Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista ALCONPAT

versión On-line ISSN 2007-6835

Rev. ALCONPAT vol.7 no.3 Mérida sep./dic. 2017

https://doi.org/10.21041/ra.v7i3.159

Applied research

Proposed Reference Values for the Diagonal Compressive Strength and Compressive Strength of Masonry Design in Guerrero State, Mexico

1 Facultad de Ingeniería-Universidad Autónoma de Guerrero, Chilpancingo, Cuerpo Académico Riesgos Naturales y Geotecnología-UAGRO-CA-93, México.

2 Facultad de Ingeniería-Universidad Autónoma de Guerrero, Chilpancingo, Cuerpo Académico Calidad de los Materiales de Construcción- UAGRO-CA-107, México.

3 Laboratoire de Modélisation et Simulation Multi-Échelle (MSME)-UMR8208 CNRS, Université Paris-Est, Cité Descartes, France.

In this study, reference values for the diagonal compressive strength (DCS) and compressive strength (CS) of masonry designs were obtained for Guerrero State, Mexico. The results of masonry testing programs during the last 16 years were studied using a statistical analysis. DCS values of 0.45 MPa for solid clay brick masonry and 0.20 MPa for hollow concrete block masonry, using type I or II mortars, were calculated. In solid concrete block masonry with type I mortar, the DCS was 0.45 MPa. Additionally, for masonry elaborated with any type of masonry piece and mortar (I or II), the CS had a value of 1.9 MPa. These calculated values can be used for both masonry design and the revision of masonry buildings.

Keywords: design resistance; masonry constructions; normativity; seismic risk; Guerrero

El objetivo del presente artículo es proponer valores de resistencia de diseño a compresión diagonal y compresión de la mampostería en Guerrero. Para esto se normalizó la información histórica experimental de 16 años. Considerando las características de los datos se evaluaron los resultados mediante comparación de valores y análisis de coeficientes de variación. Del primer parámetro se propuso 0.45 MPa y 0.20 MPa en mampostería de tabique recocido y bloques huecos pegada con morteros tipos I y II; valor sugerido es 1.9 MPa para todas la piezas y morteros. Los resultados servirán como una guía de diseño y revisión en construcciones de mampostería.

Palabras clave: resistencia de diseño; construcciones de mampostería; normatividad; riesgo sísmico; Guerrero

O objetivo deste artigo é propor valores de resistência ao projeto à compressão diagonal e compressão da alvenaria no Estado de Guerrero, México. Para isso, a informação histórica experimental de 16 anos foi normalizada. Considerando as características dos dados, os resultados foram avaliados por comparação de valores e análise de coeficientes de variação. Do primeiro parâmetro, foram propostos 0,45 MPa e 0,20 MPa em alvenaria maciça recozida e blocos ocos presos com argamassas tipo I e II; Na alvenaria de partição e argamassa tipo I, foi proposto 0,45 MPa. Em relação ao segundo parâmetro, o valor sugerido é de 1,9 MPa para todas as peças e argamassas. Os resultados servirão como um guia de projeto e revisão em construções de alvenaria.

Palavras-chave: resistência ao projeto; construções de alvenaria; normatividade; risco sísmico; Guerreiro

1. INTRODUCTION

Masonry is composed of solid or hollow (concrete or clay) units bonded with mortar made from fine aggregate, cement, and occasionally lime. It may also include vertical and horizontal reinforcements, which are vertical and horizontal, and confining elements made of small cross-section reinforced concrete. In its various forms, this system is one of the most used in the construction of housing and low-rise buildings (Tomazevic, 2006).

In Mexico, masonry buildings are often damaged by earthquakes. For example, damage has been recorded from the earthquakes in Manzanillo in 1995 (Juárez et al., 1997), in Caleta de Campos in 1997 (Rodríguez et al., 1998), in Tehuacán and Oaxaca in 1999 (Alcocer et al., 2002, Alcocer et al., 1999) and in Tecomán in 2003 (Alcocer et al., 2003). Recently, the earthquake of April 4, 2010 with M = 7.2 and an epicenter near Mexicali, Baja California caused the shear failure of the short span walls making up the perimeter of the ISSSTECALI Hospital (Figure 1a).

Figure 1 Masonry Walls Damage in Mexicali Earthquake, Baja California (Martínez and Martínez, 2010): a) Short Perimeter Walls, b) Housing-building Wall

The houses also showed substantial damage, especially in the transverse direction, where there is less wall length in the architectural design. Figure 1b shows the shear failure in walls made with hollow concrete blocks (Rangel et al., 2011; Martínez and Martínez, 2010).

Some masonry constructions in Guerrero State were affected by two earthquakes that occurred in the last six years. The first occurred in 2011 with M = 6.5 and an epicenter in the mountainous area of Sierra Madre del Sur, 62 km from the city of Chilpancingo. This earthquake damaged both historic buildings and several more recent buildings located in the city, as shown in Figure 2a, (Arroyo-Matus et al., 2014). The second earthquake occurred in August, 2013 with M = 6.0 and an epicenter east of the city of Acapulco. Although no damage was reported to houses or buildings, there was non-structural damage to city hospitals. Figure 2b shows the diagonal stress failure of masonry dividing walls at the Donato G. Alarcón Hospital (Sánchez-Tizapa, 2013).

Figure 2 Masonry Walls Damage: a) In Chilpancingo, Gro. (Arroyo-Matus et al., 2014), b) At Donato G. Alarcón Hospital in Acapulco, Gro. (Sánchez-Tizapa, 2013)

Furthermore, considering that masonry is a combination of various materials, its failure depends on several factors:

a) Presence or absence of reinforcement (horizontal and vertical steel, confining elements)

b) Aspect ratio of the walls

c) Mechanical, geometric, and physical characteristics of the units, including their roughness

d) Type and magnitude of the loads

e) Physical-mechanical characteristics of the mortar

f) Relationship between the mechanical characteristics of the mortar and the units

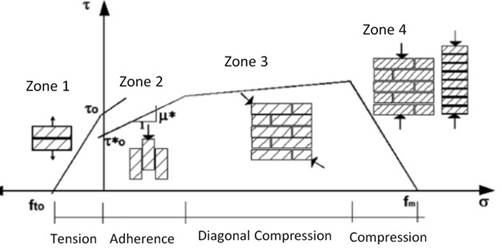

g) Level of saturation of the units at the time of bonding

Under these scenarios, masonry failures occur due to stress, poor adhesion of the joint, diagonal tension stress (unit and/or mortar cracking, separation of units) and compression. Figure 3 shows the envelope curve of the masonry capacity (Mann and Muller, 1982; Crisafulli, 1997; Flores et al., 2013). To obtain useful values from this curve, at least four types of tests need to be conducted, of which three are proposed by the Mexican building code: adherence-shear (Zone 2), diagonal compression (Zone 3) and compression (Zone 4), (NTCDCM, 2004; NMX-C-082-ONNCCE-2013, 2013; NMX-C-464-ONNCCE-2010, 2010).

Additionally, Guerrero State has a complex problem: there is a high seismic risk due to its geographical location, but the most important properties for masonry design are unknown. The diagonal and normal compressive strength (Zones 3 and 4 inFigure 3) are the most important variables in typical masonry design. Due to a lack of knowledge and/or a lack of local values, designers use complementary technical regulations from Mexico City (NTCDCM, 2004), which could be different from the actual values (Flores et al., 2013). Additionally, these regulations specify a maximum diagonal compressive strength of 0.34 MPa, which is inadequate given the demands of high-rise design defined in local regulations, preventing the design of buildings higher than three stories.

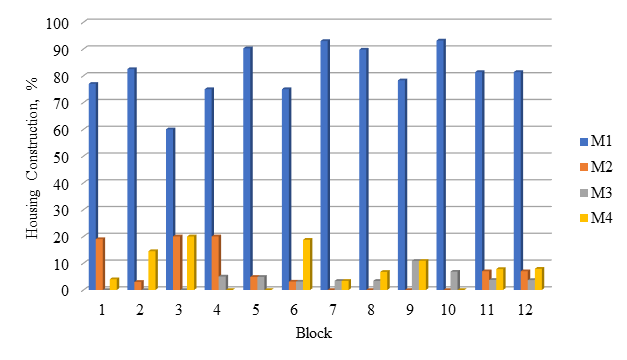

This study is justified by the widespread use of the different forms of masonry, (Figure 4). A random sampling from 10 blocks (431 constructions) of the City of Chilpancingo, Guerrero, indicates that solid clay brick and confined masonry predominate. The types of material and structure used are 81.4 % confined masonry walls (M1), 7 % reinforced concrete walls and/or frames (M2), 3.7 % adobe walls (M3) and 7.9 % other materials (steel and provisional materials, M4), as shown in Figure 5. On average, 82 % are solid clay bricks, 7.8 % are concrete components (bricks and/or blocks), and 10.2 % are materials that could not be identified.

2. MATERIALS AND METHODS

2.1 Objective

The objective of this study is to propose reference compressive strength and diagonal compressive strength design values based on historical experimental information in accordance with the compressive strength of the mortar and components used.

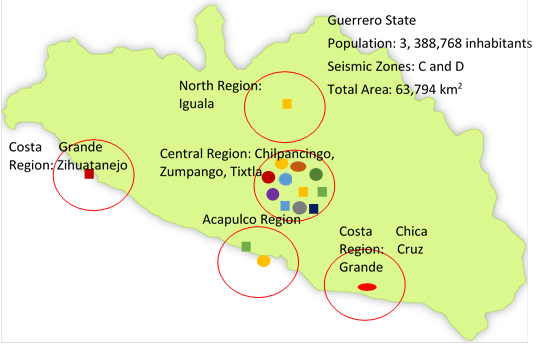

2.2 Standardization of historical experimental data

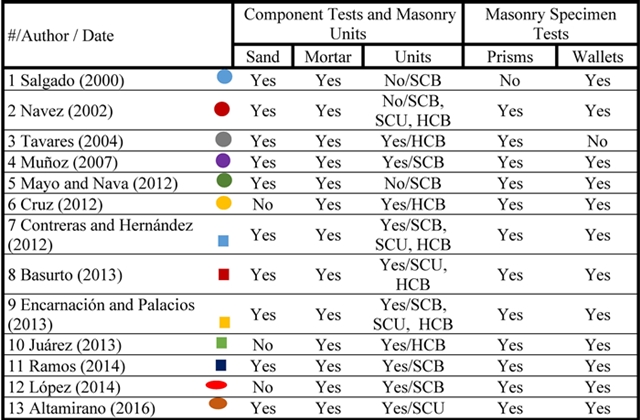

A total of 13 experimental researches conducted between 2000 and 2016 were analyzed. Table 1 and Figure 6 show both a listing and the type of information obtained, as well as the origin of the units. The materials and dosages used in the preparation of the specimens were those commonly used in masonry construction in the different cities of the state (Caballero, 2016).

Table 1 List of Experimental Researches (Caballero, 2016)

SCB: Solid Clay Brick, SCU: Solid Concrete Unit, HCB: Hollow Concrete Block

The data were standardized using the specially developed index card shown in Figure 7, where the physical-mechanical characteristics of the components (sand, mortar and units) and masonry (compressive strength in prisms and diagonal compression strength in masonry wallets) are shown. From the 13 consulted studies, 43 index cards similar to that in Figure 7 were prepared.MFrefers to the fineness module of sand,PVSS is the volumetric weight of loose dry sand,C vr is the experimental coefficient of variation, C vn is the standard coefficient of variation, f j is the average compressive strength of mortar, f j * is the compressive strength design value of the mortar, f p is the average compressive strength of the unit, f p * is the compressive strength design value of the unit, f m is the average compressive strength of the masonry, and v m is the average diagonal compressive strength of the masonry. The header of each index card has a serial number, the type of unit analyzed, the author and the year of the study.

Figure 7 Developed Index Card (Caballero, 2016)

| Index Card # 21. SCB from Atliaca, Gro. (Mayo and Nava, 2012). Units: MPa, m. | |||||||

| Sand | Prisms | Wallets | |||||

| MF | 2.95 | N.º | Size | fm | N.º | Size | vm |

| PVVS | 164.59 KN/m3 | 1 | 0.26x0.24 | 4.39 | 1 | 0.41x0.37 | 1.29 |

| Density | 2.51 | 2 | 0.26x0.21 | 2.82 | 2 | 0.40x0.36 | 1.45 |

| Origin | 3 | 0.26x0.24 | 2.73 | 3 | 0.41x0.37 | 1.35 | |

| Absorption (%) | 1.15 | 4 | 0.25x0.23 | 4.29 | 4 | 0.41x0.37 | 1.70 |

| Mortar | 5 | 0.25x0.23 | 2.98 | 5 | 0.40x0.36 | 1.51 | |

| Dose | 1:0:2 | 6 | 0.26x0.22 | 4.71 | 6 | 0.40x0.36 | 1.58 |

| Cjr | 0.10 | 7 | 0.26x0.23 | 2.97 | 7 | 0.38x0.36 | 1.47 |

| Cjn | 0.20 | ||||||

| fj | 22.38 | ||||||

| fj * | 14.92 | ||||||

| Units | |||||||

| Type | SCB | ||||||

| Absorption, % | |||||||

| Cr | |||||||

| Cn | fm | 3.55 | vm | 1.48 | |||

| f | Cmr | 0.25 | Cvr | 0.09 | |||

| f* | Cmn | 0.15 | Cvn | 0.20 | |||

In Figure 7, the first subscript of the coefficients indicates the type of specimen - mortar (j), unit (p), prism (m) and wallet (v) - and the second subscript indicates if it is experimental (r) or standard (n).

According to the information obtained, in most cases, the mortar was made with cement and sand, but it sometimes also contained lime. Thus, the volumetric mix ratio of mortar indicated in the index card has three parts, which correspond to the amounts of cement, lime and sand.

3. RESULTS

3.1 Average values of mechanical properties

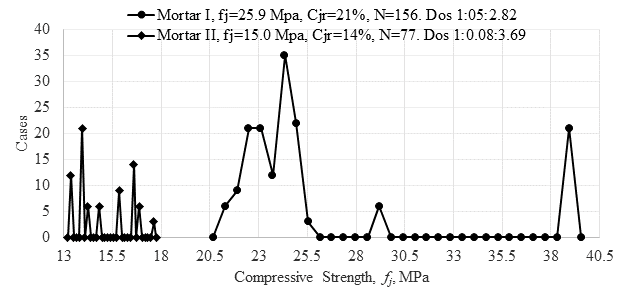

According to regulations, the design strength of type I mortar is equal to or greater than 12.3 MPa. Equation 1 was used with 156 recorded data points across a variety of units to assess the compressive strength design value, which was found to be f j * = 16.98 MPa. In this equation, C j is the coefficient of variation that is greater than or equal to 0.20 (NTCDCM, 2004). The average volumetric mix ratio for this strength was 1:0.05:2.82 (cement:lime:sand), and the historical experimental coefficient (C jr ) was 21 %. Similarly, 77 data points were obtained from type II mortar, and the compressive strength design value was f j * = 10.0 MPa with a coefficient of variation C jr = 14 % (Figure 8).

Table 2 shows the design parameters of the mortar and the units obtained from a statistical analysis. The compressive strength and diagonal compressive strength design values could not be assessed due to the nature of the data, and thus, the variablesf m1 ** and v m1 ** were defined, respectively. In equation 1, the average value and the higher coefficient of variation (experimental or standard,C p , C j , C m , C v ) of the parameter under study were replaced. Because the data used here were from different test series over a 16 year period, it was necessary to use a proper evaluation criterion. For the compressive strength, a Colombian standard (NSR-98, 1998) proposes 70 % of the historical average value as the design value when there are between 10 and 30 results with a coefficient of variation lower than 30%. The parametersf m2 ** and v m2 ** shown in Table 2were obtained with this criterion.

Table 2 Design Values for Units and Masonry (MPa)

| Unit | Mortar | Mortar | Unit | Masonry | |||||||

| Cj | fj * | Cp | fp * | Cm | fm1 ** | fm2 ** | Cv | vm1 ** | vm2 ** | ||

| SCB | I | 0.20 | 16.56 | 0.35 | 2.15 | 0.21 | 1.86 | 1.99 | 0.23 | 0.45 | 0.50 |

| II | 0.20 | 10.52 | 0.35 | 3.52 | 0.21 | 2.03 | 2.17 | 0.22 | 0.46 | 0.50 | |

| SCU | I | 0.20 | 17.90 | 0.30 | 7.48 | 0.21 | 1.89 | 2.02 | 0.21 | 0.55 | 0.59 |

| HCB | I | 0.20 | 17.66 | 0.30 | 3.87 | 0.19 | 1.87 | 1.93 | 0.22 | 0.23 | 0.25 |

| II | 0.23 | 8.89 | 0.30 | 5.01 | 0.15 | 2.91 | 2.80 | 0.24 | 0.40 | 0.45 | |

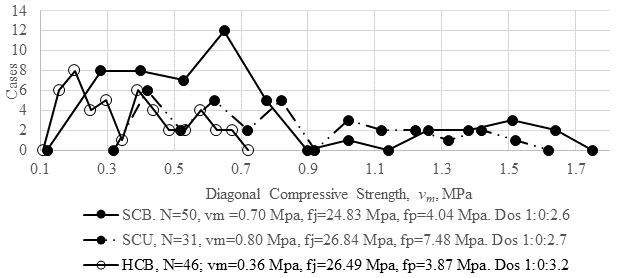

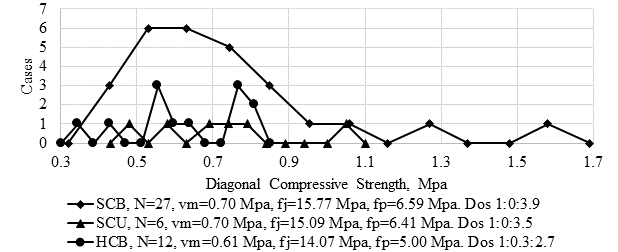

Figures 9 and 10show the distribution of the diagonal compressive strength,v m , of both mortars for each type of unit. The graphs also show the number of cases, the average values of the compressive strength of the joint (f j ) and the unit (f p ) and the mix ratio of the mortar. The experimental coefficients of variation with type I and II mortars were 23 % and 22 % in SCB, 21 % and 26 % in SCU, and 22 % and 24 % in HCB, respectively. The standard proposes a minimum value of 20 %.

3.2 Comments

Table 3 shows the maximum diagonal compressive strength values measured. Each row was obtained by standardizing the available data, as in Figure 7. The maximum value, v m1 ** = 0.99 MPa, was obtained in SCB saturated for 24 hours and bonded with a type I mortar with a compressive strength f j * of 14.92 MPa (case (2)). Case (3) had v m1 ** = 0.79 MPa, which was the maximum stress for the SCU bonded with a mortar with a compressive strength design value f j * of 16.2 MPa, a compressive strength design value for the unit of f p * = 3.1 MPa, and an absorption of 5 %. For HCB, the maximum value was v m1 ** = 0.40 MPa with a compressive strength design value of the mortar and the units of 9.34 MPa and 2.35 MPa, respectively (case (4)).

Table 3 Analysisof Diagonal Compressive Strength (MPa)

| Unit | Mortar | Row | MF | fj * | fp * | Absorption % | vm1 ** |

| SCB | I | 1 | 2.00 | 13.99 | 5.88 | 22.94 | 0.22 |

| 2 | 2.13 | 16.15 | 2.55 | 21.50 | 0.25 | ||

| 3 | 2.85 | 16.54 | 0.86 | 28.40 | 0.47 | ||

| 4 | 2.95 | 14.77 | S/D | S/D | 0.51(1) | ||

| 5 | 2.95 | 14.92 | S/D | S/D | 0.99(2) | ||

| II | 6 | 2.00 | 9.88 | 5.88 | 22.94 | 0.43 | |

| 7 | 3.07 | 10.53 | 2.35 | 26.36 | 0.47 | ||

| 8 | 3.07 | 8.86 | 2.35 | 26.36 | 0.57 | ||

| SCU | I | 9 | 2.13 | 16.15 | 2.09 | 20.20 | 0.35 |

| 10 | 2.30 | 15.89 | 7.30 | 15.00 | 0.70 | ||

| 11 | 2.13 | 16.15 | 3.05 | 5.10 | 0.79(3) | ||

| II | 12 | 3.53 | 11.26 | 2.53 | 8.93 | 0.37 | |

| 13 | 2.00 | 8.86 | 4.79 | 19.07 | 0.52 | ||

| HCB | I | 14 | 2.30 | 19.55 | 1.08 | 12.00 | 0.11 |

| 15 | 3.53 | 15.77 | 1.37 | 7.94 | 0.15 | ||

| 16 | S/D | 16.70 | 4.57 | S/D | 0.37 | ||

| II | 17 | S/D | 9.34 | 2.35 | S/D | 0.40(4) |

The thresholds of MF, fj*, fp*, absorption, and the diagonal compressive strength design (v m * ) are defined in regulations. Additionally, the range of the fineness modulus of sand is between 1.75 and 2.83, in accordance with the grain size distribution (NMX-C-486-ONNCCE-2014, 2014). The orange cells indicate values below the regulatory standard, and the green cells indicate values that meet it.

The mortar and units used in case (1) and case (2) were the same, except that in case (1), the units were wetted just prior to preparing the samples instead of being saturated for 24 hours, which decreased the strength of case (2) by 50 %.

The relationship between the mixture of the components (aggregates, cement, and unit) that achieves an acceptable diagonal compressive strength is complex; there were at least four mechanical-physical variables to assess in addition to the construction quality of the wallets and controlling the tests. The first variable was the fineness modulus (MF) of the sand, the next two were the compressive strength design values of the mortar (f j * ) and of the unit (f p * ), and the last variable was the absorption of the unit. In the first row, the four variables were within the standardized limits, whereas in the second row, the strength of the unit was lower than the standard value; in both cases the diagonal compressive strength design value (v m * ) was not met. This strength was met in the third row, but only 3 of the 4 variables were in compliance. In the sixth row, all the parameters were met, while in the last two rows, only one of four parameters met the standard; however, in both cases, the regulatory value was reached.

There were five cases using SCU. In four of them, two variables met the requirements, and in the remaining case, only one variable did not meet the requirements; for all five cases, the desired value of v m * was reached. Finally, only the HCB with type II mortar met the desired strength.

According to these results, increases in the compressive strength of the mortar used with SCB did not significantly increase the diagonal compressive strength of the masonry, and consequently, a type II mortar can be used in place of a type I mortar. For the case of HCB, a higher strength is achieved with type II mortar, as shown in Table 2.

Although it was possible to obtain diagonal compressive strength design values that were higher than the regulatory values without complying with three of the four variables measured, a question remains: What is the maximum value that can be obtained with adequate quality control of materials and procedures? Furthermore, there is historical experimental evidence that the diagonal compressive strength (case (2), Table 3) increases when SCB are in water for 24 hours, yet here, it decreased by 50 % when the units were soaked before being bonded; therefore the advantages of this process are questioned. It should be mentioned that the Colombian Code specifies pre-moistening times as a function of masonry unit absorption (NTC 4205, 2000).

3.3 Comparison of the results

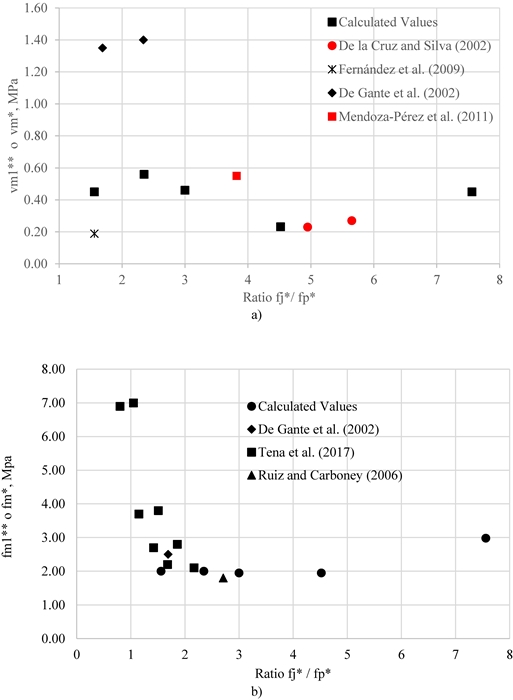

As stated above, the information processed in this study corresponds to 43 test series conducted over the course of 16 years. For that reason, the values cannot be accepted as the compression and diagonal compression design parameters, and thus, the variablesf j1 ** and v m1 ** were defined, which are not significantly different from other tests conducted in Mexico. These tests were performed by De la Cruz and Silva (2002) on SCU from Colima, De Gante et al. (2002) on SCB From Puebla, Ruiz and Carboney (2006) on SCB from Tuxtla Gutiérrez, Fernández et al. (2009) on HCB from Merida, Mendoza-Pérez et al. (2011) on SCB from Queretaro, and Tena et al. (2017) on SCU from the Valley of Mexico. In the case of diagonal compression, the calculated values were within 0.20-0.55 MPa and were similar to those referenced. It should be noted that the highest strength was recorded in Puebla (1.4 MPa). Most compressive strength values, including the calculated ones, were lower than 3.0 MPa, and only four were higher, as shown in Figures 11a and 11b.

Additionally, due to the historical nature of the data, the equation proposed in the Colombian Code was used, but the calculated variables f m2 ** and v m2 ** were slightly higher than the values off m1 ** and v m1 ** , respectively.

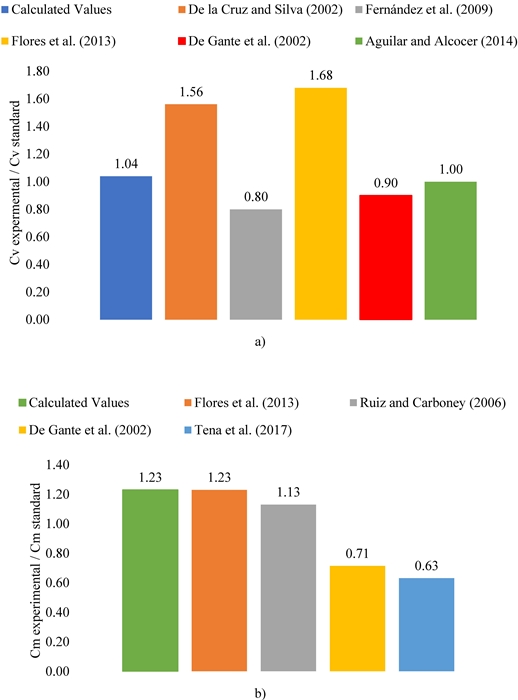

An additional comparison factor is the ratio of experimental coefficients of variation to the standard coefficients of the two variables studied (compression and diagonal compression). Figure 12a shows this relationship for four additional cases. For the calculated values, there are two test series with greater dispersion, while another has the same level (Aguilar and Alcocer, 2014), and two have less dispersion. Two cases have similar dispersions in their compressive strengths, while in the remaining two, the dispersion is reduced (Figure 12b).

4. DESIGN VALUES PROPOSED FOR GUERRERO STATE

Based on this analysis, the average compressive strength and diagonal compressive strength design values (f m * , v m * ) for both mortars were proposed based on the minimum compressive strength values of the units (f p * ) shown in Table 4. The average mix ratios (cement:lime:sand) of the mortars for practical construction applications were 1:0.0:2.8 and 1:0.1:3.7 in type I and II mortars, respectively. Because the quantity of solid concrete unit specimens reported with type II mortar was small, a reference value was not proposed.

5. CONCLUSIONS

Masonry is the most widely used material in the construction of buildings. However, it has a high seismic risk in Guerrero State due to the lack of design mechanical parameters and quality control in the construction process.

Furthermore, the interaction between masonry components is complex. Thus, to study the diagonal compressive strength, four variables were analyzed: two for the mortar (fineness modulus and design compression strength) and two for the units (design compression strength and absorption). However, the results do not regularly achieve the standard value.

A comparison of the compressive and diagonal compressive strength values of this masonry with other values recorded in Mexico and those obtained with the equation proposed by the Colombian Code, which uses a percentage of a historical average value, verified this analysis. The relationship of the experimental coefficients of variation with respect to the standard coefficients was also verified.

Finally, from the analysis, it was concluded that the compressive strength design value (f m * ) is 1.9 MPa for any type of unit bonded with mortars of type I or II. For the diagonal compressive strength design (v m * ), a value of 0.45 MPa was proposed for SCU bonded with type I mortar and for SCB regardless of the mortar used (type I or II); if HCB were used, this value is reduced to 0.20 MPa for any mortar.

The proposed values were valid when the compressive strength design values of the units (f p * ) were above 2.8 MPa for SCB, 6.0 MPa for SCU, or 4.4 MPa for HCB.

The results obtained in this study will serve as a guide for designing, reviewing, building and supervising constructions as well as for planning pilot programs in different parts of Guerrero State where this information is unavailable.

6. REFERENCES

Aguilar, G., Alcocer, S. (2014), “Efecto del refuerzo horizontal en el comportamiento de muros de mampostería confinada ante cargas laterales” (México, México: CENAPRED), p. 190. [ Links ]

Alcocer, S., Aguilar, G., Flores, L., Bitrán, D., Durán, R., López-Bátiz, O., Pacheco, M., Reyes, C., Uribe, C., Mendoza, M. (1999), “El sismo de Tehuacán del 15 de junio de 1999” (México, México: CENAPRED), p. 196. [ Links ]

Alcocer, S., Durán, R., Echavarría, A., Flores, L., López, O., Pacheco, M., Reyes, C. (2003) “El sismo de Tecomán, Colima del 21 de enero de 2003 (Me 7.6)” (México, México: CENAPRED), p. 196, pp. 79-160. [ Links ]

Alcocer, S., Reyes, C., Bitrán, D., López-Batiz, O., Durán-Hernández, R., Flores, V. (2002), “The 1999 Tehuacan (mw = 7.0) and Oaxaca (Mw = 7.5) Mexican Earthquakes: Lessons Learned”, Special Publication American Concrete Institute, Vol. 209, pp. 65-87. [ Links ]

Arroyo-Matus, R., Sánchez-Tizapa, S., Téllez-Tapia, C., y Guinto-Herrerra, R. (2014), “Diagnóstico del comportamiento observado en edificaciones durante el sismo de Zumpango, Guerrero, México (Mx=6.5) del 11 de diciembre de 2011 y propuestas para reducir la vulnerabilidad estructural”, Tlamati, V.5, No. 2, pp. 22-30. [ Links ]

Caballero, I. (2016), “Comparativo de la resistencia a compresión y esfuerzo cortante en pilas y muretes de mampostería realizados en la Unidad Académica de Ingeniería-UAGro”, Tesis de Licenciatura, Universidad Autónoma de Guerrero, p. 74. [ Links ]

Crisafulli, F. (1997), “Seismic Behaviour of reinforced concrete structures with masonry infills”, Thesis of Doctor of Philosophy in Civil Engineering, University of Canterbury, p. 416. [ Links ]

De Gante, J., Contreras, S., Torres, H., Serrano, S. (2002), “Obtención de propiedades de piezas de mampostería empleadas en las construcciones de la ciudad de Puebla”, XIII Congreso Nacional de Ingeniería Estructural, Puebla (México), pp. 1261-1267. [ Links ]

De la Cruz, J., Silva, C. (2002), “Estudio de resistencias a compresión diagonal (cortante), de muretes de mampostería fabricados con materiales de la zona conurbada Colima-Villa de Álvarez”, XIII Congreso Nacional de Ingeniería Estructural, Puebla (México), pp. 349-356. [ Links ]

Fernández, L., Marín, F., Varela, J., Vargas, G. (2009), “Determinación de la resistencia a compresión diagonal y el módulo de cortante de la mampostería de bloques huecos de concreto”, Ingeniería, Vol. 13, No.2, pp. 41-50. [ Links ]

Flores, V., Sánchez-Tizapa, S., Arroyo, R., Barragán, R., (2013), “Propiedades mecánicas de la mampostería de tabique rojo recocido”, Informes de la Construcción, Vol. 65, No. 531, pp. 387-395. Doi 10.3989/ic.12084. [ Links ]

Juárez, H., Whitney, R., Guerrero, J., Gama, A., Vera, R., Hurtado, F. (1997), “The October 9, Manzanillo, Mexico Earthquake”, Seimological Research Letters, Vol. 68, No. 3, pp. 413-425. [ Links ]

Mann, W., Muller, H. (1982), “Failure of shear stressed masonry an enlarged theory, tests and application to shear walls”, Proc. British Ceramic Society, Vol. 30, pp. 223-235. [ Links ]

Martínez, J., Martínez, J. (2010), “Fallas estructurales comunes en las edificaciones de Mexicali, B.C., debido al sismo de 4 de abril del 2010 ”, XVII Congreso Nacional de Ingeniería Estructural, Guanajuato (México), pp. 1-15. [ Links ]

NMX-C-082-ONNCCE-2013. (2013). “Industria de la construcción-Mampostería-Determinación de la adherencia por esfuerzo cortante entre el mortero y las piezas de mampostería. Método de ensayo” (Ciudad de México, México: ONNCCE), p. 10. [ Links ]

NMX-C-464-ONNCCE-2010. (2010). “Industria de la construcción-Mampostería-Determinación de la resistencia a compresión y módulo cortante de muretes, así como determinación de la resistencia a compresión y módulo de elasticidad de pilas de mampostería de arcilla o de concreto - Métodos de ensayo” (Ciudad de México, México: ONNCCE ), p. 24. [ Links ]

NTC 4205. (2000). “Norma Técnica Colombiana. Ingeniería Civil y Arquitectura. Unidades de mampostería de arcilla cocida. Ladrillos y bloques cerámicos” (Bogotá, Colombia: Ministerio de Desarrollo Económico), p. 14. [ Links ]

NTCDCM. (2004). “Normas técnicas complementarias para diseño y construcción de estructuras de mampostería” (Ciudad de México, México: Gaceta Oficial del Distrito Federal), p. 50. [ Links ]

NSR-98. (1998). “Reglamento de construcciones sismo resistente, NSR-98. Título D. Mampostería Estructural” (Bogotá, Colombia: Ministerio de Desarrollo Económico ), pp. 374-437. [ Links ]

Rangel, J., Tena, A., Gómez, A. (2011), “Report on geotechnical and structural reconnaissance of the El Mayor Cucupah Earthquake, April 4, 2010, Baja California”, Pan AM CGS Geotechnical Conference (USA), pp. 1-9. [ Links ]

Rodríguez, M., Alarcón, P., Machicao, R. (1998), “Evaluación del comportamiento sísmico de edificaciones de mampostería en los sismos de Michoacán de 1985 y 1997”, Revista de Ingeniería Sísmica, Vol. 59, pp. 37-58. [ Links ]

Ruiz, A., Carboney, J. (2006), “Caracterización geométrica y mecánica de piezas de ladrillo de barro rojo recocido de Tuxtla Gutiérrez, Chiapas ”, XV Congreso Nacional de Ingeniería Estructural, Puerto Vallarta (México), pp. 1-15. [ Links ]

Sánchez-Tizapa, S. (2013), “Reporte interno sobre el sismo de agosto 2013 ”, Universidad Autónoma de Guerrero, p. 11. [ Links ]

Tena, A., Liga, A., González, F. (2017), “Proposal for improved mixes to produce concrete masonry units with commonly used aggregates available in the Valley of Mexico ”, Revista ALCONPAT, Vol. 7, No. 1, pp. 35-56. [ Links ]

Tomazevic, M. (2006), “Earthquake-resistant design of masonry buildings” (London, England: Imperial College Press), p. 268. [ Links ]

Received: December 14, 2016; Accepted: August 09, 2017

texto en

texto en