Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista ALCONPAT

versión On-line ISSN 2007-6835

Rev. ALCONPAT vol.5 no.3 Mérida sep./dic. 2015

Articles

Analytic Hierarchy Process to choose the cement type to protect reinforced concrete to corrosion caused by chloride ions attack

1 Departamento de Construcción Civil, Universidade Federal do Paraná (UFPR), Brasil. Email: sarahhlds@gmail.com

2 Departamento de Construcción Civil, Universidade Federal do Paraná (UFPR), Brasil. Email: carolinalondero7@gmail.com

3 Departamento de Construcción Civil, Universidade Federal do Paraná (UFPR), Brasil. Email: medeiros.ufpr@gmail.com

4 Escola Politécnica, Universidade de Pernambuco, Brasil.

5 Escola Politécnica, Universidade de Pernambuco e Universidade Católica de Pernambuco, Brasil. Email: eliana@poli.br

This paper discuss cement types combinations to obtain the best one to protect against the steel reinforcement corrosion caused by chloride ions. In this case, it was used the method of Analytic Hierarchy Process (AHP), which is based on the definition of the main elements for making fast, reliable and objective decision. Three types of cement (CPII-Z-32: pozzolanic admixture, CPIII-40: blast furnace slag admixture and CPIV-32: pozzolanic admixture), two water/cement ratio (0,4 and 0,7) and two curing times (7 and 28 days), were analyzed trough results of five experiments. The application of AHP was effective to choose the type of cement, concluding that the CPIII-40 cement showed the best performance compared to the other cements.

Keywords: Analytical hierarchy process; Reinforced concrete; Steel corrosion

Este trabajo discute las combinaciones de tipos de cemento buscando obtener el de mayor capacidad de proteger al concreto de la corrosión de las armaduras ante la acción del ion cloruro. Para ello se usó el método de análisis jerárquico (AHP), basado en la definición de elementos principales para la toma de decisión rápida, confiable y objetiva. Fueron analizados tres tipos de cemento (CPII-Z-32: con adición de puzolana, CPIII-40: con adición de escoria y CPIV-32: con adición de puzolana), dos relaciones agua/cemento (0,4 y 0,7) y dos tiempos de curado (7 y 28 días), a través de los resultados de cinco ensayos. La aplicación del AHP se mostró eficaz en La elección Del tipo de cemento, generando La constatación que el cemento CPIII-40 presento El mejor desempeño entre los cementos evaluados.

Palabras clave: Análisis Jerárquico; concreto armado; corrosión de las armaduras

Este trabalho discute combinações de tipos de cimento, buscando obter o de maior capacidade de proteger o concreto quanto à corrosão das armaduras sob ação de cloretos. Para isso, utilizou-se o método Análise Hierárquica (AHP), baseado na definição de elementos principais para uma tomada de decisão rápida, confiável e objetiva. Foram analisados três tipos de cimento (CPII-Z-32: com adição de pozolana, CPIII-40: com adição de escória e CPIV-32: com adição de pozolana), duas relações água/cimento (0,4 e 0,7) e dois tempos de cura (7 e 28 dias), através do resultado de cinco ensaios. A aplicação do AHP mostrou-se eficaz na escolha do tipo de cimento, gerando a constatação que o cimento CPIII-40 apresentou o melhor desempenho entre os cimentos avaliados.

Palavras-chave: Análise hierárquica; Concreto armado; Corrosão de armadura

1. INTRODUCTION

Concrete consists in one of the main construction materials used in modern society, being the Portland cement the most appropriate construction material to those structures, overcoming also feasible alternatives as steel and wood. This is due to a combination of two materials that work to resist distinct efforts, concrete that has a good compressive strength and steel which resist tensile stresses, allowing a variety of applications.

Its intense use started from the 50s, however, until 70s it was believed that reinforced concrete was a material that does not deteriorate. Nevertheless, at this time, reinforced concrete structures began to show significant pathological manifestations, causing a concern about their durability (MEDEIROS, 2008).

Based on this, a lot of researches were accomplished with the aim to express the pathological manifestations incidence in reinforced concrete structures. Thus, Andrade (1997) established that 64% of pathological manifestations found in buildings at the state of Pernambuco were steel corrosion due to intense chloride ions attack.

Hence, the reinforced concrete structures deterioration due to steel corrosion represents one of the biggest problems of civil construction. That is because the repair cost is high, corresponding to 3,5% of the annual loss of Brazil's gross national product, occasioned by investments to prevent corrosion and to maintain or substitute structural elements damaged by corrosion (DOTTO, 2006).

Corrosion happens by an electrochemical mechanism that affords at least one oxidation reaction and one reduction reaction occurring simultaneously. Even so, there are three basic conditions for steel corrosion to occur: existence of an electrolyte; electrode potential difference and presence of oxygen (BARBOSA et al., 2012). According to Pereira et al. (2013), steel corrosion may be influenced by factors such as concrete properties, exposure time to aggressive agents, surface conditions of the steel bar, environmental characteristics around the structure, etc. Commonly concrete offers a protection against corrosion, due to a formation of a thin protective oxide layer on bars surface, because of the high material alkalinity. However, when the presence of chloride ions achieve a level of 0,4% of cement (in mass), the layer that once protected the reinforcement is destroyed and the steel becomes despassivated providing corrosion.

Therefore, researchers such as Page et al. (1986), Tessari (2001), Mather (2004), Sakr (2004) e Pereira (2011), studied about the influence of cement types and its admixtures in protecting against chloride ions attack. Based on those researchers, the admixtures of the different types of cement may contribute with benefits like capillary porosity and permeability reduction. Thus, with these benefits and their influences on steel corrosion, arose the assumption that the types of cement influence the protection against steel corrosion due to chloride ions.

Thereby, and using the data from Pereira's master dissertation (PEREIRA, 2011), this work presents a discussion, from Hierarchical Analysis, on choosing some cement types from Northeast region of Brazil, CPII-Z-32 (pozzolan Portland cement compound), CPIII-40 (blast furnace Portland cement) and CPIV-32 (pozzolanic Portland cement), regarding steel corrosion due to chloride ions.

2. INFLUENCE FACTORS ON CHLORIDE PENETRATION IN PORTLAND CEMENT COMPOSITE

Steel corrosion may occur by harmful chemical or electrochemical processes. In the case of reinforced concrete structural elements exposed to chloride ions attack, mainly on marine environments, it has been noticed frequent pathological manifestations like: cracking, spalling and severed of the concrete cover. Therefore, the cause of these manifestations is the loss of the steel bar section due to its corrosion, that on the other hand leads to the formation of expansive products inside concrete.

To avoid this corrosion process it is necessary that the concrete is in an alkaline environment provided by hydroxides. Hence, owing to a high alkalinity, there is a formation of a thin oxide layer on steel surface acting as a protective barrier. Thus, if there is a chloride contamination, steel corrosion may happen even with an alkaline concrete pH around 13.

As that kind of corrosion occurs in aqueous environment, the process is called as electrochemical, in other words, it implies that there is an oxide reaction and a reduction reaction, and circulation of ions through the electrolyte, being responsible for concrete deterioration (HELENE, 1993).

One of the main factors that influence corrosion is the pore structure of the concrete cover, and if it has a high absorption it must result to a more accelerated corrosion process. Thereby, the water ingress, dependent porosity variable, is of great significant because it controls the water, oxygen, CO2 and chloride content inside concrete (CERVO, 2001). Therefore, it is important to evaluate the type of cement, the water/cement ratio (w/c) and cure conditions as influences to steel corrosion process due to chloride ions attack.

Cement chemical composition also has an influence on corrosion process due to chloride ions, because tricalcium aluminate (C3A) and tetracalcium aluminoferrite (C4AF) combine with chloride forming chloroaluminate. The tricalcium aluminate has the ability to immobilize the chloride ions by forming an insoluble compound, the chloroaluminate and hidrated lime (PAGE et al., 1986). The work of Hoppe Filho et al. (2013), applying the X-ray diffraction technique also indicates the formation of chloroaluminate on concrete subjected to contact with a chloride ion aqueous solution.

It is important to emphasize that a mineral admixture, as pozzolans, on cement composition decreases porosity leaving concrete less susceptible to fluids percolation, and so, decreasing permeability. Besides, pozzolans have great ability to chloride retention, related to high levels of aluminates (CERVO, 2001).

As well as cement chemical composition, the w/c ratio directly influence shape, size and pores distribution being one of the factors that controls chloride penetration. That happens because a low w/c ratio decreases concrete porosity decreasing penetrability and diffusivity.

Hence, several surveys proposed studies about chloride ions related to different water/cement ratios. These studies proved that the lower w/c ratio the smaller chloride penetration (GASTALDINI et al., 2010).

Another influence factor about diffusivity of chloride ions in Portland cement composite is the cure process, which also acts on pore structure formation on Portland cement paste. The longer cure time of concrete, the higher the resistance against aggressive agents ingress because of a better internal and superficial concrete cover conditions, occasioned by cement hydration.

3. EXPERIMENTAL PROGRAM

This paper consists of an application of a decision-making tool designated Analytic Hierarchy Process (AHP), that needs a data base to justify a given choice of a specific application. Hereafter, there are presented the conditions and assumptions of this paper, which focused on choosing the most suitable type of cement to execute a job inserted in a contaminated environment by chloride ions.

3.1. Data from the study used as data base to

The work used as data base do apply the AHP was developed by Pereira (2011) using the following variables:

Water/cement ratio (2 levels - w/c = 0,4 e 0,7) - it was chosen two different w/c ratio to avoid the effect of this parameter in a significant way;

Type of cement (3 levels - CPII-Z-32, CPIII-40 and CPIV-32) - This choice was based on each cement capacity to protect concrete in contaminated environments by chloride. The cement CPII-Z-32 and CPIV-32 are composed, respectively, of 12% and 43% of natural pozzolan from rocks, and the cement composition of CPIII-40 there is 67% of blast furnace slag;

Cure process (2 levels - 7 and 28 days at a moist chamber) - It was chosen two cure periods at moist chamber in order to quantify how much important is to increase de cure period on Portland cement composites.

During the experimental program it was worried to maintain the same conditions of the specimens producing them in the same range of workability, varying in the interval of 260 mm and 300 mm. It was used cylindrical mortar specimens with dimensions of 50 mm, in diameter, and 100 mm, in high, to execute the complementary tests. For the accelerated corrosion test it was made prismatic specimens (60 x 80 x 25 mm) with two steel bars with 5 mm in diameter, 100 mm of length and 10 mm of cover.

After properly dried and cured in a laboratory environment for 15 days, the prismatic specimens were subjected to a corrosion test that consists of half cycles of partial drying and wetting in an aqueous solution with 5% of NaCl, for three months. The half cycles occurred for 5 days and the specimens stayed inside the storage, after 2 days they were submerged on the solution cited.

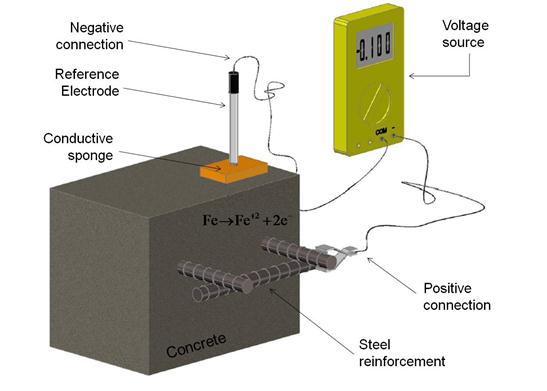

To execute the accelerated corrosion test it was needed the following equipment: a reference electrode, an electrical junction device, electric wires and a high impedance voltmeter. It was connected the positive pole to the steel bar and the negative pole to the reference electrode to measure the corrosion potential. In this way, the voltmeter indicates the potential difference intensity between the cells, representing a parameter to determine the occurrence of steel corrosion (PEREIRA, 2011).

It is necessary a conductive interface between the reference electrode and the steel bar to close the circuit, and it was made using a saturated sponge placed in electrical contact between the reference electrode and concrete surface. Figure 1 illustrates the configuration of the test for determining the corrosion potential (MEDEIROS et al., 2013).

Figure 1 Circuit configuration for determining the corrosion potential (ROCHA, 2012; MEDEIROS et al., 2013)

The aim of the method is not quantify the corrosion of steel, since the corrosion rate is not determined by the procedure. According to Medeiros, Balbinot and Helene (2010), the potential for corrosion identifies part in the study sites where the thermodynamic conditions are favorable to the start of the corrosion process, although the armor does not show signs in the concrete surface that surrounds it.

For the assessment of the likelihood of corrosion was used the procedure recommended in the ASTM C 876 (2009) , and for relating the corrosion potential of the reference electrode copper/ copper sulphate (Ecorr) of less than -350 mV , the probability corrosion is higher than 90%. In addition, for Ecorr greater than -200 mV, the likelihood of corrosion is less than 10%.

In addition to the accelerated aging test was held the testing of immersion absorption (NBR 9778: 1987), wicking (NBR 9779: 1995) and compressive strength (NBR 7215: 1997) . The author's intention to conduct the testing was to assist in the understanding and interpretation of the main trial.

3.2. Analytic Hierarchy Process

Decision-making for complex problems requires treatment of simplified data, however systematic in order to get results fast, reliable and are inexpensive.

Taking into account factors of importance to the realization of a particular choice, Saaty developed in 1971 the technique of hierarchical analysis (Analytic Hierarchy Process - AHP). The AHP consists of a multi-criteria decision tool addressing factors that are organized in a hierarchical structure (SAATY, 1990).

In civil engineering, the potential of hierarchical analysis has been little explored, but it is possible to cite examples of studies using this tool as a decision making tool, such as: 1 - Marchezetti et al. (2011), in the treatment of household waste; 2 - Silva and Souza (2011), the check-gatherer solid waste compactor trucks; 3 - Lisboa e Waisman (2006) and Zayed et al. (2008), in decisions related to highway project area; 4 - Pan (2008), in the selection of bridge construction methods; 5 - Lai et al. (2008), the public works project; 6 - Pereira, Medeiros and Levy (2012), for selecting replacement percentage construction waste as aggregate in concrete dosage; 7 - Mattana et al. (2012), the choice of coating mortars; 8 - Pereira et al. (2014), the choice of adhesive mortars for use in floor system on floor.

The method AHP develops three main operations, which correspond to build a hierarchy of priorities analysis and consistency checks. The construction of the hierarchy is to tease out the component parts of the problem and organize them into levels. As for the priority analyzes carried out a comparison of the elements of each level based on the knowledge and experience of the decision maker. Finally, it is executed consistency checks to ensure consistency among comparisons (HO, 2008).

Thus, before you start implementing the AHP technique it is necessary to define the objective , which in this work is to choose a type of cement a water/cement ratio (w/c) and a time of healing , as previously specified , able to better protect the concrete for corrosion of the reinforcement under the action of chloride ions . So the alternative of choice for this work are shown in Table 1. We analyzed each situation seeking to obtain and compare the best type of cement for each w/c ratio and healing time.

Table 1 Combination of the types of cement for two levels of the w/c ratio and curing

| Cement type | w/c ratio | Curing time |

|---|---|---|

| CP II-Z-32 | 0.4 | 07 days |

| CP II-Z-32 | 0.4 | 28 days |

| CP II-Z-32 | 0.7 | 07 days |

| CP II-Z-32 | 0.7 | 28 days |

| CP III-40 | 0.4 | 07 days |

| CP III-40 | 0.4 | 28 days |

| CP III-40 | 0.7 | 07 days |

| CP III-40 | 0.7 | 28 days |

| CP IV-32 | 0.4 | 07 days |

| CP IV-32 | 0.4 | 28 days |

| CP IV-32 | 0.7 | 07 days |

| CP IV-32 | 0.7 | 28 days |

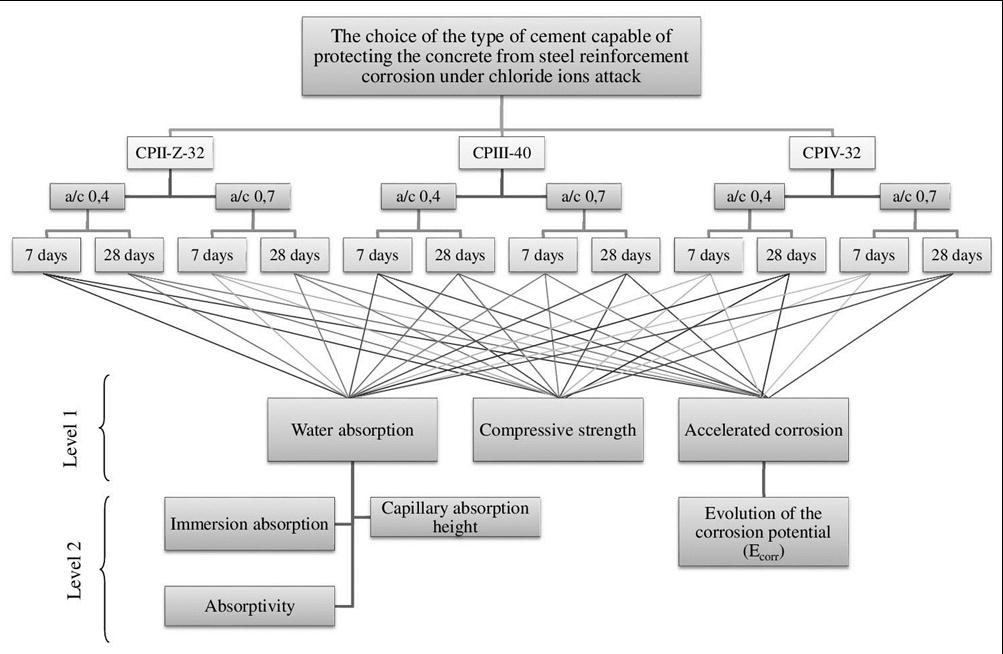

After the definition of choice, shown in Table 1, it has established the criteria to be considered in assessing the performance of alternatives. Pereira (2011) analyzed the results of three major trials being water absorption, compressive strength and accelerated corrosion, which are the primary level of the hierarchy. The water absorption test includes three other trials arranged on the secondary level of the hierarchy, and accelerated corrosion test also involves test data evolution of the corrosion potential, based on data obtained from the variation of mass of the specimens.

Figure 2 is a tree showing the hierarchical levels analyzed and considered criteria.

Table 3 shows the values of the first hierarchical level decision matrix indicating the weights of each parameter. As the water absorption and compressive strength tests was considered slightly less important than the accelerated corrosion test by comparing these with the last received values for standardizing the inverse of the data trend.

Table 3 Decision matrix of the first level of AHP

| Water absorption | Compressive strength | Accelerated corrosion | Line Total (Tl) | Relative importance | |

| Water absorption | 1.00 | 1.00 | 0.33 | 2.33 | 0.20 |

| Compressive strength | 1.00 | 1.00 | 0.33 | 2.33 | 0.20 |

| Accelerated corrosion | 3.00 | 3.00 | 1.00 | 7.00 | 0.60 |

| General total (Gt) | 11.67 | 1.00 |

In preparing the second hierarchical level decision matrix was decided to consider all the criteria considered as equally important. This practice was carried out because it is very difficult and subjective to assign different levels of importance for each of the three results of water absorption. In Table 4 are willing values of the decision matrix of the second hierarchical level.

Table 4 Decision matrix of the second level of AHP

| Immersion absorption | Capillary absorption height (cm) | Absorptivity (Kg/m²h1/2) | Line Total (Tl) | Relative importance | |

| Immersion absorption | 1.00 | 1.00 | 1.00 | 3.00 | 0.3333 |

| Capillary absorption height (cm) | 1.00 | 1.00 | 1.00 | 3.00 | 0.3333 |

| Absorptivity (Kg/m²h1/2) | 1.00 | 1.00 | 1.00 | 3.00 | 0.3333 |

| General Total (Gt) | 9.00 | 1.00 |

After developing matrices, decision with the weights of each criterion was calculated consistency AHP through the reasoned consistency test by Saaty (2000) and pointed out by (2002). Thus, we determined the ratio of consistency, it should be a value less than or equal to 0,1. In the case of this study, because of the calculation resulted in 0 (zero) for both developed arrays, being less than the limit. Thus, the AHP is mounted considered perfectly consistent.

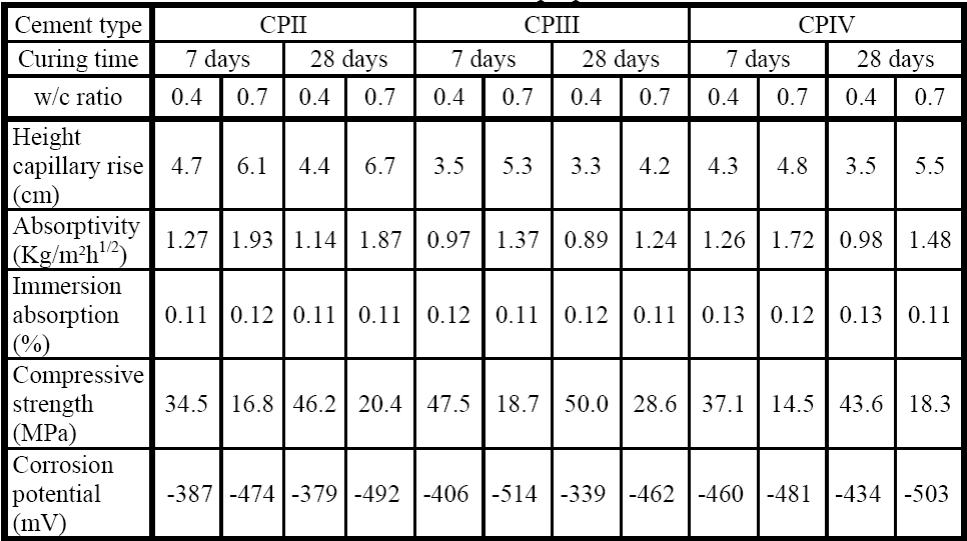

In this work, all the data used in the comparison analysis of quantitative criteria are requisites, that is, we used the numerical values extracted from the results of tests performed by Pereira (2011), as follows in Table 5.

The test evolution of the corrosion potential was performed with 12 cycles of drying and wetting (in 5% NaCl solution) and total duration of 84 days. For the cement performance evaluation considered the average of all the results only of the phases of wetting, that the presence of water presents the most representative values in relation to the likelihood of corrosion.

4. RESULTS - APPLICATION OF HIERARCHICAL ANALYSIS

With this research. using test data performed by Pereira (2011) and by the method of Analytic Hierarchy. sought to get the best type of cement (CPII-Z-32. CPIII-40 e CPIV-32) or corrosion reinforcement under the action of chloride ions . also considering two level w/c ratio (0.4 e 0.7) and two cure times (7 e 28 days). The results of the analysis were verified separately by combination of the selection elements. generating two analysis matrices comparing the types of cement with the 0.4 w/c ratio of to as much as 7 days cure for 28 days. and two arrays with types of cement 0.7 w/c ratio of and cure times of 7 days and 28 days.

To optimize space and objectify the results of this study. it was decided to present the details of the evaluation procedures only of the cement kinds decision matrix for w/c ratio of 0.4 to 7 days . which is described the item that follows. For other matrices. we chose to show only the final tables with the performance and final evaluation indexes. Therefore. it is clear to the reader how to get up in the final analysis by AHP.

4.1. Choice of cement to w/c ratio = 0.4 and curing time = 7 days

After meeting the criteria considered in AHP and establish the weighting factors for comparison of these properties. the appraiser must perform the normalization of data for performance verification. For the calculation divides the value of each item of the line by the larger value. so that all criteria exhibit the same magnitude of values between 0 and 1.

The values of the tests relating to water absorption and corrosion potential needed to be reversed. since the results were the smaller. the better the performance. When converting the data it is possible to standardize analysis by greater values getting coherence in the assessment. In Table 6 are standardized and normalized data of the water absorption test (immersion absorption and capillary absorptivity). The compressive strength and accelerated corrosion (potential corrosion).

Table 6 Modified and standard values used in the AHP

| Data | Modified values | Normalized values | |||||

| CP II | CP III | CP IV | CP II | CP III | CP IV | ||

| Criteria | immersion absorption (%) | 9.09 | 8.33 | 7.69 | 1.00 | 0.92 | 0.85 |

| Altura ascensão capilar (cm) | 0.21 | 0.29 | 0.23 | 0.74 | 1.00 | 0.81 | |

| Absorptivity (Kg/m²h1/2) | 0.79 | 1.03 | 0.79 | 0.76 | 1.00 | 0.77 | |

| Compressive strength | 34.50 | 47.52 | 37.09 | 0.73 | 1.00 | 0.78 | |

| Potential corrosion (mV) | 0.00259 | 0.00246 | 0.00217 | 1.00 | 0.95 | 0.83 | |

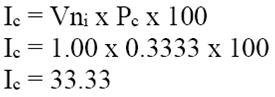

The normalized value of each item (Table 6) multiplied by the relative importance of each criterion (Table 4). and also by 100 (percentage). it was possible to achieve the performance levels. An example: Equation (1) describes the procedure for calculating the performance index of the immersion absorption criterion to the cement type CP II, w/c ratio 0.4 and 7 days.

Where.

Ic : |

performance index of the criterion |

Vni : |

normalized value of the criterion |

Pc : |

relative importance of the criterian |

After that. we add up all the performance indices of comparison criteria corresponding to water absorption. The performance indices of the compressive strength criteria and evolution of the corrosion potential are not added for each criterion it is an isolated test. Table 7 shows the performance indices of the criteria.

Table 7 Performance index for cement types. w/c = 0.4 and 7 days of curing

| Data analyzed | Performance index | |||

| CP II | CP III | CP IV | ||

| water absorption | Immersion absorption (%) | 33.33 | 30.56 | 28.21 |

| Height capillary rise (cm) | 24.82 | 33.33 | 27.13 | |

| Sortivity (Kg/m²h1/2) | 25.46 | 33.33 | 25.66 | |

| Performance index | 83.62 | 97.22 | 81.00 | |

| Compressive strength | Compressive strength | 72.60 | 100.00 | 78.05 |

| Performance index | 72.60 | 100.00 | 78.05 | |

| Accelerated corrosion | Corrosion Potential (mV) | 100.00 | 95.26 | 83.99 |

| Performance index | 100.00 | 95.26 | 83.99 | |

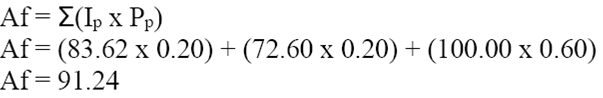

Finally. the final evaluation is the sum of the performance index multiplied by the relative importance (Table 3) of each property analyzed. The calculation procedure for the final evaluation of the cement type CP II is exemplified by Equation (2).

Where.

Table 8 shows the evaluation of each cement type. The best result among the combinations of cement types. w/c ratio and cure times presents the highest value in the final assessment.

Table 8 Final assessment for cement types. w/c = 0.4 and 7 days of curing

| water absorption | Compressive strength | Accelerated corrosion | Final Evaluation | |

| Relative importance | 0.20 | 0.20 | 0.60 | |

| CP II | 83.62 | 72.60 | 100.00 | 91.24 |

| CP III | 97.22 | 100.00 | 95.26 | 96.60 |

| CP IV | 81.00 | 78.05 | 83.99 | 82.21 |

For the case study. seeking the best cement type to protect the reinforced concrete to corrosion in chloride ion environment. to w/c equal to 0.4 and cure time of 7 days. the option that presented the best performance using the Analytic Hierarchy Process (AHP) was the cement type CPIII-40. followed by the CPII-Z-32 and CPIV-32.

4.2. Choice of cement to other combinations of w/c ratio and curing time

The calculation procedures stated above for the choice of the type of cement. with w/c ratio equal to 0.4 and 7 days of curing. were the same as those used for the other combinations of w/c ratio and curing time. Thus. in order to simplify the presentation of results in Tables 9. 10 and 11 are placed data from performance indicators and the final evaluation of other matrices analyzed.

Table 9 Final assessment for cement types. w/c = 0.4 and 28 days of curing

| water absorption | Compressive strength | Accelerated corrosion | Final Evaluation | |

| Weight | 0.20 | 0.20 | 0.60 | |

| CP II | 84.36 | 92.41 | 89.36 | 88.97 |

| CP III | 97.22 | 100.00 | 100.00 | 99.44 |

| CP IV | 89.91 | 87.21 | 78.09 | 82.28 |

Table 10 Final assessment for cement types. w/c = 0.7 and 7 days of curing

| water absorption | Compressive strength | Accelerated corrosion | Final Evaluation | |

| Weight | 0.20 | 0.20 | 0.60 | |

| CP II | 80.45 | 90.04 | 100.00 | 94.10 |

| CP III | 96.86 | 100.00 | 92.17 | 94.68 |

| CP IV | 90.44 | 77.68 | 98.35 | 92.63 |

Table 11 Final assessment for cement types. w/c = 0.7 and 28 days of curing

| Absorção água | Resistência a Compressão | Corrosão Acelerada | Avaliação final | |

| Peso | 0.20 | 0.20 | 0.60 | |

| CP II | 76.33 | 71.38 | 94.01 | 85.95 |

| CP III | 100.00 | 100.00 | 100.00 | 100.00 |

| CP IV | 86.72 | 64.03 | 91.84 | 85.25 |

Individually analyzing each test. it was found that the cement CPIII-40 stands out with respect to water absorption performing better as identified with w/c ratio equal to 0.4 with a cure time of 28 days. This result is due to the improvement of Portland cement composite microstructure caused by the extension of the curing period. In relation to the w/c ratio. it influences the amount of voids in mortar. that controls the porosity influencing the properties related to transport mechanisms in concrete (MENDES et al.. 2010).

Using Analytic Hierarchy Process (AHP). regarding the compressive strength it was confirmed which is expected: the compression strength tends to increase with decreasing the water/cement ratio (MEHTA e MONTEIRO. 2008).

It was noted that the CPIII-40 cement showed the highest compressive strength values because of the very high blast slag furnace quantity. Pereira (2011) showed that such cement has a greater fineness in relation to the other studied. which results in a higher reactivity of the cement.

Evaluating final results of accelerated corrosion tests is noticed again that in all matrices analyzed to choose the best cement type corresponded to CPIII-40. followed by the CPII-Z-32 and CPIV-32. This is in accordance with the statements of Tumidajski and Chan (1996). that concretes incorporating blast furnace slag. in partial replacement of Portland cement. are more efficient in preventing the penetration of chloride ions compared to concretes proportionated with ordinary cements.

Finally. it was found that for the samples made with CPIII-40. which was chosen in all matrices analyzed. water/cement ratio values resulted in relatively similar effects. and in favor of the concrete protection by chloride attack. For curing. prolonged time also improved the CPIII-40 in concrete protection.

This work was carried out taking as a database Pereira (2011) and it should be noted that the AHP application would be more complete if the database includes corrosion rate data and even another indication of rebar corrosion as occurrence of corrosion spots on the surface of the concrete. However. this study shows that AHP is an open system to include other parameters. which can enrich the result of choice.

5. CONCLUSIONS

Analytic Hierarchy Process (AHP) is a tool for decision making with advantages such as ease of application method and the possibility of modifying the factors in a choice by providing clear and objective results. The AHP allows the construction of hierarchies that consider multiple variables and acknowledge the comparison and evaluation criteria prioritizing the results.

The AHP application of this work helped to choose the type of cement capable to protecting the reinforced concrete by corrosion induced by chloride ion. also considering different water/cement ratio and curing times.

Evaluating the selection criteria through the water absorption tests. compressive strength and accelerated corrosion performed by Pereira (2011). it was found that the CPIII-40 cement showed the best performance in all combinations evaluated in this work. However. according to the curing time. the better performance of the chosen cement was 28 days. as expected due to the higher hydration degree.

It is important to note that the relative importance in the considered criteria were established by the authors and informed in Pereira (2011). And the intention of this work is to demonstrate the utility and application of the AHP. when it involves a decision-making among various possibilities and data combinations related to reinforced corrosion studies under chloride ion attack.

Thus. it can be concluded that the Analytic Hierarchy Process (AHP) was efficient for the systematization of choices and a new analysis of the results of Pereira (2011). The variables to be considered and their respective weights can be discussed in future work. aiming to improve the method developed in this work. One point of improvement to be suggested is considers the corrosion rate.

Referencias

AMERICAM SOCIETY FOR TESTING AND MATERIALS. ASTM C 876: Standard test method for half-cell potentials of uncoated reinforced steel in concrete - (1999 reaproved 2009). Annual Book of ASTM Standard, 2009. [ Links ]

______. ASTM E 1765: standard practice for applying analytical hierarchy process (AHP) to multiattribute decision analysis of investments related to buildings and buildings systems. 2011. [ Links ]

ASSOCIACAO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7215: Cemento Portland - determinacao da resistencia a compresión. Rio de Janeiro, 1997. [ Links ]

______. NBR 9778: Argamassa e concreto endurecidos - Determinacao da absorción de agua por inmersión, índice de vacíos e massa específica. Rio de Janeiro, 1987. [ Links ]

______. NBR 9779: Argamassa e concreto endurecidos - Determinacao da absorción de agua por capilaridade. Rio de Janeiro, 1995. [ Links ]

CALLISTER, W. D. Ciência e engenharia dos materiais: uma introducao. Trad. Sérgio Murilo Stamile Soares. 5. Ed. Rio de Janeiro: LTC, 2000. [ Links ]

CERVO, T. C. Influencia da finura e do teor de puzolana na penetracao de cloruros e na solución aquosa dos poros do concreto. Dissertacao de Mestrado em Engenharia Civil. Universidade Federal de Santa Maria, Rio Grande do Sul, 2001. [ Links ]

COSTA, H. G. Introducao ao Método de Análisis Jerárquica: análisis multicriterio no auxilia a decisión. 1 ed. Niterói, 2002. [ Links ]

DOTTO, J. MR. Corrosión do acero induzida por iones cloruro - uma análisis crítica das técnicas eletroquímicas aplicadas ao sistema acero-concreto como e sem puzolanaDissertacao (Mestrado em Engenharia Civil) - Universidade Federal do Rio Grande do Sul. Porto Alegre, 2006. [ Links ]

GASTALDINI, A. L. G.; ISAIA, G. C.; SACILOTO, A. P.; MISSAU, F.; HOPPE, T. F. Influence of curing time on the chloride penetration resistence of concrete containing Rice husk ash: A technical and economical feasibility study. Cement and Concrete Composites, v. 32, p. 783-793, 2010. [ Links ]

HELENE, P. Contribuicao ao estudo da corrosión em armaduras de concreto armado. Sao Paulo, 1993. Tese (Livre docência) - Escola Politécnica, Universidade de Sao Paulo. [ Links ]

HO, W. Integrated analytic hierarchy process and its applications - a literature review. European Journal of Operational Research, v. 186, p. 211-228. 2008. [ Links ]

HOPPE FILHO, J.; MEDEIROS, M. H. F.; PEREIRA, E.; HELENE, P.; ISAIA, G. C. High-Volume Fly Ash Concrete with and without Hydrated Lime: Chloride Diffusion Coefficient from Accelerated Test. Journal of Materials in Civil Engineering, v. 25, p. 411-418, 2013. [ Links ]

LAI, Y.; WANG, W.; WANG, H. AHP and simulation-based budget determination procedure for public builging construction projects. Automation in Construction, v. 17, n. 5, p. 623-632, 2008. [ Links ]

LISBOA, M. V.; WAISMAN, J. Multicriteria analysis in the selection of urban highway alignment alternatives with application of the Analytic Process. An environmentally sustainable approach. In: Urban transport, XII, Anais. 2006, Praga. [ Links ]

MARCHEZETTI, A. L; KAVISKI, E; BRAGA, M. C. B. Aplicación do método de AHP para a hierarquizacao das alternativas de tratamiento de residuos sólidos domiciliares. Ambiente Construído, v. 11, n. 2, p. 173-187, 2011. [ Links ]

MATTANA, A. J; MEDEIROS, M. H. F; SILVA, N. G; COSTA, M. R. M. M. Análisis Jerárquica para elección entre agregado natural ou areia de britagem de rocha para confeccao de argamassas de revestimento. Ambiente Construído, v. 12, p. 63-79, 2012. [ Links ]

MATHER, B. Concrete durability. Cement & Concrete Composites, v. 26, p. 3-4, 2004. [ Links ]

MEDEIROS, M. H. F. Contribuicao ao estudo da durabilidade de concretos com protección superficial frente a acao de iones cloruros. 2008. Tese (Doutorado em Engenharia de Construcción Civil e Urbana) - Escola Politécnica, Universidade de Sao Paulo, Sao Paulo, 2008. [ Links ]

MEDEIROS, M. H. F.; BALBINOT, G. B.; HELENE, P. . Inspecao em prédios no Rio de Janeiro: corrosión em pilares. Concreto & Contrucao, v. Ano 38, p. 58-66, 2010. [ Links ]

MEDEIROS, M. H. F.; KNUUTILA, M.; PEREIRA, E.; HELENE, P. Inspection of Buildings in Rio de Janeiro-Brazil: Proving the greater tendency of corrosión at the base of reinforced concrete columns using potential corrosión technique. American Journal of Engineering Research (AJER), v. 2, p. 102-112, 2013. [ Links ]

MEHTA, K.; MONTEIRO, P. J. M. Concreto: microestrutura, propiedads e materiais. 3. ed. Sao Paulo: IBRACON, 2008. [ Links ]

MENDES, M. V. A. da Silva; CASCUDO, O.; CARASEK, H.; FERREIRA, R. B. Evaluación das propiedads de transporte massa em concretos contendo adiciones minerais. In: CONGRESSO BRASILEIRO DO CONCRETO, 52, 2010, Fortaleza. Anais... Fortaleza: IBRACON, 2010. [ Links ]

MOTA, J. M. F.; BARBOSA, F. R.; COSTA E SILVA, A. J.; FRANCO, A. P. G.; CARVALHO, J. R. Corrosión de armadura em estruturas de concreto armado devido ao ataque de iones cloruro. 54º Congresso Brasileiro de Concreto. Anais... Maceió, 2012. [ Links ]

PAGE, C. L.; SHORT, N. R.; HOLDEN, W. R. The influence of different cements on chloride-induced corrosión of reinforcing steel. Cement and Concrete Research, v. 16, p.79-86, 1986. [ Links ]

PAN, N. Fuzzy AHP approach for selecting the suitable bridge construction method. Automation in Construction, v. 17, n. 8, p. 958-965, 2008. [ Links ]

PEREIRA, V. C. O. Estudo da influencia do tipo de cemento em relación a corrosión de armaduras sob acao de iones clorurosDissertacao (Mestrado em Engenharia - Construcción Civil), Universidade de Pernambuco - Escola Politécnica de Pernambuco. Recife, 2011. [ Links ]

PEREIRA, E; MEDEIROS, M. H. F; LEVY, S. M. Durabilidade de concretos com agregados reciclados: uma aplicación de análisis Jerárquica. Ambiente Construído, v. 12, n. 3, p. 125-134, 2012. [ Links ]

PEREIRA, E.; RESENDE, A.; MEDEIROS, M. H. F.; MENEGUETTI, L. C. Ensayo acelerado por cloruros: efeito da sílica ativa, relación agua/aglomerante e espessura de cobrimento do concreto. Revista IBRACON de Estruturas e Materiais v. 6, n. 4, p. 561-581, 2013. [ Links ]

PEREIRA, E.; MARTINS, L. A.; MEDEIROS, M. H. F.; COSTA, M. R. M. M. Análisis Jerárquica para a elección de argamassa colante aplicada no assentamento de piso sobre piso. Revista de Engenharia e Tecnologia, v. 6, p. 203-214, 2014. [ Links ]

ROCHA, F. C. Leituras de potencial de corrosión em estruturas de concreto armado: influencia da relación a/c, da temperatura, da contaminacao por cloruros, da espessura de cobrimento e do teor de humedad do concreto. Dissertacao (Mestrado em Engenharia de Construcción Civil) -Universidade Federal do Paraná. Curitiba, 2012. [ Links ]

SAATY, T. L. How to make a decision: the analytic hierarchy process. European Journal of Operational Research. Norte da Holanda, v. 48, p. 9-26. 1990. [ Links ]

SAKR, K. Effect of cement type on the corrosión of reinforcing steel bars exposed to acidic media using electrochemical techniques. Cement and Concrete Research, v. 35, p. 1820-1826, 2004. [ Links ]

SILVA, F. J. A.; SOUZA, R. O. AHP na selección de caminhoes coletores-compactadores de residues sólidos. Acta Scientiarum Technology, v. 33, n. 3, p. 259-264, 2011. [ Links ]

TESSARI, R. Estudo da capacidade de protección de alguns tipos de cementos nacionais, em relación a corrosión de armaduras sob acao de iones cloruroDissertacao (Mestrado em Engenharia Civil) - Universidade Federal do Rio Grande do Sul. Porto Alegre, 2001. [ Links ]

TUMIDAJSKI, P. J.; CHAN, G. W. Effect of sulfate and carbon dioxide on chloride diffusivity. Cementand Concrete Research v. 26, n. 4, p.551-556, may. 1996. [ Links ]

ZAYED, T; AMER, M; PAN, J. Assessing risk and uncertainty inherent in Chinese highway projects using AHP. International Journal of Project Management, v. 26, n. 4, p. 408-419, 2008. [ Links ]

Received: November 20, 2014; Accepted: June 12, 2015

texto en

texto en