1. Introduction

Composite materials are the most favoured engineering materials due to their exquisite mechanical properties. Composites are materials in which the desirable properties of distinct materials are mixed by means of mechanically or metallurgically binding them together (Ward et al., 1996). Numerous composite materials and production categories exist and each day new materials are being added. For the metal matrix composite, matrix binds are done by all the engineering materials (Manna et al., 2002). The most used metal matrix binds are aluminium, magnesium and their alloys. The properties such as lightness and ductility of these materials construct it as the most often used matrix materials in the production of MMC (Foltz & Blackmon, 1990). The composite mainly consists of one matrix and two or more reinforcements and is called hybrid composite. Hybrid composite materials that are formed by reinforcing two or more materials, each has varying properties with matrix phase so that they can be able to produce enhancement in stiffness, showing good strength, producing high strength to weight ratio and other mechanical properties (Gauthier, 1995).

Composites based on Al are found to be apt choices in applications involving factors like light weightiness, enhanced strength and high values of rigidity (Davis, 1993). A particulate reinforced aluminium matrix composites not only enhance the strength and hardness of aluminium and its alloys significantly, but also reduces the plasticity and ductility in properties in a noticeably way. This will affect the safety and dependability of components manufactured from aluminium matrix composites (Gandra et al., 2011).

Elements like Si-C, SiO2, Al2O3 and MgO are the most used reinforcement composite materials. Among all, aluminium silicon carbide alloy composite materials are preferred used for engineering structures, enterprise and digital applications, sporting goods and so on (Chennakesava Reddy, 2009). Aluminum matrix composite material reinforcement with silicon carbide particles affords excessive wear-resistant, greater modulus better dimensional stability than traditional aluminium alloy (Silva et al., 2010). Silicon carbide particle is stirred uninterruptedly with wetting agent magnesium in order to enhance the wettability (Devi et al., 2014). At the same time, the metal matrix composites slurry is solidifying to increase wettability SiC with aluminium matrix alloy. The wettability can also be increased by reducing this solidification time. However, increasing the volume fraction of existing SiC particle will give reverse outcome (Lashgari et al., 2010).

Among the various manufacturing processes exists to access the intermittent metal matrix composites, the most extensively used and acknowledged for viable and practical approach is stir casting, because of its ease, flexibility, applicability to a bulk production and most cost-effective method in making of metal matrix composites (Seo & Kang, 1999). A stirring was advanced for consistent dispersion of fabricating particulate metal matrix composites in an economic (Lee et al., 2006). In this article, the various mechanical properties and microstructural examination were taken for aluminium metal matrix composite with reinforcement of silicon carbide and magnesium oxide by stir casting method.

2. Materials and methods

AA6061-MgO-SiC composites were prepared by stir casting technique, aluminum alloy 6061 was used as a matrix and the chemical composition is shown in Table 1. Magnesium oxide and silicon carbide particles shown in Figures 1 and 2 were used as reinforcement materials and their corresponding properties are listed in Table 2. The reinforcement of magnesium oxide and silicon carbide particles grain size is 50µm. The AA6061 pieces were heated in a crucible; the reinforced particles SiC, MgO are preheated distinctly at 2500C for 20 minutes so that the wettability can be improved. The ceramic materials were mixed with the AA6061 to prepare composites with wt of about 0, 3, 6 and 9 % reinforcement by using stir casting route shown in Figure 3. The AA6061 was melted in crucible and the preheated. Following it, the SiC & MgO particles are gradually added at temperatures of 800ºC. A five-minute stirring at 700rpm is done in a dynamic manner. The stirring was used to make sure the homogeneity of the molten metals.

Table 1 Al6061 alloy composition by weight %.

| Al | Si | Mg | Cr | Cu | Fe | Mn | Ti | Zn |

| 95.50-98.60 | 0.42-0.82 | 0.8-1.2 | 0.04-0.35 | 0.15-0.40 | 0.0-0.7 | 1.0-0.15 | 0.0-0.25 | 0.0-0.25 |

Table 2 Properties of MgO & SiC powders.

| S. No | Properties | Values |

| Magnesium Oxide | ||

| 1. | Density | 3.58 g/cm3 |

| 2. | Molar mass | 40.30 g/mol |

| 3. | Melting point | 852°C |

| 4. | Boiling point | 3600°C |

| Silicon Carbide | ||

| 1. | Density | 3.2g/cm3 |

| 2. | Molar mass | 40.096 g/mol |

| 3. | Melting point | 2,730° C |

| 4. | Boiling point | 2700 °C |

A stirrer was used for even spreading reinforcement over the entire matrix. The rod form of the mixture is obtained by pouring the molten mixture into cast iron mold. The molten mixture was poured into cast iron mold as a rod form. The other components in the testing setup include the Brinell hardness tester, Charpy V-notch test and Pin-on-disc machine rated and specified as per ASTM standards (Ray,1993). Evaluation metrics like the tensile strength, the hardness, impact strength and the wear rate are studied through these experimental investigations.

Al6061-SiC-MgO composites have been prepared by changing SiC and MgO weight percentage about 3%, 6% and 9% each respectively. The weight of sample taken as 600 grams and % varies accordingly.

Table 3 Composition of samples.

| Sample No. | Al 6061 alloy gram | SiC gram | MgO gram | Weight percentage |

| 1 | 600 | - | - | Al 100% |

| 2 | 564 | 18 | 18 | Al 94%, SiC 3%, MgO 3% |

| 3 | 528 | 36 | 36 | Al 88%, SiC 6%, MgO 6% |

| 4 | 492 | 54 | 54 | Al 82%, SiC 9%, MgO 9% |

The Aluminum composite material specimen is made as shown in Figure 4. In this Material made of 94% Al 6060 material with reinforcement of 3% SiC and 3% MgO.It is made of Specimen in three different sizes. First specimen is 30mm diameter, 300mm length and second specimen is 30mm diameter, 150mm length and third specimen is 150mm×100mm×5mm.specimens made in these sizes were easily subjected to mechanical tests.

2.1. Mechanical testing

2.1.1. Hardness test

The Brinell hardness test was carried with 250 kg load and 10mm steel ball indenter on Al 6061 composite with varying weight percentage of reinforcement particles (MgO and SiC). According to the ASTM standards, the specimens were prepared. The test was conducted on each specimen of Al 6061 composite as shown in Figure 5 with various surfaces to obtain average hardness value.

2.1.2. Tensile test

The tensile test was accomplished on a universal testing machine. Based on ASTM standard, specimens were prepared. The maximum capacity of UTM is 300 KN. Test was carried out for all specimens respectively.

2.1.3. Compression test

In this test, the compression loads were steadily increased, and the corresponding strain was noted till the specimen failed universal testing machine is used to conduct the compression test. Accordance with ASTM standard, the test was conducted on each specimen of Al 6061 composite as shown in Figure 6.

2.1.4. Impact test

Tests conducted using Charpy test is popularly known as impact strength test or impact test. It computes the volume of energy absorbed by the material before the actual fracture takes place (Abdizadeh et al., 2014). The evaluation procedures are done as per ASTM standards and conducted before fracture. The nature of testing is usually of a high strain type of testing. The test specimens were machined as per the standard.

2.1.5. Wear rate test

Wear rate Test was conducted on pin and the disc. It was computed by evaluating the amount of wear for the pin and disk based on the amount or volume of material removed during the testing process (Kingston et al., 2014). It is usually expressed in weight percentages. During the testing process, variables such as time, contact pressure and speed of the movement can be controlled.

3. Result and discussion

The composition of aluminium 6061- silicon carbide- magnesium oxide as follows

Specimen 1 = 100% 0f aluminium 6061

Specimen 2 = 94% of Al 6061 +3% of SiC + 3% of MgO

Specimen 3 = 88% of Al 6061 + 6% of SiC + 6% of MgO

Specimen 4 = 82% of Al 6061 + 9% of SiC + 9% of MgO

3.1. Hardness test

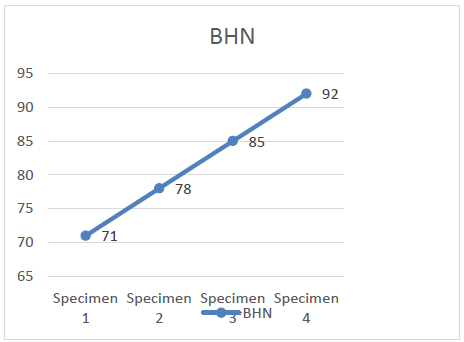

The hardness of Al 6061 with different percentage of reinforcement is tested using Brinell hardness test and the experimental results are analyzed as shown in Figure 7.

Figure 7. Reflects the hardness of the HMMC specified as BHN is compared against reinforcement percentage. From the results, it can be concluded that increasing the weight percentage tends to improve the robustness towards plastic deformation which alternately defines an increasing hardness of the specimen. The hardness of specimen Al 6061 is 71 BHN and reaches its maximum value of 92 BHN for the Composition of 82% of aluminium 6061 + 9% of SiC + 9% of MgO.

3.2. Tensile test

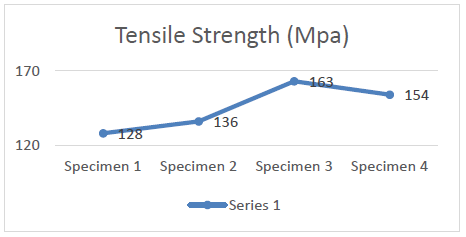

The effect of weight percentage of silicon carbide and magnesium oxide on the 4 tensile strength of aluminium ally Al 6061.

From the above Figure 8, the result shows that there is an increase in the value of ultimate tensile strength up to 6%. And then decrease in the values of tensile strength happened due to poor wettability and poor bonding between Al 6061 matrix and SiC - MgO reinforcement.

3.3. Compression test

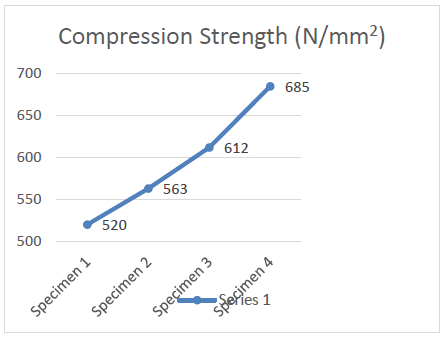

The effect of compression test was shown in Figure 9.

The above results show that, by increasing the reinforcement percentage increases the compressive strength of aluminium alloy Al 6061. The compressive strength of unreinforced aluminium alloy Al 6061 is 520 N/mm2 and this value increases to maximum of 685 N/mm2 for the composition of 82% of aluminium 6061 + 9% of SiC + 9% of MgO composite.

3.4. Impact Test

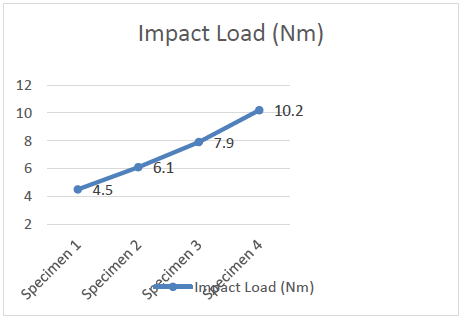

The Charpy impact test was carried out for different specimens and the outcomes were shown in Figure 10.

The above graph shows that with increase of reinforcement, the impact strength of composites was also improved. The impact attains a maximum value of 10.2 Nm for the composition of 82% of aluminium 6061 + 9% of SiC + 9% of MgO composite.

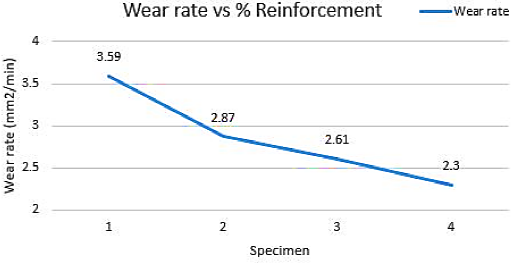

3.5. Wear rate test

The findings of the wear rate test have been projected in Figure 11. The experimental plot projects the variation of wear rate as a function of increasing weight percentages. Wear rate is computed for AA6061 with differing weight percentages of SiC-MgO. The decrease in wear rate causes a significant improvement in the weight percentage of reinforcing SiC-MgO as compared to unreinforced AA6061 composites. Adequate lubrication and its associated features coupled together with the hardened nature of the reinforced particles is the primary cause for the observed phenomena (Ramesh et al., 2015). However, in the case of unreinforced AA6061, during the stages where the metal has not received the complete finishing (as - cast), an increase in wear condition is observed. The observed homogeneity in the unfinished structure is the primary cause of this phenomena. At the same time, the decrease in wear rate can be attributed to an increase in fraction of SiC-MgO particles which possessed high hardness with better interfacial bonding between the SiC-MgO particles and AA6061 hybrid matrix formed during stir casting process. At all levels of loads, the lowest wear rate is attained against 9 wt. % of SiC-MgO composites. Whenever the load increases, then the wear rate goes on increasing correspondingly. After attaining sliding speed, wear rate goes on decreasing and concludes that over sliding speed is directly proportional to test time. The increase in test time of samples and disk causes decrease in wear rate. Another interesting observation is that the friction coefficient tends to decrease with increasing distances of sliding velocity. However, this friction coefficient is greatly reduced by the hard and thermally stable nature of SiC-MgO (Çalin et al., 2011). The SiC-MgO was able to enhance wear resistance of the composites at a temperature higher than the room temperature.

An oxide layer of the materials that act as an effective insulation layer between pin and the disc is formed due to high temperature. This is attributed to the observed high sliding velocity. This in turn tends to increase the oxide layer formation on the materials which consequently improves the wear resistance.

4. Conclusions

Aluminium based HMMC have been produced by applying stir casting method. The particles silicon carbide and magnesium oxide are stirred for uniform spreading. The following conclusions were observed in this existing study,

The BHN of Al 6061- SiC- MgO composite was found to be more than base aluminium alloy Al 6061 and BHN increase with reinforcement percentage.

The tensile strength value was increase as adding reinforcement up to 6% and upon adding reinforcement, strength decreased subsequently. The optimum value of ultimate strength achieved at 6% of SiC and 6% of MgO reinforcement.

Comparing monolithic Al 6061 alloy, the compression strength and impact strength increases gradually by adding reinforcements.

The reinforced composites are compared against the unreinforced AA6061 composites. The decrease in wear rate is accomplished with increase in the weight percentage of SiC-MgO reinforcing as compared to unreinforced. This is due to the lubricating properties and hardened nature of reinforced particles.

nueva página del texto (beta)

nueva página del texto (beta)