1. Introduction

Nowadays, concrete is the modern world's most widely used building material. Estimates indicate that, by the year 2050, the consumption of Portland cement could increase up to 225% with respect to the current values, mainly due to the high demand of this binder from emerging countries, such as China, India, Brazil and Mexico (Garcés et al., 2012). According to the CANACEM (National Chamber of cement), in 2016, cement production was 40.6 million tons and the consumption was 40.1 million tons.

It is known that the world production of cement produces approximately 7% of the generation of carbon dioxide in the atmosphere (Mehta, 2001; Nath et al., 2011). Also, structures built with cement in corrosive environments begin to deteriorate after 20 to 30 years, although they have been designed for more than 50 years of useful life (Chandra et al., 2015). With the purpose of reducing the use of natural resources, energy and emissions of carbon dioxide, the development of ecological concretes is being researched that besides from being friendly to the environment, provide sustainability and durability for the long service life of structures (Madhavi et al., 2014; Mishra, 2017).

One of the options that is being considered to achieve this is the partial replacement of Portland cement (CP), in particular with materials such as natural pozzolans, silica fume, slag and fly ash (FA) (Al-Amoudi et al., 1996; Malhotra, 1990; Mehta, 2002; Garcés et al., 2012; Moffatt et al., 2017; Mishra, 2017; Saha, 2018).

FA is an industrial byproduct generated in large quantities around the world, almost 800 million tons per year (Heidrich et al., 2013; International Energy Agency Coal Industry Advisory Board, 2014), but a significant amount of this material (around 50%) is deposited in landfills, causing a serious environmental risk and decreasing the reactivity of the FA due to weathering conditions (Mishra, 2017).

Even though FA has been used as an additive in concrete for a while and there is extensive research based on its use as a cement replacement material in concrete, the level of replacement according to the available literature is still limited to a maximum of 35% of cement mass. The latter is based on the argument that higher replacement percentages of FA do not improve the strength characteristics in its natural form (Hemalatha et al., 2017). To improve properties, increasing the percentage of FA replacement, different approaches were explored. These were: reduction of the water/cementitious material ratio, replacement of Portland cement of high initial strength by ordinary Portland cement, replacement of a portion of FA by a more reactive pozzolan, such as silica fume or rice husk ash, incorporation of nanomaterials and accelerated curing (Yu et al., 2017). Chemical, mechanical and thermal methods, or a combination of these methods, have also been used with the aim of improving the reactivity of this disposal (Mucsi, 2016; Sahoo, 2016). Alkaline activation consists of a chemical process that allows the transformation of a material with a partially or fully amorphous structure into compact cementing compounds (Palomo et al., 1999). Mechanical activation is defined as activation using a grinding process or using sieving and separation by air, and thermal activation refers to slow or fast cooling producing changes in the vitreous and crystalline relationships (Hela et al., 2013; Mucsi, 2016). In addition to these methods, there is electrometagenesis, which consists of the activation of FA from the entry of ions in an alkaline solution by the application of an electric field through the hardened concrete. (Lizarazo et al., 2015). Up until now, the use of FA is considered an effective solution (Zobal et al., 2017).

Considering the background use of FA, positive effects on concrete properties, low cost and current availability of FA in Mexico (stored), this article focuses on determining durability properties, which were: quality concrete through ultrasonic pulse velocity (UPV), apparent electrical resistivity (ρ), rapid chloride permeability, mechanical resistance to compression and mixtures with FA with different contents of Portland cement (CPC). The tested cement widely used in construction in Mexico, and the Mexican FA subjected to a chemical activation process using chemicals in the dust and a grinding method (with the aim of improving its reactivity). Due to the existence of a confidentiality contract, the characterization of the evaluated mixtures cannot be disclosed yet.

2. Experimental procedure

2.1. Materials

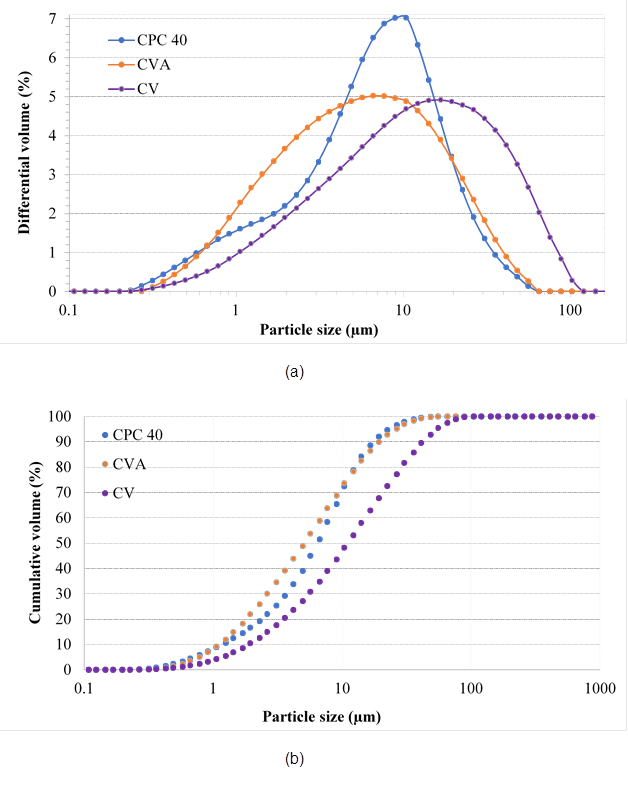

The raw materials used in this investigation were FA activated by the addition of chemicals from dust and grinding in a ball mill, limestone rock, and tap water. The Fraunhofer laser diffraction sizing distribution of the raw materials is shown in Figure 1. The suspension of particles was prepared in ethanol, used as a means of dispersing bath, and stirred ultrasonically for 5 mins. Portland cement (CPC) was used as received and FA was ground in a ring mill. As seen, 90% of CPC and activated fly ash (AFA) particles are less than 20 µm in size, whereas FA has a larger particle size when first received

Figure 1 Granulometry distribution by laser ray diffraction: a) particle distribution and b) particle size.

Table 1 shows characteristics of the aggregates used. These values were obtained according to the standards ASTM C127 and ASTM C128.

2.2. Preparation of test specimens

Five mixtures with different percentages of substitution of AFA (0, 30, 50, 65 and 75%) with respect to the weight of cement were prepared. The mixtures named, M1, M2, M3, M4, and M5, respectively, had a water/cement material ratio of 0.35. Additive thinning and water reducer were used to achieve this relationship. The proportions of the mixtures are presented in Table 2.

Table 2 Mixture design.

| Material | Units | M1 | M2 | M3 | M4 | M5 |

|---|---|---|---|---|---|---|

| Cement CPC 40 | kg/m3 | 450 | 315 | 225 | 157.5 | 112.5 |

| CVA | kg/m3 | 0 | 135 | 225 | 292.5 | 337.5 |

| Gravel | kg/m3 | 1006 | 1006 | 1006 | 1006 | 1006 |

| Sand | kg/m3 | 710 | 710 | 710 | 710 | 710 |

| Curing condition | °C | Curing room | Curing room | Curing room | Curing room | Curing room |

| w/cm | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 |

*cm: cement material (FA+CPC or CPC)

The five mixtures cast into 10 cm × 20 cm cylindrical molds, were manufactured according to the standard procedure NMX-C-159-16, hydrated with tap water and cured following the standard NMX-C-148-10. After the curing period (28 days), all samples were kept at room temperature and in a wet condition. This was achieved by spraying the samples with water daily and keeping them in plastic containers.

2.3. Durability tests

The measurements carried out were ultrasonic pulse velocity (UPV) (ASTM C-597-02), apparent electrical resistivity (ρ) (NMX-C514-16), rapid chloride permeability (ASTM C1202-10) and compressive strength (NMX C-083-02) at different ages over 122 days. It is necessary to mention that, in each of the age tests of UPV and electrical resistivity, fifteen cylinders of each mixture along with three cylinders were evaluated and tested for compressive strength and rapid chloride permeability testing (two samples required).

3. Results

Below, the results of each performed test are described.

3.1 UPV

Figure 2 presents the behavior of the ultrasonic pulse rate.

UPV values obtained in the five mixtures and for different age tests are reported in Figure 2. They were all above 4000 m/s, indicating that the quality in all cases was durable. However, in the mix with a higher content of AFA (M5), the values are lower compared to the rest of the mixtures. This behavior may be due to the lack of calcium hydroxide content in the mixture provided by the Portland cement.

The UPV results obtained in this research with AFA are like the results reported by Al-Amoudi who evaluated mixtures of concrete with and without FA (up to a 40%). The values are in the same order ~4000 m/s (Al-Amoudi et al., 1996).

3.2 Apparent electrical resistivity (ρ)

Figure 3 shows the apparent electrical resistivity of five mixtures with respect to time. Standard NMX-C-514 defines the apparent electrical resistivity as: “the resistivity measured on concrete not saturated with water”.

According to Figure 3, the mixtures with AFA content showed apparent electrical resistivity values higher than the mixture without AFA (M1), which reached a maximum of 18 kΩ.cm. After 122 days, M2 reached 110 kΩ.cm, while M3 and M4 reached values close to 140 kΩ.cm. In the case of M5, there was a decay of the resistivity measurement at day 122; it decreased from 116 kΩ.cm to 76 kΩ.cm. An increase in the chloride ion permeability value was observed on this date as shown in Figure 3. This behavior is thought to be due to two possible causes: 1) at this age the AFA reaction is more sensitive to the moisture content in the concrete matrix, slowing down its reaction or 2) the ash content in the mixture is excessive to maintain a constant reaction of the AFA. However, even with the decrease seen in M5, the electrical resistivity values of the AFA mixtures exceeded those achieved with the M1 mixture (0% FA). From the criteria established in the Mexican standard NMX C-514-16 and Figure 3 values, the mixture M1 showed a considerate interconnected porosity, while the mixtures M2, M3 and M4 indicated extremely low interconnected porosity and M5 had low interconnected porosity.

3.3 Rapid chloride permeability

Figure 4 shows the results of the rapid chloride permeability test for the five mixtures. The reported values correspond to ages of 28, 56, 90 and 122 days.

Considering the values of Figure 4 and the criteria established in standard ASTM C-1202-12, the results of the mixture without AFA (M1) initially showed values higher than 2500 C, but as the time increased it decreased to 1100 C after 122 days. With these values this mixture reached a level of penetrability of the chloride ion that was first moderate and then later low.

For mixtures with AFA content, the amount of charge that passed at all ages of evaluation was less than 500 C, which is a very low level of penetrability. The tendency of permeability with respect to time of M2, M3 and M4 was decreasing. The behavior was variable only in the case of M5, but it exceeded 500 C at no time.

Mixtures with AFA content showed lower chloride permeability compared to the mixture without AFA, these results coincide with investigations that report that the presence of FA promotes a low level of permeability to this ion (Malhotra, 1990; Nath et al., 2011; Saha, 2018; Mittal).

3.4 Compressive strength

Figure 5 shows the compressive strength and the standard deviation (σ in MPa) obtained from three tests of the mixtures at ages of 3, 7, 14, 28, 56 and 90 days, according to standard NMX-C-083-14.

According to Figure 5, the compressive strength at early ages (3 and 7 days) of the samples with AFA content was lower compared to the control samples (0% AFA), However, with the passage of time, a gradually increasing trend can be seen that is associated with the slow ash pozzolanic reaction (Nath and Sarker, 2011, Mishra, 2017, Saha, 2018).

The compressive strength values of M1 were developed after 56 days with a value of 60 MPa. For M2 and M3 after 14 days they had a compressive strength greater than 45 MPa, while M4 achieved this after 28 days. M5 showed increasing resistance values with time, however, at all ages, the compressive strength was lower than the other mixtures. It achieved a maximum value of 35 MPa. This result is mainly attributed to the lack of calcium hydroxide in the mixture (Saha, 2018), mainly contributed by the Portland cement, as in this case the content in the M5 mix was 25% with respect to the total weight of the cementitious material.

The compressive strength values were lower with higher AFA content in the mixture; however, at the age of 28 days, the M2, M3 and M4 mixtures exceeded 45 MPa, which is the compressive strength considered necessary for concrete to have high resistance according to the Manual of the DURAR network.

3.5 Apparent electrical resistivity vs. compressive strength

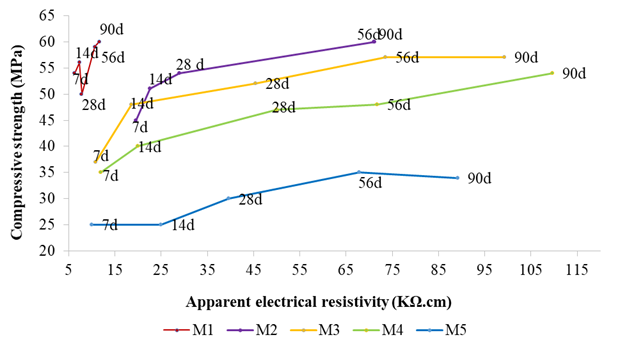

Figure 6 shows the electrical resistivity vs. the compressive strength for the five mixtures after 7, 14, 28, 56 and 90 days.

Figure 6 Apparent electrical resistivity vs. compressive strength for mixtures M1, M2, M3, M4 and M5 obtained at 7, 14, 28, 56 and 90 days.

According to Figure 6, M1 showed an upward trend for the apparent electrical resistivity with respect to time. The initial value (7 days) was 6 kΩ.cm and the end value (90 days) was 12 kΩ.cm. In terms of compressive strength, the initial value was 54 MPa and the final value was 60 MPa. In this case, even though there was an increase in both parameters with respect to time, it was not as considerable as that observed in the mixtures with AFA content (M2, M3, M4 and M5), where it was evident that the apparent electrical resistivity and the compressive strength increased. This progressive behavior, with mixtures containing FA, is attributed to the benefit provided by FA in the compactness of the concrete with respect to time.

In all of the mixtures, it was determined that the evolution of the resistivity is parallel to that of the resistance. This behavior was also reported by Andrade (Andrade and D'Andrea, 2011).

Considering that the compressive strength and electrical resistivity required for a durable concrete must be at least 45 MPa and 50 kΩ.cm, respectively, the percentages of AFA that met this requirement were 30%, 50% and 65%.

3.6 UPV vs. compressive strength

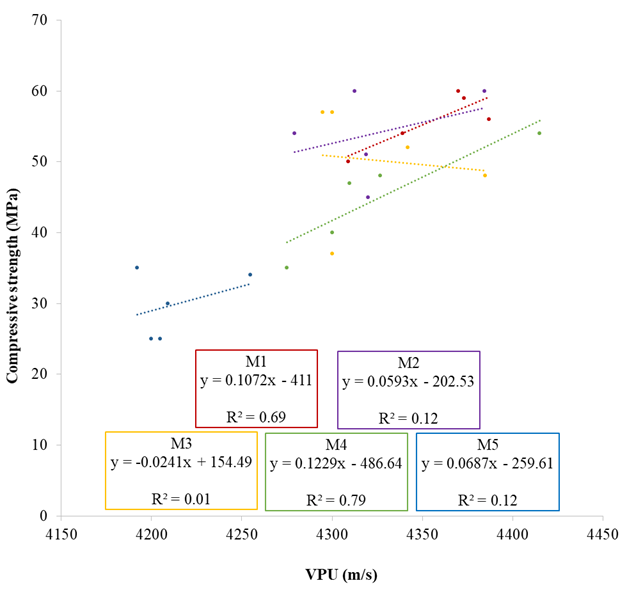

Figure 7 shows the compactness of concrete (UPV) vs. the compressive strength for the five mixtures after 7, 14, 28, 56 and 90 days.

Figure 7 UPV vs compressive strength for mixtures M1, M2, M3, M4 and M5 obtained at 7, 14, 28, 56 and 90 days.

According to Figure 7, it can be observed that M1 and M2 are higher than 4275 m/s and 45 MP at all ages and evaluated values. For the cases of M3 and M4, at all ages, the UPV values were higher than 4275 m/s, but the compressive strength at 7 days was lower than 45 MPa. This value increased with time. Only for M5 the values of compressive strength and UPV were lower than those of the other mixtures. This behavior is attributed to the high content of FA (75%) and low content of calcium hydroxide (25% in CPC 40). From these results it is observed that for UPV values less than 4250 m/s the compressive strength values obtained were less than 35 MPa (M5), and when the UPV values exceeded 4250 m/s the compressive strength values were greater than 35 MPa. However, the R2 values indicate that the UPV and compressive strength are not proportional, and therefore, it is necessary to evaluate each parameter independently.

3.7 Apparent electrical resistivity vs. rapid chloride permeability

Figure 8 shows that the apparent electrical resistivity has a correlation with rapid chloride permeability. It was noted that greater electrical resistivity permeability level was lower. Mixtures with AFA content exceeded the values of electrical resistivity obtained with M1 (no AFA content) and as a result the level of permeability was lower. Concrete resistivity increases with time due to refinement of the pore structure (Andrade et al., 2009). The presence of FA favors a pore structure causing lower permeability.

4. Conclusions

The use of AFA as a replacement material for Portland cement (CPC 40) in concrete mixtures improves apparent electrical resistivity, and therefore, the transport of aggressive agents is much lower than that in mixtures without AFA.

The level of chloride permeability in the concrete mixtures with AFA contents was very low. This means that when the FA is subjected to a chemical and mechanical treatment it is favorable to reach materials that are not very permeable to this ion, which benefits its durability.

The behavior of the compressive strength of the mixtures with 30%, 50% and 65% AFA after 28 days was greater than 45 MPa. This points to the possibility of sustainably manufacturing concretes for the construction sector that do not require high resistance at an early age.

The electrochemical behavior of the steel reinforcement embedded in the above mixtures, the resistance to sulfates and the characterization of the reaction products are currently being studied. The results will be reported in a future publication.

nueva página del texto (beta)

nueva página del texto (beta)