1. INTRODUCTION

In recent years, motivated by the increase in deterioration cases of reinforced concrete structures, the study of cementitious materials durability became focus of several researches.

Mineral additions use and their benefits to concrete, among them: better resistance to thermal cracking due to low hydration heat, increase of mechanical strength and reduction of permeability due to pore refinement and strengthening of transition zone, is a consensus in literature (Mehta; Monteiro, 2014).

Silica fume is a mineral addition classified as super pozzolana and due to its particles being finer than cement particles, with average diameter between 0.1 and 0.2 μm, it also considered a filler (Dal Molin, 2011).

At nanotechnology era, silica nanoparticles have been incorporated in cementitious materials. Li et al. (2017a) explain that, because their granulometry is lower than silica fume, nanosilica has a larger specific surface, which potentiates its pozzolanic effect. Authors also comment that, if used together, the synergistic effects of nanosilica and silica fume can make them even more effective in filling cementitious matrix voids and in microstructure densification.

Silica fume has already been established as an effective mineral addition in improving cementitious materials properties. However, nanosilica has still been subject of recent research that aims to study its effects on concrete properties, both in fresh and hardened state, in addition to durability parameters against different aggressive agents (Berra et al., 2012; Lim; Mondal, 2015; Ganesh et al., 2016; Ghafoori; Batilov; Najimi, 2016; Joshaghani; Moeini, 2017; Li et al., 2017a; Li et al., 2017b).

Among these different aggressive agents present in environment are chloride ions and their ability to initiate reinforcement corrosion, even when the solution contained in concrete pores has high pH. In addition, after their reaction with steel, chloride ions are not fixed and are available to continue the reaction (Silva, 2006). These peculiarities make chloride’s attack one of the main mechanisms of concrete structures degradation.

Therefore, this paper aims to evaluate the influence of nanosilica addition, as well as its combined effect with silica fume, on mechanical and physical properties and on durability parameters of concrete subjected to chlorides attack.

2. MATERIALS AND METHOD

1.1. Materials

For this research, following materials were used: Portland cement, fine and coarse aggregates, nanosilica, silica fume and superplasticizer additive.

An early high strength cement (CPV ARI) was used. Results of physical and chemical characterization are presented in Table 1.

Table 1 Chemical and physical properties of CPV ARI.

| Chemical properties | Results (%) | Physical properties | Results | |

|---|---|---|---|---|

| SiO2 | 19.17 | Density (g/cm³) | 3.12 | |

| Al2O3 | 5.03 | Initial setting time (min) | 135 | |

| Fe2O3 | 3.21 | Final setting time (min) | 210 | |

| CaO | 63.97 | Normal consistency paste (%) | 31.5 | |

| MgO | 0.61 | Fineness | Retained #200 (%) | 0.1 |

| Na2O | 0.06 | Blaine (m²/kg) | 473 | |

| K2O | 0.61 | Compressive strength (MPa) |

1 day | 27.5 |

| SO3 | 2.84 | 3 days | 42.0 | |

| Insoluble residue | 0.85 | 7 days | 48.7 | |

| Loss on ignition | 3.79 | 28 days | 52.2 | |

Physical characterization of fine and coarse aggregates is shown in Table 2 and granulometric distribution curves, obtained based on NBR NM 248 (ABNT, 2003), are presented in Figures 1 and 2, respectively.

Table 2 Physical characterization of fine and coarse aggregates.

| Parameters | Methodology | Fine aggregate | Coarse aggregate |

|---|---|---|---|

| Density (g/cm³) | NBR NM

52 NBR NM 53 |

2.64 | 2.77 |

| Dry unit weight (kg/m³) | NBR NM 45 | 1505 | 1422 |

| Dry-rodded unit weight (kg/m³) | NBR NM 45 | 1704 | 1568 |

| Water absorption (%) | NBR NM

30 NBR NM 53 |

0.34 | 2.26 |

| Powder material (%) | NBR NM 46 | 1.33 | 1.00 |

Fine aggregate had fineness modulus equal to 1.33 and maximum characteristic size equal to 0.6 mm. Although fine aggregate has a particle size distribution outside the usable zone established by NBR 7211 (ABNT, 2009), the same standard allows its use, whereas previous dosage studies prove its applicability. Therefore, and because it is a material commercialized in the region of study development, its use was maintained.

A nanosilica dispersed in a polycarboxylate superplasticizer liquid additive was used and the recommended content ranges from 0.5 to 3.0% relative to binder mass. Their characteristics are presented in Table 3. Table 4 shows physical and chemical characteristics of silica fume.

Table 3 Nanosilica characterization.

| Product | Nanosilica |

|---|---|

| Aspect | Homogeneous liquid |

| Density (g/cm³) | 1.06 |

| Solid content (%) | 31.5 |

| pH | 2.6 |

| Water-soluble chlorides (%) | ≤ 0.15 |

From: Silicon Industry and Commerce of Chemical Products LTDA.

Table 4 Physical and chemical characterization of silica fume.

| Physical parameters | Chemical parameters | ||

|---|---|---|---|

| Density (g/cm³) | 2.10 | Loss on ignition (%) | 3.7 |

| Na2O (%) | 0.7 | ||

| Specific surface (m²/kg) | 20000 | SiO2 (%) | 93.0 |

| Na2O (%) | 0.2 | ||

| Humidity (%) | 0.1 | Fe2O3 (%) | 0.5 |

| CaO (%) | 0.5 | ||

| Retained 45 mm (# 325) (%) | 3.7 | MgO (%) | 0.4 |

| Al2O3 (%) | 0.2 | ||

| K2O | 0.9 | ||

From: Dow Corning Silicon of Brazil.

In reference concrete, without silica fume and nanosilica incorporation, was used a superplasticizer additive (SP) based on polycarboxylic ether, MasterGlenium® Sky 150, which specifications are presented in Table 5.

1.2. Concrete mix proportioning

Nanosilica influence was studied on 1:1.6:1.6 concrete (cement: fine aggregate: coarse aggregate) and water/binder ratio (w/b) equal to 0.4.

As already mentioned, the nanosilica used in this work is dispersed in superplasticizer additive, which limited the contents to be used. As concretes workability, obtained according to NBR 13276 (ABNT, 2016), increase with increasing nanosilica content, the limits (0.5% to 3.0%) recommended were not possible to being explored. SP additive used in reference concrete also has their content defined based on mixture workability.

Therefore, nanosilica contents between 0.1 and 0.7%, isolated and with silica fume, were added to concrete as a partial cement replacement (10% in volume).

Concretes were identified by a C-N-S type nomenclature, where N and S represent nanosilica and silica fume contents used, respectively and reference concrete is identified as REF. Concretes compositions and their flow spread are shown in Table 6.

Table 6 Proportion of materials for concretes mixtures.

| Concrete | Materials (kg/m³) | Flow spread (mm) |

||||||

|---|---|---|---|---|---|---|---|---|

| Cement | SF | FA | CA | NS | SP | Water | ||

| C-0.1-0 | 524.90 | - | 839.84 | 839.84 | 0.52 | - | 209.96 | 180 |

| C-0.3-0 | 524.38 | - | 839.00 | 839.00 | 1.57 | - | 209.75 | 240 |

| C-0.5-0 | 523.86 | - | 838.18 | 838.18 | 2.62 | - | 209.54 | 285 |

| C-0.5-10 | 474.76 | 35.51 | 844.03 | 844.03 | 2.55 | - | 204.11 | 220 |

| C-0.7-10 | 474.31 | 35.47 | 843.21 | 843.21 | 3.57 | - | 203.91 | 250 |

| REF | 524.39 | - | 839.02 | 839.02 | - | 1.57 | 209.75 | 240 |

Legend: SF = silica fume; FA = fine aggregate; CA = coarse aggregate; NS = nanosilica.

Total mixing time of materials was 7 minutes, according to following order of placement: fine aggregate, 90% water, cement, additive SP, 10% water and coarse aggregate. In concrete containing silica fume, this material was added to mixture with cement.

After mixing, cylindrical specimens of 50 mm diameter x 100 mm in length were molded. After 24 h, specimens were demoulded and taken to humid chamber, where they remained until tests date.

1.3. Tests

The nanosilica and silica fume influence was evaluated in mechanical and physical properties of concretes, by means of mechanical resistance and water absorption by capillarity tests, and their durability against the chloride attack.

1.3.1. Mechanical strength

Mechanical strength was evaluated by means of compressive strength test at the age of 1, 7 and 28 days (ABNT NBR 5739, 2007) and tensile strength by diametrical compression at the age of 28 days (ABNT NBR 7222, 2011).

1.3.2. Water absorption by capillarity

Water absorption by capillarity test was performed based on NBR 9779 (ABNT, 2012).

After 28 days of curing, concretes were dried at 105 ± 5 ° C until reaching constant mass and then dry mass was determined at 23 ± 2 ° C. Specimens were placed on water above metal supports, to allow water contact with the specimen’s base, avoiding contact with other surfaces. The test lasted for 72 hours and the specimens were weighing at 3h, 6h, 24h, 48h and 72h after test beginning. After last weighing, specimens were broken to visualize maximum capillary rise reached by water.

1.3.3. Chloride ions penetration

The deep of chloride ions penetration was determined by drying and wetting cycles in sodium chloride (NaCl) solution.

After 28 days of curing, concretes were left in a laboratory environment for 4-day drying and then immersed up to half the height in the NaCl solution (3.5%) for 3 days. After 3 days, specimens were removed from solution and the cycle was started again, which were repeated for 16 weeks.

After 8 and 16 weeks, specimens were broken and a silver nitrate solution (0.1 M) was sprayed onto fractured surface. In free chlorides presence, silver nitrate reacts and results in silver chloride (light color), and in absence, it generates silver oxide (dark color). The contrasting colors allow the verification of the depth of chloride ions penetration in concrete to be verified.

3. RESULTS AND DISCUSSION

3.1 Mechanical strength

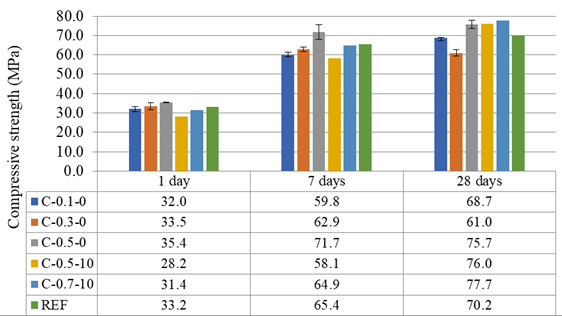

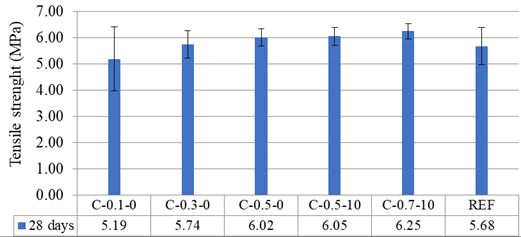

The mean values of results obtained from compressive strength at the ages of 1, 7 and 28 days and 28-day tensile strength by diametrical compression tests are presented in Figures 3 and 4, respectively.

Results indicated that 0.5% nanosilica addition to concretes (C-0.5-0) induce a 9.6% and 7.1% increase in 7-day and 28-day compressive strength compared to reference concrete (REF), respectively.

When combining nanosilica with silica fume, it is noticed that in early ages REF reached a higher compressive strength. However, at 28 days, the concretes C-0.5-10 and C-0.7-10 reached 76.0 MPa and 77.7 MPa, respectively, while REF reached 70.2 MPa. The greatest resistance gain at 28 days, and even at 90 days, was also observed by other researchers (Senff et al., 2010; Joshagani; Moeini, 2017).

Evidences of a synergistic effect between these additions was not observed, since when adding silica in the mixture, for the same content of nanosilica (C-0.5-0 and C-0.5-10) there were no compressive strength gains.

Differently from that observed by Li et al. (2017a), who found that addition of 2% powder nanosilica caused a 17% increase in 28-day compressive strength, whereas at 10% silica fume the increase was 11%. By combining two additions, 2% nanosilica + 10% silica fume, the increase was 48%, evidencing the existence of a synergistic effect between the additions.

Regarding tensile strength by diametrical compression (Figure 4), results indicated that additions use did not induce significant improvements, especially when considering the standard deviations. However, Ganesh et al. (2016) observed gains of 17% and 24% in 28-day tensile strength of concrete, incorporating 1% and 2% nanosilica solution, respectively.

It should be emphasized that the nanosilica used in this work is dispersed in superplasticizer and it makes the study of its incorporating at higher levels difficult, including the recommended levels. Moreover, the real content of silica present in material is not known, making it impossible to determine its percentage in relation to binder.

3.2 Water absorption by capillarity

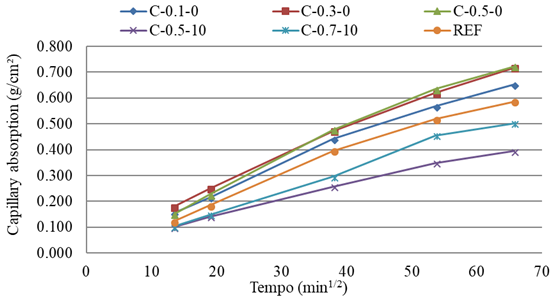

The results obtained in water absorption by capillarity test made possible to plot curves of capillary absorption versus square root of time for each studied concrete, during 72 hours of test (Figure 5).

Note that isolated nanosilica addition in the analyzed contents did not improve the water absorption by capillarity, since C-0.1-0, C-0.3-0 and C-0.5-0 presented higher capillary absorption (between 0.652 g/cm² and 0.722 g/cm²) than the REF (0.587 g/cm2). However, by raising the nanosilica content to 0.7% and adding silica fume (C-0.7-10), it was possible to reduce capillary absorption to 0.395 g/cm².

These results indicate that silica fume, with its filer and pozzolanic effects, was able to refine cementitious matrix microstructure. On the other hand, the nanosilica dispersed in superplasticizer does not have physical and chemical effects expected.

Other researchers studied the nanosilica effects on physical properties of cementitious materials and obtained positive results with reduction of sorptivity, absorption and voids index (Li et al., 2017b, Ganesh et al. 20116, Joshaghani and Moeini, 2017).

Should be commented that in the cited studies, the nanosilica were in powder or solution form. Therefore, it is possible that the dispersion of nanosilica in superplasticizer additive impaired the positive results in this work.

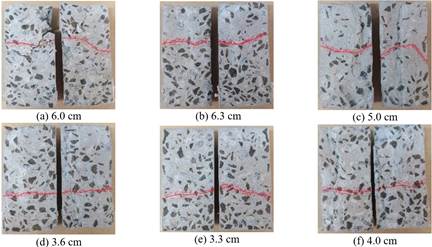

Figure 6 shows maximum capillary rises observed in concretes after 72 hours of test. It was observed that the concretes that had lower capillary absorption index (C-0.5-10 and C-0.7-10) also presented lower ascending height, corroborating the assertion that the silica fume was efficient in microstructure matrix refinement, unlike to concretes with nanosilica only (C-0.1-0, C-0.3-0 and C-0.5-0), which presented a maximum capillary rise higher than the REF.

Figure 6 Fractured specimens after water absorption by capillarity test: a) C-0.1-0; b) C-0.3-0; c) C-0.5-0; d) C-0.5-10; e) C-0.7-10 e f) REF.

Besides filler effect, responsible for filling voids between cement grains and aggregates, the pozzolanic effect of silica fume also contributes to microstructure densification, due to additional C-S-H formation.

3.3 Chloride ions penetration

The depth of chloride penetration in concretes was determined after 8 and 16 weekly cycles of drying and wetting in NaCl solution. Results are shown in Table 7 and the specimens submitted to the colorimetric test are shown in Figures 7 and 8.

Table 7 Depth of chloride ions penetration

| Chloride ions depth (mm) | ||

|---|---|---|

| Concrete | After 8 weeks | After 16 weeks |

| C-0.1-0 | 9.4 | 11.7 |

| C-0.3-0 | 7.6 | 11.4 |

| C-0.5-0 | 8.6 | 12.3 |

| C-0.5-10 | 5.4 | 6.4 |

| C-0.7-10 | 5.6 | 5.1 |

| REF | 8.3 | 8.0 |

Figure 7 Fractured specimens after colorimetric test - 8 weeks: a) C-0.1-0; b) C-0.3-0; c) C-0.5-0; d) C-0.5-10; e) C-0.7-10; f) REF.

Figure 8 Fractured specimens after colorimetric test - 16 weeks: a) C-0.1-0; b) C-0.3-0; c) C-0.5-0; d) C-0.5-10; e) C-0.7-10; f) REF.

Overall, nanosilica addition did not prevent chlorides penetration into concrete. After 8 weeks, the depth of penetration on C-0.1-0, C-0.3-0 and C-0.5-0 concretes were similar to reference concrete (REF). Already after 16 weeks, REF presented a lower value than those containing additions.

On the other hand, concretes with combined addition of nanosilica and silica fume presented reduction in depth of penetration. The values obtained after 16 weeks for concretes C-0.5-10 and C-0.7-10 were 1.6 mm and 2.9 mm smaller than REF, respectively. These results were expected since they were the same concretes that obtained lower capillary absorption index, as discussed previously.

Silva (2006) realized the same tests on high performance concretes with 5 and 10% silica fume, and after 16 cycles drying and wetting cycles, obtained a reduction in the depth of penetration of 1.9 mm and 2.7 mm, respectively, compared to the reference concrete, which had a penetration front of 5.7 mm.

Regarding the nanosilica addition, although the present work has not obtained satisfactory results, some studies indicate that 3% and 6% colloidal nanosilica addition in mortars could reduce 70% and 77% 28-day chlorides migration, respectively, in comparison to reference mortars (Joshaghani; Moeini, 2017).

Likewise, Ganesh et al. (2016) studied the nanosilica solution on concrete’s durability, by means of chloride migration test. The authors observed that, at 28 days, 2% nanosilica addition increased the concrete resistance to aggressive ions penetration. These positive results were attributed to filler effect of nanosilica and its ability to fill the voids present in concrete, thus reducing chlorides penetration.

4. CONCLUSIONS

With obtained results, it was concluded that the addition of nanosilica dispersed in superplasticizer, in contents of 0.1% to 0.5%, did not give improvements to concrete as regards mechanical and physical properties, analyzed compressive strength, tensile strength by diametrical compression and water absorption by capillarity tests. Likewise, nanosilica did not reduce the depth of chloride penetration compared to reference concrete.

However, when used in contents of 0.5% and 0.7%, together with 10% silica fume, improvements were observed in both properties, increasing the mechanical resistance and reducing the water absorption by capillarity, besides reduction in depth of chloride penetration, when compared to reference concrete.

It should be emphasized that as nanosilica is dispersed in superplasticizer additive, it was not possible to evaluate other contents within the limits recommended, since the added content increasing leads to the workability increase, being able to culminate in loss of cohesion and exudation of the mixtures.

nueva página del texto (beta)

nueva página del texto (beta)