1. INTRODUCTION

Despite the advances in technologyies in the construction industry, in many cases, there is a lack of there are still many quality poor-quality concrete structures. This fact may affect the performance and useful life of these constructions (Geiker, 2012). In this way, iIt is therefore necessary to understand the constructive failures in concrete structures and the the mechanisms that lead to the deterioration of the concrete these structures. With further the knowledge of the failures that occur in the concrete structures, it is necessary to proceed with technical interventions can be carried out that, aiming to improve their performance and the useful life of the structures.

There are cCurrently products on the market, there are products that help to solve the pathological manifestations of construction. However, the same material can be marketed in order to as a remedy for structural problems of with quite different properties. For concrete structures, if the properties of substrate and repair materials have different values, are incompatibleility and may occur. In this way, the repair can be compromised (Helene, 1992). In short, the incompatibility incompatibilities between the repair materials and the substrates can generate future problems with the repair service (Luković et al., 2012). In this way Therefore, one must it is necessary to understand the differences between polymer mortars in order to use them efficiently.

The contributions given to mortars by the addition of polymeric adhesives allow repairs to concrete structures to be more effective in their application. When polymer additives are added, the properties of adhesion, plasticity, cohesion, flexibility, impermeability, and durability are improved, and in this way, it becomes possible to perform several types of repair (Soufi et al., 2016).

Among the properties required for a mortar used for repairing concrete structures, adhesion is one of the most important. In most cases of rupture in repairs, most cases, the fracture is located in the transition zone between new and old materials (Ueda et al., 2011). In this way Therefore, the adhesion between the different cementitious materials can be considered to depend mainly on the rigidity, cleanliness, and roughness of the substrate (Espeche and León, 2011).

The verification of the adherence adhesion capacity between the materials can be carried out by indirect traction techniques where. In these situations, direct traction loads are not applied. However, the adhesion values are obtained by equations that relate items such as applied load, test body geometry, among and other factors. Tensile tests on diametral compression bending and traction are examples of tests that refer to indirect traction (Espeche and León, 2011).

The diametral compression tensile test is commonly used to determine the tensile strength of composite cement materials. This test, also known as the "Brazilian test,", has guidelines described by national standard NBR 7222 of 2011, and has been verified as being applicable to. Thus, in view of the conditions of the test, the applicability of this test was verified for the verification of adhesion between two different materials.

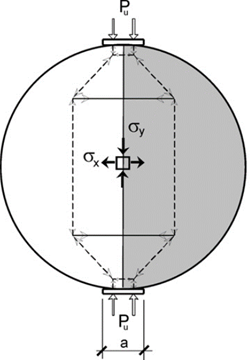

This same method was used for the analysis of binding between new materials and old materials, and a study for recovery of structures (Espeche and León, 2011). Figure 1 illustrates the assay performed. Pu represents the load applied linearly on the test body, and σx and σy represent the tensions on the horizontal (x) and vertical (y) axisaxes, respectively.

Figure 1 Representation of loading and stress distribution in the determination of traction by diametral compression.

Other studies using the same test method have been conducted to determine the adhesion of pavement repair materials (Alanazi et al., 2016). The same procedure was used by different authors to analyze the adhesion of a material composed of rubber (styrene-butadiene) (Sprinkel and Ozyildirim, 2000).

The operation of the test consists of the application of diametrically opposed loads and the verification of the traction in the same plane, as shown in Figure 1. In this way, tensions will occur in the plane of connection between the materials. Using these, it is possible to determine the bond strength between the parts.

As the repair usually deals with elements of different ages, it is necessary to evaluate the bonding tension between the materials (Espeche and León, 2011), and the quality of bonding can be classified according to five classes: excellent, very good, good, regular, and poor (Sprinkel and Ozyildirim, 2000). These bond quality levels are related to the bond strength between the materials, as shown in Table 1.

Table 1 Quality of the adhesion resistance between the repair and the substrate.

| Quality of adhesion | Adhesion strength (MPa) |

|---|---|

| Excellent | ≥ 2,1 |

| Very good | 1,7 - 2,1 |

| Good | 1,4 - 1,7 |

| Regular | 0,7 - 1,4 |

| Bad | 0 - 0,7 |

This work is based on the analysis of the properties of acrylic-based polymer mortars; styrene-butadiene (SBR), vinylic copolymer, and polyvinyl acetate (PVA). The polymers were added to the reference mortar, which was composed of one part of cement to three parts of sand. The analysis was based on its mechanical strength and adhesive strength, which were tested by diametral compression tensile tests, following the proposal of Espeche and León (2011), in a transition plane between the materials (concrete and polymer mortar).

The importance of this work is associated with the analysis of each polymer material and its efficiency. Through this work, it will be possible to perform the repair of concrete structures using only cement, sand, and a polymeric adhesive. In addition, their ability to perform repairs on different substrate properties will be analyzed based on a theoretical basis for guided repair materials, similar to the studies by Helene (1992).

2. MATERIALS AND EXPERIMENTAL PROGRAM

In order to verify the results and analyze the impact of the polymers on the mortars, a reference mortar was created. This material was composed of the same ratio of cement and sand (one part cement to three parts sand, by mass) used in the polymer mortars. However, the reference mortar did not contain any polymer additives. Industrial sand of fine particle size (<600 μm), Portland cement of type CP II Z 32, and water were used to create the mortar.

Three types of polymeric adhesives were used for the preparation of the repair mortars: vinylic copolymer, PVA, and SBR. Table 2 presents some properties of the adhesive materials used in this work.

Table 2 Properties of the polymeric adhesives used in the repair mortars.

| Basic composition | pH | Density (kg/l) |

|---|---|---|

| Vinylic copolymer | 4-5 | 1,02 |

| Polyvinyl acetate - PVA | 4-6 | 1,05 |

| Styrene-butadiene - SBR | 6-8 | 1,0 |

Source: Vedacit Impermeabilizantes® (2017); Sika ® (2015); TekBond® (2015).

The polymers studied were included in the blend together with the kneading water as indicated by the manufacturers. The volume ratios of polymer to water (polymer:water) used were 1:2 for vinylic copolymer, 1:3 for PVA, and 1:4 for SBR.

In order to obtain a mortar with thixotropic properties, sufficient kneading water was used only to allow the molding of beads by hand without any gloss on the surface, since gloss on the surface would indicate in principle excess water (Souza and Ripper, 1998).

In order to maintain the same thixotropic property, which was evaluated qualitatively, the proportion of cement and sand was maintained and the amount of kneading water of the mortars was varied. Thus, the water/cement mass ratios (total kneading water equal to the amount of water plus the amount of polymer) used were 0.52 for vinylic copolymer, 0.42 for PVA, and 0.38 for SBR.

The mortar characterization was performed by molding cylindrical specimens measuring 5 cm in diameter and 10 cm in height. These specimens were tested for compression and diametral compression traction. In addition to these mechanical properties, the bond strengths of these materials to concrete were verified through test bodies composed of concrete and mortar of 10 cm in diameter and 20 cm in height. In this way, diametral compression tensile tests of cylindrical test specimens composed of concrete and mortar were carried out, as shown in Figure 2. The guidelines of ABNT NBR 7222 of 2011 were followed to evaluate the adhesion between different materials, as used by Espeche and León (2011), Alanazi et al. (2016), and Radhakrishna et al. (2012).

Concrete specimen halves were initially molded. To obtain the substrate, a concrete trait that is common in construction sites was used, with an average resistance of approximately 25 MPa.

After 28 days’ minimum cure of the concrete, water saturation of the surface and filling of the cylindrical specimen (10 cm × 20 cm) with the repair material were performed. The filling was carried out with manual densification of the layers.

The adhesion between the parts of the specimen (Figure 2) was evaluated in two ways. The first method was to evaluate the adhesion of the new material to the old one only with the saturation of the bonding surface between the materials. The other method sought to evaluate the bond between the materials in the presence of an epoxy-based adhesion bridge. This application has the function of improving the adhesion between the concrete material, as well as the saturation of the surface with water.

The verification of the adherent strength was performed by means of diametrical compression (Figure 3- B), which was performed in diametrically opposite lines, in the specimen (Figure 3- A). By obtaining the breaking load, it was possible to calculate the bond strength between concrete and mortars by means of ABNT NBR 7222 of 2011.

Figure 3 (A) Test body used to determine the adhesion between the repair and the concrete; (B) Test to determine the adhesion between the repair and concrete by diametral compression.

For each mortar, four test specimens (5 cm × 10 cm) were tested for compressive strength, four (5 cm × 10 cm) for tensile strength, four (10 cm × 20 cm) for bond strength without bridge adhesion strength, and four (10 cm × 20 cm) for adherent bond strength.

The failure of the material was considered by the rupture in the plane of connection between the materials, which was subjected to a diametrically opposite loading, according to the guidelines of Norm NBR 7222 of 2011 that define diametral compression traction. The failure initially stabilizes the applied load and, subsequently, separates the repair materials and substrate. The loading application is automated, and it is interrupted when the material breaks. At this point, failure of the repair material is considered to have occurred.

3. RESULTS

The results obtained for mechanical resistances for the repair mortars and reference mortar are presented in Table 3. The results refer to the compressive and tensile strengths of the mortars and the adhesion strengths between the mortar and concrete.

Table 3 Mechanical resistance of repair and reference mortars.

| Mechanical properties | Reference | Vinylic

copolymer |

PVA | SBR | |

|---|---|---|---|---|---|

| Compressive strengtd |

Minimal resistance (MPa) | 17,55 | 16,99 | 12,22 | 15,08 |

| Maximum resistance (MPa) | 21,31 | 20,93 | 15,89 | 17,93 | |

| Average resistance (MPa) | 19,34 | 19,72 | 14,5 | 16,74 | |

| Standard deviation (MPa) | 1,55 | 1,86 | 1,98 | 1,48 | |

| Tensile strengtd |

Minimal resistance (MPa) | 1,90 | 1,66 | 1,50 | 2,27 |

| Maximum resistance (MPa) | 1,09 | 1,91 | 1,68 | 3,31 | |

| Average resistance (MPa) | 2,00 | 1,75 | 1,57 | 2,83 | |

| Standard deviation (MPa) | 0,09 | 0,11 | 0,09 | 0,43 | |

| Bond strengtd - Witdout adhesion bridge |

Minimal resistance (MPa) | 0,28 | 0,56 | 0,41 | 0,71 |

| Maximum resistance (MPa) | 0,77 | 0,68 | 0,78 | 0,90 | |

| Average resistance (MPa) | 0,50 | 0,61 | 0,65 | 0,80 | |

| Standard deviation (MPa) | 0,25 | 0,05 | 0,21 | 0,80 | |

| Bond strengtd - Witd adhesion bridge |

Minimal resistance (MPa) | 0,73 | 1,11 | 1,33 | 1,64 |

| Maximum resistance (MPa) | 1,22 | 1,60 | 1,59 | 2,09 | |

| Average resistance (MPa) | 1,04 | 1,38 | 1,44 | 1,91 | |

| Standard deviation (MPa) | 0,22 | 0,23 | 0,11 | 0,19 | |

| Note: For all assays, four (4) test bodies were used. | |||||

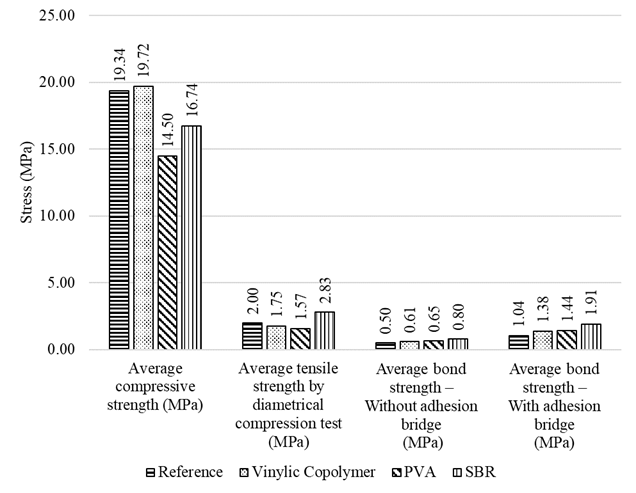

When analyzing the results presented in Table 3, it can be observed that the polymer mortars tested in this work present improvements over the reference mortar in some properties, while in other properties they show lower values than the reference mortar. The results are presented graphically in Figure 4.

The results obtained for compression show that the mortar modified with vinylic copolymer has a small increase in the resistance compared to the reference, as shown in Figure 4. Among the other polymeric materials, a reduction of the average resistance for the SBR-modified mortar is observed, as predicted in the literature (Ukrainczyk and Rogina, 2013). The lowest results for compressive strength were recorded for mortar composed of PVA.

For the diametral compression tensile strength, the results showed that the SBR-modified mortar has a higher tensile strength than the other materials tested. The other materials tested (mortars composed of vinylic copolymer and PVA) obtained lower results than those of the reference. An improvement of the repair material was therefore observed when using the SBR base polymeric adhesive.

The results of the verification of the adhesion strength between the mortar and the concrete, in cases with and without the presence of an adhesion bridge, are shown in Figure 4. From the results obtained (Figure 4) the presence of polymer components may contribute to the adhesion between different materials.

In the first case, without the adhesion bridge, the composite material with sbr presented better results. This shows that the presence of SBR base adhesives in mortars contributes to the adhesion of the repair to the substrate (Ukrainczyk and Rogina, 2013). The other materials were also improved in adherence, if compared to the reference, however, the results were lower than the SBR. In the first analysis, an adhesion obtained for the material composed of SBR is configured as regular, since it presents values higher than 0.7 MPa (Sprinkel and Ozyildirim, 2000).

When analyzing the results for the adhesion resistance between the repair and substrate in the presence of an adhesion bridge, it was observed that there is a contribution from the bridge. In general, when comparing the results for bridgeless and bridged adhesion, an increase of more than 100% in resistance in the presence of the adhesive material can be observed. These values show the influence of the adhesion bridge in repair situations.

The material that obtained the highest values was composed of SBR. In this evaluation, the lowest result was related to the reference material. It was noticed that the presence of polymers in the mortars contributes directly to the adhesion, with or without an adhesion bridge. “Very good” behavior was observed for the material composed of SBR, as it presents an adhesion strength value between 1.7 and 2.1 MPa (Sprinkel and Ozyildirim, 2000). The mortar composed of PVA presents "good" behavior, since its result is between 1.4 and 1.7 MPa. On the other hand, the reference mortar presents “regular” behavior, since its adherent strength is between 0.7 and 1.4 MPa.

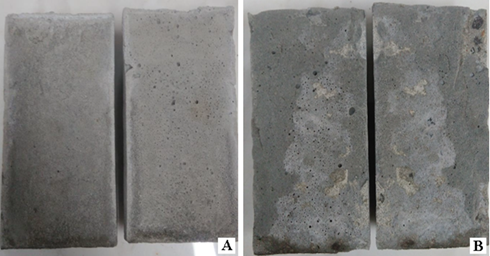

After verification of the rupture planes between the concrete and the repair material, as shown in Figure 5, it can be observed that the loading may have obeyed the plane of union between both materials.

Figure 5 (A) Plan of rupture of a test specimen tested in adhesion without an adhesion bridge; (B) Plan of rupture of a test specimen tested in adhesion with an adhesion bridge.

In the first situation, without the adhesion bridge (Figure 5- A), it was observed that the two halves separated perfectly. In other words, there was no presence of mortar in the concrete half or the presence of concrete in the middle of the mortar. This is an indication that the plane of rupture is more brittle than the resistances of the two materials. This assertion is corroborated by the values of the results, presented in Table 3. In other words, the properties of the polymeric materials do not confer great adhesion resistance between cementitious materials.

In cases where an epoxy-based adhesion bridge was used (Figure 5- B), it was observed that there was the presence of concrete parts next to half of the mortar and parts of the mortar next to the concrete half. This may indicate that the adhesion strength is improved by the adhesion bridges. It is possible to verify this numerically from the data in Table 3. It was observed that the failure occurs in part of the bonding material, with a perfect separation between the two materials, and in another part it was observed that one of the two bonded materials failed. It was considered that the same situation did not occur in the absence of an adhesion bridge. By observing the results, it was considered that the presence of the bridge contributed to the adherent properties between the materials.

4. CONCLUSIONS

From the results obtained in the laboratory and their respective analyses, it was concluded that the physical and mechanical properties of the mortars used in structural repairs can be improved by the presence of polymeric components. The following highlights are presented from the research carried out:

a). Vinylic copolymer: The mortar modified with vinylic copolymer showed an increase in the compressive strength, traction, and adhesion between the concrete and repair, relative to the reference;

b). PVA: The base repair material PVA showed an increase in its adhesion to the reference. However, the values of compression and traction were lower than those of the reference material. In the analysis of the results, it was possible to observe a relationship between the composite mortars composed of vinylic copolymer and PVA. Both are vinyl-based, however, the best results were recorded for the vinylic copolymer, with a small unfavorable difference in the adhesive capacity;

c). SBR: Among the materials tested, the mortar modified with SBR presented the best results, mainly with respect to the adhesion to the substrate. The compressive strength was lower than the reference. However, for the other analyzed properties, the material showed good behavior.

Regarding the adhesion of the tested materials, two analyses can be performed. In the first, which is related to the application of the repair material on a saturated surface, it was observed that there was an average improvement in the results of approximately 30% with respect to the reference mortar.

In the presence of the epoxy-based adhesion bridge, an improvement in adhesion strength values of at least 120% relative to the saturated surface was noted. From these results, it was observed that the use of the adhesion bridge allows the binding capacity between the materials to be considered from "good" to "very good". This shows that the presence of a bonding material between the repair and substrate is advisable in order to ensure an efficient adhesion interface.

nueva página del texto (beta)

nueva página del texto (beta)