Introduction

The low yield of rainfed crops is due to water stress (Acosta-Díaz, Acosta-Gallegos, Trejol-López, Padilla-Ramírez, & Amador-Ramírez, 2009). To mitigate this limitation and increase annual crop yields, researchers from the National Institute of Forestry, Agriculture and Livestock Research (INIFAP) designed, validated, and transferred the pileteadora (diking implement) to harvest rainwater in situ (Galindo-González & Zandate-Hernández, 2007). This attachment is embedded in the cultivator’s tines to form micro-basins along the furrow bottom, where rainwater is stored so that moisture remains available to crops for longer. This harvesting practice, also called pileteo in Mexico, is mainly applied in semi-arid regions of Mexico (Acosta-Díaz, Amador-Ramírez, Padilla-Ramírez, Gómez-Delgado, & Valadez-Montoya, 2007).

Additionally, INIFAP researchers have reported increases in the yield of bean and corn grown under rainfed conditions by increasing their planting density and complementing the crop with in situ rainwater harvesting practices (Arellano-Arciniega, Osuna-Ceja, Martínez-Gamiño, & Reyes-Muro, 2015; Osuna-Ceja, Reyes-Muro, Padilla-Ramírez, & Martínez-Gamiño, 2012; Osuna-Ceja et al., 2013; Osuna-Ceja & Martínez-Gamiño, 2017). Osuna-Ceja et al. (2012) planted 'Pinto Saltillo' bean in the traditional way in furrows at 76 cm apart with 90 thousand plants·ha-1, and in beds with three rows at 40 cm apart and six rows at 20 cm apart with 145 and 260 thousand plants·ha-1, respectively. These authors reported a 28.6 % yield increase with the three-row system and a 41 % increase in the six-row system, compared to traditional planting. Similarly, Osuna-Ceja and Martínez-Gamiño (2017) obtained more dry matter (t·ha-1) when they planted Cafime corn in four-row beds, compared to traditional planting. In these planting methods, the crop's foliage covers the soil quickly, which prevents moisture loss from direct radiation and makes more use of solar energy, inhibiting weed development (Arellano-Arciniega et al., 2015).

To date, bean planting methods in three- and four-row beds, complemented by rainwater harvesting practices, have been adopted in several parts of Aguascalientes, San Luis Potosí and Zacatecas, Mexico, due to the profit margin obtained in comparison to the traditional planting method (Borja-Bravo, Osuna-Ceja, Arellano-Arciniega, García-Hernández, & Martínez-Gamiño, 2018). However, as there are no commercial planters in the region to implement such planting methods, producers modify their mechanical horizontal plate and straight tine planters. The problem lies in the fact that these planters accumulate stubble in their tines because of the narrow spacing required by these methods; in addition, due to their metering system, they produce a low quality plant distribution that ultimately affects crop yield (Mahl, Furlani, & Gamero, 2008).

Arellano-Arciniega et al. (2015), Osuna-Ceja et al. (2012), Osuna-Ceja et al. (2013), and Osuna-Ceja and Martínez-Gamiño (2017) evaluated the planting results obtained with two experimental planter prototypes developed at INIFAP, exclusively designed to establish the methods mentioned above. However, these planters presented problems in practice, since both have independent row units, but with a static common seed hopper that feeds them through flexible discharge hoses. These hoses are frequently clogged because they are bent by the micro-relief of the soil, which generates vertical oscillations in the row units without the hopper moving. The geometry of the discharge tubes and the fall distance directly affect the distribution of seeds in the soil (Piveta et al., 2016). Therefore, in order to mechanize the four-row bed planting method, the objective was to design and evaluate a planter to distribute seeds in four-row beds, with individual row units that adapt to the micro-relief of the soil, and also to equip it with a system that forms micro-basins in the soil to harvest rainwater in situ.

Materials and methods

Planter design

The research was carried out at INIFAP’s Pabellón Experimental Field in Aguascalientes, Mexico, during 2016, 2017 and the first half of 2018. Initially, the design conditions that the planter had to comply with were established, such as establishing monograin sowings of medium-size seeds such as those of corn and beans, regulating the distance between seeds in the range of 10 to 30 cm with intermediate variations, regulating the planting depth according to the agronomic needs of the seed, forming a planting bed 15 cm high with width equivalent to the gauge of a category II tractor (1.52 m on average) (since they are the most common in Mexico) (Ayala-Garay et al., 2013), distributing four rows of seeds 30 cm apart over the bed, depositing solid and granulated fertilizer at the side of the planting line and buried 5 cm, and forming dikes at the sides of the planting bed so that the rainwater can stagnate.

Once the need to develop a planter was detected and the operating characteristics identified, the stages involved in mechanical engineering design were followed: 1) conceptualization of the solution, 2) choice of the best solution, 3) detailed design and 4) construction (Budynas & Nisbett, 2012).

The best solution concept was a pneumatic planter with four independent row units with a four-bar mechanism to adapt to the micro-relief of the soil, pneumatic metering units, and press wheels to tamp the seed and regulate the planting depth. To form the beds for planting, the idea was to use conventional agricultural coulters. The system for fertilization had to be a common hopper and helical roller metering units. The rainwater harvesting system was integrated with three compact, intermittently rotating paddles attached to a single shaft. The movement transmission of the components would be done with two agricultural wheels at the sides of the beds.

At the detailed design stage, the chassis, the sowing system, the fertilizer metering system, the rainwater harvesting system and the transmission were analyzed. The main chassis was standardized for category II tractors, in accordance with standard ASAE S217.12 (American Society of Agricultural and Biological Engineers [ASABE], 2007). In order to ensure the mechanical strength of some critical elements, and in some cases to optimize their geometry, a structural analysis was carried out using the finite element method with the SALOME 8.4.0 software.

In the design of the sowing system, the commercial components (pneumatic turbine, pneumatic metering units, V-shaped furrow opener discs and press wheels) were first acquired and then integrated to form the four row units. In order to ensure constant seed feeding into the metering units, the angle of repose of the bean and corn, reported by Ospina-Machado (2001), was considered in the design of the hoppers. The movement limit of the input link of the four-bar mechanism was obtained by Equation (1), as a function of the desired planting depth range, and its length was determined under the design criteria.

Where ∅ is is the angle of movement of the input link (°), Ps is the planting depth (cm) and Le is the length of the input link (cm).

To determine the fertilizer metering volume of the helical roller, a maximum metering quantity of 700 kg·ha-1 of urea was considered, which has a density of 710 kg·m-3 and 4 mm diameter grains on average (Ortiz-Cañavate, 2003), which is equivalent to adding 986 L·ha-1. Therefore, each metering unit should throw 37.52 cm3·m-1 with the four-row planting method. Subsequently, to ensure the fertilizer flow according to the crop's needs, an independent gate was placed at the hopper outlet to vary the discharge area. The movement of the metering rollers was obtained from a planter wheel, after calculating its transmission ratio.

The intermittent rotation of the paddles that would form the dikes at the side of the beds was done by pivot stoppers driven by disc cams with 2 cm lift and abrupt return, which, in turn, are driven by sprockets and chains through the two planter wheels.

The sowing system was also driven, in the same way, by one of the planter’s wheels. To vary the distance between seeds, first the necessary general transmission ratio was obtained by means of Equation (2); then, with the theory of drive train calculation, the number of shafts needed and number of teeth of the sprockets were obtained for each transmission ratio of the desired spacing.

Where i is the transmission ratio for each desired seed spacing, D is the effective tire diameter (m), k is the number of holes in the distributor disc and d is the desired seed spacing (m).

The planter was built in the machine and tool workshop of INIFAP’s Pabellón Experimental Field.

Planter test

The planting and fertilization systems of the planter were separately evaluated on the same test bench. The first system was evaluated with 'Pinto Saltillo' bean and XR60 hybrid corn seeds certified on all four row units (T1, T2, T3 and T4) and under the following operating conditions: horizontal position with no vibration (HWNV), horizontal position with vibration (HWV) and inclined position at 10° with no vibration (IWNV). This was done based on the methodology described in the NMX-O-222-SCFI-2004 standard (Secretaria de Economía, 2004). Each test condition was done with ten operating speeds, from 3 to 7.5 km·h-1 with increments of 0.5 km·h-1, and three replications of 20 s duration at each speed. For bean seeds, a sowing distance of 10 cm between seeds was set, and for corn, 27.1 cm. The fertilization system was evaluated with urea, only in a horizontal position without vibration and with theoretical speeds of 3 to 7 km·h-1, with increments of 1 km·h-1. Each metering unit was subjected to three 15-second tests for each theoretical operating speed.

The angular movement of the seed and fertilizer metering units was taken from a Baldemor three-phase, 220 VAC, 1 hp, 1 725 rpm engine, to which a transmission with a 1:65 ratio was coupled to obtain 26.5 rpm at the output. The maximum forward speed that was simulated in the planter was achieved by placing the sprockets with the number of teeth needed. In order to reduce engine revolutions as needed, a frequency shifter with single-phase 120 VAC input and three-phase 220 VAC output (ATV12H075F1, Schneider Electric, Indonesia) was used. Therefore, the required speed adjustment was made by changing the engine frequency through the shifter and placing a digital tachometer (461895, ExtechTM, Taiwan) over a shaft where it was possible to determine the transmission ratio to metering units. The vibration provided to the row units was made by means of disc cams with 2 cm lift and abrupt return, which are driven by the same engine that powers the metering units. The rotation frequency of the cams with respect to the planter’s drive wheels was set at 1:0.38. That is, for every meter of the planter’s theoretical advance, the cams made 0.21 revolutions.

The planter was coupled to a New Holland 5610 2WD 80 hp tractor to characterize the operating pressure of the pneumatic turbine with a 24-hole metering plate in vacuum chambers. Then, the number of grains per revolution of the metering plates was determined in 0.249 kPa increments of the turbine’s operating pressure. This was done for both seeds with three replications. Prior to testing, the beans were screened with a 6.35 mm sieve, and the one left on top of it was used. Subsequently, the length (mm), width (mm), thickness (mm), sphericity (%) and mass of one hundred seeds (g) were determined for both seed species.

As study variables, the number of seeds per linear meter, the percentage of damaged seeds and the mass of fertilizer metered per linear meter were evaluated. The first variable was estimated by dividing the number of seeds metered, during the 20-s test, by the theoretical meters traveled by the planter at each speed. The second variable was calculated by dividing the number of damaged seeds by the number of total seeds, and the ratio was multiplied by one hundred. The last variable was obtained by dividing the mass of fertilizer metered during the 15-s test by the theoretical meters travelled by the planter at each speed. This variable was estimated for the maximum metering capacity.

Planter evaluation in the field

The field evaluation was conducted at INIFAP’s Pabellón Experimental Field in Aguascalientes, Mexico, located at 22° 11’ N and 102° 20’ W, at an elevation of 1 912 m. The soil where the experiment was conducted has a sandy loam texture (55.24 % sand, 26 % silt and 18.76 % clay) (Osuna-Ceja, Garibaldi-Márquez, & García-Hernández, 2019).

Two experiments were established, one with bean seeds and the other with corn seeds, with four treatments each, which consisted of four forward speeds of the planter (3.63, 4.79, 5.84 and 7 km·h-1) manipulated with a New Holland 5610 tractor. The treatments were distributed in a randomized complete block design with four replications. The experimental unit consisted of a 100 m long planter pass. Bean was planted on June 28, 2019 and corn on July 2, 2019.

The bean and corn seeds were the same as those used on the test bench. In this experiment, the germination percentage of both types of seeds was determined. For this, 100 seeds of each species were distributed equidistantly, with four replications, in a transparent square plastic container 20 cm per side and 7 cm high. Water-saturated cotton was used as substrate. The containers were then placed in a bioclimatic chamber (720KBW, Binder, Germany) at 26 °C until germination occurred.

Operating speeds were established prior to planting on the same ground, determining the time (s) it took for a tractor's drive wheel to travel a certain distance (m), with the planter engaged and in the operating position. Five replications per speed were carried out. The average data were substituted in the equation: v = 3.6(d/t); where, v is the planting speed (km·h-1). In addition, a theoretical planting depth of 6 cm was set for both seed species.

The seed spacing set in the planter was 10 cm between bean seeds and 25 cm between corn seeds. However, both distances were weighted considering the germination percentage and the slippage percentage of the planter's drive wheel, for each of the previously set forward speeds.

The slippage percentage of the planter's drive wheel was determined by Equation (3), with four replications per speed.

Where δ is the slippage (%), l l is the distance the planter travels in operation at 15 revolutions of its drive wheel (m) and l 0 is the distance the planter travels on a hard surface at 15 revolutions of its drive wheel and with the tractor moving slowly (m). Therefore, the theoretical seed spacing was obtained from the following equation:

where d t is the theoretical seed spacing (cm), d is the seed spacing set in the planter (cm), x is the slippage percentage of the planter’s drive wheel (%), y is the germination percentage of the seeds (%) and c is a constant assigned the value of 100 %.

Immediately after planting, the soil moisture in the arable layer (from 0 to 20 cm) was estimated, for which 30 readings were taken on each main diagonal of the ground, for a total of 60 readings in each experiment. For this parameter, a TDR probe (300, Fieldscout, USA) previously calibrated for soil texture was used.

The study variables considered in both experiments were overall mean spacing and overall standard deviation (OSD) between plants (cm), multiple index (%), miss index (%), quality /index (%) and precision index (%), which indicate the horizontal distribution of the seed. In addition, the planting depth (cm) and the volume of the dikes (L) were estimated. The horizontal distribution variables of the seeds were obtained according to the methodology described by Kachman and Smith (1995); for this, 60 consecutive spaces between plants were measured thirteen days after planting, on the two central lines of each of the treatments, with which 120 observations were collected per treatment.

To estimate the depth, the seed was uncovered and measured with a ruler from the soil surface to where it was located. Ten observations were made on the two center lines. This activity was estimated immediately after the planter’s passage, and only in the bean experiment. On the other hand, the volume of the dikes was estimated only in the corn experiment the day after planting, considering three random replications. For this, a thin plastic film was placed on the entire internal surface of the dikes, which were then filled with water using graduated cylinders to determine the volume.

Statistical analysis

The data set obtained on the test bench was subjected to an analysis of variance under a completely randomized design. Considering the range of variation in the seed metering results, the data were transformed by the arcsen function prior to analysis. The field data were subjected to an analysis of variance under a randomized complete block design and Tukey’s multiple comparison test (P ≤ 0.05). For all analyses, Statistical Analysis Systems version 8 (SAS, 2009) was used. Additionally, for the variable number of seeds per meter, linear regressions were performed in the Excel professional 2016 program.

Results and discussion

Planter design

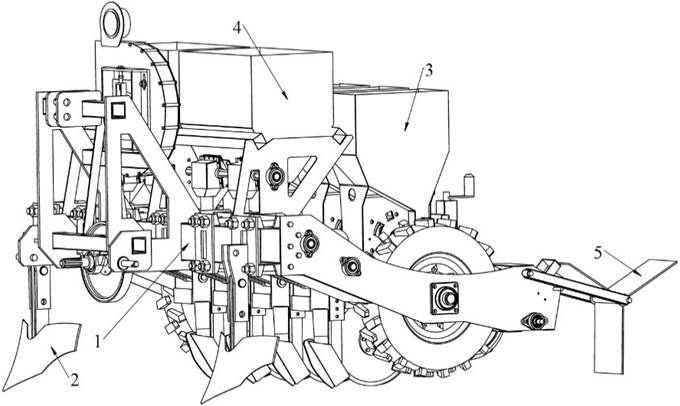

The planter that was the best solution concept (Figure 1) consists of: a main chassis (1) where all the systems and components are coupled, bed-forming coulters (2), a sowing system (3), a fertilization system (4) and a rainwater harvesting system (5). The dimensions of the implement are: 1.72 m long, 1.62 m high and 2.10 m wide, with a mass of 512 kg; it can be operated with category II tractors.

Figure 1 Sketch of equipment for sowing in four-row beds: 1) main chassis, 2) bed-forming coulters, 3) row unit, 4) fertilization system, and 5) rainwater harvesting system.

The coulters are winged and are separated from each other by 1.52 m, coinciding with the tractor’s wheel track. In addition, they can be raised to avoid forming beds, which is optional.

The sowing system consists of four row units, each one of them with a 38 L hopper. At the bottom of the hopper there is a pneumatic vertical plate metering unit that operates in conjunction with a turbine. It also has a pair of discs with a V-shaped configuration to cut the soil to a depth defined by a press wheel. The depth is set according to the agronomic needs of the seed. It also has a machete with an inner duct for fertilizer drop. This machete opens the soil to a depth of 5 cm and 5 cm to the side of the planting line. Each row unit is coupled to the main chassis by a four-bar mechanism, which allows the row unitto adapt to sow in beds and oscillate depending on the micro relief of the ground.

The fertilization system consists of two 91 L hoppers with two outlets at the bottom. A helical roller 100 mm in length and 76.20 mm in diameter is located at each hopper outlet. All the rollers theoretically meter 110 cm3 per revolution. Therefore, each metering roller provides fertilizer to a planting line. To reduce the metering as needed, each outlet has a gate.

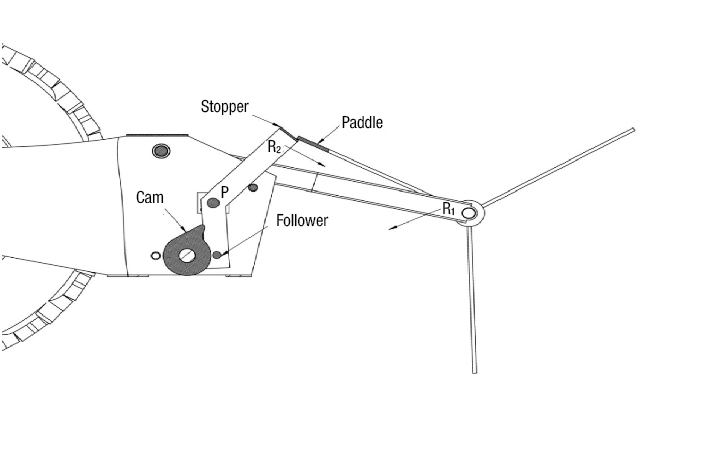

The dike-forming system (Figure 2) consists of three paddles welded onto a shaft, distributed 120° in a circular arrangement. The paddles rotate on their shaft, which is attached to two pivoting arms embedded in the chassis of the wheels. To form a dike, one paddle must be in contact with the ground so that it can accumulate earth as the tractor moves forward for a certain distance, so there are two R1 tension springs so that it always remains in contact with the ground. The locking of the paddles’ rotation is achieved with a stopper that pivots at point P, which is also a cam follower; when the follower coincides with the cam’s maximum lift point, it moves to release the rotation of the paddles. The rapid return of the stopper to its locking point is obtained with an R2 tension spring. Theoretically, this system makes 2.9 m dikes. In Mexico, the attachment to form dikes is 2.4 m long on average (Galindo-González & Zandate-Hernández, 2007).

In the planter, the transmission of the movement to the seed metering plates, the fertilizer metering rollers and the cam of the rainwater harvesting system is done by means of sprockets and chains. The main source of movement is two agricultural wheels.

In order to vary the distance between seeds, the implement has a main box of sprockets where combinations between them can be made, from a tree A and a tree B, which is also a function of the number of holes in the metering plate (Table 1).

Table 1 Combination of sprockets and metering plates to vary the spacing between seeds.

| Combination (A-B) | Train transmission ratio (i) | Distance between seeds (cm) | ||

|---|---|---|---|---|

| 22-hole plate | 24-hole plate | 26-hole plate | ||

| A24-B15 | 0.7579 | 10.9 | 10 | 9.3 |

| A24-B18 | 0.6316 | 13.1 | 12 | 11 |

| A24-B20 | 0.5684 | 14.6 | 13.4 | 12.3 |

| A24-B22 | 0.5167 | 16 | 14.7 | 13.6 |

| A16-B15 | 0.5053 | 16.4 | 15 | 13.9 |

| A24-B25 | 0.4547 | 18.2 | 16.7 | 15.4 |

| A16-B18 | 0.4211 | 19.7 | 18 | 16.6 |

| A13-B15 | 0.4105 | 20.2 | 18.5 | 17 |

| A16-B20 | 0.3789 | 21.8 | 20 | 18.5 |

| A16-B22 | 0.3445 | 24 | 22 | 20.3 |

| A13-B18 | 0.3421 | 24.2 | 22.2 | 20.5 |

| A13-B20 | 0.3079 | 26.9 | 24.7 | 22.8 |

| A16-B25 | 0.3032 | 27.3 | 25 | 23.1 |

| A13-B22 | 0.2799 | 29.6 | 27.1 | 25 |

| A13-B25 | 0.2463 | 33.6 | 30.8 | 28.4 |

Planter test

The physical characteristics of the seeds used in the sowing system test are presented in Table 2, in which it is observed that the bean seed is more oblong than the corn seed, and is corroborated with its sphericity.

Table 2 Dimensions and mass (mean ± standard error) of the seed used for the planter tests.

| Seed | Dimensions (mm) | Sphericityz (%) | Mass of 100 seeds (g) | ||

|---|---|---|---|---|---|

| Length (l) | Width (a) | Thickness (e) | |||

| ‘Pinto Saltillo’ bean | 12.79 ± 0.21 | 6.98 ± 0.06 | 5.10 ± 0.11 | 60.15 | 33.64 ± 0.14 |

| XR60 hybrid corn | 10.76 ± 0.32 | 9.50 ± 0.17 | 4.91 ± 0.10 | 73.86 | 40.62 ± 0.19 |

z

When characterizing the pneumatic turbine, it was determined that the proper working pressure to hold the corn and bean seeds in this metering unit was 2.49 kPa. This was because the average number of seeds metered per revolution of the metering plate corresponded to the number of holes in it. It has been reported that the vacuum pressure varies according to the shape of the seed, the design of the vacuum chamber and the number of holes in the plate (Önal, Değirmencioğlu, & Yazgi, 2012).

The result of the analysis of the number of seeds per linear meter indicated that there was a significant effect (P ≤ 0.05) of the test condition (C), row unit (T) and theoretical forward speed (V) on both types of seed. In addition, the analysis detected significant differences (P ≤ 0.05) in the CxV interactions in bean and corn, and in the TxV interaction in bean. The IWNV condition favored the highest seed metering in both species. In relation to the row units, T1 was the one that metered more bean seeds; however, in corn seeds, T1 and T2 outperformed the other units. Regarding speed, the highest number of seeds of each species was obtained at 3 km·h-1; in bean, the metering provided 99.2 % of the desired number of seeds, while in corn it was 100 % of the desired number of seeds (data not shown).

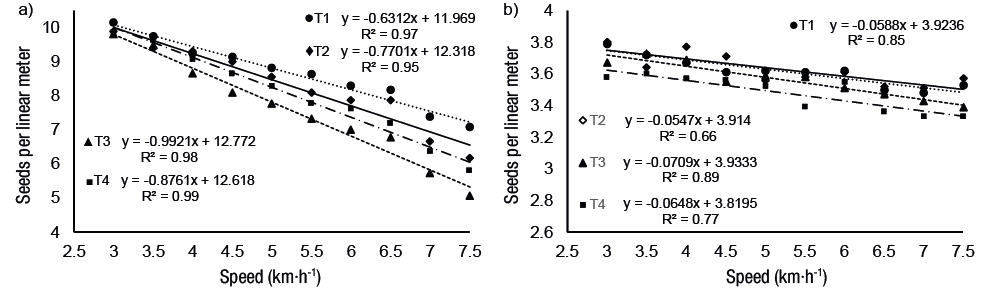

In general, the four row units (T1, T2, T3 and T4) metered more corn and bean seeds with the lowest speed, and reduced the value of this variable for each km·h-1 increase in speed (Figure 3). Laboratory planter metering tests usually focus on evaluating a single row unit, as in the case of Musa (2006), Panning, Kocher, Smit and Kachman (2000), Singh, Singh, and Saraswat (2005), and Wei, Fu, Hai, and Qing (2013); however, when evaluating the metering of the units separately, it can be corroborated that they meter different amounts of seed, as can be seen in this study.

Figure 3 Seed metering as a function of the row units and speed: (a) bean and (b) corn. T1, T2, T3 and T4 indicate the evaluated row unit number.

Singh and Gautam (2015) reported metering differences between row units in a gladiolus corm planter. In this sense, when analyzing the integrated sowing system, it was observed that the number of bean seeds was reduced by a rate of 0.82 for each km·h-1 increase in speed (R2 = 0.98), while the number of corn seeds was reduced by 0.06 for each km·h-1 increase in speed (R2 = 0.94). The effect of speed on the metering rate has also been reported for sunflower (Celik, Ozturk, & Way, 2007) and corn seeds (Santa-Ormond et al., 2018). In this study, the metering rate of bean seeds, compared to corn seeds, decreased more with each km·h-1 increase in speed. Celik et al. (2007) attribute this behavior to the fact that the force to hold the seed in the metering disc is reduced in oblong seeds, as is the case with bean.

The three test conditions (HWNV, HWV and IWNV) in interaction with the theoretical operating speed caused a significant effect (P ≤ 0.05) on the number of metered seeds of both species (Figure 4). The operating condition that yielded the most bean seeds was HWV in the range of 3 to 6.5 km·h-1, after which it was surpassed by IWNV (Figure 4a). In corn, IWNV was the condition that provided the most seeds at each speed evaluated (Figure 4b). Overall, Figure 4 also shows that with increasing speed the number of seeds was significantly reduced (P ≤ 0.0.5) in both species.

Figure 4 Number of seeds per linear meter as a function of test conditions and speed: (a) bean and (b) corn. HWNV = horizontal position with no vibration; HWV = horizontal position with vibration; IWNV = inclined position at 10° with no vibration.

The standard deviation of the number of seeds per linear meter in all three test conditions increased as the operating speed increased (Figure 5). This behavior is due to the vibration of the transmission chains with increasing speed (Staggenborg, Taylor, & Maddux, 2004). It is also due to the increase in the angular velocity of the metering plates at each speed. That is, the seeds held by the plate impact with the other seeds in the hopper with a force proportional to its angular speed; when this speed increases, the impact force exceeds the suction force of the seed, causing its release before being transported out of the feeding area.

Figure 5 Standard deviation of the sowing system as a function of the test conditions and operating speeds: a) bean and b) corn.

In relation to the percentage of damaged seed, it averaged 0.09 % in bean and 0.03 % in corn for the three operating conditions. The row units damaged an average of 0.08 % of bean seed and 0.03 % of corn. The speed that caused the most bean seed damage was 3 km·h-1 with 0.14 %, whereas in corn it was 5 km·h-1 with 0.08 %. The damaged seed in this sowing system was lower than the maximum limit established by the NMX-O-222-SCFI-2004 standard (Secretaria de Economía, 2004), which is 0.5 %.

The fertilizer metering was evaluated at the planter’s 3, 4, 5, 6 and 7 km·h-1 theoretical forward speeds, with urea as the source. This variable did not differ statistically (P ≤ 0.05) in the first four speeds, which provided 30.84, 30.84, 30.28 and 31.45 g·m-1, respectively. However, the metering obtained at 7 km·h-1 was different (33.1 g·m-1). Theoretically, the metering units should provide the same amount for every km·h-1 increase in speed; nevertheless, fertilizer machines are designed for a nominal metering range, which may vary, so they should be calibrated according to the type of fertilizer to be used and the specific application (Reyes-Aroca, Berrios-Araya, Ortega-Blu, & Esquivel-Flores, 2011). The metering system of the equipment used in the present study has the capacity to provide an average of 824 kg·h-1 urea at maximum discharge, which can be reduced by closing the discharge gates.

Planter evaluation in the field

Immediately after bean planting, the minimum soil moisture was 8.94 %, the maximum 21.14 % and the average 14.59 %, whereas in corn planting, the soil moisture was 9.63, 21.18 and 15.23 %, respectively.

The planter’s slippage was 7.96, 9.08, 9.88 and 12.09 % for each sowing speed (3.63, 4.79, 5.84 and 7 km·h-1, respectively). Yang et al. (2015) attribute the slippage of the ground wheel to its inadequate interaction with the ground, and increases with the increase in the forward speed.

The germination percentage was 96 % in bean seeds and 99 % in corn seeds. Therefore, the theoretical bean seed spacing distances were 11.32, 11.46, 11.56 and 11.85 cm for each forward speed (3.63, 4.79, 5.84 and 7 km·h-1, respectively), and 27.45, 27.78, 28.02 and 28.73 cm for each forward speed (3.63, 4.79, 5.84 and 7 km·h-1, respectively) in corn planting.

Regarding the overall mean spacing between bean plants, no significant differences (P ≤ 0.05) were observed among the speeds of 3.63, 4.79 and 5.84 km·h-1, and increased significantly at 7 km·h-1 (Table 3), while in the corn crop this variable did not vary statistically with any speed. Linear regression analysis (R2 = 0.89) indicated that the spacing between bean plants increased at a rate of 0.82 cm for each km·h-1 increase in speed, and in corn this variable increased 1.27 cm for each km·h-1 increase in speed (R2 = 0.91). Panning et al. (2000) and Staggenborg et al. (2004) also reported the same behavior in the cultivation of sugar beet and corn, respectively.

Table 3 Horizontal distribution variables of the planter at four operating speeds in the field, with bean and corn seeds.

| Crop | Speed (km·h-1) | Overall mean spacing (cm) | OSD1 (cm) | Multiple index (%) | Miss index (%) | Quality index (%) | Precision index (%) |

|---|---|---|---|---|---|---|---|

| Bean | 3.63 | 13.42 bz | 8.75 b | 18.63 a | 29.60 a | 51.76 a | 27.04 b |

| 4.79 | 13.39 b | 9.34 b | 22.76 a | 28.94 a | 48.29 a | 28.94 a | |

| 5.84 | 14.89 ab | 10.85 a | 19.11 a | 32.19 a | 48.69 a | 29.50 a | |

| 7.00 | 15.98 a | 11.05 a | 18.31 a | 36.71 a | 44.97 a | 28.66 ab | |

| LSD | 1.69 | 1.06 | 6.59 | 8.59 | 8.22 | 1.77 | |

| Corn | 3.63 | 22.88 a | 12.08 a | 24.26 a | 7.22 a | 68.51 a | 23.53 a |

| 4.79 | 25.24 a | 12.73 a | 19.66 a | 8.81 a | 71.51 a | 26.68 a | |

| 5.84 | 26.73 a | 14.34 a | 21.73 a | 12.86 a | 65.40 a | 25.69 a | |

| 7.00 | 27.12 a | 17.10 a | 27.10 a | 15.77 a | 57.12 a | 27.59 a | |

| LSD | 5.303 | 6.448 | 16.31 | 13.340 | 18.976 | 7.830 |

1OSD = overall standard deviation; LSD = least significant difference. zMeans with the same letter within each column do not differ statistically (Tukey, P ≤ 0.05).

The OSD of the spacing between plants was statistically equal at 3.63 and 4.79 km·h-1 in the bean crop, and increased at the two highest speeds (Table 3). The trend for this variable is to increase (R2 = 0.92) 0.75 cm for each km·h-1 increase in speed. In contrast, the OSD in corn was the same with all speeds; however, an increase of 1.49 cm was observed for each km·h-1 increase in speed (R2 = 0.93). Staggenborg et al. (2004) state that standard deviation increases with the operating speed because the efficiency of the metering disc decreases with the increase in its angular speed. In addition, these authors warn that the vibration of the row units increases with increasing speed, which affects the distribution of the plants. Panning et al. (2000) suggest that the variability of the spacing between plants may be more related to the bounce and roll of the seeds in the soil than to the irregularities of the metering system.

When observing the overall mean spacing between plants in the bean crop (Table 3), it is evident that it was greater than the theoretical spacing expected at each speed. The overall mean spacing increased 5.4 % for each km·h-1 increase in speed (R2 = 0.83), compared to the expected spacing. In corn, all mean distances between plants were less than the theoretical expected spacing at each speed. Staggenborg et al. (2004) note that the average spacing between plants and the standard deviation are the most reported variables when evaluating planter performance. This has led the authors to obtain results regarding plant distribution and yield estimation, so they suggest that the multiple index, the miss index, the quality index and the precision index better describe the distribution between plants.

Regarding the multiple index, no significant differences (P ≤ 0.05) were observed between speeds for both crops (Table 3); that is, the percentage of spaces less than or equal to 0.5 times the theoretical seed spacing was similar at each operating speed for both crops. Similarly, the percentage of spaces equal to or greater than 1.5 times the theoretical seed spacing was similar at each speed and in each crop, so there were no significant differences (P ≤ 0.05) in the miss index. Although there was no trend, positive or negative, in the multiple index in both crops, the miss index showed an upward trend with the operating speed at a rate of 2.2 % in bean (R2 = 0.81) and 2.7 % in corn (R2 = 0.97). An, Wang, Duan, Yang, and Yu (2017) observed a greater tendency for the miss index to increase in the corn and soybean crops with an increased operating speed, this compared to the multiple index. In contrast, Brandelero, Adami, Modolo, Baesso, and Adelar (2015) report upward trends in these indices with soybean seeds. Similarly, Bilandžija, Fabijanić, Sito, and Kiš (2017) state that both indices increased with higher sowing speed in red beet seeds with four different precision drills.

The quality index was similar between speeds in both crops, although it was higher in corn, indicating that a higher percentage of plants were located within the 0.5dt-1.5dt range. In addition, this index decreased more in bean than in corn (3.6 and 1.8 %, respectively, for each km·h-1 increase in speed). Liu et al. (2017) obtained a quality index of 70 % in corn when a vacuum-type planter was used, similar to the one in this work.

The precision index in the bean crop was lower at the speed of 3.63 km·h-1, differing significantly (P ≤ 0.05) from the three other speeds, while in corn this variable did not show significant differences (P ≤ 0.05) among treatments. Since the precision index is the coefficient of variation of all the observations of the quality index, it increases with speed (Staggenborg et al., 2004), which indicates that planters are more precise with lower indices. Kachman and Smith (1995) note that 29 % is the maximum acceptable accuracy value to say that plant spacing is uniform within the range covered by the quality index.

In general, several factors are involved in the spacing between plants. A high miss index is related to metering errors when taking or dropping the seeds, and with the seeds that do not emerge. A high multiple index is related to double seed metering. In this sense, the design of the seed drop tube and soil conditions, among other factors, determine the seed’s final position (Kachman & Smith, 1995; Singh et al., 2005).

As for planting depth, this was statistically equal (P ≤ 0.05) between the speeds of 3.63 and 4.79 km·h-1, which yielded an average of 6.15 and 6.11 mm, respectively. However, at 5.84 and 7 km·h-1 the average was 5.83 mm in both cases, differing statistically (P ≤ 0.05) from the first two. The coefficient of variation of depth increased with speed, which was 2.45, 3.57, 4.28 and 4.72 % for 3.63, 4.79, 5.84 and 7 km·h-1, respectively. These results are consistent with those reported by Yang et al. (2016), who evaluated a double-disk furrow opener in wheat planting, and observed that depth decreased and the coefficient of variation increased with increasing speed.

Finally, the water volume in the dikes was greater with the lowest speed and decreased with increasing speed, with significant differences (P ≤ 0.05) being found (Table 4). In this sense, a 7 L reduction rate was observed for each km·h-1 increase in speed (R2 = 0.77). Although the length of the dikes increased when the speed was 7 km·h-1, the low volume is attributed to the irregularity of its cross section and the height of the counter (mound of earth dragged by the pileteadora’s paddle). At a lower speed, the earth that accumulates in the collection system's paddle is less, which is due to its low interaction with the ground, and as a result a low height counter is obtained.

Table 4 Characteristics of the dikes made with the planter at four operating speeds.

| Speed (km·h-1) | Length (m) | Width (m) | Height (m) | Volume (L) |

|---|---|---|---|---|

| 3.63 | 2.95 abz | 0.34 a | 0.13 a | 55.96 a |

| 4.79 | 2.81 b | 0.30 b | 0.10 b | 35.19 b |

| 5.84 | 2.86 b | 0.34 a | 0.12 a | 35.65 b |

| 7.00 | 3.03 a | 0.30 b | 0.10 b | 29.96 c |

| LSD1 | 0.148 | 0.024 | 0.016 | 5.042 |

1LSD = least significant difference. zMeans with the same letter within each column do not differ statistically (Tukey, P ≤ 0.05).

Conclusions

A pneumatic planter was designed and built to establish medium-sized seed plantings in four-row beds. The planter has conventional winged coulters to form beds in the ground, a sowing system with four independent row units that adapt to the irregularities of the ground and a system for fertilization. In addition, an attachment was integrated to form dikes on the bed’s sides for storing rainwater.

Seed metering, fertilizer and horizontal and vertical distribution variables indicate that this equipment has similar behavior to the planters that exist in the market; therefore, it is an option to mechanize the method of sowing four-row beds for medium grain crops.

The rainwater harvesting system will maintain soil moisture for a longer period of time, which will be used by the crops. In addition, this implement will reduce production costs, since it integrates the practice of sowing and diking in a single operation.

texto en

texto en