Introduction

In the market there are fermented or acidified creams whose butterfat content must be at least 30 % and acidity 0.5 %, a quality that gives them their characteristic acid taste (Procuraduría Federal del Consumidor [PROFECO], 2007). In making a cream, various additives can be added, such as thickeners, emulsifiers, stabilizers, dyes and flavorings, among others (Organización de las Naciones Unidas para la Alimentación y la Agricultura - Organización mundial de la salud [FAO - OMS], 2011). In recent years, hydrocolloids, or gums, used as stabilizing, thickening and gelling agents in the preparation of the cream have been the subject of growing interest due to their obvious advantages in industrial production (Van Lent, Thu-Le, Vanlerberghe, & Van der Meeren, 2008). The use of these gums in dairy products helps improve the body, texture and mouthfeel, as well as modify the consistency and viscosity (Ramírez-Sucre & Vélez-Ruiz, 2009); the above has allowed generating new products accepted by consumers. Among these additives are starch, carrageenan, xanthan gum, guar gum, pectin and other lesser-used ones (Dziezak, 1991).

Xanthan gum has the ability to stabilize emulsions, it is compatible with various additives and the resulting solutions have a shear thinning behavior. On the other hand, some studies have shown that locust bean gum increases the stability of emulsions at low concentrations (Camacho, Martinez-Navarrete, & Chiralt, 2005). The two gums are known to interact strongly with each other in aqueous solutions (Dolz, Hernández, Delegido, & Muñoz, 2007); as a consequence, there is a great increase in viscosity, or even gel formation, depending on their concentrations and the physical conditions in which the interactions take place (Ramírez, Barrera, Morales, & Vázquez, 2002). Thixotropic-type fluids arise from this mixture (Dolz et al., 2007). The synergistic effects between these hydrocolloids are advantageous in the food industry, so they represent an important field of research. If the stabilizers added to the cream exert the appropriate functionality, they can mitigate the separation of the phases and provide the desired viscosity, thereby improving their sensory quality (Sharma, Naresh, Dhuldhoya, Merchant, & Merchant, 2006).

Schmidt and Smith (1992) defined milk reactivity as the ability of a gum to produce higher viscosities in milk than in water. Mixtures of locust bean and xanthan gums in skim milk powder (SMP) and in whey protein concentrate (WPC), both reconstituted to 11 % solids, showed that 0.2 % locust bean gum showed reactivity with SMP and WPC, while 0.05 % xanthan gum only did so with WPC.

There are several models that explain the intermolecular associations between xanthan gum and locust bean gum (Takemasa & Nishinari, 2016). One model proposes that there is an association between the unsubstituted regions of the mannose backbone of the locust bean gum with the surface of the xanthan helix. A second model expresses that locust bean gum is attached to the cellulosic backbone of xanthan in the disordered state, at low temperatures or in the presence of sufficient amounts of salt, initially giving a fluid solution, but after heating it forms a gel. A third model explains that there are non-covalent bonds between the galactomannan molecules of the locust bean gum and the xanthan side chains, which allow gelation.

Grisel, Aguni, Renou, and Malhiac (2015) found in locust bean gums, where galactomannans are poorly substituted by galactose, that the junction zone model is the main mechanism that governs the interactions with xanthan gum and does not depend on the fine structure of galactomannans. Therefore, the regularity of the substitution of galactose along the mannoses backbone in galactomannans (locust bean and guar gums) is a key point in the interactions of these gums with xanthan.

Sandolo et al. (2010) reported that guar/xanthan gum systems form different types of networks depending on the ratio of the two polymers (1:1, 1:3, 1:9) and the preparation temperature. The formation of gels, through physical interactions, was observed using light scattering techniques, rheology and scanning microscopy. At the highest concentration of guar gum (1:1), a gel was always obtained; at intermediate concentrations (1:3), weak gels were obtained, under hot gum preparation conditions; and at the lowest concentration (1:9), gel spots were observed under hot preparation conditions and solutions under cold preparation conditions.

The objective of this study was to evaluate the effect of xanthan and locust bean gums on the physical and sensory properties of acidified dairy creams, in order to obtain the best acceptability by consumers.

Materials and methods

Extraction of the cream

Raw milk from Holstein breed cows kept in the Dairy Technological Unit stable at the Universidad Autónoma Chapingo, Mexico, was used to extract the cream; for this, an Elecrem® ELE-3 skimmer (Elècrem, Corp., France) with 22-L storage capacity was used. Xanthan gum, locust bean gum and citric acid (purity = 98.5 %) were provided by Química Laitz S.A. (Mexico City, Mexico).

The experiment was divided into three parts. In phase 1, the effect of the xanthan and locust bean gums at different acidity levels was evaluated. In 2, the effect of mixing the gums on the cream was determined, taking as a basis the best results obtained from phase 1. For phase 3, the best cream formulation with a mixture of stabilizers was compared with three commercial creams. In each of the phases, consistency, adhesiveness, viscosity and drainage stability were evaluated as physical parameters.

Preparation of the cream

The percentage of fat solids in the cream was determined by the Köehler method and adjusted with skim milk to obtain 30 % (v/v). The acidity level (% w/w) for each formulation was adjusted with citric acid (Santos-Moreno, 1995); this adjustment consists of making a correction of the amount of citric acid equivalent to lactic acid (Equation 1).

Where:

CA = Amount of citric acid (g) to be added to reach A f

C = Cream mass (kg)

A f = Acidity to which it must be adjusted (%)

A i = Acidity before adjustment (%)

P A = Purity of citric acid (%)

1.4 = Correction Factor (equivalent weight of lactic acid per equivalent weight of citric acid)

For each experimental unit, the amounts of acid and stabilizer (locust bean gum and xanthan gum) were weighed and stored in small plastic bags. This mixture (citric acid plus stabilizer) was called "powders." On the other hand, the cream was heated in a water bath to 60 °C. Subsequently, 400-mL cream batches were mixed with the "powders" in an Osterizer® model 450-10 blender (Sunbeam Corp., E.U.A.) for 5 s. The mixed cream was placed in 1-L glass jars and pasteurized in a water bath at 80-85 °C, for 3 min; finally, the jars were covered and refrigerated for 24 h.

The method of adding powders may not favor a complete hydration of the xanthan gum and possibly favor the formation of conglomerates. Doublier and Llamas (1991) reported dispersion of a xanthan solution at 25 °C with stirring for 2 h. On the other hand, Ramírez et al. (2002) added xanthan (X) and locust bean (LB) gum mixtures without hydrating in surimi gels and found that the shear and strain stress decreased with the increase in the X/LB ratio, and when the gums were solubilized, but the increase in xanthan gum in the X/LB ratio from 0/1 to 0.5/0.5 improved the shear and strain stress of the surimi gels.

Determination of physical characteristics

Consistency and adhesiveness. 80-g cream samples were placed in cylindrical containers to employ the back-extrusion procedure with a TA-Xt2i® texturometer (Stable Micro Systems, UK) using the Texture Expert Analyzer® ver. 7.15 H procedure. For the above, the 5-kg cell was used and the head applied a uniaxial compression with pre-test, test and post-test speeds of 1 mm·s-1 and a penetration distance of 30 mm.

Viscosity. 200-mL cream samples placed in 250-mL beakers (diameter 7.0 cm and height 9.5 cm) were measured for viscosity using a Brookfield® model DV2T viscometer (Brookfield Engineering Lab, 2000) with LV3 (63) and LV4 (64) spindles. The rotation period for the measurement was 30 s at 15 rpm.

Drainage stability. This parameter was measured according to the procedure described by Van Lent et al. (2008), for which a 30-g cream sample (mcream) was placed on a stainless-steel mesh, with openings of approximately 1.14 mm, and it on a plastic cup to capture the released liquid. After one hour, the drained liquid (mliquid) was weighed and the quotient obtained between it and the initial cream mass represented the drainage percentage.

Sensory evaluation

Acceptability test. Number-zero plastic cups with 10 mL of cream each were presented randomly in triad form. After each three samples, the panelists were asked to take a break of between 5 and 10 min, while they were served an apple slice, to clean the palate and avoid the sensory fatigue caused by the samples. The acceptability of the individual attributes of the creams (Table 1) and the overall acceptability were determined using a nine-point hedonic scale. A total of 99 panelists (56 women, 43 men) who were cream users (with once-a-month consumption frequency) were recruited, and each panelist evaluated the nine samples with locust bean gum in one day and nine samples of xanthan gum another day.

Table 1 Attributes, description and procedures to evaluate the acceptability in dairy creams.

| Attribute | Description | Evaluation procedure |

|---|---|---|

| Consistency | As a texture characteristic, it describes a product that, during chewing, opposes certain resistance to breaking (Bourne, 2002). In relation to viscosity, it refers to the ability of a fluid to remain with a certain shape (Clark, Costello, Drake, & Bodyfelt, 2009). | With a spoon, take a little cream and observe the shape you get on the spoon (Clark et al., 2009); a cream with high firmness keeps its shape in the spoon, while a cream less firm falls from the spoon (flows). |

| Acidity | Characteristic sensation of the predominant acid in the cream, either lactic or citric added, on the tongue (sense of taste). | Put a spoonful of cream on the tongue and taste it, paying special attention to this attribute. |

| Viscosity | Force required to flow a liquid by the tongue (Anzaldua-Morales, 1994). | Take cream with a spoon and make it flow with a rolled tongue. |

| Sensation of fat in the mouth | Sensation that is generated in the mouth when tasting a fatty food. | Taste the cream, pass it through the mouth and discriminate the sensation of fat in the mouth. |

JAR test. The five treatments were evaluated on a single day with 105 panelists (57 women and 48 men). Panelists were asked to express their opinion on the adequacy of the perceived intensity of each attribute. For each of them, a five-point Just About Right (JAR) scale was used. The evaluations of these attributes allowed elucidating those treatments that do not have the appropriate levels of each factor. With the data obtained from JAR and the overall acceptability of the samples, a penalty analysis was performed with the XLSTAT® program (Addinsoft SARL, 2017) for each treatment.

Contrast with commercial creams. The physical characteristics of the treatment with the greatest degree of acceptability in this research were compared with those of commercial creams of the Lyncott®, Lala® and Alpura® brands. The response variables were viscosity, consistency, adhesiveness and drainage stability.

Statistical analysis

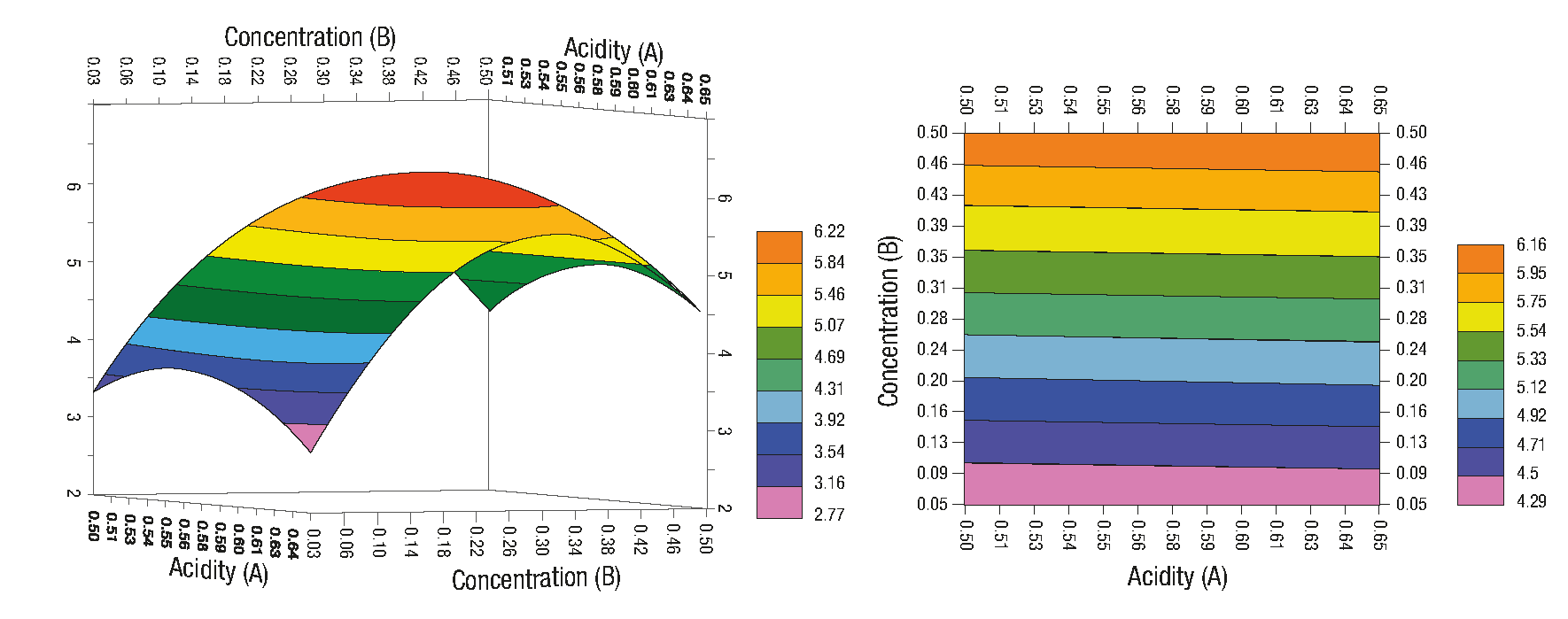

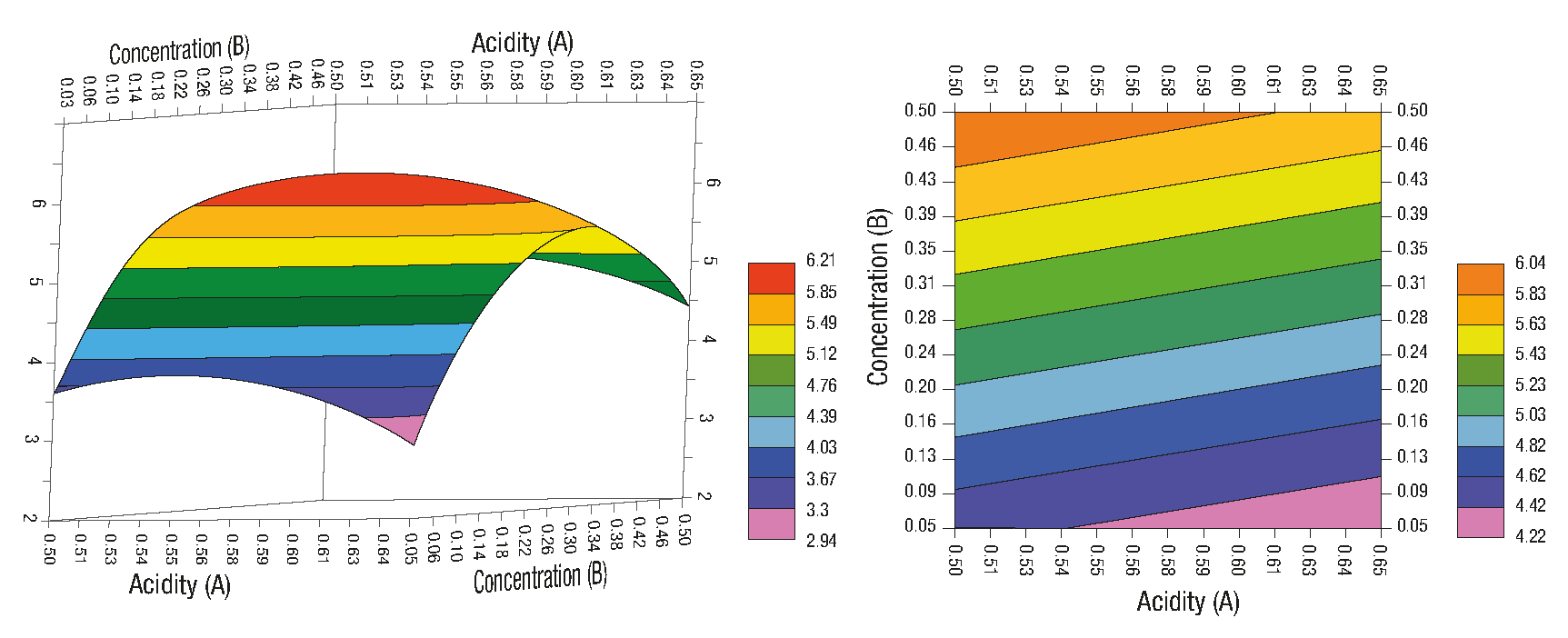

Optimization design. For the evaluation of the effect of the gum (either xanthan or locust bean) and acidity factor levels, an inscribed central composite (ICC) optimization design was used in a randomized distribution (Montgomery, 2011) of two factors with five levels each. The design distribution was made up of a central point, four axials, four factorials, three repetitions and a type I error of 0.05. The designs for each gum were obtained with the The Unscrambler 10.2 program (Unscrambler, 2012), with a total of nine treatments and three repetitions. The acidity factor was designed with levels from 0.5 to 0.65 % in both experiments (expressed as grams of lactic acid per 100 g of cream), and in the gum concentration factor a range of 0.025 to 0.5 % and 0.05 to 0.5 % was used for xanthan and locust bean gums, respectively. The results were analyzed with the response surface method (Figure 1).

Figure 1 Inscribed central composite (ICC) design in a randomized distribution (Montgomery, 2011). Design for locust bean gum (left) and xanthan gum (right).

Mixture design. We used an increased simplex-centroid mixture design, where the total amount of gum did not exceed 0.5 %, specified in the Mexican standard NMX-731 (Cámara Nacional de Industriales de la Leche [CANILEC], 2012). The amount of xanthan and locust bean gums was limited to a range of 0.1 to 0.4 % (Figure 2). The design was obtained with the XLSTAT® program (Addinsoft SARL, 2017), using five treatments and three repetitions.

Comparison with commercial creams. We used a completely randomized design, where the experimental units were 1 kg of each cream, Lala®, Alpura®, and Lyncott®, and the cream studied, with three repetitions (giving a total of nine experimental units). The means of each treatment were subjected to a least significant difference (LSD) test.

Results and discussion

Creams with xanthan or locust bean gums as stabilizers and different acidity percentages

Linear array models were used for all response variables. The goodness of fit test proved not to be significant (P > 0.05), indicating that the theoretical model fit the observed data. The acidity factor was not significant for any variable; however, in the gum factor, a significant difference was found for all the response variables, except for the viscosity in locust bean gum (Table 2).

Table 2 Significance of the factors in the variables and goodness of fit test.

| Gum | Response variable | Acidity* | Gum* | Model’s goodness of fit* |

|---|---|---|---|---|

| Xanthan | Consistency | 0.721 | * | 0.837 |

| Adhesiveness | 0.443 | * | 0.839 | |

| Viscosity | 0.626 | * | 0.208 | |

| Drainage | 0.958 | * | 0.904 | |

| Locust bean | Consistency | 0.084 | * | 0.778 |

| Adhesiveness | 0.113 | * | 0.491 | |

| Viscosity | 0.174 | 0.108 | 0.402 |

(*) P ≤ 0.05

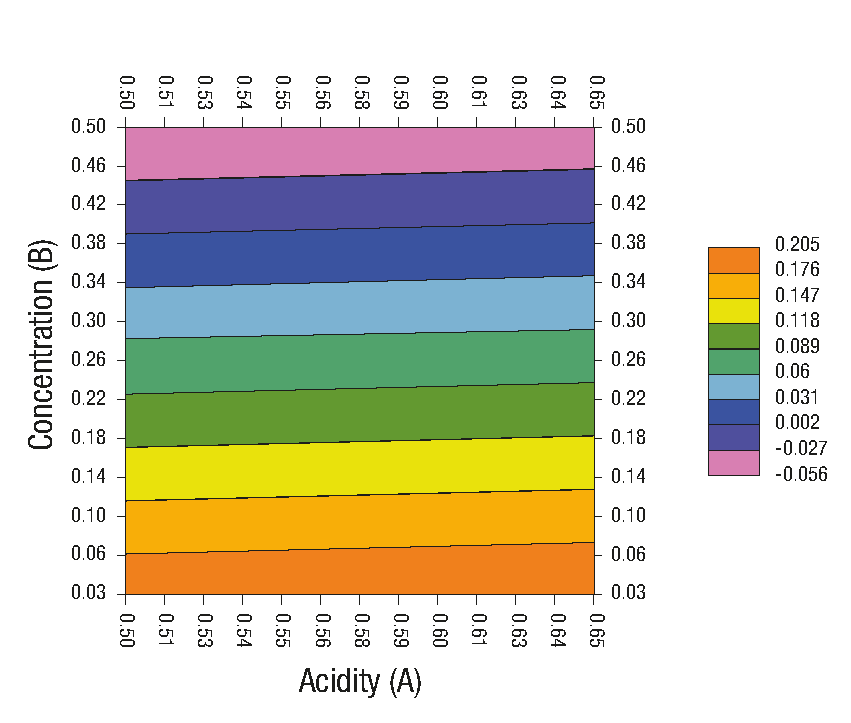

Figure 3 shows the cream consistency values, which increased with increasing concentrations of xanthan gum (P < 0.05), with values of approximately 300 to 4,000 gf. The acidity factor showed no influence on the consistency of the cream (P = 0.72); this can be explained by the stable behavior of xanthan gum to changes in acidity and temperature. Due to its shear thinning behavior (pseudoplasticity), xanthan is used as a thickening, stabilizing and dispersing agent (Habibi & Khosravi-Darani, 2017).

Figure 3 Response surface in the consistency of cream with xanthan gum (left) and locust bean gum (right). The consistency values are expressed in units of gf.

Adding xanthan gum to the cream favored the creation of a semi-solid product, which was formed thanks to the negative charges of the carboxyl groups of the xanthan gum’s lateral chains, causing the molecules to form a viscous fluid, which makes the cream spreadable. The high viscosities of xanthan solutions, subjected to low shear, have been attributed to the weak associations between their helical structures; a network easily destroyed, but easily restored by removing the shear stress (Mannion et al., 1992). On the other hand, the best consistency with locust bean gum was achieved with 0.43 % gum rubber and below 0.54 % acidity, with maximum values of 600 gf .

In the variable adhesiveness (Figure 4), a statistical difference was found in the gum factor (P < 0.05), but not in the acidity factor (P > 0.05). The adhesiveness range found was lower for creams with locust bean gum.

Figure 4 Response surface in the adhesiveness of cream with xanthan gum (left) and with locust bean gum (right). Adhesiveness values expressed as -gf.

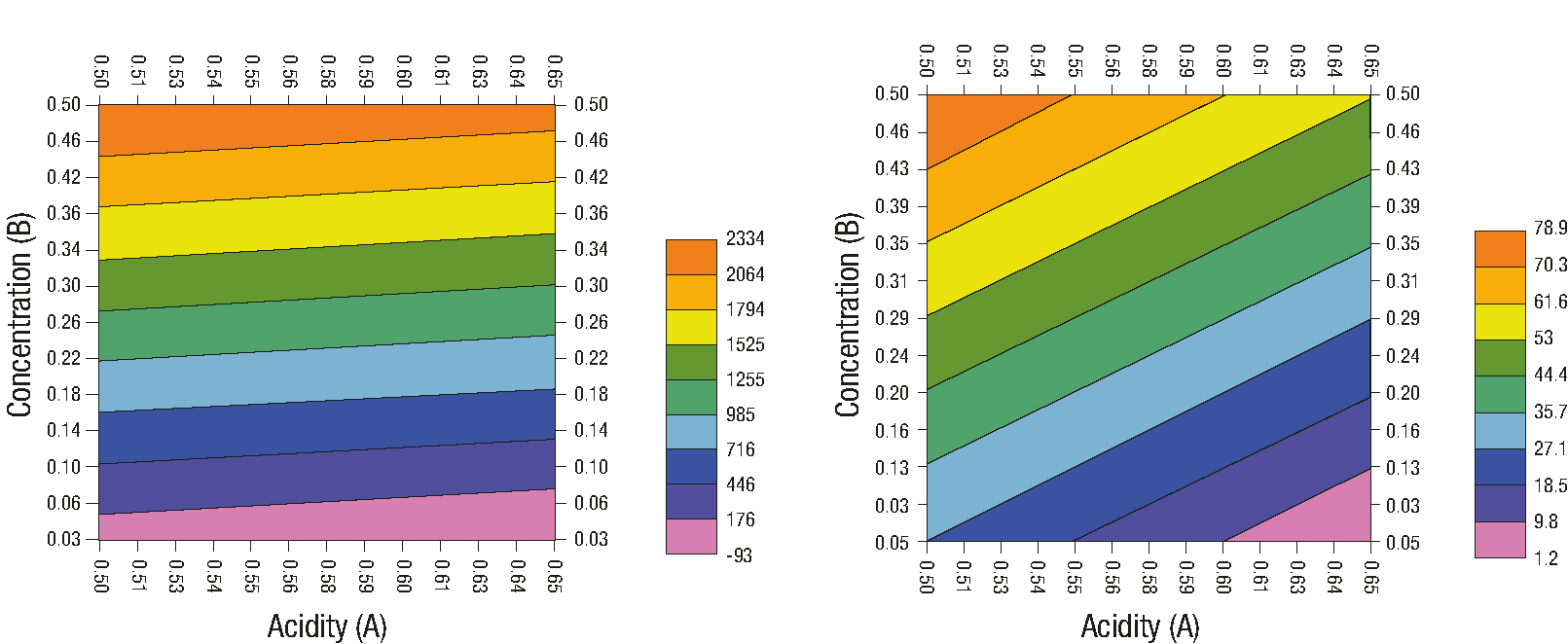

The xanthan gum factor affected the viscosity, showing difference among the treatments. This behavior has been reported by Gaviria, Restrepo-Molina, and Suarez-Mahecha (2010) in a dairy product. When the particles of a hydrocolloid are hydrated in a dispersion, the viscosity increases because the hydrated particles offer greater resistance to flow (Ramírez-Sucre & Vélez-Ruiz, 2009). The viscosity had values of 0.5 kg·m-1·s-1 with 0.025 % gum and up to 20 kg·m-1·s-1 with 0.5 % hydrocolloid, which shows the influence of xanthan gum on cream viscosity (Figure 5).

Figure 5 Response surface in the viscosity of the cream with xanthan gum (left) and with locust bean gum (right). Viscosity x 10-3 (kg·m-1·s-1).

The viscosity of cream with locust bean gum reached values higher than 1.4 kg·m-1·s-1 with 0.43 % of this gum and 0.61 % acidity. Ünal, Metin, and Işıklı (2003) reported the absence of a significant effect of locust bean gum on yoghurt viscosity, but an effect on the reduction of syneresis and pH. The low viscosity produced by locust bean gum can be explained by the few interactions between the same macromolecules (Doublier & Llamas, 1991).

In the drainage evaluation it was observed that at higher concentrations of xanthan gum the cream did not drain through the mesh, which means that the stability increased (Figure 6). Due to the strengthening of the gum bonds that more effectively trap the liquid phase of the cream, the stabilizers increased the viscosity of the serum phase, increasing the resistance of the product to drainage (Stanley, Goff, & Smith, 1996). In the case of cream with locust bean gum, the method used did not allow us to measure the drainage, because the samples showed low viscosity and drained completely through the mesh.

Acceptability test

In the sensory test, for the creams with xanthan gum, quadratic models were used, and with locust bean gum, linear models. The goodness-of-fit test showed that the quadratic model in xanthan gum was fitted for all acceptability variables (P > 0.05), except for viscosity (P < 0.05). The effect of the acidity factor was not significant (P > 0.05) in the acceptability of the specific attributes of the creams with xanthan gum added, except for the acceptability of the viscosity. On the other hand, it was observed that the acidity of the creams with locust bean gum showed significant differences in the acceptability of the acidity and overall acceptability (P < 0.05). The concentration of xanthan and locust bean gums in the creams (Table 3) had a significant effect (P < 0.05) on overall acceptability and on the acceptability of specific attributes.

Table 3 Significance of the factors in the sensory acceptability variables studied, and goodness of fit of the model used in the experiments involving cream with xanthan gum and locust bean gum.

| Response variable | Acidity (A) | Gum (G) | Interaction A - G | A2 | G2 | Model’s goodness of fit * | |

|---|---|---|---|---|---|---|---|

| Xanthan gum | Overall acceptability | 0.178 | * | 0.480 | 0.261 | * | 0.098 |

| Consistency | 0.418 | * | 0.434 | * | * | 0.197 | |

| Acidity | 0.741 | * | 0.300 | 0.715 | * | 0.572 | |

| Viscosity | * | * | 0.608 | * | * | * | |

| Locust bean gum | Overall acceptability | * | * | 0.803 | |||

| Consistency | 0.843 | * | 0.480 | ||||

| Acidity | * | * | 0.232 | ||||

| Viscosity | 0.143 | * | 0.742 |

(*) P ≤ 0.05

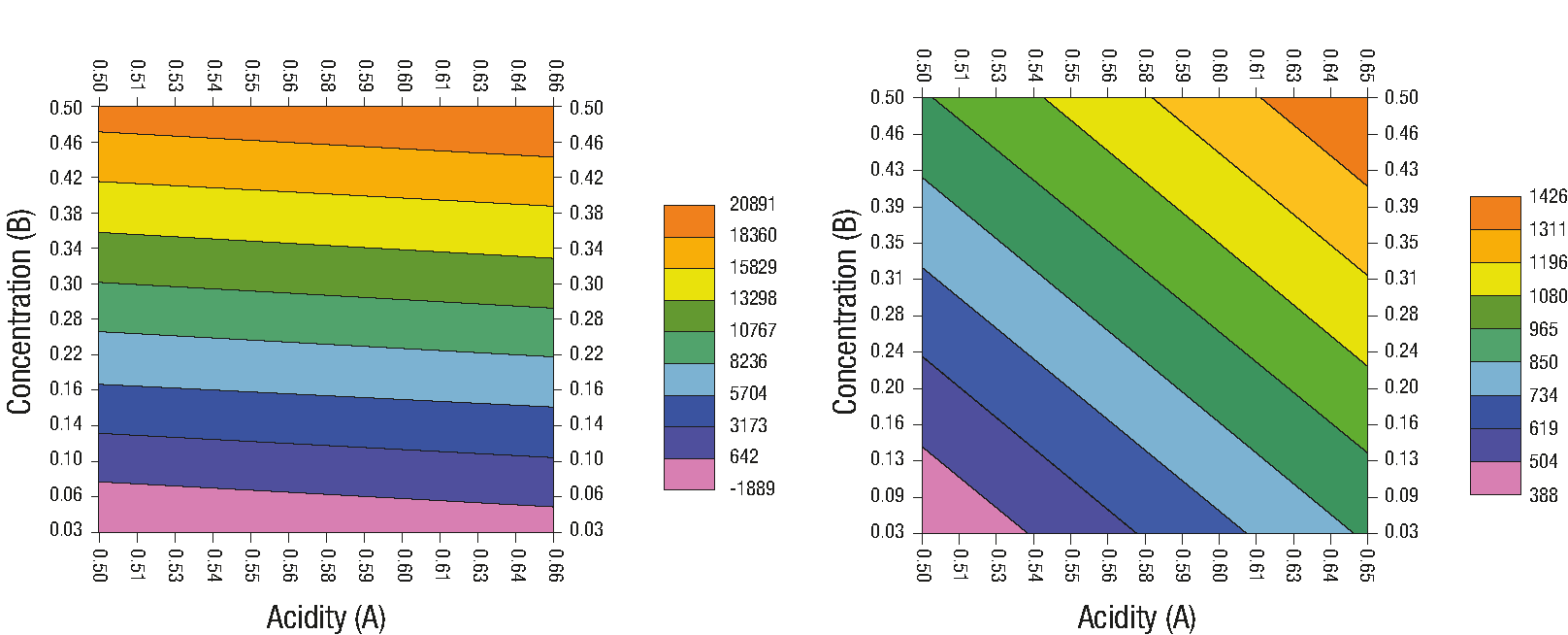

A three-dimensional graph of response surface for consistency acceptability showed a positive maximum range on the hedonic scale for concentrations between 0.13 and 0.5 % xanthan gum, while the cream with locust bean gum showed it at concentrations of 0.25 to 0.5 % ( Figure 7).

Figure 7 Response surface in the consistency acceptability of cream with xanthan gum (left) and locust bean gum (right).

The response surface for acidity acceptability (Figure 8) showed a "peak" (maximum) surface between the 0.22 and 0.5 % concentrations of xanthan gum. It is possible to assume a masking effect of acidity thanks to the xanthan gum; thus, people did not detect a difference between acidity levels. Ayenew, Puri, Kumar, and Basal (2009) suggest that increasing viscosity through the use of viscosity enhancers, such as xanthan gum, slows the migration of acid molecules to taste receptors in the mouth. Recent studies have also reported this phenomenon with pectin and guar gum in sour milk for a yogurt type drink (Aysel & Meral, 2004).

Figure 8 Response surface in the acidity acceptability of cream with xanthan gum (left) and locust bean gum (right).

In the acidity acceptability of the creams with locust bean gum, statistical significance (P < 0.05) was found in both study factors (acidity and gum concentration). The graph clearly shows a minimum "peak" of acceptability. The values predicted by the model, in this case the percentages of gum and acidity with greater acceptability, are oriented towards the upper left quadrant; the less accepted treatments are found above 0.64 % acidity and below 0.2 4% concentration of locust bean gum (Figure 8).

Viscosity is often a very important property, both for the quality control of dairy products and sensory properties, especially in products where the consumer's pleasure is focused on the appearance and mouthfeel (Lewis, 1996). Aysel and Meral (2004) report the need for increased viscosity and consistency to raise the degree of acceptance of yogurt. With respect to the physical variables, locust bean gum showed lower viscosities than those obtained with xanthan gum; therefore, higher acceptability values were expected in the creams made with xanthan gum, which was verified. Furthermore, in concentrations of approximately 0.26 % xanthan gum, higher viscosity acceptances were obtained, while with locust bean gum, percentages of up to 0.45 % were necessary to obtain the same results (Figure 9).

Figure 9 Response surface in the viscosity acceptability of cream with xanthan gum (left) and locust bean gum (right).

The three-dimensional graph for the overall acceptability of the cream with xanthan gum (Figure 10) presented a parabolic shape with a maximum acceptability on the hedonic scale of more than 6, including a range of gum concentrations from 0.2 to 0.38 %. An acceptability below five was observed in xanthan gum concentrations lower than 0.15%. To obtain the maximum overall acceptability in the cream with locust bean gum, the gum concentration should have been 0.46 %. On the contrary, at lower concentrations, such as 0.28 %, the acceptability decreased.

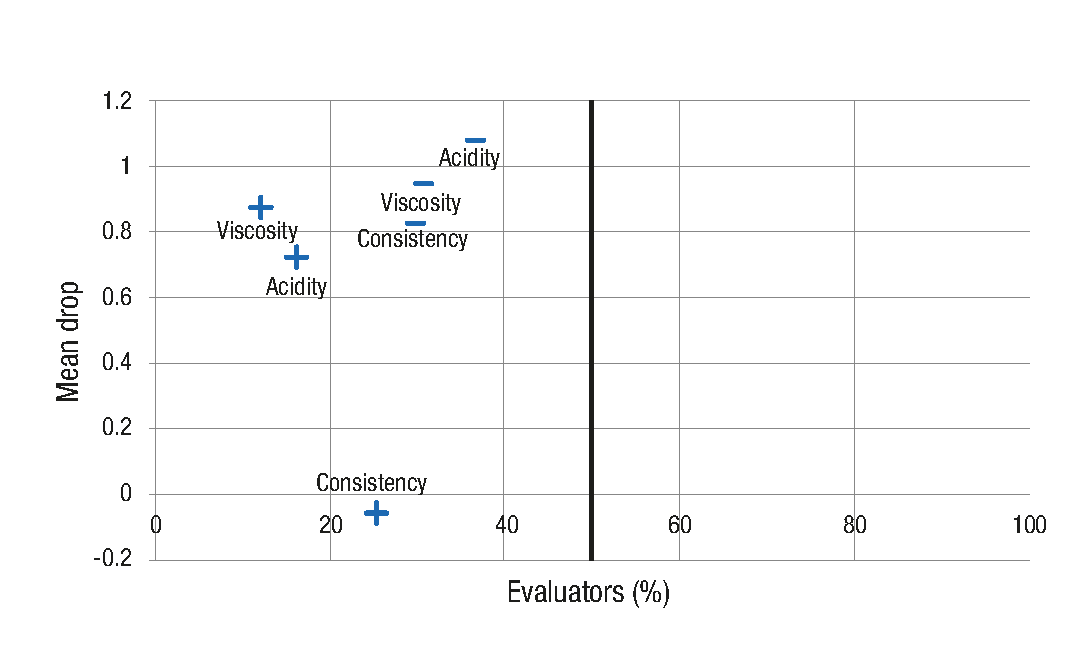

Penalty analysis

The penalty of each attribute is given by the decrease in the acceptability average of the characteristic in the product and the percentage of consumers that defined the intensity of the attribute as not adequate (often referred to as non-JAR %). Thus, a product with a high acceptability value and a small non-JAR percentage will have little effect in terms of reducing the average (Gacula, Rutenbeck, Pollack, & Moskowitz, 2007). The penalty analysis often uses a "pruning" of the non-JAR % in the attributes that have the least impact on the product. This cut obeys the Pareto principle, which establishes that 80 % of the effects correspond to 20 % of the causes; therefore, the smallest 20 % is taken as "not important" to explain the total analysis of the product (Narayanan, Chinnasamy, & Jin, 2014). In this case, a "threshold" of 50 % of the evaluators was established, which allows separating the intensities to be corrected from the attributes with problems of subjective perception of the intensity.

In this section, the most accepted treatments are discussed: T5 with xanthan gum (0.262 %) (Figure 11) and T9 with locust bean gum (0.5 %) (Figure 12). T5 showed all non-JAR attributes below 50 % of the evaluators. For all the above, it is possible to take this as the best formulation, corresponding to 0.262 % xanthan gum and 0.575 % acidity. On the other hand, formulations 6, 7, 8 and 9 (not shown), with greater amounts of xanthan gum, showed that the percentage of consumers who perceived the viscosity and consistency to be in excess increased, moving away from the optimal treatment.

Figure 11 Penalty analysis for the treatment 5 (0.262 % xanthan gum and 0.575 % acidity). Insufficient intensity (-), excessive (+).

Figure 12 Penalty analysis for the treatment 9 (0.5 % locust bean gum and 0.575 % acidity). Insufficient intensity (-), excessive (+).

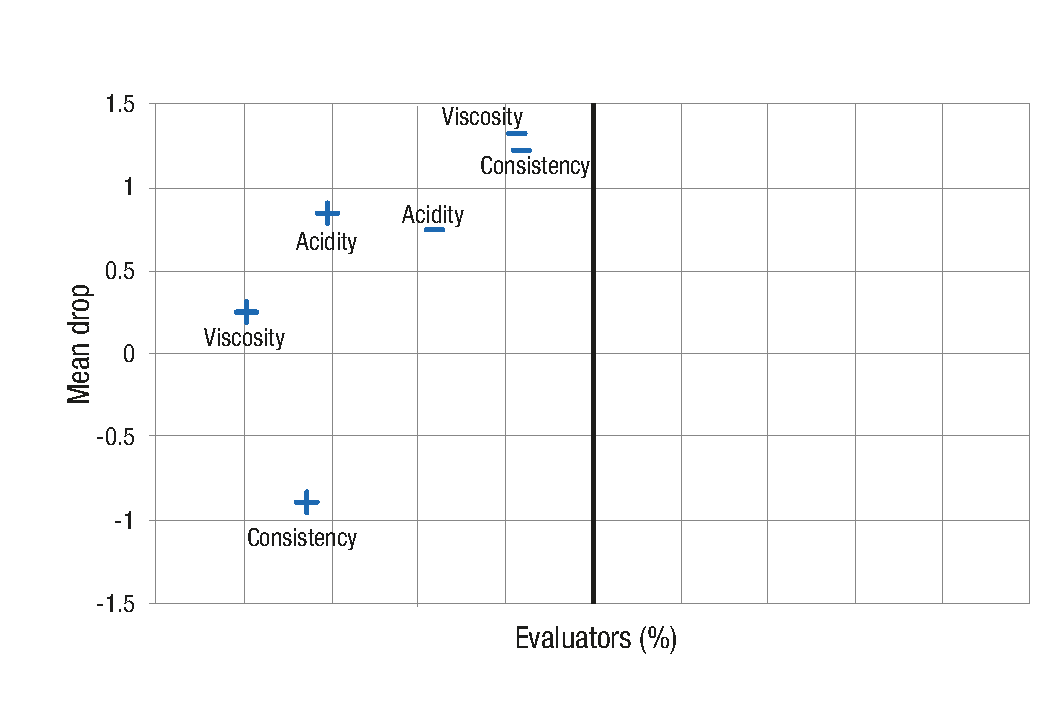

For locust bean gum, the formulation with the maximum amount (0.5 %) showed that the average overall acceptability penalties, imposed by consumers, were below the established threshold of 50 % of the total judgments. The acidity coincided with that used in the treatment with xanthan gum (0.575 %), and in this case only 30 % of consumers thought that it was insufficiently acidic. With 0.5 % locust bean gum, the percentage of consumers who found the intensity of the viscosity and consistency attributes not to their liking decreased considerably, with respect to the other amounts of locust bean gum tested.

Cream with gum mixture

For the second phase, the effect of the acidity factor remained constant, using the minimum necessary (0.5 % lactic acid) for economic convenience, since it showed no significant difference in the acceptability of both gums; in addition, the viscosity masked the perception of acidity. The selection of the gum ranges to be used in this phase was made taking into account the acceptability and penalty values obtained. In the previous analysis, xanthan gum was found to have greater influence on the variables of consistency, adhesiveness and viscosity of the cream. Therefore, it was taken as the basis of the formulation.

On the other hand, locust bean gum gave the creams more attractive visual properties, so it was a complement of xanthan gum, with the premise of improving the characteristics of the cream. This gum achieved acceptability levels of greater than 5 points on the hedonic scale, at concentrations of 0.1 to 0.4 %. Taking into account that the legal standard for dairy for dairy creams (CANILEC, 2012) restricts the maximum value of stabilizers to 0.5 % (alone or as a mixture), the values of locust bean gum in this mixture were adjusted by supplementing the established xanthan gum concentrations so that the mixture could reach 0.5 %.

The results showed significant difference among treatments for all attributes (P < 0.05). The fit of the linear models (R2) was greater than 95 %. The effects of the formulations on physicochemical properties are shown in Table 4, where it can be seen that with the addition of xanthan gum and the decrease in the proportion of locust bean gum the values of the three physical parameters increased. In addition, the grouping of means showed that the treatments with a greater and equal proportion of locust bean gum compared to that of xanthan belonged to the same group, and those with a higher concentration of xanthan gum and a lower concentration of locust bean gum were identified as different treatments; this behavior was presented in all response variables.

Table 4 Analysis of the physical parameters of the cream formulations with xanthan gum and locust bean gum.

| Treatment (% XG1: % LBG) | Consistency (gf) | Adhesiveness (-gf) | Viscosity (kg·m-1·s-1) |

|---|---|---|---|

| T1 (0.1:0.4) | 1595.9 az | 729.5 a | 2.87 a |

| T2 (0.175:0.325) | 1309.6 a | 463.2 a | 3.33 a |

| T3 (0.25:0.25) | 1710.6 a | 841.3 a | 4.50 a |

| T4 (0.325:0.175) | 3939.8 b | 2099.6 b | 11.93 b |

| T5 (0.4:0.1) | 10784.6 c | 5385.0 c | 16.85 c |

| LSD | 1826.2 | 1134.7 | 3.03 |

1XG: xanthan gum, LBG: locust bean gum, LSD: least significant difference.

zMeans with the same letter within each column do not differ statistically (P < 0.05).

There is evidence to suggest a synergistic effect between xanthan gum and locust bean gum, due to the increase in the viscosity or strength of the dispersant medium gel (Mannion et al., 1992; Schorsch, Garnier, & Doublier, 1997). On the other hand, using solutions based on mixtures of these gums in mayonnaise, Dolz et al. (2007) did not find a synergistic effect of the gums, but they did have an effect separately. Smith et al. (2010) attributed the synergistic behavior of these two gums in the formation of stiffer gels to the interaction between the helices of xanthan gum and the non-galactose region of the main chain of locust bean gum, in which a xanthan chain could be associated with one or more locust bean gum molecules. This interaction allows the liquid to be trapped more effectively and to form a stiffer gel than that resulting from the individual effect of each gum (Stuart-Tipson & Horton, 1975). On the other hand, Mannion et al. (1992) found that stronger xanthan/locust bean gels were formed when the dispersions were heated at 80 °C for 30 min, and in diluted solutions of 0.12 % xanthan/locust bean gums (0.5/0.5) they reported the formation of a super-aggregate network, which could be reversibly fragmented by shearing to give aggregates.

The consistency, adhesiveness and viscosity in the cream with a hydrocolloid mixture did not correspond to the arithmetic sum of the values of the creams formulated with each gum separately, so it was an enhancement synergy. The viscosity and consistency of the treatments T1, T2 and T3 are two to three times greater than the effects of the similar concentrations of locust bean gum individually evaluated (Table 4). In T4 (0.325:0.175), the viscosity and consistency values were approximately double those of the 0.325 % xanthan gum treatments in the first phase, while in T5 (0.4:0.1) the effects tripled with respect to the 0.4 % xanthan gum treatment individually tested. These results are consistent with the findings reported by Mannion et al. (1992), where the storage modules of the xanthan/locust bean gum mixture were larger than the individual xanthan module.

In aqueous solutions, xanthan gum does not form gels, but its anionic behavior allows it to interact with proteins that are positively charged (below its isoelectric point), and the electrostatic interactions are responsible for the hydrocolloid-protein interaction. In surimi with 1 % xanthan gum added, the addition of 0.4 % calcium allowed the formation of gels (Ramírez et al., 2002). Ma and Cánovas-Barbosa (1997) reported that some cations could interact with xanthan gum to form gels; sodium and calcium increased the stiffness, but the ferric ion gave the gel the greatest rigidity. On the other hand, Sharma et al. (2006) reported that at high pH levels (> 10) xanthan gum tends to form gels in the presence of divalent ions.

Acceptability test

The Friedman test (Table 5) showed significant statistical difference in consistency and viscosity acceptability (P < 0.05), but not overall acceptability (P > 0.05); therefore, it can be assumed that there were attributes that were not studied and that influenced the overall acceptability of each cream formulation.

Table 5 Acceptability analysis of the creams with a gum mixture.

| Treatment (% XG1: % LBG) | Consistency accept. | Viscosity accept. | Global accept. |

|---|---|---|---|

| T1 (0.1:0.4) | 5.73 az | 5.36 ab | 5.62 a |

| T2 (0.175:0.325) | 5.79 a | 5.44 a | 5.57 a |

| T3 (0.25:0.25) | 5.36 ab | 4.92 ab | 5.22 a |

| T4 (0.325:0.175) | 5.21 ab | 4.78 ab | 5.19 a |

| T5 (0.4:0.1) | 4.84 b | 4.67 b | 5.00 a |

| R2 | 0.95 | 0.76 | 0.976 |

1XG: xanthan gum, LBG: locust bean gum.

zMeans with the same letter within each column do not differ statistically (P < 0.05).

Penalty analysis

The evaluation with the JAR scale showed differences in the intensity of practically all the attributes for all the formulations, except for the consistency of T3. The treatments T1, T2 and T3 had penalties in the lack of consistency and viscosity (data not shown). However, the addition of xanthan gum that contributes to improving consistency and viscosity helped provide the better perception and valuation of these attributes, since in T4 (Figure 13) there was a decrease in the non- JAR % of all the attributes; therefore, the JAR % (that is, the percentage of consumers who considered this formulation adequate) was greater. This treatment corresponded to a ratio of 1:3 (locust bean gum:xanthan gum). The above agrees with the findings reported by Sandolo, Coviello, Matricardi, & Alhaique (2007), who observed that proportions of locust bean gum/xanthan gum between 1:1 and 1:3 produced gels ranging from very rigid to weak. Moreover, Sworn (2009) also suggests that the optimum ratio for the use of locust bean gum/xanthan gum is 2:3, due to the synergistic interaction of xanthan gum with galactomannans.

Comparison with commercial creams

The commercial creams (Table 6) showed very high and different values of viscosity, consistency and adhesiveness (P < 0.05). The treatment with 0.325 % xanthan gum and 0.175 % locust bean gum was better accepted and presented values similar to those of Lyncott® cream (P > 0.05). The difference in the drainage percentage was not statistically significant (P > 0.05). The similarity found between the cream made in this experiment and the Lyncott® one is explained by the use of xanthan and locust bean gums, as shown on its label. The Lyncott® cream additionally uses guar gum and carboxymethylcellulose (CMC), the Lala® cream uses guar gum and the Alpura® one a combination of guar gum, CMC and carrageenan.

Table 6 Comparison of physical parameters of three commercial creams vs the treatment with the best results in phase 2.

| Brand | Viscosity (kg·m-1·s-1) | Consistency (gf) | Adhesiveness (-gf) | Drainage (%) |

|---|---|---|---|---|

| Lala® | 2,006.6 ± 200.97 a | 14,005 ± 364 a | 8,641 ± 306 a | 1.72 ± 0.02 a |

| Alpura® | 630.6 ± 120.77 b | 9,258 ± 396 b | 6,675 ± 748 b | 0 |

| Lyncott® | 17.2 ± 1.08 c | 4,239 ± 249 c | 2,600 ± 376 c | 0 |

| Cream with gums | 11.9 ± 2.88 c | 3,939 ± 202 c | 2,099 ± 1,187 c | 0.77 ± 0.01 a |

| LSD | 266.324 | 2152.2 | 1674.8 | 0.0173 |

LSD: least significant difference.

zMeans with the same letter within each column do not differ statistically (P < 0.05).

Conclusions

The acidity factor did not show a significant statistical difference between the response variables of the creams that used both xanthan gum and locust bean gum, so the use of 0.5 % acidity was sufficient to preserve their acceptability. Xanthan gum gave higher values in the textural and viscosity properties; in addition, it is possible to assume the existence of a masking effect of the sensory perception of acidity due to the high viscosities provided by the gum.

The cream with xanthan gum showed higher acceptability values at concentrations of 0.2 to 0.38, while cream with locust bean gum showed greater acceptability at concentrations of 0.46 to 0.5 %. In both cases, acceptability values greater than 6 were scored on the hedonic scale.

The JAR test revealed that the best cream was the one containing 0.325 % xanthan gum and 0.175 % locust bean gum, as it favored consistency and viscosity, and reduced the percentage of people who penalized or punished the attributes.

The data obtained from the instrumental measurements of the best gum mixture were similar to those of the commercial creams whose viscosity and consistency values were approximately 10 kg·m-1·s-1 and 4,000 gf, respectively.

texto en

texto en