Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista ALCONPAT

versión On-line ISSN 2007-6835

Rev. ALCONPAT vol.7 no.3 Mérida sep./dic. 2017

https://doi.org/10.21041/ra.v7i3.223

Review

Infrared thermography as a non-destructive test for the inspection of reinforced concrete bridges: A review of the state of the art

1Universidade de Pernambuco, Brasil.

This article aims to present the methodologies, advantages and limitations of the infrared thermography test for the inspection of reinforced concrete bridges. A systematic review of articles and academic material related to the area was carried out. This review focuses mainly on the passive application and on both laboratory and field studies. A critical approach to the information available was used in relation to its scope was used. The test is presented as a real alternative for the detection of defects in these structures, being more effective the more superficial these anomalies. Depending on the work to be done, it is necessary to contemplate some considerations to obtain better results. And it is effective in combination with other tests.

Keywords: infrared thermography; bridge inspection; concrete pathologies

Este artículo tiene como objetivo presentar las metodologías, ventajas y limitaciones del ensayo de la termografía infrarroja para la inspección de puentes de hormigón armado. Se realizó una revisión sistemática de artículos y de material académico relativo al área. Esta revisión se centra principalmente en la aplicación pasiva y en estudios tanto de laboratorio como de campo. Se utilizó un abordaje crítico de la información disponible con relación a su alcance. El ensayo se presenta como una alternativa real para la detección de defectos en estas estructuras, siendo más eficaz cuanto más superficiales sean estas anomalías. Dependiendo del trabajo a realizar, es necesario tener en cuenta algunas consideraciones para obtener mejores resultados. Y es eficaz en combinación con otros ensayos.

Palabras clave: termografía infrarroja; inspección de puentes; patologías del concreto

Este artigo tem como objetivo apresentar as metodologias, vantagens e limitações do ensaio da termografia infravermelha para a inspeção de pontes de concreto armado. Foi realizada uma revisão sistemática de artigos e de material acadêmico relativo à área. Esta revisão foca-se principalmente na aplicação passiva e em estudos tanto de laboratório quanto de campo. Utilizou-se uma abordagem crítica da informação disponível quanto a seu alcance. A termografia infravermelha apresenta-se como uma alternativa real para a detecção de defeitos nestas estruturas, sendo mais eficaz quanto mais superficiais sejam estas anomalias. Dependendo do trabalho a ser realizado é necessário levar em conta algumas considerações para obter melhores resultados. E é eficaz em combinação com outros ensaios.

Palavras chaves: termografia infravermelha; inspeção de pontes; patologias do concreto

1. INTRODUCTION

The inspection and maintenance of reinforced concrete structures are important activities for their useful life preservation, safety guarantee, and functionality for the users (Bagavathiappan et al., 2013). Despite that, as structures age, these activities are increasingly complex to perform; however, they are necessary to determine and control structural integrity, in addition to assessing the damage nature (Chang; Flatau; Liu, 2003; Rehman et al., 2016).

Bridges are structures that deteriorate rapidly, especially their decks, since they are directly exposed to traffic and the environment (Gucunski et al., 2015). Concrete degradation, steel corrosion, weakening of connections, among other problems are causes of permanent concern in the maintenance of bridges. Proper inspection and evaluation of bridges and their parts are necessary to avoid deterioration of structural integrity and service over time (Islam et al., 2014).

In the United States, bridges are inspected twice a year (GPO, 2015) and 40% of bridges evaluated are classified as structurally deficient and not functional (Pines and Aktan, 2002). These structures are designed and built to operate for at least 50 years, but the average life span of a bridge in the United States is about 42 years, as opposed to technical specifications (Herrmann, 2013).

In Brazil the situation is similar. According to NBR 9452 (ABNT, 2016), bridges should be inspected each year, but only with routine inspection. More detailed inspections should take place between 5 and 8 years, depending on the case. Research in the area (Mendes; Moreira; Pimienta, 2012; Pintan et al., 2015; Vitório and Barros, 2012) shows that more than a third of the bridges studied have poor characteristics, associated in many cases to lack of adequate or timely maintenance.

Although visual inspection is the most widely used method for inspecting concrete structures and the first step in evaluating structures (Chang; Flatau; Liu, 2003; Estes and Frangopol, 2003; ACI, 2013; Alani; Aboutalebi; Killic, 2014; Rehman et al., 2016), its scope is limited to subjective qualitative analysis because it depends on the inspector criteria (Jain and Bhattacharjee, 2011). In addition, visual inspection is unable to detect internal problems of the structure, unless they are so advanced that present external signs, which is an undesirable and should be avoided (Vilbig, 2014).

Non-destructive test methods provide relevant information on the structure condition (McCann and Forde, 2001) which allows the damage to be assessed quickly and efficiently (Chang; Flatau; Liu, 2003) thus preventing premature and unpredictable collapse (Rehman et al., 2016). Several researchers have demonstrated the application of these methods for the structures inspection and evaluation, providing guidance for their uses (Clark; McCann; Forde, 2003; Scott et al., 2003; Meola, 2007). McCann and Forde (2001) present a variety of non-destructive methods suitable for civil construction, while Rehman et al. (2016), present in detail the non-destructive test methods for the inspection of bridges.

Infrared thermography as a nondestructive test has been used for civil structures inspection with satisfactory results (Meola, 2007; Fox; Goodhew; Wilde, 2016; Hiasa; Birgul; Catbas, 2016), and its specific application in the inspection of bridges is being increasingly consolidated (Watase et al., 2015; Ellenberg et al., 2016; Dabous et al., 2017; Hiasa; Birgul; Catbas, 2017a). However, infrared thermography has some limitations regarding defect detection depth, the influence of environmental conditions and data collection time for example. In this sense, the objective of this article is to analyze the scope of infrared thermography in the inspection of reinforced concrete bridges, describing infrared thermography operation basic concepts, besides methodologies and techniques of the information analysis, aiming to provide a better diagnostic evaluation of pathologies in bridges.

2. LITERATURE REVIEW

2.1 Historic review and operation principle

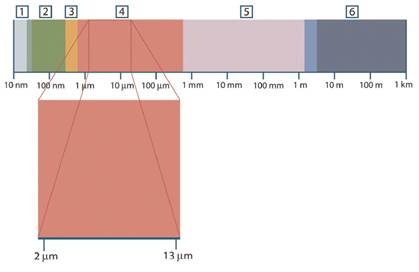

All objects with temperature above absolute zero (0 K) emit radiation in the infrared range of the electromagnetic spectrum. According to the wavelength, infrared radiation is in the range of 0.75 to 1000 μm (micrometer), located between the visible and microwave range (Figure 1) (Clark; McCann; Forde, 2003; Meola, 2012; Bagavathiappan et al., 2013).

Figure 1 Electromagnetic spectrum. 1: X-ray; 2: Ultraviolet; 3: Visible; 4: Infrared; 5: Microwave; 6: Radio wave (FLIR, 2013)

William Herschel discovered infrared radiation in 1800 and his son, John Herschel, made the first thermal image in 1840 (FLIR, 2013). Despite this progress, infrared thermography was not used until recent decades due to the lack of equipment development and technical knowledge (Bagavathiappan et al., 2013).

Infrared radiation emitted by an object is detected in a non-contact way by an infrared detector in the camera, using the Stefan-Boltzmann equation (1) to obtain the object temperature (Clark; McCann; Forde, 2003; Washer, 2012; ACI, 2013; Watase et al., 2015).

Where E is the radiation emitted by the object (W/m2), q is the degree of energy emission (W), A is the area of the emitting surface (m2), T is the absolute temperature (K), is the Stefan-Boltzmann constant of 5.676x10-8W∙m-2K-4, and ε is the emissivity of the emitting surface. Emissivity is the efficiency measure of a surface to act as an emitter (Clark; McCann; Forde, 2003). A perfect blackbody has an emissivity value equal to one, considered as a perfect emitter; however, for other surfaces, the value is less than one. In the case of concrete, it has a relatively high emissivity, between 0.9-1 (Washer; Fenwick; Bolleni, 2010).

2.2 Methodology and analysis

The application of infrared thermography can be divided into active and passive categories, depending on the resources of heat stimulation (Kee et al., 2012; Rehman et al., 2016). Passive thermography requires no source of external stimulation (Oh et al., 2013); it uses solar energy and ambient temperature as the main heating resources, and this technique is used for bridges inspection (Kee et al., 2012; Vaghefi et al., 2012; Alfredo-Cruz et al., 2015), as well as for other structures and other fields (Buyukozturk, 1998; Lahiri et al., 2012; Barreira; Almeida; Delgado, 2016; Fox; Goodhew; Wilde, 2016; O’Grady; Lechowska; Harte, 2016). In contrast, active thermography requires external sources of stimulation (Kee et al., 2012; Rehman et al., 2016). It can even be sub-divided according to the nature of the stimulation as Pulsed, Lock-in and Pulsed-Phase for example (Maldague, 2001). Among other uses, the application of the active thermography techniques is related to defect detection in metals and industrial processes monitoring (Meola et al., 2002; Montanini, 2010; Yuanlin et al., 2015; Zhao et al., 2017).

There are two types of measurements and analyses in infrared thermography. The first (quantitative) consists in obtaining the object temperature with precision; the second (qualitative) is the obtaining of relative values of hot spots in relation to other parts of the same object, using these parts as reference. In a qualitative analysis, some applications do not require the determination of the exact temperature; instead, only relative temperatures and data collection to be interpreted quickly are needed. The analysis, however, may have flaws in accuracy. In a quantitative analysis, the procedure is more rigorous and is used for specific applications (Jadin and Taib, 2012).

2.3 Advantages and limitations

Infrared thermography is presented as a fast, non-invasive, contactless technique that allows the recording of real-time dynamic variations. It can be applied over large distances, analyze and inspect large areas in small time intervals, and provide easy results and quick interpretation (Yehia et al., 2007; Washer; Fenwick; Bolleni, 2010; Sham; Lo; Memon, 2012; Watase et al., 2015; Hiasa; Birgul; Catbas, 2016; Rehman et al., 2016); besides having a simple instrumentation. In most cases, all it takes to observe thermal images are a thermographic camera, the camera support and a video output (Bagavathiappan et al., 2013).

Despite the many advantages offered by this technique in the inspection, the equipment may be expensive and insensitive to detect the depth of defects and anomalies in the concrete. In addition, the testing is highly influenced by environmental conditions, such as wind, solar radiation, humidity and surface emissivity (Manning; Holt, 1980; Yehia et al., 2007; Washer; Fenwick; Bolleni, 2009; ACI, 2013).

2.4 Thermografic cameras

Thermal cameras have undergone many changes in recent decades. The first generations of cameras had low spatial resolution, high noise levels, low dynamic range and limited data storage (Zhang; Tsai; Machin, 2009). Each day the cameras are lighter and portable, with new types of infrared detectors with better resolution and accuracy, covering more and more applications (Bagavathiappan et al., 2013).

At the moment of choosing a thermographic camera, some performance parameters, such as spectral range, spatial resolution, temperature resolution, temperature range and frame rate must be taken into account. However, other factors as: power, weight, size, image processing capacity, calibration, storage capacity, cost, service, among others, can be considered depending on the type of work to be performed (Venkataraman and Raj, 2003).

Spectral range is the portion of the infrared region in which the camera is capable of operating. It is known that as the object temperature increases, the thermal radiation emitted is in short wavelengths (Bagavathiappan et al., 2013); however, objects at ambient temperature emit long wavelengths (7.5-14 µm). Therefore, in this case, cameras with this wavelength system would be preferable because measurements would not be affected by solar radiation, which are generally in short-length ranges. On the other hand, cameras with short wave systems (2-5 µm) may perform better on cloudy days or at night, because solar radiation is in the same wavelength range and cannot influence the results (Jaldin and Taib, 2008).

The quality of the image depends on how big the spatial resolution is. Spatial resolution is the ability of the thermographic camera to distinguish two objects in the visual field. It depends directly on the lens system, the detector size, and the distance between the object and the camera. The larger this distance, the smaller the spatial resolution (Venkataraman and Raj, 2003).

Temperature resolution is the minimum thermal differential that can be detected by the thermal camera. It depends on many parameters such as: object and environment temperature, distance from the camera to the object, filters, among others (Venkataraman and Raj, 2003).

Temperature range refers to the maximum and minimum values that the camera can measure. These values may vary according to camera specifications. Frame rate is the number of frames that can be acquired per second, which is important in the case of monitoring moving objects or dynamic events (Venkataraman and Raj, 2003).

3. INSPECTION OF BRIDGES

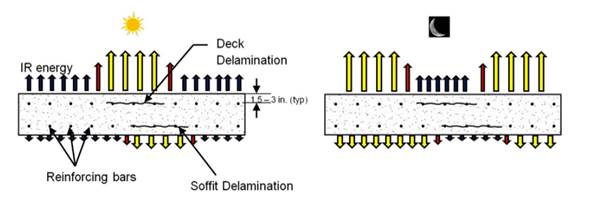

The concept of infrared thermography applied for inspection is based on the fact that the voids, defects or anomalies within the concrete affect the heat transfer properties of the structure. As the temperature rises during the day, the defects interrupt the heat transfer inside the concrete, heating these areas rapidly, and this is because the defects are filled with air or water, which have a different thermal conductivity from that of concrete. Conversely, at night, when temperatures drop, the same defect areas are cooled faster than problem-free areas (Figure 2). The cameras can detect these defects through the measurement of the radiation emitted by the surface of the concrete surface with the Stefan-Boltzmann equation (1) (Maser and Roddis, 1990; Washer; Fenwick; Bolleni, 2010; Sham; Lo; Memon, 2012; ACI, 2013; Gucunski et al., 2013; Farrag; Yehia; Qaddoumi, 2016; Rehman et al., 2016; Vemuri and Atadero, 2017).

Radiation, conduction and convection are the main heat transfer mechanisms that affect the heat flow through concrete. Although radiant energy is the parameter that can be measured by a thermographic camera, the thermal conductivity inside the concrete and the heat convection around the concrete influence the taking of thermograms (Vaghefi et al., 2011).

The detection of defects or delaminations in the concrete is performed through the gradient or thermal contrast (ΔT), defined by equation (2) (Washer et al., 2015).

Where T D is the temperature that is above the defect surface, and T C is the temperature of the intact concrete.

The application of infrared thermography for the inspection of buildings and their components is widely regulated (ASTM, 2013a; ASTM, 2015a; ASTM, 2015b); and, specifically for the inspection of reinforced concrete bridges, only the standard D4788-03 (ASTM, 2013b) is available.

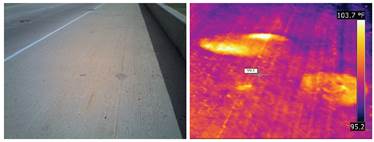

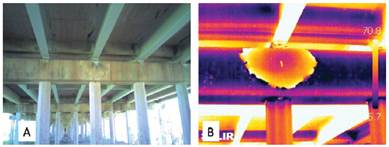

The application in concrete structures is mainly focused on the detection of surface defects, porosity, cracks, damage assessment (McCann and Forde, 2001; Maierhofer; Arndt; Röllig, 2007; Poblete and Pascual, 2007; Arndt, 2010; ACI, 2013; Baggathiappan et al., 2013) and, particularly in the case of reinforced concrete bridges, in the detection of delaminations and voids (Figure 3), in a visual way in thermograms or by thermal gradients calculated using equation (2) (Clark; McCann; Forde, 2003; Washer; Fenwick; Bolleni, 2010; ASTM, 2013b; Gucunksi et al., 2013).

Figure 3 Detection of delaminations: a) Digital photography and b) Thermogram (Washer; Fenwick; Bolleni, 2009)

Defects with higher thermal gradients are more detectable even at great depths (Washer et al., 2015). In this sense, the standard D4788-03 (ASTM, 2013b) indicates that this gradient should be at least 0.5°C for good detection accuracy. However, Clark, McCann and Forde (2003) detected defects and delaminations in the internal structure of reinforced concrete and masonry bridges, located at low ambient temperature and indicated that these defects can be detected when the gradient is approximately 0.2-0.3°C. Washer, Fenwick and Bolleni (2010) claim that infrared thermography is appropriate to inspect sun exposed parts of bridges as it generates large gradients. However, in extreme cases, the sun can limit the technique by generating false detections (Washer et al., 2015). For parts not exposed to direct sunlight, Figure 4a, Washer (2012) concludes that delaminations and defects can be detected when temperature variations during day and night are large enough to generate gradients, Figure 4b; the author also emphasizes that during the cooling and heating periods of the day the thermal gradients are small, resulting in ineffective inspection during these periods. Farrag, Yehia and Qaddoumi (2016) used a minimum gradient of 0.8°C for detection of defects in addition to visual detection in thermograms.

Figure 4 Application in bridge infrastructure: a) Digital photography and b) Thermogram (Washer, 2012)

Procedural factors refer to the experimental conditions and previous knowledge of the object of study; they can be minimized by using qualified thermographers to obtain data and data correction or interpretation (Buyukozturk, 1998; Uemoto, 2000; Vemuri and Atadero, 2017).

Environmental conditions refer to their direct influence on measurements (Washer et al., 2015). Infrared thermography is a very sensitive technique in relation to environmental conditions (Yehia et al., 2007; Oh et al., 2013). Sun exposure is considered the main force to generate thermal gradients as it affects the measured temperature values, generating thermal energy on the concrete surface. Likewise, an increase in ambient temperature produces an increase in the object temperature, unlike events such as humidity, rain or snow that reduce the object temperature. However, higher temperature variations during the day may generate higher thermal gradients (Washer; Fenwick; Bolleni, 2010). Wind can also interfere with the temperature of the objects studied, especially when the wind is strong, due to the temperature-cutting effects generated on the surface (Davis, 2003).

Next, the main capabilities and limitations of the technique in the inspection of reinforced concrete bridges are described in relation to depth and size of delamination, the ideal time for data collection, concrete quality influence, data collection speed and combination with other tecniques.

3.1 Depth and size of delamination and inspection time

Delamination depth and size detection have been well-researched. Many authors use artificial defects to be captured with the infrared camera and thus evaluate the technique reach. Likewise, there are many recommendations for the ideal time to obtain data (Hiasa, 2016). Table 1 presents a summary of the main investigations in the detection of defects in relation to size, depth and time.

Table 1 Detection of delaminations in relation to size, depth and time

| Authors | Deph of delamination (cm) | Area of delamination (cm 2 ) | Detection | Recommended inspection time |

|---|---|---|---|---|

| Sakagami and Kubo (2002) | 2 - 3 - 5 | 10x10 | Yes | Active thermography |

| 10 | 10x10 | No | ||

| Maierhofer et al. (2006) | 2 - 4 - 6 - 8 | 20x20 | Yes | Active thermography |

| 2 - 4 - 6 - 8 | 10x10 | Yes | ||

| Meola (2007) | 1.5 to 7 | 12.5 to 78.5 | Yes | Active thermography |

| Abdel-Qader et al. (2007) | 2.54 to 7 | 19.35 to 103 | Yes | Active thermography |

| 8.9 to 10.16 | 14.5 to 103 | No | ||

| Yehia et al. (2007) | 1.9 - 2.5 - 5.1 | 3.8x3.8 to 10.3x10.2 | Yes | 10 a.m. to 3 p.m. |

| 5.6 - 10.1 | 3.8x3.8 to 10.3x10.2 | No | No defects are seen at any time of day | |

| Cheng, Cheng and Chiang (2008) | 0.5 - 1 - 1.5 - 2 - 3 | 10x10 | Yes | Active thermography |

| 5x5 | Yes | |||

| Washer, Fenwick and Bolleni (2009) | 5.1 | 30x30 | Yes | 5 to 7 hours* |

| 7.6 | 30x30 | Yes | 7 to 9 hours* | |

| Washer, Fenwick and Bolleni (2010) | 2.5 | 30x30 | Yes | 5 hours and 40 minutes* |

| 12.7 | 30x30 | Yes | More than 9 hours* | |

| Washer (2012) | 2.5 | 30x30 | No | 1 hour* |

| 5.1 | 30x30 | No | 1 hour and 30 minutes* | |

| 7.6 | 30x30 | No | 2 hours* | |

| Kee et al. (2012) | 6.35 | 30.5x30.5 | Yes | 45 minutes |

| 61x30.5 | Yes | 3 hours and 45 minutes* | ||

| 61x61 | Yes | 7 hours and 45 minutes* | ||

| Gucunski et al. (2013) | 6.35 | 30.5x30.5 - 61x30.5 - 61x61 | Yes | 40 minutes* |

| No | Noon | |||

| Vaguefi et al. (2015) | 5.1 - 7.6 | Real delaminations | Yes | Noon |

| Watase et al. (2015) | 1-2-3 | 30x30 | Yes | Noon |

| 30x30 | Yes | Midnight | ||

| Alfredo-Cruz et al. (2015) | 2.5 - 5.0 - 7.5 | 15x15 | Yes | 8 a.m. to 11 p.m. |

| Hiasa et al. (2016) | 1.27 - 2.54 - 5.08 | 10.2x10.2 | Yes | Night time |

| 7.62 | 10.2x10.2 | No | No defects are seen at any time of day |

*After Sunrise

The literature review (Table 1) shows that the larger and more superficial the defect area is, the easier its detection. In this sense, Farrag, Yehia and Qaddoumi (2016) concluded that if the R/d ratio (R: short dimension of defect, and d: depth of defect from the surface) is greater than 1, defects are detected; if this R/d ratio equals 0.45, they are detectable up to a depth of 10 cm.

In more recent investigations on detection depth, Hiasa, Birgul and Catbas (2017b) presented a methodology for data processing through numerical modeling for better analysis and subsequent evaluation, where the results for defects at depths of 1.27 and 2.54 cm were detected more accurately than through a simple color analysis in the thermogram.

The effect of time of day in data collection is controversial, since the recommendations of the authors are contradictory in some cases. In fact, it all depends on the environmental conditions of the place where the object under study is located; even so, some authors (Uemoto, 2000; Watase et al., 2015; Hiasa et al., 2016) recommend bridge inspection at night to eliminate the solar radiation effects, and to have a better view of the space between the defect and intact regions, avoiding false detections. However, Hiasa, Birgul and Catbas (2017a) showed the potential of finite element models with infrared thermography for the inspection of bridges, providing the estimation of detection parameters such as depth and size of defects and even ideal inspection times.

3.2 Concrete quality

Farrag, Yehia and Qaddoumi (2016) applied this technique to several concrete mixtures to observe their influence on defect detection, demonstrating that high strength concrete - therefore, with higher density and higher thermal conductivity - is better for defect detection.

According to the literature, delamination detection limits are not clearly established in relation to concrete depth and quality, water-cement ratio, and compressive strength. Yehia et al. (2007) found voids and defects to a depth of 4 cm in a concrete with compressive strength of 28 MPa, while Kee et al. (2012) found delaminations at 5 cm in a concrete of the same strength. Maierhofer et al. (2006) found voids at a depth of 6 cm in a concrete of 48 MPa using active infrared thermography. Alfredo-Cruz et al. (2015), in a concrete of 38 MPa and a water-cement ratio of 0.35, detected delaminations up to a depth of 5 cm, being the defects of 7.5 cm the least visible. Farrag, Yehia and Qaddoumi (2016) found delaminations and voids at 10 cm depth with a compressive strength concrete of 50 MPa.

3.3 Data collection speed

Hiasa et al. (2016) compared three cameras as to the effect of speed on the thermograms. The experiments were conducted at speeds of 0 km/h and 48 km/h. The camera with higher technology gave better results than those with lower technology, capturing not only thermograms in static form, but also in motion. In addition, the results reveal that compared to the 320x240 pixels camera, the 640x480 pixels camera is more efficient, since it allows analysis of larger areas in a short time with good accuracy.

3.4 Combination with other non-destructive tests

Infrared thermography has been widely used in combination with other non-destructive techniques in order to confirm or supplement information for a more complete analysis of the structure. Yehia et al. (2007) compared the results obtained with different non-destructive techniques, such as infrared thermography, IE (Impact Echo) and GPR (Ground Penetrating Radar) used in the inspection and evaluation of bridges. It was concluded that each technique meets specific objectives and together they provide more information about the state of the structure.

Aggelis et al. (2010) studied the characterization of subsurface cracks in concrete. In this study, infrared thermography was used to detect position of those cracks; subsequently the ultrasonic test was used for a more detailed depth study.

Kee et al. (2012) performed a fusion between the non-destructive techniques of IE and infrared thermography, demonstrating that the combination of the data obtained allows a coherent, practical, and sensitive defect detection. Oh et al. (2013) compared the same methods with the drag chain technique. The results were comparable; however, the drag chain was less accurate and reliable for the detection of defects in bridges. Though economical, it is technologically limited and subjective, as it depends on the experience of the operator.

Vemuri and Atadero (2017) and Dabous et al. (2017) consider that the combination of infrared thermography with GPR is advantageous for bridge inspection because they work in a complementary way: corrosion and cracks in early stages can be detected for both defects and their quantification. Even though there is an asphalt layer on the bridge deck, detection is still possible, according to Vemuri and Atadero (2017).

Alfredo-Cruz et al. (2015) studied nondestructive testing techniques: ultrasonic, infrared thermography, and sclerometer to evaluate bridge elements. They concluded that the combination of these techniques presents more complete results such as the evaluation of uniformity and quality in the concrete matrix, detachments detection and the estimation of the concrete compressive strength.

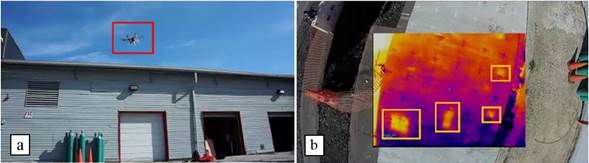

Ellenberg et al. (2016) demonstrates the ability to use UAV (Unmanned Aerial Vehicle) equipped with a thermographic camera to identify delaminations during the inspection of bridges, as shown in Figure 5.

Figure 5 a) UAV on the location of the delaminations, and b) Delaminations identified in real time from the drone (Ellenberg et al., 2016)

Watase et al. (2015) consider that technologies complementary to infrared thermography, such as GPR, ultrasonic, and others used in concrete can be useful in the analysis and characterization of concrete problems, which would improve decisions on the evaluation and maintenance of these structures. Vaghefi et al. (2015) presented the results of infrared thermography with 3DOBS (Three-Dimensional 3D Optical Bridge Evaluation System), a system based on the principles of photogrammetry, capable of quantifying delaminated areas and determining their percentage in relation to the area of the bridge deck. The combination of infrared thermography and 3DOBS is a fast and easy method to locate and quantify deficient areas.

It can be observed that the combination of the IR technique with other nondestructive methods is generally performed in the inspection of bridges, presenting satisfactory results on the state of these structures.

4. CONCLUSIONS

In the present article the different applications, methodologies, scope and limitations of the infrared thermography in the inspection of reinforced concrete bridges were presented, leading to the conclusions that follow.

Because infrared thermography does not require direct contact and may be remote, it is useful for inspecting structures and elements that would otherwise be inaccessible. Moreover, results are immediate which can be important to avoid accidents or emergency situations.

IR has good accuracy in detecting different structure damages, such as voids and delaminations, with some limitations as to the depth and size of these defects. The investigations show a greater advancement in the detection of anomalies with the improvement of camera technology. Nevertheless, the ideal time for inspection is still a limitation, due to the technique dependence on the environmental conditions that vary according to where the test takes place. However, the continuous development of tools and technologies increasingly allows automation of the inspection process and data analysis. In turn, as the correct analysis of larger areas is conducted in less time, more reliability and effectiveness are conferred to results.

The combination of infrared thermography with other nondestructive methods allows to maximize advantages and compensate some limitations in the inspection and evaluation of reinforced concrete bridges structures by improving the vision of their structural condition and functionality which ultimately helps in the maintenance and conservation decisions.

5. ACKNOWLEDGEMENTS

To CAPES (Coordination of Improvement of Higher Level Personnel) for the financial support.

REFERENCES

Abdel-Qader, I., Yohali, S., Abudayyeh, O., Yehia, S. (2008), “Segmentation of thermal images for non-destructive evaluation of bridge decks”. NDT&E International, V.41, No. 5, pp. 395-405. https://doi.org/10.1016/j.ndteint.2007.12.003 [ Links ]

ABNT-Associação Brasileira de Normas Técnicas. (2016), “NBR 9452: Inspeção de pontes, viadutos e passarelas de concreto - Procedimento” (Rio de Janeiro, Brasil: ABNT), p. 48. [ Links ]

ACI-American Concrete Institute. (2013), “228:2R-13 Report on nondestructive test methods for evaluation of concrete in structures” (Detroit, United States: ACI Publications), p. 82. [ Links ]

Aggelis, D., Kordatos, E., Soulioti, D., and Matikas, T. (2010), “Combined use of thermography and ultrasound for the characterization of subsurface cracks in concrete”, Constr. Build. Mater., V.24, No. 10, pp. 1888-1897. https://doi.org/10.1016/j.conbuildmat.2010.04.014 [ Links ]

Alani, A., Aboutalebi, M., Kilic, G. (2014), “Integrated health assessment strategy using NDT for reinforced concrete bridges”, NDT & E International, V.61, pp. 80-94. https://doi.org/10.1016/j.ndteint.2013.10.001 [ Links ]

Alfredo-Cruz, R., Quintero-Ortiz, L., Galán-Pinilla, C., Espinosa-García, E. (2015), “Evaluación de técnicas no destructivas en elementos de concreto para puentes”, Revista Fac. Ing., V.24, No. 40, pp. 83-96. http://dx.doi.org/10.19053/01211129.3850 [ Links ]

Arndt, R. (2010), “Square pulse thermography in frequency domain as adaptation of pulsed phase thermography for qualitative and quantitative applications in cultural heritage and civil engineering”, Infrared Physics & Technology, V.53, No. 4, pp. 246-253. https://doi.org/10.1016/j.infrared.2010.03.002 [ Links ]

ASTM. (2013b), “D4788-03: Standard Test Method for Detecting Delaminations in Bridge Decks Using Infrared Thermography”, (West Conshohocken, United States: ASTM International), p. 3. http://dx.doi.org/10.1520/D4788 [ Links ]

ASTM. (2015a), “C1060-11a: Standard Practice for Thermographic Inspection of Insulation Installations in Envelope Cavities of Frame Buildings”, (West Conshohocken, United States: ASTM International ), p. 7. http://dx.doi.org/10.1520/C1060-11AR15 [ Links ]

ASTM. (2015b), “C1153-10: Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging”, (West Conshohocken, United States: ASTM International ), p. 6. http://dx.doi.org/10.1520/C1153-10R15 [ Links ]

ASTM-American Society of Testing Materials. (2013a), “C1046-95: Standard Practice for In-Situ Measurement of Heat Flux and Temperature on Building Envelope Components”, (West Conshohocken, United States: ASTM International ), p. 7. http://dx.doi.org/10.1520/C1046 [ Links ]

Bagavathiappan, S., Lahiri, B., Saravanan, T., Philip, J. (2013), “Infrared thermography for condition monitoring - A review”, Infrared Physics & Technology , V.60, No. 1, pp. 35-55. https://doi.org/10.1016/j.infrared.2013.03.006 [ Links ]

Barreira, E., Almeida, R., Delgado, J. (2016), “Infrared thermography for assessing moisture related phenomena in building components”, V.101, pp. 251-269. https://doi.org/10.1016/j.conbuildmat.2016.02.026 [ Links ]

Buyukozturk, O. (1998), “Imaging of concrete structures”, NDT&E International, V.31, No. 4, pp. 233-243. https://doi.org/10.1016/S0963-8695(98)00012-7 [ Links ]

Chang, P., Flatau, A., Liu, S. (2003), “Review paper: health monitoring of civil infrastructure”, Structural Health Monitoring, V.2, No. 3, pp. 257-267. [ Links ]

Cheng, Ch., Cheng, T., Chiang, Ch. (2008), “Defect detection of concrete structures using both infrared thermography and elastic waves”. Automation in Construction, V.18, No. 1, pp. 87-92. [ Links ]

Clark, M., McCann, D., Forde, M. (2003), “Application of infrared thermography to the non-destructive testing of concrete and masonry bridges”. NDT&E International, V.36, No. 4, pp. 265-275. https://doi.org/10.1016/S0963-8695(02)00060-9 [ Links ]

Dabous, S., Yaghi, S., Alkass, S., Moselhi, O. (2017), “Concrete bridge deck condition assessment using IR Thermography and Ground Penetrating Radar technologies”, Automation in Construction. http://dx.doi.org/10.1016/j.autcon.2017.04.006 [ Links ]

Davis, A. (2003), “The nondestructive impulse response test in North America:1985-2001”, NDT&E International, V.36, No. 4, pp. 185-193.https://doi.org/10.1016/S0963-8695(02)00065-8 [ Links ]

Ellenberg, A., Kontsos, A., Moon, F., Bartoli, I. (2016). “Bridge Deck delamination identification from unmanned aerial vehicle infrared imagery”, Automation in Construction, V.72, No. 2, pp. 155-165. https://doi.org/10.1016/j.autcon.2016.08.024 [ Links ]

Estes, A., Frangopol, D. (2003), “Updating bridge reliability based on bridge management systems visual inspection results”, J. Bridge Eng., V.8, No. 6, pp. 374-382. [ Links ]

Farrag, S., Yehia, S., Qaddoumi, N. (2016), “Investigation of Mix-Variation Effect on Defect-Detection Ability Using Infrared Thermography as a Nondestructive Evaluation Technique”, J. Bridge Eng., V.21, No. 3, pp. 1-15. http://dx.doi.org/10.1061/(ASCE)BE.1943-5592.0000779 [ Links ]

FLIR-Forward Looking Infrared. (2013), “User’s manual FLIR Exx Series” (Wilsonville, United States: FLIR), p. 100. [ Links ]

Fox, M., Goodhew, S., Wilde, P. (2016), “Building defect detection: External versus internal thermography”, Building and Environment, V.105, pp. 317-331. [ Links ]

GPO-Government Publishing Office. (2015), “Electronic Code of Federal Regulations: Subpart C, Title 23, 650.311” (Washington D.C., United States: GPO) [ Links ]

Gucunski, N., Imani, A., Romero, F., Nazarian, S., Yuan, D., Wiggenhauser, h., Shokouhi, P., Taffe, A., Kutrubes, D. (2013), “Nondestructive Testing to Identify Concrete Bridge Deck Deterioration” (Washington D.C., United States: SHRP 2 Research Reports, Transportation Research Board of the National Academies), p. 85. https://doi.org/10.17226/22771 [ Links ]

Gucunski, N., Kee, S., La, H., Basily, B., Maher, A. (2015), “Delamination and concrete quality assessment of concrete bridge decks using a fully autonomous RABIT platform”, Structural Monitoring and Maintenance, V.2, No. 1, pp. 19-34. http://dx.doi.org/10.12989/smm.2015.2.1.019 [ Links ]

Herrmann A. (2013), “ASCE 2013 Report card for America’s Infrastructure” (Washington D.C., United States: ASCE), p. 74. http://dx.doi.org/10.1061/9780784478837 [ Links ]

Hiasa, S. (2016), “Investigation of infrared thermography for subsurface damage detection of concrete structures”. Tese de Doutorado, University of Central Florida, p. 224. [ Links ]

Hiasa, S., Birgul, R., Catbas, F. (2016), “Infrared thermography for civil structural assessment: demonstrations with laboratory and field studies”, J Civil Struct Health Monit, V.6, No. 3, pp. 619-636. http://dx.doi.org/10.1007/s13349-016-0180-9 [ Links ]

Hiasa, S., Birgul, R., Catbas, N. (2017a), “Investigation of effective utilization of infrared thermography (IRT) through advanced finite element modeling”, Construction and Building Materials, V.150, pp. 295-309. http://dx.doi.org/10.1016/j.conbuildmat.2017.05.175 [ Links ]

Hiasa, S., Birgul, R., Catbas, N. (2017b), “A data processing methodology for infrared thermography images of concrete bridges”, Computers & Structures, V.190, pp. 205-218. https://doi.org/10.1016/j.compstruc.2017.05.011 [ Links ]

Hiasa, S., Catbas, F., Matsumoto, M., Mitani, K. (2016), “Monitoring concrete bridge decks using infrared thermography with high speed vehicles. Structural Monitoring and Maintenance”, V.3, No. 3, pp. 277-296. https://doi.org/10.12989/smm.2016.3.3.277 [ Links ]

Holt, F., Manning, D. (1980), “Detecting Delamination in Concrete Bridge Decks”, Concrete International, V.2, No. 11, pp. 34-41. [ Links ]

Islam, A., Li, F., Hamid, H., Jaroo, A. (2014), “Bridge Condition Assessment and Load Rating using Dynamic Response” (Youngstown, United States: ODOT), p. 128.0 [ Links ]

Jadin, M., Taib, S. (2012), “Recent progress in diagnosing the reliability of electrical equipment by using infrared thermography”, Infrared Physics & Technology, V.55, No. 4, pp. 236-245. https://doi.org/10.1016/j.infrared.2012.03.002 [ Links ]

Jain, K., Bhattacharjee, B. (2011), “Application of fuzzy concepts to the visual assessment of deteriorating reinforced concrete structures”, Journal of Construction Engineering Management, V.138, No.3, pp. 399-408. http://dx.doi.org/10.1061/(ASCE)CO.1943-7862.0000430 [ Links ]

Kee, S., Oh, T., Popovics, J., Arndt, R., Zhu, J. (2012), “Nondestructive bridge deck testing with air-coupled impact-echo and infrared thermography”. Journal of Bridge Engineering, V.17, No. 6, pp. 928-939. http://dx.doi.org/10.1061/(ASCE)BE.1943-5592.0000350 [ Links ]

Lahiri, B., Bagavathiappan, S., Jayakumar, T., Philip, J. (2012) “ Medical applications of infrared thermography: a review”, Infrared Physics & Technology , V.55, No. 4, pp. 221-235. https://doi.org/10.1016/j.infrared.2012.03.007 [ Links ]

Maierhofer, C., Arndt, R., Rollig, M. (2007), “ Influence of concrete properties on the detection of voids with impulse-thermography”, Infrared Physics & Technology , V.49, No. 3, pp. 213-217. [ Links ]

Maierhofer, C., Arndt, R., Rollig, M., Rieck, C., Walther, A., Scheel, H., Hillemeier, B. (2006), “Application of impulse thermography for non-destructive assessment of concrete structures”, Cement & Concrete Composites, V.28, No. 4, pp. 393-401. https://doi.org/10.1016/j.cemconcomp.2006.02.011 [ Links ]

Maldague, X. (2001), “Theory and Practice of Infrared Technology for Nondestructive Testing” (New York, United States: John Wiley and Sons), p. 704. ISBN: 978-0-471-18190-3 [ Links ]

Maser, K., Roddis, W. (1990), “Principles of thermography and radar for bridge deck assessment”, J. Transport. Eng., V.116, No. 5, pp. 583-601. https://doi.org/10.1061/(ASCE)0733-947X(1990)116:5(583) [ Links ]

McCan, D., Forde, M. (2001), “Review of NDT methods in the assessment of concrete and masonry structures”, NDT & E International, V.34, No. 2, pp. 71-84. https://doi.org/10.1016/S0963-8695(00)00032-3 [ Links ]

Mendes, P., Moreira, M., Pimienta, P. (2012), “Pontes de concreto armado: efeitos da corrosão e da variação do módulo de elasticidade do concreto”, IBRACON de Estruturas e Materiais, V.5, No. 3, pp. 389-401. http://dx.doi.org/10.1590/S1983-41952012000300008 [ Links ]

Meola, C., Carlomagno, G., Squillace, A., Giorleo, G. (2002), “Non-destructive control of industrial materials by means of lock-in thermography”, Measurement Science & Technology, V.13, No. 10, pp. 1583-1590. https://doi.org/10.1088/0957-0233/13/10/311 [ Links ]

Meola, C. (2007), “Infrared thermography for masonry structure”, Infrared Physics & Technology, V.49, No. 3, pp. 228-233. https://doi.org/10.1016/j.infrared.2006.06.010 [ Links ]

Meola, C. (2012), “Origin and theory of infrared thermography”, in: C. Meola (Ed.), Infrared Thermography Recent Advances and Future Trends, Bentham eBooks, pp. 3-28. [ Links ]

Montanini, R. (2010), “Quantitative determination of subsurface defects in a reference specimen made of plexiglas by means of lock-in and pulsed phase infrared thermography”, Infrared Physics & Technology, V.53, No. 5, pp. 363-371. https://doi.org/10.1016/j.infrared.2010.07.002 [ Links ]

O’Grady, M., Lechowska, A., Harte, A. (2016), “Infrared thermography technique as in-situ method of assessing heat loss through thermal bridging”, Energy and Buildings, V.135, pp. 20-32. https://doi.org/10.1016/j.enbuild.2016.11.039 [ Links ]

Oh, T., Kee, S., Arndt, R., Popovics, J., Zhu, J. (2013), “Comparison of NDT Methods for Assessment of a Concrete Bridge Deck”, Journal of Engineering Mechanics, V.139, No. 3, pp. 305-314. http://dx.doi.org/10.1061/(ASCE)EM.1943-7889.0000441 [ Links ]

Pines, D., Aktan, A. (2002), “ Status of structural health monitoring of long-span bridges in the United States”, Prog. Struct. Mater. Eng., V.4, No. 4, pp. 372-380. [ Links ]

Pintan, N., Berenguer, R., Silva, A., Lins, C., Monteiro, E. (2015), “Pathological Manifestations and the Study of Corrosion Present on Bridges of the City of Recife”, Electronic Journal of Geotechnical Engineering, V.20, No. 24, pp. 11893-11907. [ Links ]

Poblete, A., Pascual, M. (2007), “Thermographic measurement of the effect of humidity in mortar porosity”, Infrared Physics & Technology, V.49, No. 3, pp. 224-227. https://doi.org/10.1016/j.infrared.2006.06.009 [ Links ]

Rehman, S., Ibrahim, Z., Memon, S., Jameel, M. (2016), “Nondestructive test methods for concrete bridges: A review”, Construction and Building Materials, V.107, No. 15, pp. 58-86. http://dx.doi.org/10.1016/j.conbuildmat.2015.12.011 [ Links ]

Sakagami, T., Kubo, S. (2002), “Development of a new non-destructive testing technique for quantitative evaluations of delamination defects in concrete structures based on phase delay measurement using lock-in thermography”, Infrared Physics & Technology , V.43, No. 3-5, pp. 311-316. https://doi.org/10.1016/S1350-4495(02)00157-3 [ Links ]

Scott, M., Rezaizadeh, A., Delahaza, A., Santos, C., Moore, M., Graybeal, B. (2003), “A comparison of nondestructive evaluation methods for bridge deck assessment”, NDT&E International, V.36, No. 4, pp. 245-255. https://doi.org/10.1016/S0963-8695(02)00061-0 [ Links ]

Sham, J., Lo, T., Memon, S. (2012), “Verification and application of continuous surface temperature monitoring technique for investigation of nocturnal sensible heat release characteristics by building fabrics”, Energy Build., V.53, pp. 108-116. https://doi.org/10.1016/j.enbuild.2012.06.018 [ Links ]

Uemoto, T. “Maintenance of concrete structure and application of nondestructive inspection in Japan”, in: T. Uemoto (Ed.), Proc. Non Destructive Testing in Civil Eng., ELSEVIER, 2000, Kidlington: OX (UK), (2000) pp. 1-11. [ Links ]

Vaghefi, K., Ahlborn, T., Harris, D., Brooks, C. (2015), “Combined Imaging Technologies for Concrete Bridge Deck Condition Assessment”. Journal of Performance of Constructed Facilities, V.29, No. 4, pp. 1-8. http://dx.doi.org/10.1061/(ASCE)CF.1943-5509.0000465 [ Links ]

Vaghefi, K., Oats, R., Harris, D., Ahlborn, T., Brooks, C., Endsley, K., Roussi, C., Shuchman, R., Burns, J., Dobson, R. (2012), “Evaluation of Commercially Available Remote Sensors for Highway Bridge Condition Assessment”, Journal of Bridge Engineering, V. 17, No. 6, pp. 886-895. http://dx.doi.org/10.1061/(ASCE)BE.1943-5592.0000303 [ Links ]

Vaghefi, K., Melo e Silva, H., Harris, D., Ahlborn, R. (2011), “Application of thermal IR imagery for concrete bridge inspection”. In: PCI National Bridge Conference, PCI/NBC, Salt Lake City: UT (USA), pp. 1-12. [ Links ]

Vemuri, S., Atadero, A. (2017), “Case Study on Rapid Scanning Techniques for Concrete Bridge Decks with Asphalt Overlay: Ground-Penetrating Radar and Infrared Thermography”, Pract. Period. Struct. Des. Constr., V.22, No. 2, pp. 1-8. https://doi.org/10.1061/(ASCE)SC.1943-5576.0000313 [ Links ]

Venkataraman, B., Raj, B. (2003), “Performance parameters for thermal imaging systems”, Insight, V.45, No. 8, pp. 531-535. https://doi.org/10.1784/insi.45.8.531.52914 [ Links ]

Vilbig, R. (2013), “Air-Coupled and ground-coupled ground penetrating radar techniques”, Tese de Mestrado, Northeastern University - Boston, p. 60. [ Links ]

Vitório, J., Barros, R. (2013), “Análise dos danos estruturais e das condições de estabilidade de 100 pontes rodoviárias no Brasil”, In: P. Cruz, R. Calçada, T. Mendonça (Eds), Segurança, Conservação e Reabilitação de Pontes, ASCP, Porto: Portugal, pp. 62-70. [ Links ]

Washer, G. (2012), “Advances in the use of thermographic imaging for the condition assessment of bridges. Bridge Structures”, V.8, No. 2, pp. 81-90. http://dx.doi.org/10.3233/BRS-2012-0041 [ Links ]

Washer, G., Fenwick, R., Bolleni, N. (2009), “Development of Hand-held Thermographic Inspection Technologies” (Jefferson City, United States: MODOT), p. 120. [ Links ]

Washer, G., Fenwick, R., Bolleni, N. (2010), “Effects of Solar Loading on Infrared Imaging of Subsurface Features in Concrete”, Journal of Bridge Engineering, V.15, No. 4, pp. 384-390. https://doi.org/10.1061/(ASCE)BE.1943-5592.0000117 [ Links ]

Washer, G., Trial, M., Jungnitsch, A., Nelson, S. (2015), “Field Testing of Hand-Held Infrared Thermography, Phase II” (Columbia, United States: MODOT), p. 104. [ Links ]

Watase, A., Birgul, R., Hiasa, S., Matsumoto, M., Mitani, K., Catbas, F. (2015), “Practical identification of favorable time windows for infrared thermography for concrete bridge evaluation”, Construction and Building Materials, V.101, No. 1, pp. 1016-1030. https://doi.org/10.1016/j.conbuildmat.2015.10.156 [ Links ]

Yehia, S., Adudayyeh, O., Nabulsi, S., Abdelqader, I. (2007), “Detection of common defects in concrete bridge decks using nondestructive evaluation techniques”, Journal of Bridge Engineering, V.12, No. 2, pp. 215-225. https://doi.org/10.1061/(ASCE)1084-0702(2007)12:2(215) [ Links ]

Yuanlin, L., Qingju, T., Chiwu, B., Chen, M., Pingshan, W., Jiansuo, Z. (2015), “Pulsed infrared thermography processing and defects edge detection using FCA and ACA”, Infrared Physics & Technology, V.72, pp. 90-94. https://doi.org/10.1016/j.infrared.2015.07.010 [ Links ]

Zhang, Z., Tsai, N., Machin, G. (2009), “Radiometric Temperature Measurements” (Oxford, United Kingdom: Academic Press), p. 480. ISBN: 978-0-123-75091-4 [ Links ]

Zhao, H., Zhou, Z., Fan, J., Li, G., Sun, G. (2017), “Application of lock-in thermography for the inspection of disbonds in titanium alloy honeycomb sandwich structure”, Infrared Physics & Technology, V.81, pp. 69-78. https://doi.org/10.1016/j.infrared.2016.12.020 [ Links ]

Received: July 06, 2017; Accepted: September 06, 2017

texto en

texto en