Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista mexicana de ciencias agrícolas

versión impresa ISSN 2007-0934

Rev. Mex. Cienc. Agríc vol.8 no.1 Texcoco ene./feb. 2017

https://doi.org/10.29312/remexca.v8i1.85

Investigation note

Chemical composition and yield of maralfalfa biomass for the production of second generation bioetanol

1Colegio de Postgraduados-Campus Montecillo. Carretera Federal México-Texcoco, km 36.5. Montecillo, Texcoco, Estado, México. CP. 56230. Tel. 01 595 9520279. (joelventur@gmail.com; hvaquera@colpos.mx).

2Campo Experimental, San Martinito. Carretera Federal México-Puebla, km 56.5. Col. San Martinito, Tlahuapan, Puebla, Puebla, México. CP. 74100. Tel. 01 248 4830424. (ahonorato650@gmail.com).

3Instituto Mexicano del Petróleo. Eje Central Lázaro Cárdenas núm.152. Col. San Bartolo Atepehuacan, Gustavo A. Madero. Ciudad de México, México. CP. 07730. Tel. 01 559 1758247. (jaburto@imp.mx).

4C. E. La Posta- INIFAP. Carretera Veracruz -Córdoba Paso del Toro, km 22.5. Col. Paso del Toro, Medellín de Bravo, Veracruz, México. CP. 94277. Tel. 01 229 2622222. (quiroz_jf@yahoo.com).

The objective of this experiment was to evaluate the production of biomass, chemical composition, proximal analysis, calorific value and bioethanol yield of the maralfalfa grass (Pennisetum glaucum*Pennisetum purpureum) harvested at six cutting frequencies. The highest production of biomass, calorific value and bioethanol yield was found at the cut-off frequency of 180 days with 28.5 Mg MS ha-1; 18.2 MJ kg-1 MS; 6982 L ha-1 of ethanol (p< 0.05), respectively. The ash and volatile matter content was higher (p< 0.05) in the cutoff frequency of 60 and 150 days (9.6% and 77.8%, respectively); while the moisture and fixed carbon content was higher at the cut-off frequency of 30 days (8.4% and 18.4%, respectively). The chemical composition varied significantly (p< 0.01) across the different physiological states, while the extractive content was higher (p< 0.05) in the cutoff frequency of 150 days (15.1%). The biomass yield, chemical composition, calorific value and proximal analysis of the maralfalfa grass allow it to be a good bioenergetic source for the liquid fuel industry.

Keywords: Pennisetum; bioethanol; calorific value; chemical composition; proximal analysis

El objetivo de este experimento fue evaluar la producción de biomasa, composición química, análisis proximal, poder calorífico y rendimiento de bioetanol del pasto maralfalfa (Pennisetum glaucum*Pennisetum purpureum) cosechado a seis frecuencias de corte. La mayor producción de biomasa, poder calorífico y rendimiento de bioetanol se encontró en la frecuencia de corte de 180 días con 28.5 Mg MS ha-1; 18.2 MJ kg-1 MS; 6982 L ha-1 de etanol (p< 0.05), respectivamente. El contenido de cenizas y materia volátil fue mayor (p< 0.05) en la frecuencia de corte de 60 y 150 días (9.6% y 77.8%, respectivamente); mientras que el contenido de humedad y carbono fijo fue mayor en la frecuencia de corte de 30 días (8.4% y 18.4%, respectivamente). La composición química varió de manera significativa (p< 0.01) a través de los diferentes estados fisiológicos, mientras el contenido de extractivos fue mayor (p< 0.05) en la frecuencia de corte de 150 días (15.1%). El rendimiento de biomasa, composición química, poder calorífico y análisis proximal del pasto Maralfalfa permiten que sea una buena fuente bioenergética para la industria de combustibles líquidos.

Palabras clave: Pennisetum; análisis proximal; bioetanol; composición química; poder calorífico

In recent years, the production of first-generation bioethanol has been much debated by using raw material of prime necessity for humanity and increasing its costs, where the production is based on maize (starch) and sugar cane juice (sucrose). The production of second generation bioethanol is a future alternative, since agricultural resources are abundant in nature; however, studies in this area are still limited. In the sub-humid tropics of Mexico, varieties of the genus Cenchrus purpureus (Schum.) Morrone, [previously Pennisetum purpureum, (Chemisquy et al., 2010)] have been introduced in the last decade for common use in animal feed, due to their growth potential and capacity to produce biomass above 37 Mg MS ha-1 (Calzada et al., 2014); however, there are few studies that show the optimal age at which the highest production and chemical composition of the biomass is reached for better use (Ramos et al., 2013). The objective of the present study was to evaluate the chemical composition, calorific value, proximal analysis and theoretical yield of bioethanol of maralfalfa grass (Pennisetum glaucum*Pennisetum purpureum) harvested at different cutting frequencies in order to be used as raw material in the production of bioethanol.

Location of the study area

The experiment was carried out at the Experimental Site “Papaloapan” of INIFAP, at 18° 06’ north longitude and 95° 31’ west latitude and 65 msnm, at Cd. Isla, Veracruz. The sowing was carried out on july 22, 2011, in furrows with spacing of 0.5 m, in experimental plots of 5*16 meters. The meadows were fertilized with the following formula: 120-80-00 kg ha-1 of N and P2O5 and el N was divided in two applications at 43 and 112 days after sowing. The treatments consisted of six cutoff frequencies (30, 60, 90, 120, 150 and 180 days) distributed in a randomized block design in divided plots.

Biomass yield (kg MS ha-1). It was determined for each frequency after the cut of homogenization, by destructive sampling, for one year. To do this, a central area of 2 m x 3 m was harvested in each plot, leaving one meter of border on each side and 50 cm between cutting frequencies (6 m2) and cutting the total fodder (whole plant), leaving the remnant to 20 cm of height, for the recovery of the plant. The harvested biomass was weighed in a precision balance, then a sub sample was taken, the fresh weight was recorded and it was introduced in a forced air oven at 55 °C until constant weight and the amount of dry matter (MS). The dried samples were then pulverized in a Wiley® mill and sieved in meshes núm. 40 (0.42-1 mm) and 60 (0.25-0.42 mm), for subsequent chemical and calorific value determinations.

Chemical composition and theoretical yield of bioethanol. To release extractives, TAPPI T-264 norm was used. The holocellulose content was determined by the acid chlorination method (Rowell et al., 2005) and ASTM D1104 norma for cellulose. The hemicellulose resulted from holocellulose cellulose subtraction. The Lignin was determined according to TAPPI Standard T-222 os-74. To estimate the bioethanol yield, the formula proposed by Badger (2002) was used based on the chemical composition of the dry matter, using for the calculations the content of cellulose (glucose) and hemicelluloses (xylose).

Proximal analysis and calorific value. To determine moisture, volatile material and ash was used ASTM E871, ASTM E872 and ASTM D 1102-84 norm, respectively, and for fixed carbon the following formula was used: (CF)= 100 - (Humidity + Ash + Volatile Material). To evaluate the calorific value, the ASTM standard (E711) and a temperature of 30±0.5 °C were used, with compressed pellets of weight equal to or less than 1 g. At the same time, moisture content of the samples was determined on balance Ohaus MB45®.

Statistical analysis

The data were grouped annually for statistical analysis, according to the experimental design of random blocks according to divided plots, where the large plot is the genotype and the small plot, the cut-off frequency (30, 60, 90, 120, 150 and 180 ddch) with three replicates. The multiple comparison of the means of treatment was performed using the Tukey test (α= 0.05), using the statistical procedure PROC GLM of SAS software for Windows version 9.3 (SAS, 2011).

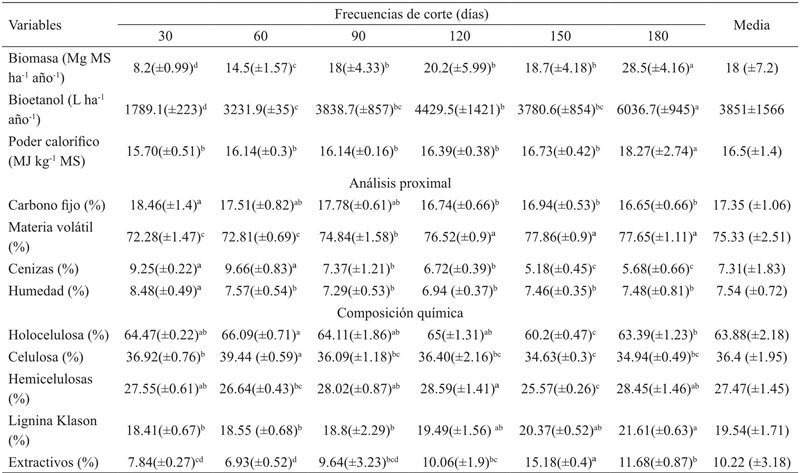

Biomass yield. The annual forage production increased linearly as the plant progressed in its physiological development; the highest yield was obtained at the cut-off frequency of 180 days with 28.5 Mg MS ha-1 and was statistically different (p< 0.05) at the other cut-off frequencies (Table 1). The cut-off frequency of 180 days significantly exceeded the other frequencies (p< 0.05) and produced 248 and 97% more biomass than the cut-off frequencies of 30 and 60 days, respectively. The cut-off frequencies at day 90, 120 and 150 were similar (p> 0.05) and produced 18, 20.2 and 18.7 Mg MS ha-1 year-1, respectively.

Table 1 Biomass and bioethanol yield, calorific value, proximal analysis and chemical composition of the Maralfalfa grass at six cutting frequencies.

Fixed carbon. The highest fixed carbon content was found at early ages, when harvesting every 30 (18.4%), 60 (17.5%) and 90 (17.7%) days, without presenting differences (p> 0.05); however, the frequency of each 30-day cut was different (p< 0.05) than that of 120 (16.7%), 150 (16.9%) and 180 (16.6%) days, which showed the lowest content (Table 1). Parikh et al. (2005) obtained 18.6% fixed carbon in Sudan grass (Sorghum drummondii), which is similar to the cutoff frequency every 30 days.

Volatile matter. In volatile material, the cut-off frequencies of 120 (76.5%), 150 (77.8%) and 180 (77.6%) days were not different (p> 0.05); however, were higher (p< 0.05) at the cutoff frequencies for every 90 (74.8%), 60 (72.8%) and 30 (72.2%) days, which showed the lowest volatile content (Table 1). In previous studies, Demirbas (2004) reported 76.7% volatile matter in the Switchgrass (Panicum virgatum) pasture, which is similar to the cut-off frequencies of 120, 150 and 180 days, which showed the highest content (p> 0.05).

Humidity and ashes. The highest moisture content was presented in the cut every 30 days (8.4%), which was higher and different (p< 0.05) at the other cut frequencies (Table 1), while the ash content was higher in the cut frequencies of 30 (9.2%) and 60 (9.6%) days, with similar amounts of ash (p> 0.05), but superior (p< 0.05) to the other cutoff frequencies. In energy assessments it is important to consider the moisture and ash content, as these compounds can limit the energy performance of the lignocellulosic biomass.

Heat power. The highest calorific value was presented at the cut-off frequency of 180 days (18.2 MJ kg-1 MS), which was higher and different (p< 0.05) at the other cut-off frequencies (Table 1); between cuts every 30 (15.7 MJ kg-1 MS), 60 (16.1 MJ kg-1 MS), 90 (16.1 MJ kg-1 MS), 120 (16.3 MJ kg-1 MS) and 150 days (16.7 MJ kg-1 MS) there were no significant differences (p> 0.05). In previous work, Jenkins et al. (1998) and Parikh et al. (2005) reported 18 and 17.8 MJ kg-1 MS for Switchgrass (Panicum virgatum) and corn stubble, respectively, which agree with the highest calorific value recorded at the cut-off frequency of 180 days.

Structural carbohydrates. The highest holocellulose content was found in the cut-off frequency at day 60 (66.0%), which was different (p< 0.05) and higher than the cutoff frequency of 150 (60.2%) and 180 (63.3%) days (Table 1); while the highest cellulose content was found at the cutoff frequency at day 60 (39.4%), which was different (p< 0.05) at the other cut-off frequencies. On the other hand, the highest hemicelluloses content was present in the cut every 120 (28.5%) days and exceeded (p< 0.05) at the cutoff frequency of 150 (25.5%) days.

In previous research, Wongwatanapaiboon et al. (2012) obtained a holocellulose content of 63.8% for king grass (Pennisetum sp.), similar to that registered in the cut frequencies of 30, 90, 120, and 180 days. Likewise, Mateus et al. (2012) reported 34.3% cellulose in the Maralfalfa grass (Pennisetum sp.), Similar to the cellulose content observed at harvesting every 90, 120, 150 and 180 days. On the other hand, Wongwatanapaiboon et al. (2012), recorded concentrations of 31.1% hemicellulose in grass king grass (Pennisetum sp.), which is 2.6% higher than that obtained by the cutoff frequency of 120 days.

Lignin Klason. The highest lignin content was presented at the cut-off frequency of 180 days with 21.6%, being higher and different (p< 0.05) at cut frequencies of 30 (18.4%), 60 (18.5%) and 90 (18.8%) days (Table 1). However, lignin at cut-off frequencies at 30, 60 and 90 days were higher in 13%, 13.4% and 15%, respectively, than reported by Mateus et al. (2012) who found 16.3% of lignin in maralfalfa (Pennisetum sp.).

Extractive. The highest content of extracts was presented at the cut-off frequency every 150 days (15.5%), which was different (p< 0.05) and higher than the other cut-off frequencies (Table 1). On average, the content of extracts was 10.2%, which is similar to that recorded by Mateus et al. (2012) who reported 10.7% for the cultivar maralfalfa (Pennisetum sp.).

Bioethanol yield

Based on the calculations proposed by Badger (2002), the higher content of glucose and xylose from cellulose and hemicelluloses, respectively, indicated that the highest yield of bioethanol per hectare is obtained at the cutoff frequency every 180 days with 2 893.5 (± 395.8) and 1 875.5 (± 352.3) kg ha-1 year-1, respectively, which were different (p< 0.05) at the other cutoff frequencies; these amounts can produce a total of 4 769 (± 747) kg ha-1 year-1 of bioethanol or its equivalent 6 037 (± 945.6) L ha-1 year-1 (Table 1). The cutoff frequency every 180 days resulted in 2 002 liters more than the cutoff frequency every 30 days (p< 0.05), and it also exceeded in 1 229 liters at the cutoff frequency of 60 days.

Conclusions

The biomass that provides the best substrate (glucose and xylose) per unit area for the production of bioethanol and combustion power was obtained by harvesting every 180 days. At early ages plants contain a greater proportion of inorganic elements, moisture and fixed carbon, such that these compounds decrease as the phenological stage of the plant increases.

The biomass yield and chemical characteristics of the maralfalfa grass make it a potential alternative for obtaining bioethanol in tropical areas.

Literatura citada

AOAC (Association of Official Analytical Chemists). 1990. Official Methods of Analysis. 15th (Ed.). Association of Official Analytical Chemists. Washington, DC, USA. 1298 p. [ Links ]

ASTM (American Society for Testing and Materials). 1977. Method of test for Holocellulose in wood ASTM D1104-56. Annual book of ASTM standards. Part 22: wood; adhesives. Pennsylvania:ASTM. 346-348. pp. [ Links ]

ASTM (American Society for Testing and Materials). 2009. Standard test method for ash in wood. ASTM D1102. Annual book of ASTM Standards. 04.10 Wood. 174-175 pp. [ Links ]

ASTM (American Society for Testing and Materials). 2012. Annual book of ASTM standards, volume 11.16 Biological effects and enviromental fate; biotechnology. ASTM E870. 96-97 pp. [ Links ]

ASTM (American Society for Testing and Materials). 1996. Standard test method for gross calorific value of refuse- derived fuel by the bomb calorimeter. ASTM E711. Annual book of ASTM Standards. Waste management. 265-271. pp. [ Links ]

Badger, C. P. 2002. Ethanol from cellulose: A general review. Trends in new crops and new uses. Janick, J. y Whipkey, A. (Eds.) ASHS Press, Alexandria , VA. 437 p. [ Links ]

Calzada, M. J. M.; Enríquez, Q. J. F.; Hernández, G. A.; Ortega, J. E. y Mendoza, P. S. I. 2014. Análisis de crecimiento del pasto maralfalfa (Pennisetum sp.) en clima cálido subhúmedo. Rev.Mex. Cienc. Pecu. 5(2):247-260. [ Links ]

Chemisquy, A. M.; Giussani M. L.; Scataglini, A.M.; Kellogg, A. E. and Morrone, O. 2010. Phylogenetic studies favour the unification of Pennisetum, Cenchrus and Odontelytrum (Poaceae): a combined nuclear, plastid and morphological analysis, and nomenclatural combinations in Cenchrus. Ann. Bot. 106:107-130. [ Links ]

Demirbas, A. 2004. Combustion characteristics of different biomass fuels.Prog. Energy. Combust. Sci. 30:219-230. [ Links ]

Jenkins, M. B.; Baxter, L. L.; Miles Jr, T. R. and Miles, T. R. 1998.Combustion properties of biomass. Fuel Process Technol.54:17-46. [ Links ]

Mateus, L.; Hernández, O.; Velázquez, M. and Díaz, J. De J. 2012.Dilute sulfuric acid pretreatment of goliath grass (Pennisetum glaucum*Pennisetum purpureum) for ethanol cellulosic. Rev.Colomb. Biotecnol. 14:146-156. [ Links ]

Parikh, J.; Channiwala, S. A. and Ghosal, G. K. 2005. A correlation for calculating HHV from proximate analysis of solid fuels. Fuel.84:487-494. [ Links ]

Ramos, T. O.; Canul, S. J. R. and Vera, F. J. D. 2013. Production of three varieties of Pennisetum purpureum fertilized with two different sources of nitrogen in Yucatán, Mexico. Rev. Bio.Cienc. 2(2):60-68. [ Links ]

Rowell, R. M.; R. Pettersen; J. S. Han; J. S. Rowell and Tshabalala, M.A. 2005. Cell wall chemistry. In: Rowell, R. M. Handbook of wood chemistry and wood composites. CRC Press, Boca Raton,Florida, USA. 35-74 pp. [ Links ]

Statistical Analysis System (SAS) Institute. 2001. SAS user’s guide.Statistics. Release 9.3. SAS Inst., Cary, NC. USA. Quality and elemental removal. J. Environ. Qual. 19:749-756. [ Links ]

TAPPI (Technical Association of the Pulp and Paper Industry). 2006-2007. Acid-insoluble lignin in wood and pulp. T 222 om-02.TAPPI Test Methods. Fibrous Materials and Pulp Testing. CD Version, Atlanta, GA. USA. 5 p. [ Links ]

Wongwatanapaiboon, J.; Kangvansaichol, K.; Burapatana, V.;Inochanon, R.; Winayanuwattikun, P.; Yongvanich, T. and W.Chulalaksananukul. 2012. The potential of cellulosic etanol production from grasses in Thailand. J. Biomed Biotechnol 2012:1-10. [ Links ]

Received: December 2016; Accepted: February 2017

texto en

texto en