative assumption is that 10% of science-oriented research, i.e. € 0.7 billion per year, should be spent on fundamental ageing research. This € 0.7 billion is only 1% of the targeted savings. Schematically this is shown in figure 6. By varying the assumptions in this exercise other values for required investments are obtained, but do not change the order of magnitude of these figures.

8. CONCLUDING REMARKS

A nation’s infrastructure makes out about 50% if its national wealth. This huge share of our national wealth, however, is ageing! With the existence, growth, maintenance and replacement of ageing infrastructure a huge responsibility comes to all actors involved in planning, design, building and operating our assets. It is a matter of responsible stewardship to mitigate the environmental impact that comes along with realizing and operating our infrastructure.

Fundamental research on ageing is recommended to improve the tools for accurate and reliable predictions of the long-term performance of our ageing infrastructure. The results of experimental research on autogenous shrinkage of traditional and modern, innovative cement-based materials illustrate the need for more research to better understand the cause of autogenous shrinkage, as well as the (sometimes unexpected) possibilities to mitigate autogenous shrinkage, for example by using low-tech waste products, like rice husk ash (Tuan, 2011). Mitigating shrinkage implies mitigating shrinkage-induced stresses and hence reducing the rate of ageing.

Performance-based design codes, in combination with new contracts in which the builder is made responsible for the long-term performance and operation of their structures, generate a strong need of knowledge of ageing phenomena in materials and structures. In this way performance-based codes may stimulate the search for innovative solutions.

Like many other industries, also the building industry is under pressure. Structures must be realised faster, but with lower environmental impact. Any product, however, realised under pressure, irrespective of what kind of pressure, has an inherent tendency to age. To cope with the risk of increasing ageing rates, in-depth knowledge of the performance of materials and structures with elapse of time is needed.

An increase of the average service life of our infrastructure by 10% would save tens of billions of euros each year. The required investments to realise these savings are estimated at 20% of these savings. Half of this amount is assumed to be needed for research on materials and structures, of which 10% has been assumed to be needed for fundamental research on ageing. Setting such targets for savings is not only challenging and a stimulus for research and innovation. The figures also illustrate that caring for our infrastructure will finally pay off.

8. ACKNOWLEDGEMENTS

Part of this paper was based on the Vision Document of the Ageing Centre for Materials, Structures and Systems of the Technical University of Delft. For the use of this material the Ageing Centre is greatly acknowledged.

REFERENCES

Darquennes, A., Roziere, E., Khokhar, M. I. A., Turcry, Ph., Loukili, A., Grondin, F. (2012) “Long-term deformation and cracking risk of concrete with high content of mineral additions”. Materials and Structures, Vol. 45, No. 11, pp 1705-1716. [ Links ]

Dobbs R., et al. (2013) “Infrastructure productivity: how to save $ 1 trillion a year”. McKinsey Global Institute, p. 88 [ Links ]

EuroCode 2. (2004) “Design of concrete structures - Part 1-1: General rules and rules for buildings” (Ref. No. EN 1992-1-1:2004: E) [ Links ]

Jensen, O. M. (2013) “Use of superabsorbent polymers in concrete. Concrete international”, Vol. 35, No.1, pp. 48-52. [ Links ]

JSCE (1996, 2002), “Standard specification for design and construction of concrete structures, part I [Construction]” (in Japanese), JSCE, Tokyo, Japan. [ Links ]

Long, A.E. (2007) “Sustainable bridges through innovative advances”. Institution of Civil Engineers, presented at Joint ICE and TRF Fellows Lecture. 23. [ Links ]

McCarter, R. (2009) “Louis I. Kahn and the nature of concrete”. Concrete International, Vol. 31, Nr. 12, pp. 27-33. [ Links ]

Mechtcherine, V., Reinhardt, H. W. (2012) “Application of Super Absorbent Polymers (SAP) in concrete construction”. STAR Prepared by Technical Committee 225-SAP, p. 165. [ Links ]

Mehta, P. K., Burrows, R.W. (2001) “Building durable structures in the 21st century”. Indian Concrete Journal, pp. 437-443. [ Links ]

Mors, R. M. (2011) “Autogenous shrinkage - cementitious materials containing BFS”. MSc-thesis, TU Delft, p. 63. [ Links ]

Tazawa, E., Miyazawa, S. (1997) “Influence of constituents and composition on autogenous shrinkage of cementitious materials”. Magazine of Concrete Research, 49, 178, pp. 15-22 [ Links ]

Van Breugel, K., Ouwerkerk, H., de Vries, J. (2000) “Effect of mixture composition and size effect on shrinkage of high strength concrete”. Proc. Int. RILEM Workshop Shrinkage of Concrete - Shrinkage 2000 . Ed. Baroghel Bouny et al., Paris, pp. 161-177. [ Links ]

Van Breugel, K. (2013) “A critical appraisal of codes as vehicles for realizing on-site quality”. Proc. fib. Symposium Engineering the concrete future: Technology, Modelling and Construction. Mumbai. [ Links ]

Van Breugel, K. , Mors, R. E., Bouwmeester, J. (2013) “New insight in the combination of autogenous and drying shrinkage”. Fib symposium Engineering the concrete future: Technology, Modelling and Construction. [ Links ]

Van Breugel, K. (2014) “Caring for ageing infrastructure - Scope, strategy and responsible stewardship”. Proc. 3rd. Int. Conf. on Service Life Design for Infrastructures. Zhuhai. [ Links ]

Van Cappellen, J. (2009) “Autogenous and drying shrinkage”, MSc-thesis, Delft University of Technology, Delft, The Netherlands. 2009. p. 95. [ Links ]

Vitruvius Pollio, M., (85-20 BC) “The ten Books on Architecture” [ Links ]

Wittmann, F. H. (1977) “Grundlagen eines modells zur beschreibung charakteristischer iigenschafften des betons”, Deutscher Ausschuss fur Stahlbeton, Heft 290, 1977, 42-101. [ Links ]

Zhutovsky, S., Kovler, K., Bentur, A. (2001) “Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage”. Proc. Int. RILEM Conf. Early Age Cracking in Cementitious Systems, AEC’01, Ed. K. Kovler et al., Haifa, pp. 365-374. [ Links ]

Received: December 18, 2016; Accepted: January 23, 2017

text in

text in