Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista ALCONPAT

versión On-line ISSN 2007-6835

Rev. ALCONPAT vol.5 no.3 Mérida sep./dic. 2015

Articles

Concrete with treated surface and exposed to chlorides solution: thickness of equivalent coatings

1 Departamento de Construcción Civil, Universidade Federal do Paraná (UFPR), Brasil. E-mail: medeiros.ufpr@gmail.con

2 Departamento de Construcción Civil, Universidade Federal do Paraná (UFPR), Brasil. E-mail: ligiavr@gmail.con

3Instituto de Pesquisas Tecnológicas (IPT), Brasil. E-mail: quarciva@ipt.br

4 Universidade de Sao Paulo (USP), Brasil. E-mail: paulo.helene@concretophd.con.br

The main purpose of the experimental tests was to obtain the chloride diffusion coefficient and generate a chloride ingress prediction for surface treated concrete that could be valid during the initiation stage and transport by ions diffusion. The prediction was based on non steady-state conditions and some of the results indicated that a concrete with this type of protection can extend the chloride ingress up to three times. Data showed in this work indicated the equivalent cover of the surface treatment, ranging between 0.3 and 3.4 cm, showing large variations in results among the surface treatment materiais tested.

Keywords: Reinforced concrete; Marine environment; Chloride migration; Service life

El principal objetivo de las pruebas era obtener el coeficiente de difusión y generar un cloruro de cloruro de entrada en previsión de hormigón con y sin superficie tratada, válido para el período de inicio de la corrosión de penetración de armadura y la difusión de iones. El pronóstico se basa en el estado inestable y algunos resultados indican que un hormigón con este tipo de protección puede aumentar el tiempo de contaminación hasta tres veces. Revestimientos equivalentes también presentados de protección de datos indica que los materiales utilizados en este experimento oscilaron entre 0,3 y 3,4 cm, es decir, los resultados mostraron una gran variación entre la protección de materiales probados.

Palabras clave: concreto armado; ambiente marino; migración de cloruros; vida útil

O objetivo principal dos testes foi obter o coeficiente de difusão de cloretos e gerar uma previsão de ingresso de cloretos em concretos com e sem superfície tratada, válida para o período de iniciação da corrosão de armaduras e penetração por difusão de íons. A previsão foi baseada no estado não estacionário e alguns resultados indicam que um concreto com esse tipo de proteção pode aumentar o tempo de contaminação em até três vezes. Também foram apresentados dados de cobrimento equivalente dos materiais de proteção indicando que os utilizados neste experimento variaram entre 0,3 e 3,4 cm, ou seja, apresentou grande variação de resultados entre os materiais de proteção testados.

Palavras chaves: concreto armado; ambiente marinho; migração de cloretos; vida útil

1. INTRODUCTION

The use of superficial protection for concrete is a possible way of increasing the service life of reinforced concrete structures exposed to marine environments. This type of protection inhibits the penetration of aggressive agents by diffusion and capillary absorption.

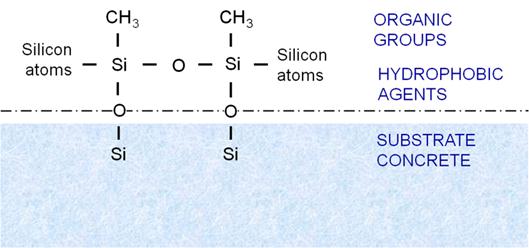

The surface protection materials for concrete can be classified into three groups: Pore liners (make the concrete water-repellent), pore blockers (react with some of the soluble concrete constituents and form insoluble products) and coatings (form continuous film on the concrete surface). Figure 1 illustrates these three groups of superficial protection.

Figure 1 Groups of surface treatments: (a) coatings and sealers, physical barrier (b) pore liners, water repellent (c) pore blockers (adapted from Keer, 1992).

1.1 Coatings and sealers

Coatings and sealers present the advantage of providing a physical barrier on the concrete surface, which isolates it from the aggressive agents of the external environment. These coatings require a homogeneous and smooth substrate with pores of 0.1 mm width at most. This means that they are capable of covering a 0.1 mm wide crack. However, the film breaks if the concrete structure cracks after painting. Moreover, coatings do not allow the concrete to dry if it is wet. This can cause the deterioration of the film, causing the formation of bubbles due to the vapor pressure of the internal humidity. From the architectural point of view, this group of surface treatment modifies the aesthetics of the structure adding brightness or color to the concrete surface, which is sometimes desired (Helene, 2000).

This group of surface treatment (coating and sealers) has been intensely studied in the last fifteen years. Delucchi et al. (1998) studied the importance of the parameters E (modulus of the material) and ( (viscosity) in the crack-bridging ability of the coating. Seneviratne et al. (2000), using mechanical thermal analysis, suggested that the most successful coating is able to maintain its elastomeric properties over the required period of exposure and over a wide range of operational temperatures. Uemoto et al. (2001) showed a correlation between the paint pigment volume content and water permeability. Al-Zahrani et al. (2002) showed that the accelerated corrosion performance of the four coating systems studied correlates well with the performance results obtained from the physical properties, in particular, water absorption, water permeability, and chloride penetration. Medeiros and Helene (2009) suggested that the determination of the chloride diffusion coefficient allows a quantitative comparison of the protection systems and, therefore, needs to be made possible in migration tests. This kind of protection is probably the most used by the construction industry and that would be the reason why they are widely studied.

1.2 Water repellent

Water repellents or hydrophobic agents always result from silicon resins that are chemically bound to the concrete base. Currently, the most commonly used are silanes, siloxanes oligomerics and a mixture of these two components (Medeiros; Helene, 2008).

Chemically, silanes are formed of small molecules that have one silicon atom and siloxanes are short chains of a few silicon atoms in which the molecules have alkoxy groups (organics) connected to the silicon atom. Silanes and siloxanes react with the silicate of the concrete, forming a stable bonding (Vries and Polder, 1997) (Figure 2). Medeiros et al. (2009) showed that the penetration of the hydrophobic agent is better in finished faces than in formwork faces, due to the higher permeability of the second. Jacob; Hermann (1998), Batista (1998) and Moriconi et al. (2002) presented an ample review on surface hydrophobic agents. The use of hydrophobic agents in the construction industry is increasing at an interesting rate and they have been reasonably studied. However, there are some items that are still being studied, such as the influence of the water penetration mechanism (capillary suction and permeability) in the efficacy of the hydrophobic treatment (Medeiros; Helene, 2008).

Figure 2 Chemical bond of the hydrophobic agent with concrete (adapted from Vries and Polder, 1997).

1.3 Pore blockers

Pore Blockers, such as sodium silicate, are used in the cement industry for some applications. For example, as slag cement activator; as treatments of vegetal fibers used for cement reinforcement, as surface treatment for concrete and as hardening/densifying of surface concrete floors (Mehta, Monteiro, 2008; Brough, Atkinson, 2002; Jones, 2002; Toledo et al., 2003; Melo Neto, 2009).

Although this group of treatment has been known for several years, little technical and scientific information about this subject has been published. On the other hand, many products of this type are commercialized and indicated for the protection of concrete surfaces. Thompson et al. (1997) explained the 3 theories on how silicates act to improve the performance of concretes:

SiO2 precipitating in the pores.

Silicates forming an expansive gel similar to that formed in alkali silicate reactions that fills the pores in the concrete by swelling.

Silicates reacting with excess calcium present in the near surface region of the concrete to form relatively insoluble calcium-silicate hydrates.

The latter theory is currently the most accepted. In this way, theoretically, the pore blockers are products composed by silicate, which penetrate the superficial pores of the concrete and react with portlandite forming C-S-H. Sodium silicate is the mostly used silicate applied in this way.

According to Thompson et al. (1997), Eq. 1 represents what happens when the sodium silicate solution penetrates the pores of the concrete.

In this way, this treatment forms a less porous layer in the concrete surface modifying the water penetration into the concrete.

This treatment requires that sodium silicate reacts with portlandite [Ca(OH)2]. Therefore, it is easy to understand that, in carbonated concrete, the reaction above fails to occur. This is why in the superficial layer the Ca(OH)2 already reacted with CO2 and originated CaCO3. In this case, it is necessary to make an impregnation with hydroxyl ions before the application of sodium silicate. This explains why Kagi and Ren (1995) affirmed that a significant reduction in the permeability of concrete due to silicate solution impregnation can only be achieved if the concrete is very fresh and repeated impregnations are carried out to fill all the concrete capillaries. Another contribution of Kagi and Ren (1995) is related with water vapour permeability of the substrate which is not significantly affected by silicates because they only cover capillary walls without blocking them fully. Ibrahim et al. (1997) focused their work on measuring the time taken for reinforced concrete specimens coated with sodium silicate to crack by corrosion and concluded that the results were similar to that of the uncoated concrete specimens. However, their results are not in accordance to those of Thompson et al. (1997) regarding water absorption. It is important to emphasize that Ibrahim et al. (1997) do not inform the concentration of sodium silicate solution used in their study. The use of a low concentration may have influenced their results. Thompson et al. (1997) compared some concentrations of sodium silicate solutions and the value around 26% presented greater efficiency.

It is important to emphasize that the pore blocker should be applied after the structure is in service. This is after it has taken all the projected loads and cracks and microcracks have been produced. However, environmental effects can cause more cracks. If there are cracks (large enough to be visible) before the application of the silicates, it is necessary to repair them prior the treatment application. If the cracks (large enough to be visible) appear after the silicates treatment, they need to be repaired immediately because the low porosity layer formed by the treatment is ruptured. This is one of the main problems of the surface treatment (Pore liners, pore blockers and coatings): they do not absorb the deformation of the concrete of substrate. This means that the formed protection layer breaks if the concrete cracks, causing the prompt imperfection of the protection system.

It is important to remember that, independently of the crack width, the remaining superficial pores will still be smaller than if they do not have the pore blocker on the surface. Then, the environment attack will be isolated to the cracked area and the other areas will keep being protected.

In general, it can be said that more information is needed about the protection capacity of silicates applied on surfaces of reinforced concrete. On the other hand, the use of these types of concrete protection is wide and their application is contributing to many of the several concerns about service life prediction since they can be applied as preventive or corrective methods. The service life approach has significantly changed during the last years (Castro-Borges, Helene, 2007) and this is mainly due to the recent introduction of more quantitative parameters than a few years ago. These parameters include new concepts such as serviceability, functionality, security, reliability and durability.

Part of this work focuses on some additional contributions to the study of concrete surface treatments in the sense that they can constitute a useful tool in the field of protection of new reinforced concrete structures. However, based on the real concerns promoted by their application, the main purpose of this paper is to indicate a way to estimate the influence of concrete surface treatments in the service life of a reinforced concrete structure exposed to chloride contamination. This type of results presentation was made possible with the use of the diffusion theory developed by Fick.

2. EXPERIMENTAL PROCEDURES

2.1 Substrate concrete

The substrate concrete was produced with a Brazilian Portland cement designated CPII E-32, which is equivalent to ASTM C 595 (Slag-modified Portland cement). This cement has blast furnace slag admixture and is one of the most widely used cements in the state of São Paulo, Brazil. The chemical composition and physical properties of the cement are listed in Table 1. Coarse aggregate was a dense, crushed granitic stone. Fine aggregate was natural siliceous sand.

The mix proportions details are summarized in Table 2. After mixing, a vibrating table was used to ensure appropriate compaction. The curing adopted was conditioning the specimens in wet chamber with relative humidity of 100 % and 24oC temperature for 91 days. This curing period was chosen to produce a high hydration level and eliminate the influence of an additional curing that could occur in the specimens exposed to water. This could especially affect the control series.

2.2 Surface protection materials

The surface treatment systems investigated in this study are presented in Table 3. Table 4 shows the curing type, number of coatings and the manufacturer's recommended consumption rate for each surface treatment material.

Table 3 Characteristic of surface treated systems.

| Product | Density (g/cm3) | Viscosity CPs (temperature = 20 oC) | Setting time (h) |

| Silane/siloxane | 1.0 | 10 | 2 - 6 |

| Acrylic | 0.9 | 45 | 1 |

| Polyurethane | 0.95 | 32 | 8 |

| Sodium silicate | 1.3 | 20 | 2 |

| Silane/siloxane + Acrylic | --- | --- | --- |

Table 4 Curing type and manufactures recommended rate.

| Product | Consumption rate (g/m2/coating) | Number of coatings | Cure type |

| Silane/siloxane dispersed in water | 300 | 1 | Water loss + reaction |

| Acrylic dispersed in solvent | 150 | 2 | Drying |

| Polyurethane | 180 | 2 | Reaction |

| Sodium silicate | 200 | 2 | Reaction |

| Silane/siloxane + Acrylic | --- | --- | --- |

2.3 Estimation of chloride diffusion coefficients

The method used to estimate the chloride diffusion coefficient followed the procedure described by Luping and Nilsson (1992), which involves measuring the depth of color change of a freshly broken concrete surface in the direction of the chloride flow using 0.1 M AgNO3 aqueous solution (Andrade et al., 1999) and in the application of Eq. (2) in a migration test. fixed chlorides are ignored and it is possible to release a portion of the fixed chlorides among the Since the method is based on the depth of penetration of free chlorides, it should be noted that the time, becoming free. Thus, the method may produce inaccurate results. However, this practice was implemented due the ease of testing and because the free chlorides are the ones that effectively influence the steel depassivation.

Where: D is the diffusion coefficient (cm2/s), R is the gas constant (J/molK), T is the temperature (K), z is the valency of the ion, F is the Faraday constant (J/Vmol), E is the field density (V/m), xd is the penetration depth (m), t is the test time (s), a and b are test constants. For chloride ion z = -1 and, when E = -600 V/m and T = 298 K, then, a = 1.061 and b = 0.589. The model used is based on Fick's second law because the test is developed in a non-steady state condition.

Slices of 50 mm in thickness were obtained by sawing the mid-portion of the cylindrical specimen (10 cm diameter and 20 cm length). 3 concrete slices of each case were used in this test and these slices were extracted from the same specimen, as suggested previously (Medeiros et al., 2009). Then, the slices were kept in an oven at 60 oC until obtaining constant mass. Then, the surface protection materials were applied on one of the circular surfaces of specimens. Seven days after the application of protection, the specimens were saturated using the procedure of ASTM C 1202/12. The manufacturer guidelines for the amount of material per unit of area were followed in all cases.

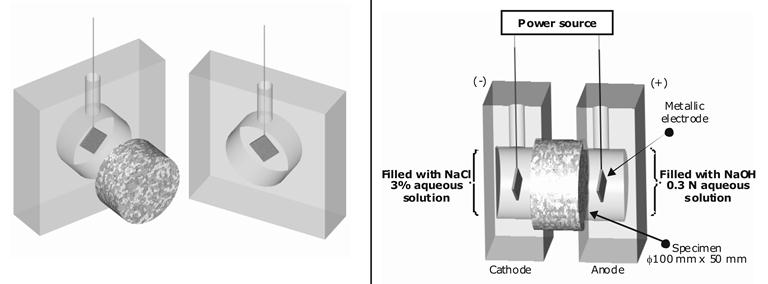

The 50 mm thick slice was placed between two acrylic cells. One cell was filled with a 0.3 N NaOH solution and the other with a 3.0% NaCl solution. The cells were connected to a 30 V power source and maintained for 30 h. The schematic presentation of the accelerated chloride migration test cell is illustrated in Figure 3.

Next, the slices were broken, and the depth of chloride penetration was determined as illustrated in Figure 4. Andrade et al. (2000), comparing methods for determining the chloride diffusion coefficient in non-steady state using the accelerated chloride migration test, indicated that the Luping and Nilsson (1992) procedure presents better reproducibility of results, thus justifying the test method here presented.

3. RESULTS

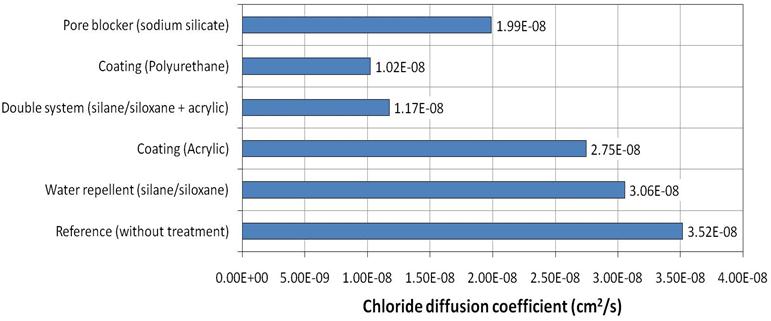

Figure 5 presents the results of chloride diffusion coefficient determined by the method proposed by Luping and Nilsson (1992). In this experiment, the concrete is saturated; therefore, the ion movement caused by absorption and permeability does not exist. Thus, the values of chloride diffusion coefficient presented in Figure 5 are for saturated concrete.

Generally, the chloride diffusion coefficient for the treated concrete surfaces was clearly reduced. This reduction increases the structure service life when exposed to a marine environment. However, there is a large difference in efficiency depending on the treatment used.

It is important to emphasize that, except for the polyurethane coating, the double system (water repellent + acrylic coating) is far more advantageous as compared to the single systems due to the double barrier formed in this category of protection. When the chloride ion passes the acrylic topcoat layer, there is still the silane/siloxane treatment, which has some capacity to inhibit the chloride ion penetration inside the concrete.

Concerning the operation, the quality coatings and sealers are more efficient because they act as a separation layer of the concrete with the external environment, like the polyurethane shown in Figure 5. On the other hand, the open pore systems such as silicates and water repellent tend to have lower protection capability when accompanied by low quality films such as of acrylic used in this study.

Table 5 shows the reduction rate of the chloride diffusion coefficients to each treatment. The double system reduced the chloride diffusion coefficient by 67%. The polyurethane coating was the most efficient protection, reducing the chloride diffusion coefficient by 71%. It is important to note that this result may not be universally regarded, since the efficiency of the treatment depends not only on the type of resin that composes it. This is in accordance with Vipulanandan and Liu (2005), which stated that for a specific type of resin, the effectiveness to reduce the penetration of chlorides can be highly different.

Table 5 Reduction rate to each protection system.

| Protection system | Chloride diffusion reduction rate (%) |

|---|---|

| Water repellent (silane/siloxane) | 13 |

| Coating (Acrylic) | 22 |

| Double system (silane/siloxane + acrylic) | 67 |

| Coating (Polyurethane) | 71 |

| Pore blocker (sodium silicate) | 43 |

The silane/siloxane reduced the chloride diffusion coefficient by 13%, indicating that this material does not greatly influence chloride penetration. However, it is important to emphasize that according to Medeiros and Helene (2009) and Medeiros and Helene (2008), hydrophobic agents significantly reduce water penetration, which is the main mechanism of protection of this treatment. Thus, when a water repellent is specified, the focus is to reduce the capillary suction, which may carry water contaminated with chlorides into the concrete. Then, the chloride penetration and the chloride migration tests on saturated concrete do not test or simulate the strength of activity of this product, although the hydrophobic agent has presented 13% of reduction in chloride diffusion coefficient. Medeiros et al. (2015) showed in their work, the use of goniometry technique for testing the hydrophobic capacity to increase the contact angle of water with the treated substrate, reducing the affinity for water.

4. DISCUSSION

Service life prediction is one of the areas that need greater advancements. Currently, many models developed in this area exist; however, their validation still needs to be studied and disseminated.

In this work, a service life prediction based on the second Fick's law of diffusion is presented. The method proposed in this work allows correlating service life with concrete cover, which can be a useful tool to design reinforced concrete structures. It is important to verify that this is an application based exclusively on the chloride diffusion phenomenon. Its extrapolation to other penetration mechanisms such as absorption, convection, or a mixture of these must be careful. It is necessary to conduct more research on these phenomena to develop a way of making these considerations. However, the application proposed in this work is valid because it allows a quantitative comparison between different materials and supplies service life estimations, although the model still needs improvements.

The method originates from Fick's second law (Equation 3), which development is shown in Equations 3 to 5.

Where: CCl is the chloride concentration in depth eCl and time t (%); CS is the surface chloride concentration, admitted as a constant (%); C0 is the initial chloride concentration into the concrete structural component; DCl is the chloride diffusion coefficient (cm2/s); t = is the service life (seconds); erf (z) is the Gauss error function; eCl = is the depth where the chloride concentration reached the threshold for reinforcement depassivation (cm).

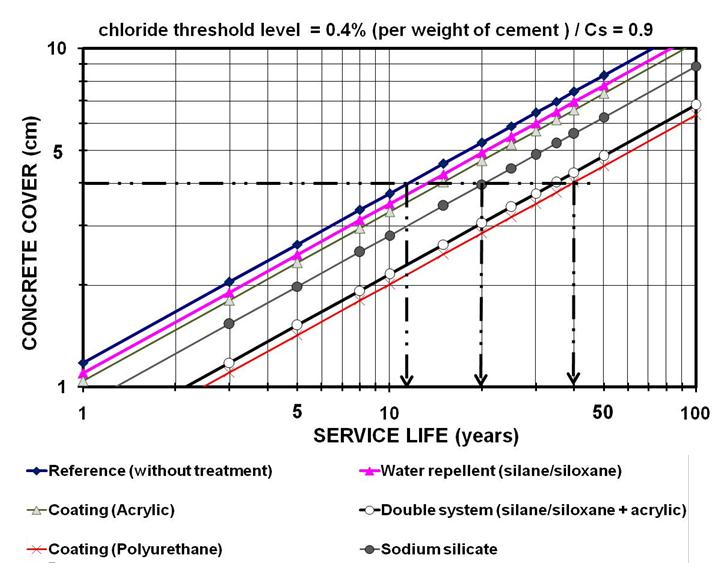

Helene (2000) presents Eq. 3 and Eq. 4 based on the second Fick' law. These equations were used in this work to analyze diffusion coefficients results, allowing the construction of a plot that correlates the chloride penetration depth with the reinforced concrete structure service life (Fig. 6).

Including z in Equation 3 and isolating erf (z), results in Equation 5.

In the construction of Figure 6 it was considered C0 = 0, ie, the concrete had no chloride at the time of molding.

Figure 6 Relation between estimated service life and concrete cover related to chloride penetration (depth where 0.4% by weight of cement was reached).

Setting a value for CS and considering CCl equal to the critical limit for depassivation of reinforcement corrosion caused by chloride attack, one obtains the Gauss error function [erf (z)]. Referring tables that relate erf (z) with z, the value of z is obtained. Substituting this value of z and chlorides diffusion coefficient in Equation 4, it is obtained an equation that relates the depth at which the limit value (for depassivation of reinforcement) is reached to the time required for this to occur. This was the reasoning for the preparation of Figure 6.

It is important to emphasize that the service life predictions presented in this work are only valid in the conditions below.

The reinforced concrete structure is at the beginning of its service life (starting from the initiation period);

The fastest degradation agent is chloride attack;

No accidental external factors have affected the properties of the concrete cover;

The chloride threshold level for the steel depassivation is 0.4% relative to cement mass, and was chosen because it is specified in some important technical documents (Bulletin 152, 1992; BS 8110-1, 1997; EN 206- Part 1, 2007).

It is important to emphasize the fact that the diffusion coefficient has been obtained by a migration process (by applying a potential difference) in non-steady state. Therefore, it is quite different from the actual transport of chloride in the concrete, which restricts its direct application in a lifetime prediction model. However, the comparation of the results of this experiment is possible and consistent.

Despite the variation cycles of the concentration of chloride in the concrete surface (De Coss et al., 1998), a restriction of this study was the fixing of the surface chloride concentration (Cs) equal to 0.9%, which was reported by Helene (1993) as suitable for concrete between 20 and 30 MPa, water/cement ratio between 0.48 and 0.68 and cement consumption between 280 and 400 kg/m3, a condition that the concrete used in the experiment of this article falls.

Another simplification of the method is to only consider the diffusion process in chlorides penetration forecast. Thus the forecasts made are more suitable for an underwater concrete than in structures subjected to conditions close to the sea.

In Figure 6, it is clear that for concrete cover equal to 4 cm, the service life of the untreated reinforced concrete structure is about 12 years and can reach 40 years depending on the treatment system applied on the surface of the concrete (extends the service life in more than three times). It is important to emphasize that the polyurethane coating and the double system presented greater efficiency than the other treatments tested in this work.

It is important to report that Castellotti and Andrade emphasize that several life prediction models were analyzed in different workshops within the RILEM TC 178-TMC and that many uncertainties remain, which prevents, in the current state of the art of making accurate predictions in the long term based on short-term experiments (Castellote, Andrade, 2006). A few years have passed since 2006, however, it is considered that such uncertainties still exist. Thus, the life time predictions in this work should not be interpreted as precise and absolute values, because the methodology has approximations as in any life prediction model.

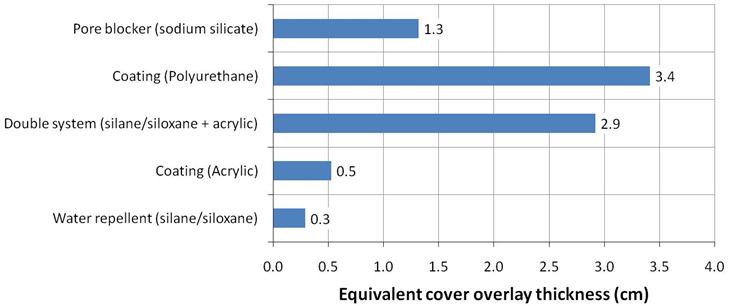

A good way to think in terms of surface protection was proposed in Medeiros and Helene (2009), where protection is represented in equivalent coatings, consisting of how many cm of concrete cover is the same as a coating of a particular protection system. That is, if a concrete is protected with surface protection that has an equivalent coating of X cm, that means that the concrete has X cm of covering, since the protection system has its performance properties maintained over time, which in practice is achieved by providing the periodic maintenance and renovation of surface protection. For example: if the concrete is protected with acrylic film, it is like the covering was increased by 5 mm.

Figure 7 shows the equivalent length for each treatment. These data are related to the specific substrate used in this study.

Figure 7: Equivalent cover overlay thickness of each treatment system related to the concrete substrate - Cs = 0.9% (chloride diffusion coefficient by the method of Luping and Nilsson, 1992).

This kind of thinking may be the way to support the application of surface protection systems in conditions where the reinforced concrete structure is already conclued and thick coatings are lowers than the specified by the standards. This can happen, for example, in the case of structures built with low quality control and in cases of structures built but not completed for reasons such as the failure of the contractor.

5. CONCLUSIONS

The conclusions expressed here apply to the characteristics of this work and materials. Any extrapolation to other materials or circumstances must be carefully conducted.

A service life prediction for the corrosion initiation stage of concrete with surface treatments was obtained through the well-known Fick´s second law and will be valid only at the mentioned initiation stage.

The chloride contamination in a reinforced concrete structure exposed to a marine environment is one of the most challenging forms of degradation to amend. The ingress of these ions in concrete occurs by chloride diffusion or penetration of contaminated water. From the research presented herein, the following conclusions can be derived:

The concrete surface protection can be an efficient means of inhibiting chloride penetration in concrete. Consequently, protection systems must be used to increase the service life of reinforced concrete in environments influenced by salt spray, such as buildings in coastal cities/towns.

The results indicated that the most efficient protection system could reduce the chloride diffusion coefficient of concrete by 71%.

It is important to emphasize that the results indicated that the use of a high efficiency protection system could extend the service life of a reinforced structure by more than three times. However, this level of increase in service life is related to the test conditions adopted in this work.

Graphs (like Figure 6) that relate service life with depth where the chloride concentration reached the threshold for reinforcement depassivation are the most efficacious means of presenting results of chloride diffusion coefficients.

The results of this article indicate that the water repellent surface protection reduced by 13% the penetration of chloride into the concrete. However, it is important to note that this treatment showed the least ability to reduce the chloride diffusion coefficient.

Polyurethane coating and double protection system are the surface treatments that showed the best efficiency in reducing the penetration of chlorides (71% and 67% reduction of chlorides diffusion coefficient, respectively).

This work proposes an interesting way to interpret chloride diffusion coefficient results. The possibility of making service life predictions, easiness of interpretation and correlation between concrete cover and service life are the advantages of this method. In this way, this interpretation procedure can become an important tool to predict the service life of reinforced concrete structures. However, it is important to observe that this is an application based exclusively on the chloride diffusion phenomenon. How to consider these other phenomena still is unknown.

Another positive aspect of the work is the conversion of the protective capacity of the surface protection to the equivalent coatings on concrete substrate. This type of approach allows to infer the equivalent thickness that the surface treatment gives to the coating. However, it is important to emphasize that this type of conversion is only valid if the surface protection material maintains its protective properties throughout the lifetime of the structure and this only occurs if the system is being renewed periodically.

Acknowledgements

The authors would like to thank the Polytechnic School of University of São Paulo (POLI-USP), Federal University of Paraná (UFPR), Institute of Technological Research (IPT) and Research Support Foundation of the State of São Paulo (FAPESP) for making this study possible by financially supporting it. We also thank M. Cristina V. Borba for revising the text and Dominique E. Giordano Gonzalez for the drawings.

REFERENCES

Al-Zahrani, M. M., Al-Dulaijan, S. U., Ibrahim, M., Saricimen, H., Sharif, F. M. (2002), Effect of waterproofing coatings on steel reinforcement corrosion and physical properties of concrete, Cement and Concrete Conposites, v. 24, pp. 127-137. [ Links ]

Andrade, C., Castellote, M., Alonso, C., González, C. (1999), Relation between colorimetric chloride penetration depth and charge passed in migration tests of the type of standard ASTM C1201-91, Cement and Concrete Research, v. 29, pp. 417-21. [ Links ]

Andrade, C., Castellote, M., Alonso, C., González, C. (2000), Non-steady-state chloride diffusion coefficients obtained from migration and natural diffusion tests - part I: conparison between several methods of calculation, Materials Structures, v. 33, pp. 21-28. [ Links ]

ASTM C 1202 - 2012 Standard test method for electrical indication of concrete's ability to resist chloride ion penetration. American Society for Testing and Materials, USA, 2012. [ Links ]

Batista, M. (1998), Siloxane and silane-perfects hydrophobics agents for all situations, Recuperar Magazine, v. 23, pp. 14-19. [ Links ]

Boletin 152 Durability of concrete structures. Conite Euro-Internacional Du Béton. CEB 152: Europe, 1992. [ Links ]

Brough, A. R., Atkinson, A. (2002), Sodium silicate-based, alkali-activated slag mortars - Part I. Strength, hydration and microstructure, Cement and Concrete Research, v. 32, pp. 865-879. [ Links ]

BS 8110-1 Structural use of concrete. Code of practice for design and construction. British Standards Institution, England, 1997. [ Links ]

Castellote, M., Andrade, C. (2006), Round-Robin test on methods for determining chloride transport parameters in concrete, Materials and Structures, v. 39, pp. 955-90. [ Links ]

Castro-Borges, P., Helene, P. (2007), Service life concepts of reinforced concrete structures - New approach" in: Proceedings of the Corrosion of Infrastructure, 3º, p. 9-14. [ Links ]

De Coss, R., Murrieta, G., Castro, P. (1998), Effect of weather cycles on chloride diffusion in porous concrete in: P. Castro, O. Troconis, C. Andrade (Eds.), Rehabilitation of Corrosion Damaged Infrastructure, NACE International, Houston: TX (USA), pp. 285-293. [ Links ]

Delucchi, M., Barbucci, A., Cerisola, G. (1998), Crack-bridging ability and liquid water permeability of protective coatings for concrete, Progress in Organic Coatings, v. 33, pp. 76-82. [ Links ]

EN-206-Part 1 Concrete - Especification, performance, production and conformity. European Conmittee for Standardization, Europe, 2007. [ Links ]

Ibrahim, M., Al-Gahtani, A. S., Maslehuddin, M., Almusallam, A. A. (1997), Effectiveness of concrete surface treatment materials in reducing chloride-induced reinforcement corrosion, Construction and Building Materials, v. 11, n. 7-8, pp. 443-451. [ Links ]

Gjorv, O. E. (2014), Durability design of concrete structures in service environments (New York, EUA: CRC Press), 2st edn., pp. 249. [ Links ]

Helene, P. (1993), "Contribuiçao ao estudo da corrosión em armaduras de concreto armado", Tese de Livre Docencia, Escola Politécnica, Universidade de Sao Paulo, Sao Paulo, p. 231. [ Links ]

Helene, P. (2000), Durabilidad. Interpretación y evaluación de resultados. Manual de Diagnosis e Intervención en Estructuras de Hormigón Armado (Barcelona, Espanha: Collegi d'Aparelladors i Arquitectes Tècnics de Barcelona), 1th edn., p. 87-102. [ Links ]

Jacob, T., Hermann, K. (1998), Protection of concrete surfaces: hydrophobic impregnations, Construcción y Tecnología, pp. 18-23. [ Links ]

Jones, J. W. (2002), "Method of Hardening and Polishing concrete floors, walls, and the Like", United States Patents. Tatent number: US 6,454,632 B1. Sep. 24, 2002. [ Links ]

Kagi, D. A., Ren, K. B. (1995), Reduction of water absorption in silicate treated concrete by post-treatment with cationic surfactants, Building and Environment, v. 30, n. 2, p. 237-243. [ Links ]

Bentur, A., Diamond, S., Berke, N. S. (1997), Steel Corrosion in Concrete - Fundamentals and Civil Engineering Practice (London, Inglaterra: E&FN SPON), 1th edn., pp. 197. [ Links ]

Luping, T., Nilsson, L. (1992), Rapid determination of the chloride diffusivity in concrete by applying an electrical field, ACI Materials Journal, v. 89, n. 1, pp. 49-53. [ Links ]

Mariconi, G., Tittarelli, F., Corinaldesi, V. (2002), Review of silicone-based hydrophobic treatment and admixtures for concrete, Indian Concrete Journal, v. 76, n. 10, pp. 637-642. [ Links ]

Medeiros, M. H. F., Helene, P. (2009), Surface treatment of reinforced concrete in marine environment: Influence on chloride diffusion coefficient and capillary water absorption, Construction and Building Materials, v. 23, pp. 1476-1484. [ Links ]

Medeiros, M. H. F., Helene, P. (2008), Efficacy of Surface Hydrophobic Agents in Reducing Water and Chloride Ion Penetration in Concrete, Materials and Structures, v. 41, n. 1, pp. 59-71. [ Links ]

Medeiros, M. H. F., Hoppe Filho, J., Helene, P. (2009), Influence of the slice position on chloride migration tests for concrete in marine conditions, Marine Structures, v. 22, pp. 128-141. [ Links ]

Medeiros, M. H. F., Helene, P. (2009), Durability and protection of reinforced concrete, Techne, v. 151, pp. 50-54. [ Links ]

Medeiros, M. H. F., Pereira, E., Figura, A. S., Tissot, F. M., Artioli, K. A. (2015), Avaliaçao da eficiencia de sistemas de protección de superfície para concreto: absorción de agua, migración de cloruros e ângulo de contato, Matéria (UFRJ), v. 20, pp. 145-159. [ Links ]

Mehta, P. K., Monteiro, P. J. (2008), "Concrete: Structure, Properties, and Materials", (New Jersey, EUA: Prentice Hall), 3th edn. [ Links ]

Melo Neto, A. A., Cincotto, M. A., Repette, W. L. (2009), Drying autogenous shrinkage of pastes and mortars with activated slag cement, Cement and Concrete Research, v. 38, pp. 565-574. [ Links ]

Seneviratne, A. M., Sergi, G., Page, C. L. (2000), Performance characteristics of surface coatings applied to concrete for control of reinforcement corrosion Construction and Building Materials, v. 14, pp. 55-59. [ Links ]

Thompson, J. L., Silsbee, M. R., Gill, P. M., Scheetz, B. E. (1997), Characterization of silicate sealers on concrete, Cement and Concrete Research, v. 27, n. 10, pp. 1561-1567. [ Links ]

Toledo Filho, R. D., Ghavami, K., George, L. (2003), England and Karen Scrivener Development of vegetable fibre-mortar conposites of improved durability, Cement and Concrete Conposites, v. 25, n. 2, pp. 185-196. [ Links ]

Uemoto, K. L., Agopyan, V., Vittorino, F. (2001), Concrete protection using acrylic latex paint: Effect of the pigment volume content on water permeability Materials Structures, v. 34, pp. 172-177. [ Links ]

Vipulanandan, C., Liu, J. (2005), Performance of polyurethane-coated concrete in sewer environment, Cement and Concrete Research, v. 35, pp. 1754-63. [ Links ]

Vries, J., Polder, R. B. (1997), Hydrophobic treatment of concrete, Construction and Building Materials, v. 11, n. 4, pp. 259-265. [ Links ]

Received: January 16, 2015; Accepted: July 28, 2015

texto en

texto en