Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista ALCONPAT

versión On-line ISSN 2007-6835

Rev. ALCONPAT vol.7 no.1 Mérida ene./abr. 2017

https://doi.org/10.21041/ra.v7i1.175

Applied research articles

Sustainability evaluation of different techniques for concrete mixing based on quality control

1 Facultad de Ingeniería, Universidad Autónoma de Chiapas, Tuxtla Gutiérrez, Chiapas, México.

2 Instituto de Ciencias Básicas e Ingeniería, Universidad Autónoma del Estado de Hidalgo, Pachuca, Hidalgo, México.

3 Departamento de Física Aplicada, Centro de Investigación y de Estudios Avanzados del Instituto Politécnico Nacional Unidad Mérida, Yucatán, México.

4 Departamento de Ingeniería Civil y Minas, Universidad de Sonora, Hermosillo, Sonora, México.

In this study emergy analysis, an environmental valuation method was applied to concrete mixing with the purpose of evaluating its dependence on non-renewable natural resources. Three concrete mixing techniques, industrialized, semi-industrialized and manual, were evaluated based on quality control. The quantity of environmental resources used in production was measured in terms of equivalent solar energy. The resulting transformities were compared to show that emergy analysis is sensible to local context and the limits of the reference system. The results obtained show that concrete mixing is highly dependent on external resources. Semi-industrialized concrete was found to be the most sustainable.

Keywords: emergy analysis; environmental accounting; sustainability; transformity; concrete

En este trabajo se aplicó un método de valoración ambiental en la producción de concreto con el fin de evaluar su dependencia de los recursos naturales no renovables. Tres técnicas de producción (industrializada, semi-industrializada y manual) se evaluaron bajo control de calidad mediante eMergía. Esto se realizó para medir la cantidad de uso de los recursos del medio ambiente en términos de energía solar equivalente. Las transformidades resultantes se compararon con el fin de poner de manifiesto que el análisis de eMergía es sensible al contexto local y los límites del sistema de referencia. Los resultados obtenidos muestran una alta dependencia en la producción de concreto sobre las fuentes de recursos externos, siendo el concreto semi-industrializado el más sustentable.

Palabras clave: análisis eMergético; contabilidad ambiental; sustentabilidad; transformidad; concreto

Este trabalho apresenta um método de avaliação ambiental na produção de concreto, baseado no consumo de recursos naturais não-renováveis. Três técnicas de produção (industrializada, semi- industrializada e manual) foram avaliadas sob o controle de qualidade eMergia. Este conceito foi utilizado para medir a quantidade do uso de recursos do meio ambiente em termos de energia solar equivalente. Os resultados foram comparados a fim de mostrar que a análise eMergia é sensível ao contexto local e aos limites do sistema de referência. Os resultados mostram uma alta dependência da produção de concreto em relação às fontes de recursos externos, sendo o concreto semi- industrializado o mais sustentável, segundo esta análise.

Palavras chave: análise eMergética; contabilidade ambiental; sustentabilidade; transformidade; concreto

1. INTRODUCTION

In recent years, economic development has generated negative environmental consequences. There is now a pressing need to develop management tools that can help minimize environmental impacts (Berardi, 2012; Vega et al., 2013). In the construction industry, and in the industrial sector in general, integrating environmental criteria in the design and manufacturing of products can significantly reduce the environmental impact of these products throughout their life cycle- from the extraction of raw materials for their manufacturing all the way to their final disposal (Ruiz de Arbulo, et al., 2016).

Numerous studies analyze the results of different methodologies that aim to improve sustainability in construction. These methodologies include green methodology, energy models, environmental declarations of product based on Life Cycle Analysis, environmental valuations, among others (Hamza y Horne, 2007). There are numerous publications regarding applied emergy analysis some of which are presented in Table 1.

Great volumes of concrete are employed for the construction of buildings, especially for the construction of foundations, structural frames, floors, concrete slabs and prefabricated elements (Pulselli et al., 2007). Cement, the main component of concrete, is also the most consumed material in the world after water. Thus, the environmental impacts of concrete are always associated to those of cement.

World production of cement has increased constantly since the beginning of 1950, especially in developing nations. According to data from the International Cement Review (ICR), in 2012, world production of cement was 3939 million tons, which represents an increase of 8 to 9% compared to 2011. World production is estimated to duplicate in 20 years. The main producers of cement are India and China, followed closely by the United States.

In 2012 Latin America and the Caribbean produced an estimated 180 million tons of cement, with Brazil heading the list as the main producer, followed by Mexico, Colombia and Argentina. In 2012, cement consumption per capita estimated for Latin America and the Caribbean was 301 kg/capita; for Mexico, 305kg/capita. Estimates from the International Cement Review (ICR Research), place Latin American and Caribbean cement production as 4.7% of global production (2012 estimate). Per the National Institute of Statistics and Geography (INEGI. 2015) production in Mexico for the year of 2012 was of 41, 608, 413 tons.

Production of cement accounts for approximately 5% of CO2 emissions in the world. The environmental impact caused by the emission of contaminants, particles, ashes and carbon dioxide (Kjellsen et al., 2005; Pade y Guimaraes, 2007), as well as the life cycle of both cement and concrete (Vold y Ronning, 1995; Nisbet y Van Geem, 1997), (Josa et al., 2004; Josa et al., 2007; Nazar, 2013 and the ecological footprint of concrete have been investigated in recent years (Bastianoni et al., 2007).

The Mexican Association of Independent Concrete-makers (AMCI) estimated, for the year of 2015 an eight percent growth in the sector, double the estimate of 2013, driven by federal infrastructure and housing development projects in the country. The production of concrete in Mexico stands presently at 32 million m3 annually. Production with existing infrastructure could be 50 million m3 annually.

Accordingly, this study refers to the intensive use of mineral non-renewable resources and fossil fuels for the extraction of inert aggregates (sand and gravel), the use of water, the production of cement for concrete mixing and, in particular, evaluates the quantity of inflows of environmental resources in the production process. Concrete mixing was evaluated as a study case, considering the standard process for the manufacturing of Composite Portland Cement 30R. In comparison with data and values calculated previously, this study shows that emergy analysis is particularly sensible to context limits and reference systems (Brown y McClanahan, 1992; Buranakarn, 1998; Björklund et al., 2001; Brown y Buranakarn, 2003; Pulselli et al., 2008). An ecological accounting method was implemented in the concrete mixing techniques included in this study with the objective of providing better comparing each technique’s sustainability.

2. METHODOLOGY

2.1 Location of the case study zone

Tuxtla Gutierrez is the capital and the largest city in the state of Chiapas, Mexico. It is the headquarters of the state government and the center of the metropolitan area. Urban growth and economic development in the city have increased with the arrival of national and foreign capital and government subsidies.

The Ease of Doing Business Index from the World Bank Group (WBG) and the International Finance Corporation (IFC), which classifies the economy of each country according to business regulations and property rights, ranks Tuxtla Gutierrez in the fifth place in Mexico. The capital of Chiapas is among the most dynamic cities in the south-southwest because of its job market, offer of goods and services, among other things.

2.2 Emergy analysis

Emergy analysis evaluates inflows and outflows of energy and materials in common units (solar emjoules, abbreviated as seJ) that allow the analyst to compare environmental and financial aspects of the system. Based on this unit, emergy can be defined as the quantity of solar energy used, directly or indirectly, to produce a particular good or service (Odum, 1971, 1983, 1988, 1996) (Brown et al., 2004). In other words, emergy is the "energy memory" that is used along a sequence of processes to obtain a good or service. Solar transformity is the solar emergy required to generate a Joule of a service or a product. Its units are the solar-emjoule/Joule (seJ/J).

The first step in the analysis is to draw a diagram of the energy-flows in the systems studied to learn what relationships exist between different components and the different resource flows. The second step consists in the construction of emergy analysis tables based on the diagrams of the previous step. In the third step, the emergy indexes that relate the flows of emergy in the economy with those in the environment are calculated. Finally, the indexes are interpreted to diagnose economic viability and the loading capacity of the systems studied.

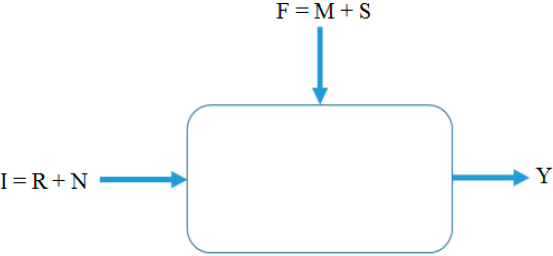

The emergy indexes developed by Odum (1971) define sustainability referring to the quantity and quality of the energy transformed for a particular production system. Odum's analysis involves the use of the diagram three branch (see Figure 1) which facilitates calculation of the indexes.

Where:

I: Natural Renewable Resources (R) plus Natural Nonrenewable Resources (N)

F: Materials (M) plus Services (S)

Y: System output.

Taking the region into account, the use of nonrenewable resources by the construction industry was evaluated by means of an emergy analysis. This procedure followed a top to bottom approach beginning with an emergy analysis of the country (Mexico), then the state of Chiapas, the municipality of Tuxtla Gutierrez, and finally at the level of each technique studied. The objectives of this study are presented as follows:

Provide a methodology that evaluates the costs and benefits of the concrete mixing.

Compare different concrete mixing techniques using emergy indexes such as the Emergy Investment Ratio (EIR), Emergy Yield Ratio (EYR), Environmental Loading Ratio (ELR), Emergy Sustainability Index (ESI), and Transformities.

According to the information collected in the study case zone and to the present knowledge of the field of emergy analysis, three techniques were identified for the production of hydraulic concrete. In addition, the local construction industry referred to f´c=24.53 MPa concrete as the most used in the zone.

For the study of the alternatives related to concrete mixing three techniques, 1) industrialized 2) semi-industrialized and 3) manual, were selected and evaluated by means of an emergy analysis. The comparison was done using the emergy indexes obtained for each case study in the city of Tuxtla Gutierrez, Chiapas, Mexico, to determine the environmental viability of each of these options. The unit of evaluation was the cubic meter.

The following specifications were considered for each technique:

Industrialized technique: This technique can be distinguished from the other two techniques by the use of heavy machinery, such as concrete plants, mixing trucks and front loaders, with eight workers required for the whole production process.

Semi-industrialized technique: The main characteristic of this technique is the use of simple machinery (portable drum mixer) combined with manpower (a group of about ten workers). Helped by a gasoline powered concrete mixer, this technique is used for the mix of moderate volumes (no more than 45 m3 by group of workers).

Manual technique: This technique uses about fifteen workers with moderate skills, including two technicians, one of them directing the workforce and the other supervising quality. With help of simple tools and without the use of fuels, electricity or mechanical energy, this method is generally employed for small volume production (no more than 10 m3 per group of workers).

For this study, the transformities for the inert aggregates (gravel and sand), cement and water were calculated for the city of Tuxtla Gutierrez, Chiapas, Mexico. The valuation was done taking into account an annual production of 70,000 m3 for industrialized concrete, and a daily production for semi-industrialized and manual concrete of 45 m3 and 10 m3 respectively. The transformity of cement was based on the annual production of 2,190,000 tons of the local cement plant. The transformity employed for sand corresponds to the extraction area of the Santo Domingo River located in the municipality of Chiapa de Corzo, Chiapas, at a distance of 30 km from the city of Tuxtla Gutierrez, Chiapas. The crushed gravel was extracted from the quarry located in the neighborhood of Plan Chiapas in the municipality of Chiapa de Corzo where it borders with the municipality of Tuxtla Gutierrez.

The emergy indexes employed in the study were: the EIR, calculated as the relationship between contribution from the economy (F) and nature (I), which is adimensional. The EYR, is considered as the relationship between the total emergy that enters the system (Y) and the contribution to the economy (F). This index is adimensional. The higher the value of this index is, the higher the impact of the system on the global economy. ELR was calculated as the relationship between the sum of non-renewable natural resources (N) and economical resources (F) multiplied by all natural renewable resources (R). It is also adimensional. The ESI shows the contribution of the natural environment, that is to say, the energetic work that the ecosystems do to generate processes for the environmental load. This value was calculated dividing the contribution of nature (EYR) by the environmental load (ELR).

Finally, the calculated emergy values of concrete in this study were compared with those in previous emergy studies with the objective of showing how emergy analysis is sensible to local context and the limits of the reference system.

3. RESULTS AND DISCUSSION

This study allowed a comparison between the different concrete mixing techniques selected, using emergy indicators such as EIR, EYR, ELR and ESI. The emergetic attributes of each system were quantified and used as indicators of the characteristics of each technique. For the evaluation of each alternative, the concrete considered was f´c= 24.53 MPa. These proportions were obtained at the Concrete Technology Laboratory at the Engineering Faculty of the Autonomous University of Chiapas, for the study cases of manual and semi-industrialized techniques. The corresponding indicators for industrialized concrete were obtained from a concrete factory in the city of Tuxtla Gutierrez, Chiapas, Mexico.

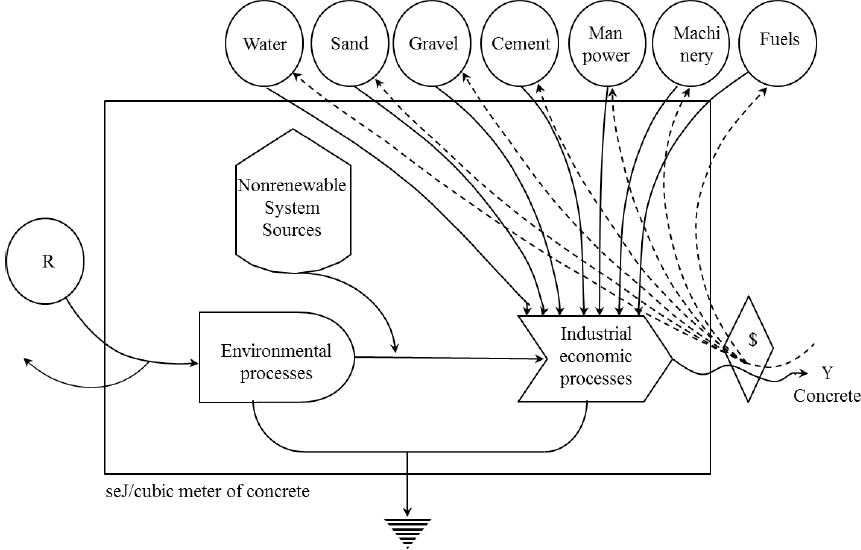

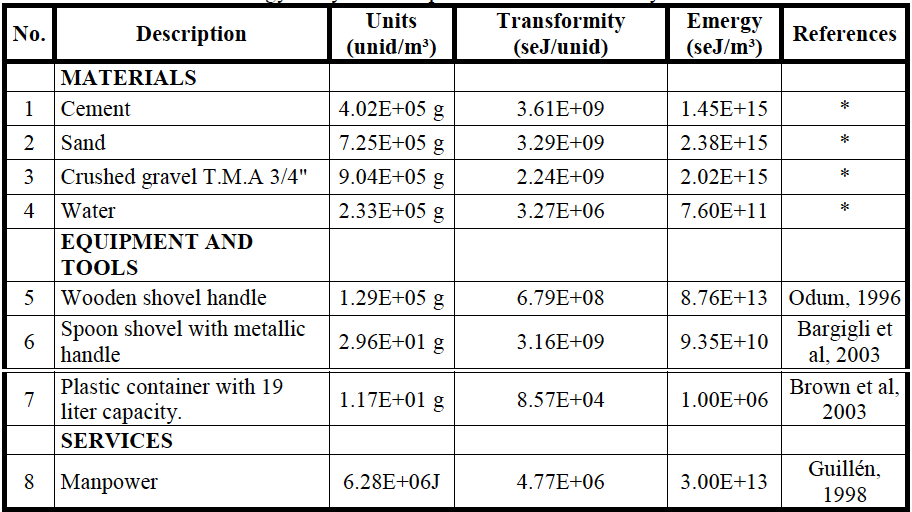

The diagram of energy flows interacting within the concrete mixing system shows (Figure 2) renewable and nonrenewable resources as well as the energy acquired by inputs (materials, services, manpower). Based on the flow diagrams, an emergy analysis was performed for each alternative and is presented in Tables 2, 3 and 4. For each case, the emergy of concrete mixing was based on the following supplies: raw materials, transportation, equipment and machinery, fuels, manpower, maintenance and insurance.

Table 2 Emergy analysis of the production of industrialized concrete

*Transformity calculated for this study.

Y = 8.32E+15

Table 3 Emergy analysis of the production of semi-industrialized concrete

*Transformity calculated for this study

Y = 5.87E+15

Table 4 Emergy analysis of the production of concrete by manual means

*Transformity calculated for this study

Y = 5.98E+15

The total emergy consumed by each mixing technique was of 5.9 E15 seJ, 5.87E15 seJ and 8.32E15 seJ, with manual means, semi-industrialized and industrialized, respectively as can be seen on Tables 2, 3 and 4. In the mixing of industrialized concrete, 98.14% of the total emergy is materialized in the sedimentary natural cycles of construction materials. Machinery accounts for (0.084%), fuel for (1.00%) and manpower for (0.24%). With semi-industrialized concrete, 99.44% is materialized during the sedimentary natural cycles of construction materials. Equipment and tools account for (0.045%), fuels (0.022%) and manpower (0.076%). Finally, concrete mixed by manual means shows that 98.02% of the total emergy is materialized in the natural sedimentary cycles of the construction materials. Equipment and machinery account for (1.47%), and manpower for (0.50%).

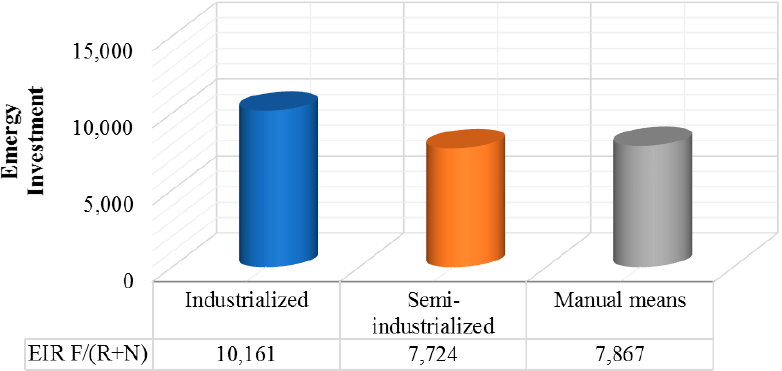

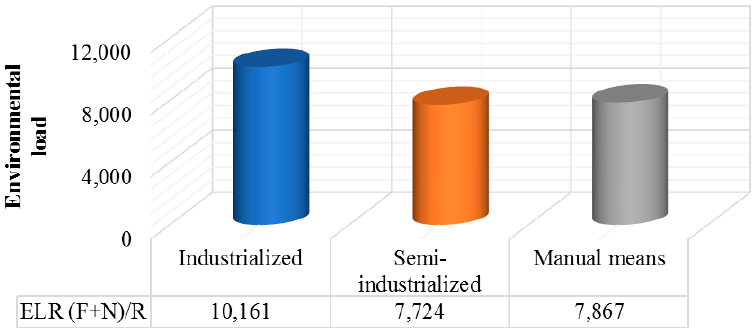

The EIR value of industrialized concrete is higher when compared with the same value for semi-industrialized concrete and concrete produced by manual means. The value stands at 10,161 for industrialized concrete, at 7,724 for semi-industrialized concrete and at 7,867 for concrete mixed by manual means. This value suggests a weak competitive capacity due to the instability of external sources of materials. Figure 3 shows a comparison of the EIR for the three different techniques.

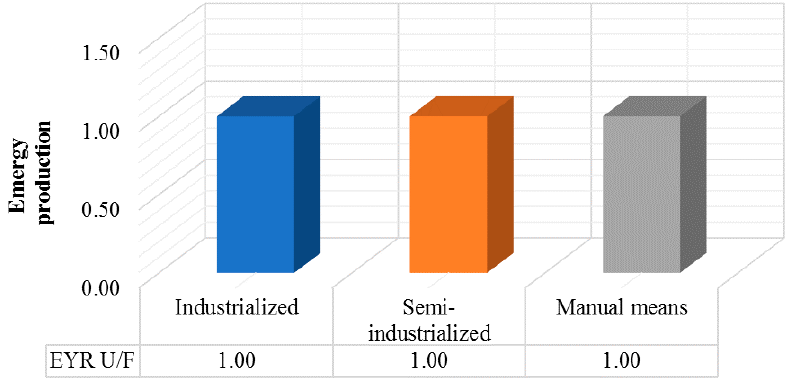

The EYR shows the contribution of nature to the productive system, or in other words, quantifies the work of the ecosystem to obtain products. The techniques analyzed in the study presented a value lower than 1.00, which indicates that the emergy liberated by these systems is equal to that invested in the form of economic resources. In other words, it implies that they are highly dependent on imported supplies and services. An EYR value higher than 1 indicates that the system analyzed generates more new resources (of emergy) than those available as inputs, otherwise, the system is a transforming consumer of resources. In Figure 4 the production of emergy in concrete has been graphically illustrated.

The analysis shows that industrialized concrete has a higher ELR, with a value of 10,161 compared to the values obtained for semi-industrialized and concrete produced by manual means (7,724 and 7,867, respectively). These values are relevant to demonstrate the degree to which concrete mixing is harmful towards the environment. It is important to note that concrete produced by manual means presents a higher environmental load than semi-industrialized concrete due to low productivity. This is evident when you consider the 10 m3 produced in 8 hours of work by manual means, compared with 45 m3 for semi-industrialized concrete. The ELR reflects the energy incorporated to the system by the manpower employed in both techniques. The Environmental Load of both techniques is compared in Figure 5.

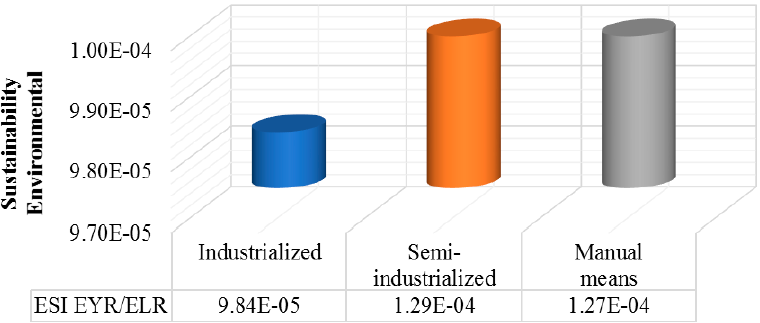

The ESI indicates the contribution of the natural environment, meaning that the energy work that is done by ecosystems to generate processes that act upon the environmental load. According to Brown and Ulgiati (2004), ESI values inferior to 1 indicate systems that consume resources and are associated with highly developed, consumption-oriented economies. The values reported in this study indicate that semi-industrialized concrete (0.000129) has a higher ESI value than that of concrete produced by manual means (0.000127) and industrialized concrete (0.0000984). This means that semi-industrialized concrete is the one that impacts environmental equilibrium to a lesser degree, and is therefore more sustainable for the environment than industrialized concrete and concrete produced by manual means. In relation to this index it is important to note that the main difference between semi-industrialized (4.44E+12) and manual production (3.00+13) is the manpower employed. Figure 6 shows a graphic comparison of the ESI results obtained for each alternative.

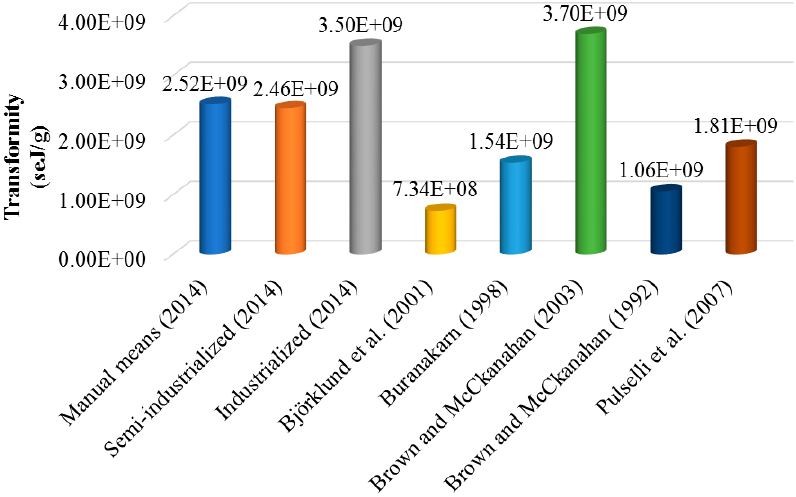

With relation to other studies conducted in reference to the mixing of industrialized concrete, the following significant differences were found:

In Bjorklund et al (2001): the authors used solar transformity values in a national context. For example, the transformity of electricity is very specific, because it was evaluated according to production processes in Sweden, which includes nuclear energy (33%- here represented with the transformity of median world electric production), and hydroelectric energy (66%). In the present study, the emergy evaluation of cement production is not considered in the whole production process, and this represents an important approximation. In regards to the main supplies used in concrete mixing, the present study only considers the use of limestone, electricity and petroleum, while other inputs such as transport, packaging and services like manpower machinery and fuel were not evaluated. Electricity and manpower were evaluated by means of an emergy/money relation.

In Buranakam (1998), specific emergy was evaluated for the United States. The analysis included an evaluation of highways, vehicles and infrastructure used, taking into account the whole national transportation system. The author calculated the total length of national highways and their production process (materials, energy, manpower and other services), taking into account the annual cost of construction. This value (in seJ/km) was divided by the percentage of buses in relation to the total weigh of vehicles (cars, buses, trucks, and others). The same was done with railroads and maritime services (boats). In general, the useful life of highways, vehicles and all relevant infrastructures was not taken into account. Manpower and other services were evaluated using an emergy/money relation.

In the work of Brown and Buranakam (2003), the emergy evaluation was done based in Buranakam 1998, and it took into account the different stages in the use of materials, demolition and reuse. Accordingly, their analysis had to do with process inputs that had to do with specific procedures. The present work had the objective of determining the transformity of concrete, from its origin, to its use in the construction of buildings- excluding the disposal stage.

Similarly, Brown and McClanahan (1992) evaluated the specific emergy of Thailand with reference to the energy sources available at the local level. This analysis was carried out in 1992, using data from 1983. The emergy analysis was very simplified in comparison to the one in the present study due to the fact that the authors considered some problems such as material flows, petroleum and electricity as energy flows and other goods and services, this last one evaluated in terms of money flow (by means of an emergy/money relation).

On the other hand, Pulselli et al. (2008) centers his attention on the production process of the Italian cement and concrete industry. Most the values of the transformities in the study were evaluated in the U.S.A. The authors carried out an evaluation of a specific process taking into account a specific amount of 23 tons of concrete and its transportation to the construction site. In the selection of this system they consider some insignificant factors such as the evaluation of the total national transportation infrastructure (highways and other services). Figure 7 compares the transformities of concrete obtained by the authors previously cited and compares them with the results obtained in this work.

Emergy analysis of concrete mixing based on quality control considers several steps in the process, from the production of materials to the concrete mixing process. The results of this study show that the impact of quarry materials on the total emergy is higher than the impact of production processes. Quarry materials, product of natural sedimentary cycles and counted in seJ, present a very high transformity. The present analysis shows that excessive use of non-renewable resources is critical for the construction industry because it considers not only human work done in quarries (process which is included in the economical analysis), but also the work done by nature (sedimentary cycle). The important part played by mineral resources in the production of cement highlights how unsustainable the construction industry is.

Transformity is presented as a measurement of the use of environmental resources in the form of materials used during construction. It provides a classification of construction materials based on an energy hierarchy. Emergy analysis combines quality (Transformity) with quantity (energy or mass). The environmental impact of the construction process will depend on the materials used (in terms of environmental cost due to energy use and mass) and on the process itself (quantity of materials needed to construct structural elements). Transformity shows that the main difference between semi-industrialized (4.44E+12) and manual manufacturing techniques (3.00+13) is the manpower employed. Consequently, this index can be taken as a measurement of the use of natural resources in the form of construction materials and can also help when creating a classification of construction materials according to an energy hierarchy.

According to Buron Maestro (2012), sustainability does not have an absolute value. Its purpose as a concept is to help compare and select the most appropriate options so that the present development of society can continue without compromising the development of the future. There are no sustainable solutions; there are only solutions that are more sustainable than others.

4. CONCLUSIONS

The emergy method allowed for an analysis that considers the relationships between natural systems and anthropic activities and helps us look for strategies that are ever more sustainable.

The EIR was evaluated as an indicator of sustainability by measuring dependency on local or external sources. It was demonstrated that concrete mixing processes depend to a high degree in supplies obtained from outside the system (emergy input from imports).

The ESI was employed as a measure of the contribution of the system hierarchically higher to the production of the system by load unit of itself. The results show that semi-industrialized concrete is more sustainable than concrete manufactured by manual means or by industrial processes.

Emergy analysis provides a way to measure the sustainability of concrete mixing techniques based on quality control in terms of energy investment. Many units of low quality energy are used to provide high quality energy (high Transformity). Energy is materialized by means of a chain of transformative processes and its memory is conserved by the production structure.

5. REFERENCIAS

Ascione, M., Campanella, L., Cherubini, F., & Ulgiati, S. (2009). Environmental driving forces of urban growth and development. An emergy-based assessment of the city of Rome, Italy. Landscape and Urban Planning, 93(3-4), 238-249. [ Links ]

Abel, T. (2015). Convergence and divergence in the production of energy transformation hierarchies. Ecological Modelling, 4-11. [ Links ]

Agostinho, F., Bertaglia, A., Almeida , C., & Gianett, B. (2015). Influence of cellulase enzyme production on the energetic-environmental performance of lignocellulosic ethanol. Ecological Modelling , 46-56. [ Links ]

Aguilar Rivera, N., Alejandre Rosas, J., & Espinosa López, R. (2015). Evaluación emergy Y LCA en la agroindustria azucarera de Veracruz, México. INCA Cultivos Tropicales , 2015, vol. 36 44-157. [ Links ]

Bargigli, S., & Ulgiati , S. (2003). Emergy and Life-Cycle assesment of steel production in Europe. Gainesville, Florida, E.U.: University of Florida. [ Links ]

Bastianoni , S., Galli , A., Pulselli, R. M. , & Niccolucci, V. (2007). Environmental and economic evaluation of natural capital appropriation through building construction: practical case study in the Italian context. Ambio. [ Links ]

Bastianoni, S., Morandi, F., Flaminio, T., Pulselli, R. M., & Tiezzi, E. B. (2011). Emergy and emergy algebra explained by means of ingenuous set theory. Ecological Modelling , 2903- 2907. [ Links ]

Berardi, U. (2012). Sustainability assessment in the construction sector: rating systems and rated buildings. Sustainable Development, 411-424. [ Links ]

Björklund, J., Geber, U., & Rydberg, T. (2001). Emergy analysis of municipal wastewater treatment and generation of electricity by digestion of sewage sludge. Resources, Conservation and Recycling, 293 - 316. [ Links ]

Brown , M. T., & Buranakarn, V. (2003). Emergy indices and ratios for sustainable material cycles and recycle options. Resources, Conservation and Recycling , 1 - 22. [ Links ]

Brown, M. T. , Odum , H. T., & Jorgensen , S. E. (2004). Energy hierarchy and transformity in the universe. Ecological Modelling , 17 - 28. [ Links ]

Brown , M., & Ulgiati , S. (2004). Emergy Analysys and Environmental Accounting. Earth Systems and Environmental Sciences, 329 - 354. [ Links ]

Brown, M. T., & McClanahan, T. R. (1992). Emergy analysis perspectives of Thailand and Mekong river dam proposals. Final Report to the Cousteau Society. Gainesville, FL.: Center for Wetlands and Water Resources, University of Florida. [ Links ]

Buranakarn, V. (1998). Evaluation of recycle and reuse of building materials using the emergy analysis method. Ph.D. Dissertation. University of Florida, FL. [ Links ]

Burón Maestro, M. (2012). El hormigón y la sostenibilidad en la normativa. Sostenibilidad: Eficiencia Energética, Evaluación de edificios y estructuras. Madrid, España: IECA. [ Links ]

Campbell, E. (2015). Emergy analysis of emerging methods of fossil fuel production. Ecological Modelling , 57-68. [ Links ]

CEIEG. (2016). Comité Estatal de Información Estadística y Geográfica. Gobierno del Estado de Chiapas. Obtenido de http://www.ceieg.chiapas.gob.mx/perfiles/Inicio [ Links ]

Doherty, S. J., Scatena, F. N., & Odum, H. T. (1994). Emergy Evaluation of the Luquillo Experimental Forest and Puerto Rico. Final Report to International Institute of Tropical Forestry. Rio Piedras, Puerto Rico. [ Links ]

Emergy Synthesis, 8. (2015). Emergy and environmental accounting: Theories, applications, and methodologies. Ecological Modelling , 1-3. [ Links ]

Ferreira C, Ó. I., Hurtado S, M. d., García, E., Bonilla Correa, C. R., & M. Rao, I. (2010). Emergía de tres sistemas agroforestales en el sur del municipio. ACTA AGRONÓMICA. 59 (3), 327-337. [ Links ]

Guillén, H. A. (1998). Sustainability of Ecotourism and Traditional Agricultural Practices in Chiapas, México. Gainesville, Florida, E.U. : Tesis Doctoral. [ Links ]

Gutierrez, L. (2003). El concreto y otros materiales para la construcción. Manizales, Colombia.: Centro de publicaciones de la Universidad Nacional de Colombia Sede Manizales. [ Links ]

Hamza, N., & Horne, M. (2007). Educating the designer: An operational model for visualizing low-energy architecture. . Building and Environment, 3841-3847. [ Links ]

INEGI. (2015). Encuesta mensual de la industria manufacturera. Estadísticas históricas de México 2014-2015. [ Links ]

Josa, A., Aguado, A., Cardim , A., & Byars, E. (2007). Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cement Concrete Research, 781 - 788. [ Links ]

Josa, A., Aguado, A., Heino, A., Byars, E., & Cardim, A. (2004). Comparative analysis of available life cycle inventories of cement in the EU. Cement Concrete Research , 1313 - 1320. [ Links ]

Kjellsen , K., Guimaraes , M., & Nilsson, A. (2005). The CO2 Balance of Concrete in a Life Cycle Perspective. Danish Technological-DTI. [ Links ]

Lacarrière, B., Deutz, K., Jamali Zghal , N., & Le Corre, O. (2015). Emergy assessment of the benefits of closed-loop recycling accounting for material losses. Ecological Modelling , 77-87. [ Links ]

Li, L., Lu, H., Tilley , D., & Qiu, G. (2014). Effect of time scale on accounting for renewable emergy in ecosystems located in humid and arid climates. Ecological Modelling , 1-8. [ Links ]

López Villalobos, I. D., & Rodríguez Salcedo, J. (2013). Análisis energético de la sostenibilidad ambiental del municipio de Palmira (Colombia). Revista de Investigación Agraria y Ambiental . Vol. 4 No. 2. [ Links ]

Mendoza Sánchez, J. F. (2014). Criterios de sustentabilidad para carreteras en México. Sanfandila: Publicación Técnica No. 392, Instituto Mexicano del Transporte. [ Links ]

Morandi, F. , Campbell, D. E., Pulselli, F. M., & Bastianoni, S. (2015). Emergy evaluation of hierarchically nested systems: application to EU27 Italy and Tuscany and consequences for the meaning of emergy indicators. Ecological Modelling , 12-27. [ Links ]

Mu, H., Feng, X., & Chu, K. H. (2012). Calculation of emergy flows within complex chemical production systems. Ecological Engineering, 88- 93. [ Links ]

Nazar, M. (2013). Estimación de las emisiones de gases de efecto invernadero atribuibles a la construcción de viviendas multifamiliares de interés social. Tuxtla Gutiérrez, Chiapas: Tesis Doctoral. [ Links ]

Nisbet , M., & Van Geem, M. G. (1997). Environmental life cycle inventory of Portland cement and concrete. World Cement, 3. [ Links ]

Odum, H. T. (1971). Environment. Power and Society. Wiley, New York, NJ. [ Links ]

Odum, H. T. (1983). Environment. Power and Society . Wiley, New York, NJ . [ Links ]

Odum, H. T. (1988). Self organization, transformity and information. Science, 1132 - 1139. [ Links ]

Odum, H. T. (1996). Environmental Accounting Emergy and Environmental Decision Making. New York, NJ.: Johl Wiley and Sons, Inc. [ Links ]

Ortega Rodríguez, E., Vallim de Melo, C., & Del Pozo Rodríguez P, P. (2014). El análisis emergético como herramienta para evaluar la sustentabilidad en dos sistemas productivos. Revista Ciencias Técnicas Agropecuarias Vol. 23 , No. 4, 59-63. [ Links ]

Pade , C., & Guimaraes, M. (2007). The CO2 uptake of concrete in a 100 year perspective. Cement Concrete Research , 1348-1356. [ Links ]

Pulselli, R. M. , Simoncini, E., F.M. Pulselli, F. M. , & Bastianoni, S. (2007). Emergy analysis of building manufacturing, maintenance and use: Em-building indices to evaluate housing sustainability. Energy and Buildings, 620-628. [ Links ]

Pulselli , R.M., Simoncini, E., Ridolfi, R., & Bastianoni, S. (2008). Specific emergy of cement and concrete: An energy-based appraisal of building materials and their transport. Ecological Indicators, 647 - 656. [ Links ]

Ruiz de Arbulo Lopez, P., Landeta Manzano, B., Díaz de Basurto Uraga, P., & Arana Landín, G. (2016). Adopción de Sistemas de Gestión de Ecodiseño en el sector de la construcción. Análisis de la perspectiva de los diferentes agentes involucrados. Dyna, 124-133. [ Links ]

Suca A, F., Suca A, A., & Siche J, R. (2014). Análisis emergético del café peruano. Revista Peruana de Química e Ingeniería Química Vol. 17 N.º 1, 43-57. [ Links ]

Tennenbaum, S. E. (2015). Emergy and co-emergy. Ecological Modelling , 116-134. [ Links ]

Tilley, D. R. (2015). Transformity dynamics related to maximum power for improved emergy yield estimations. Ecological Modelling , 96-107. [ Links ]

Vega, L., Ordoñez, J., & Pinilla , G. (2013). Towards a systemic assessment of environmental impact (SAEI) regarding alternative hydrosedimentological management practice in the Canal del Dique, Colombia. Ingeniería e Investigación, 41-48. [ Links ]

Vilbiss , C., & Brown, M. (2015). New method to compute the emergy of crustal minerals. Ecological Modelling , 108-115. [ Links ]

Vold, M., & Ronning, A. (1995). LCA of Cement and Concrete. Stiftelsen. [ Links ]

Wright, C., & Ostergard, H. (2015). Scales of renewability exemplified by a case study of three Danish pig production systems. Ecological Modelling , 28-36. [ Links ]

Wu, X., Wu, F., Tong, X., Wu, J., Sun, L., & Peng, X. (2015). Emergy and greenhouse gas assessment of a sustainable, integrated agricultural model (SIAM) for plant, animal and biogas production: Analysis of the ecological recycle of wastes. Resources, Conservation and Recycling , 40-50. [ Links ]

Zarba, L., & Brown , M. T. (2015). Cycling emergy: computing emergy in trophic networks. Ecological Modelling , 37-45. [ Links ]

Received: October 18, 2016; Accepted: January 10, 2017

texto en

texto en