Introduction

Maize is the cereal with the greatest consumption demand in Mexico with approximately 23,200 Mt. These figures are expected to increase to 24,600 Mt, by 2020 (Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación [SAGARPA], 2011); this is due to the large number of products that are derived from it, such as tortillas, tortilla chips, tostadas, tacos, flours (Valderrama-Bravo et al., 2012) and other grain-derived products.

Nixtamalization is a thermal-alkaline process native to Mexico and carried out in Central America, the northern United States and parts of Europe and Asia (Valderrama-Bravo et al., 2012). This process improves the nutritional and sensory characteristics of maize, since it allows the partial removal of the pericarp (Valderrama-Bravo et al., 2013; Acosta-Estrada, Lazo- Vélez, Nava-Valdez, Gutiérrez-Uribe, & Serna-Saldívar, 2014), starch gelling and hydrolysis of the fibers (Domínguez-Espinosa & Pacho-Carrillo, 2003).

The conditions to which maize is subjected during nixtamalization are very important, as temperature and agitation have a significant effect on the removal of superficial layers, as well as on the adsorption of water and calcium (Ruiz-Gutiérrez et al., 2010). During this process, the action of calcium hydroxide generates two products: nixtamal, which is the soft grain used for making masa or derived products (Pflugfelder, Rooney, & Waniska, 1988), and nejayote, which is the wastewater whose physicochemical properties result from the components in the maize (Acosta-Estrada et al., 2014).

Certain biological properties (antioxidant activity) of nejayote are attributed to the presence of bioactive compounds, such as arabinoxylans (AX) and polyphenols. The former are polymers of xylose replaced by an arabinofuranosyl, which are commonly present in cereals and grasses without cellulose (Mendis & Simsek, 2014). The later serve as a structural link between the pericarp and endosperm of the grain (Castro-Muñoz & Yáñez-Fernández, 2015).

It has been estimated that a maize processing plant, producing nixtamal, with a 600 t·day-1 capacity, can produce between 1,500 and 2,000 m3 of nejayote per day. This effluent is considered as a pollutant because of its high pH (12 to 14) (Salmerón-Alcocer et al., 2003) and its high organic matter load (2,540 mg·L-1) (Valderrama-Bravo et al., 2012). Recently, industrial nejayote has been dumped into water bodies (rivers or lakes), in soils or in the public sewer system, and rarely is previously treated (Salmerón-Alcocer et al., 2003). Due to its physicochemical properties (Table 1), rarely has an attempt been made to find a use for the extract.

Table 1 Physicochemical properties evaluated in nejayote.

| Properties | Parameter |

|---|---|

| Total solids content (g·L-1) | 11.68 |

| Total soluble solids (°Brix) | 1.53 |

| Total organic carbon (mg·L-1) | 2,984.10 |

| Chemical oxygen demand (mg·L-1) | 25,000 - 30,000 |

| Total polyphenols (mg gallic acid·L-1) | 1,190 |

| pH | 12 - 14 |

| Density (kg·m-3) | 1,003.54 |

| Viscosity (Pa·s) | 0.002301 |

| Free nitrogen (ppm) | 200 - 300 |

| Calcium (mg·L-1) | 1,526.21 |

| Moisture (%) | 97.72 |

| Ash (%) | 0.767 |

| Crude protein (%) | 7.42 |

| Crude fat (%) | 1.48 |

| Crude fiber (%) | 19.3 |

| Carbohydrates (%) | 0.862 |

Adapted from: Acosta-Estrada et al. (2014), Castro-Muñoz and Yáñez-Fernández (2015), González, Reguera, Figueroa, and Martínez (2003), Salmerón-Alcocer et al. (2003), Valderrama-Bravo et al. (2012) and Velasco-Martínez, Angulo, Vázquez-Couturier, Arroyo-Lara, and Monroy-Rivera (1997).

The uses that have been given to nejayote are aimed at recovering components of high added value (González et al., 2003; Niño-Medina et al., 2009; Paz- Samaniego et al., 2015), as a source of enrichment for functional foods (Acosta-Estrada et al., 2014) or as a culture medium for bacterial growth (Blanco-Gámez, Sánchez-González, Valladares, & Olvera, 2008). It has also been investigated how to treat the effluent with flocculant materials (Suarez-Meraz et al., 2016), through membrane technology (Castro-Muñoz & Yáñez-Fernández, 2015) or biological systems (Pulido, Escárcega, & Durán-de Bazúa, 1987), to diminish the polluting action generated by the extract. Based on the above, the aim of this review was to provide an overview of the main methodologies and technological developments that have been implemented to explore the physicochemical properties of nejayote and to provide it with a treatment or application.

Treatments applied to nejayote

González-Martínez (1984) began the search for alternatives to reduce the pollution caused by alkaline liquor; for that purpose, he used two aerobic systems (a fixed-film cascade reactor and the other with activated sludge, 24 and 17 L, respectively) and two anaerobic systems (packed-bed and contact reactors, 11.5 and 9.1 L, respectively). The operating time of the reactors varied from 5 to 20 days. The results showed that the packed-bed and activated sludge reactors were the most efficient in the removal of chemical oxygen demand (COD) (91 and 90 %, respectively) in the first five days of the process, whereas the lowest percentage was shown by the contact reactor (31 %). Based on the efficiency of each process, the author suggested that the pH of the nejayote should be neutralized prior to being subjected to treatment to improve COD removal.

Pulido et al. (1987) conducted assays in rotatory biological reactors of various capacities (15, 50 and 250 L), with the purpose of treating larger effluent volumes (2,500 L). The experimental results revealed that the treatment, in any of the reactors used, considerably reduces the organic matter load in nejayote (96.43, 54.62 and 70.97 %, respectively). Finally, with the use of mathematical models, the authors estimated that the organic load can be reduced by up to 92.02 % (in 2,500 L). The foregoing allows considering the biological systems as capable of reducing the pollution generated by the extract, at least at laboratory level. However, in order to consider them as viable, evaluations on an industrial scale are needed. It is also important to consider and standardize the composition of nejayote because its characteristics and properties depend, to a great extent, on the maize type (Acosta-Estrada et al., 2014), and the degradative capacity of bacteria directly depends on substrate availability.

Krishnan, Ríos, Salinas, and Durán-de Bazúa (1998) used two treatments (primary and secondary) to evaluate their effect on nejayote. Each treatment had three different percolators packed with five different possible materials (gravel, soil sawdust, bark and Sphangum peat moss) (Figure 1), where the treated effluent in each percolator of the primary treatment continued in the same secondary treatment column.

Krishnan et al. (1998) indicated that, in the primary treatment, column A was the one that most reduced pH (4.6 %), whereas column C removed COD more efficiently (45 %) and was also the most efficient for treating the extract. On the other hand, in the secondary treatment, column A decreased pH to 5.2 and column B reduced COD to 15,240 mg·L-1 showing the best results during the process. From this research it can be concluded that the procedures used are a good alternative for nejayote treatment, since the percolating materials are inexpensive and treatment columns are easy to design.

Reyes-Vidal, Aceves-Diez, Martínez-Silva, and Asaff (2012) propose the use of nanofiltration membranes for recovering phenolic acids and fermentable carbohydrates, as well as the reuse of water within the same nixtamalization process. Their results indicate the removal of 83.4 % of total solids, 77.5 % of COD and 70 % of biochemical oxygen demand (BOD).

Castro-Muñoz, Cerón-Montes, Barragán-Huerta, and Yáñez-Fernández (2015a) used an ultrafiltration (UF) system at laboratory level to treat these wastewaters. To do this, they used a polysulphone membrane with 0.2 μm pore size, which reduced (in the permeate flux) total soluble solids by 15.03 %, turbidity by 72.77 %, calcium content by 11.36 %, and total organic carbon by 16.70 % (Table 2). The retentate kept 14.70 % of the carbohydrates (from 104 to 106 Da) and 18.97 % of total polyphenols (100 to 500 Da). The loss of organic acids could be due to the fouling phenomenon that the membrane underwent, mainly due to the reversible obstruction caused by the polysaccharides when saturating the pores and the fouling by polarization, which was generated by the dynamic flux used (Choi, Zhang, Dionysiou, Oerther, & Sorial, 2005; Tejeda, Montesinos, & Guzmán, 1995).

Table 2 Physicochemical properties of nixtamalization wastewater permeates, before and after the membrane process.

| Parameter | Nejayote | MF (0.2 μm) | UF (100 kDa) | Integrated system (MF-UF-UF)* |

|---|---|---|---|---|

| Total soluble solids (°Brix) | 1.53 | 1.30 | 0.80 | 0.00 |

| Total solids (%) | 1.34 | 1.02 | 0.80 | 0.17 |

| Total organic carbon (mg·L-1) | 2,984.10 | 2,485.5 | 1,966.40 | 381.99 |

| Turbidity | 538.09 | 146.51 | 6.70 | 3.78 |

| Calcium (mg·L-1) | 1,078.30 | 955.70 | 814.80 | -- |

| Total carbohydrates (mg glucose·mL-1) | 3.47 | 2.96 | 1.61 | 0.26 |

| Total polyphenols (mg gallic acid·L-1) | 1,190.74 | 964.81 | 950.00 | 951.85 |

MF: microfiltration, UF: ultrafiltration

*Coupled system with three membranes: 0.2 μm (MF), 100 kDa (UF) and 1 kDa (UF).

Adapted from: Castro-Muñoz et al. (2015a, b) and Castro-Muñoz and Yáñez-Fernández (2015).

Castro-Muñoz, Orozco-Alvarez, Cerón-Montes, and Yáñez-Fernandez (2015b) used an ultrafiltration (UF) system with a 100 kDa membrane, called a nominal molecular weight cut-off (NMWCO). This system allowed reducing the components present in the effluent, so that in the permeate the total soluble solids were reduced by 20 %, turbidity by 95.40 %, calcium content by 14.74 % and the organic load, in terms of total organic carbon, by 29.38 % (Table 2), whereas the retentate after UF concentrated the carbohydrates by 46.69 %.

Castro-Muñoz and Yáñez-Fernández (2015) used a coupled membrane system, better known as an "Integrated Membrane System," defined as a sequential membrane operations design. The objective of the study was to analyze the fractionation of nejayote using three separation stages. The equipment was composed of three polysulphone hollow fiber membranes (MF = 0.2 μm, UF = 100 kDa and 1 kDa). The integrated membrane design was able to reduce in the permeate the total soluble solids (100 %), turbidity (99.5 %) and total organic carbon (87.2 %), as well as concentrated the polyphenols (79.94 %) (Table 2); in addition, the retentate stream maintained 92.5 % of the carbohydrates. The results showed that each membrane is efficient in the removal of solids. Similarly, by the yields obtained in the recovery of the components present, the methodology evaluated showed a high potential to be applied in the treatment of nejayote in the nixtamalization industry.

As mentioned, nixtamalization produces a highly polluting effluent due to the addition of Ca(OH)2 to perform surface hydrolysis of the grain. Carrera- Campechano et al. (2012) and Rodríguez-Méndez, Figueroa-Cárdenas, Ramos-Gómez, and Méndez-Lagunas (2013) propose replacing lime (CaO) with weaker calcium salts [CaCO3, CaCl2, CaSO4 or Ca(CH3CO2)2] to evaluate their effect on final pH. Although their assessments focus on the chemical composition of the products obtained (flour and tortillas), in relation to polyphenols, anthocyanins and antioxidants, the final pH of hydrolyzed extracts (of white maize) reported by Carrera-Campechano et al. (2012) were 5.5, 6.4, 5.8 and 6.5, respectively, and those determined by Rodríguez-Méndez et al. (2013) were 7.29, 4.92 and 4.28, respectively [they did not evaluate Ca(CH3CO2)2], whereas the pH reported with lime is 11.95.

Rodríguez-Méndez et al. (2013) indicated that products made with different salts mostly maintain the nutritional properties of maize, because the hydrolysis of the grain components (endosperm and pericarp) is less aggressive in comparison to the traditional process. Although this process benefits the characteristics of the products made, it restricts the properties of nejayote (Table 3); this is due to the hardness of the salts, which is reflected in the structural breakdown of the grain (Ruiz-Gutierrez et al., 2010) and in this case, most of the components are maintained in the nixtamal. In spite of this, the obtained effluent has a more neutral pH, turning it into a less polluting residue.

Table 3 Chemical composition of the nejayote solids from nixtamalization with different calcium salts.

| Parameter | Ca(OH)2 | CaCl2 | CaCO3 | CaSO4 | Ca(CH3CO2)2 |

|---|---|---|---|---|---|

| Ash (%) | 31.2 | 45.6 | 40.5 | 34.1 | 40.5 |

| FAt (%) | 0.3 | 0.2 | 0.4 | 0.9 | 0.9 |

| Protein (%) | 2.9 | 5 | 3.1 | 3.9 | 4.4 |

| Total dietary fiber (%) | 41.2 | 19.6 | 23.6 | 15.6 | 10.8 |

| Total soluble fiber (%) | 30.4 | 7.9 | 6.2 | 7.9 | 7.6 |

| Insoluble dietary fiber (%) | 10.8 | 11.6 | 17.4 | 7.8 | 3.2 |

Ca(OH)2: calcium hydroxide, CaCl2: calcium chloride, CaCO3: calcium carbonate, CaSO4: calcium sulfate, Ca(CH3CO2)2: calcium acetate.

Adapted from Carrera-Campechano et al. (2012).

Garcia-Zamora et al. (2015) conducted an enzymatic treatment with laccase and chitosan (as adsorbent) to reduce the COD and ferulic acid content of the alkaline extract. The enzymatic oxidation of ferulic acid was conducted with 10 mL of the extract, 0.3025 nmoles laccase and 40 mL of phosphate buffer (pH 4.5 to 6), allowing the mixture to stand for 10 min; then 1 g of chitosan was added and incubated for 24 h at 35 °C. Subsequently, NaOH was added until a pH of 6 was reached. The precipitates were eliminated through centrifugation (6,000 rpm for 5 min) and washed with 50 % isopropanol. At the end of the experiment, the authors observed a reduction in total polyphenols (70 %) and COD (78 %). Because the process involved the use of an enzyme, it can be considered viable for the reduction of polluting compounds of the effluent, in addition to potential application in the food and pharmaceutical areas.

Suarez-Meraz et al. (2016) used high and low molecular weight chitosan, exposed to different proportions (23, 35, 47, 58, 70 and 117 mg) with nejayote centrifuged at different pH (4.5 to 6.5) to remove the solids from the nixtamalization extract (46.523 g·L-1). They evaluated the turbidity and zeta potential (ζ, capacity of the colloids to adsorb ions and dipolar molecules [Aguilar, Sáez, Lloréns, Soler, & Ortuño, 2002]) that each suspension presented. They showed that the maximum ζ for low molecular weight chitosan was -2.5 and for the other -0.7. In total, 46 % of total solids was removed (using 2.35 or 2.9 g of low and high molecular weight chitosan, respectively, per liter of nejayote at pH 5.5) and with both polymers turbidity was reduced by 80 %. The values of ζ indicated that chitosan is highly encapsulating, since the agglomeration was the maximum possible. The effluent failed to be within the permissible limits for solids in wastewaters (200 mg·L-1 maximum), as indicated by the Official Mexican Standard (NOM-001-SEMARNAT-1996, Secretaría de Medio Ambiente y Recursos Naturales (SEMARNAT], 1996); they only obtained an extract that was less aggressive with the environment.

Main nejayote applications

The intention of using nejayote has been reported for more than two decades. Velasco-Martínez et al. (1997) used nejayote solids, obtained by sedimentation-centrifugation, in combination with soy and sorghum as the diet for broilers. The purpose of the study was to evaluate the growth of the animals for seven weeks, for which they were provided 3,200 kcal·kg-1 based on formulations of different proportions of solids (2, 4 and 6 %, plus a commercial feed as a control).

Velasco-Martínez et al. (1997) reported that the livestock fed with commercial feed weighed 2.686 kg on average, whereas the animals fed with the formulations weighed 2.696, 2.689 and 2.835 kg, respectively. This demonstrated that the protein and calcium provided by the solids play an important role in the nutrition, growth and development of livestock. Similarly, it was reported that the animals had no physical changes, and that mortality was not affected in the treatment period. The study provides evidence that the solids can be used as fodder in the feeding of this type of livestock, including benefits not only to the environment but also to performance due to the weight gain of the animals during the rearing period.

Domínguez-Espinosa and Pacho-Carrillo (2003) produced enzymes with amylolytic activity by incubating Aspergillus awamori in nixtamalization extract; these enzymes helped to degrade the effluent. The fermentation started with pH 4.5 and lasted 100 h, resulting in amylolytic activity of 16 IU, which caused a reduction of 42 % in soluble solids and up to 21 % in COD. While the study contributes to the treatment of industrial residue, it also proposes establishing a nejayote bio-processing plant with a 10 m3 capacity, which would produce 13.5 g of enzymatic extract with a potential for 82 UI·g-1 and 695 g of biomass (with 18 % protein). The biomass would be used as animal fodder, enabling the recovery of the initial plant investment in two years.

González et al. (2003) used nejayote as an agglutinant to form carbon black (CB) agglomerates. They analyzed the properties presented by CB using the effluent and other additives (water, furfuryl alcohol [FA] and potassium lingosulfonate [PLS]). Their results showed that nejayote pellets have cohesive strength similar to that of pellets generated with commercial additives, and electrical conductivity exceeding that of pellets manufactured with FA and very similar to PLS ones (Table 4). This shows that despite being a waste material, nejayote can be used as an agglutinant not only of CB, but also of other materials with applications in the wiring or insulator industries. In this regard, its use as an input represents an interesting application in the polymer industry.

Table 4 Electrical and physical properties of carbon black agglomerates.

| Additive | Density (g·cm-3) | Cohesive strength (g·mm-1) | Electrical conductivity (Ω-1·cm-1) |

|---|---|---|---|

| Without additive | 0.0613 | 40 | 0.25 |

| Commercial (NH-234) | 0.1055 | 50 | 0.44 |

| Potassium lingosulfonate | 0.1366 | 716 | 0.99 |

| Furfuril alcohol | 0.1594 | 660 | 0.39 |

| Water | 0.0993 | 50 | 0.28 |

| Nejayote | 0.2818 | 649 | 0.73 |

Adapted from González et al. (2003).

Salmerón-Alcocer et al. (2003) treated nejayote biologically with microorganisms isolated from soil contaminated by the same effluent. They used a triple-cascade bioreactor system (Figure 2) and used the residue as a culture medium for Paenibacillus amylolyticus, Pseudomonas putida and Acinetobacter spp. The results showed a decrease in COD from 28,000 to 3,612 ppm after treatment; moreover, the COD generated by supplying (NH4)2SO4 and KH2PO4 (with 1 and 0.3 g·L-1, respectively), as an enrichment of the medium, fell by 87.3 and 87.6 %, respectively. Additionally, due to the nature of the isolated bacteria, they may be of interest to the oil industry, since these microorganisms are used to degrade aromatic hydrocarbons and their derivatives (phenol, benzene, toluene and xylene) (Riser-Roberts, 1998).

Figure 2 Triple-cascade aerobic system for nejayote treatment (adapted from Salmerón-Alcocer et al., 2003).

Carvajal-Millán, Rascón-Chu, and Márquez-Escalante (2005) patented the process of obtaining maize gum from nixtamalization residue. The process consists of eight general stages: 1) obtaining nejayote, 2) filtrating the extract, 3) centrifuging the filtrate, 4) acidifying the supernatant, 5) precipitating by standing, 6) filtrating the gum, 7) washing the gum and 8) drying the gum. The research suggests using the residue within 4 h after the nixtamalization process. Based on this methodology, Niño-Medina, Carvajal-Millán, Gardea- Bejar, Rascón-Chu, and Márquez-Escalante (2007) characterized gum obtained from the alkaline effluent. According to the study, they obtained AX with 75 % purity (w/w), of which 47 % was identified as xylose and 28 % as arabinose. Due to the gelling capacity of the AX, gel formation was conducted with the enzyme laccase at 4 % (w/v). In the results, they rated the gum obtained as a potential food industry material.

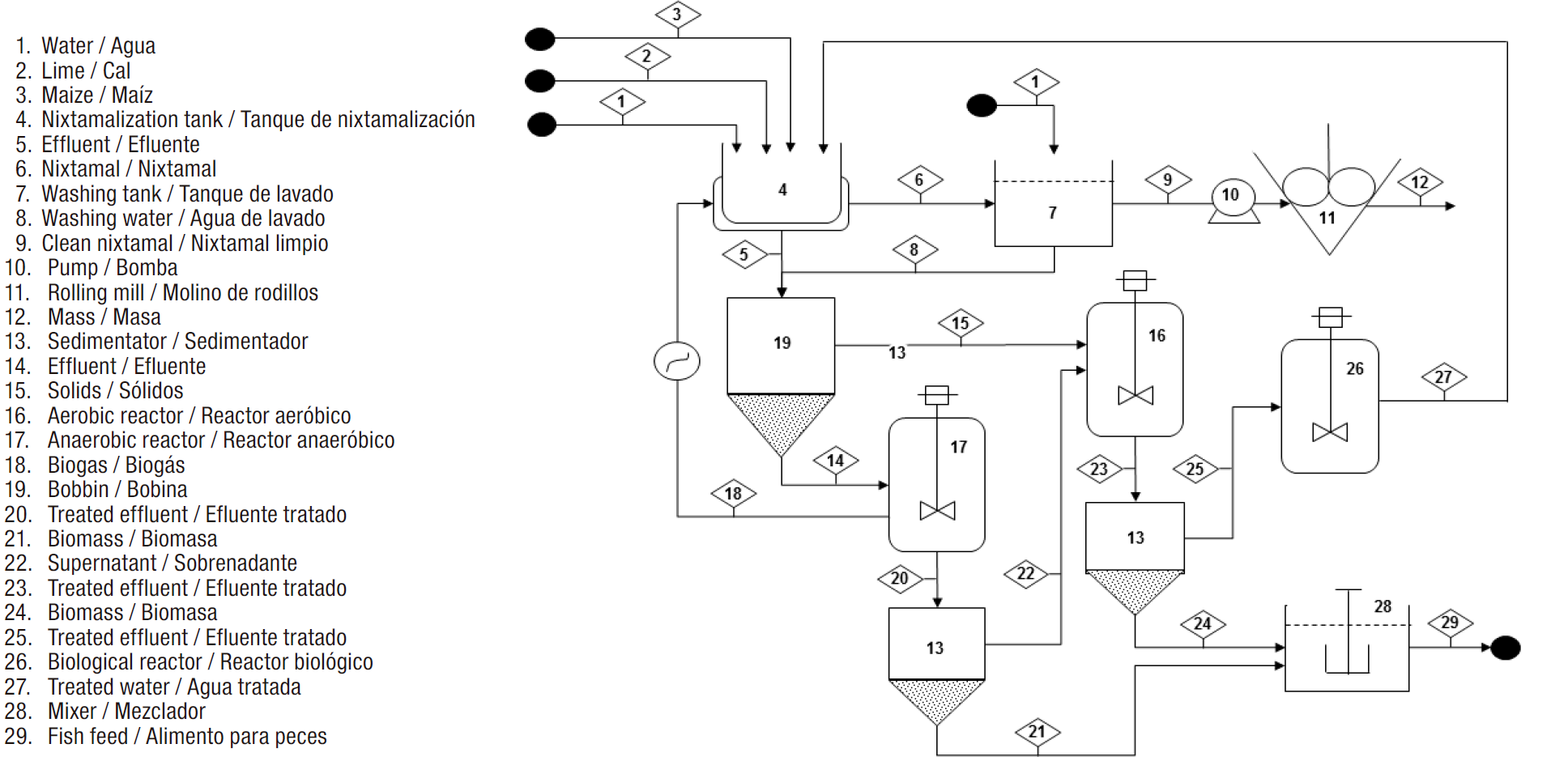

Durán-de Bazúa, Sánchez-Tovar, Hernández-Morales, and Bernal-González (2007) used an aerobic system to treat the byproduct of low-capacity (0.5 to 50 m3·day-1) nixtamal industries and an anaerobic-aerobic system for mills with greater capacity (2,500 m3·day-1) (Figure 3), in order to obtain reusable water in the same process and, at the same time, generate energy from the methane produced. The authors reported that in small mills the treatment was barely profitable, since the energy expenditure was higher. In the higher-capacity mill, production was 9.6 to 16.8 m3 of methane per ton of maize, which was used to generate energy, 23 kg of solid residue and 10.6 kg of biomass, with which pellets for fish feed were made. In addition, the treated water was reused.

Figure 3 Anaerobic-aerobic system for wastewater treatment in large mills (adapted from Durán-de Bazúa et al., 2007).

Ferreira-Rolón, Ramírez-Romero, and Ramírez-Vives (2014) used a 1.9-L UASB reactor to treat the wastewater from various maize mills in order to produce methane through seven stages. The mixture was subjected to mechanical sedimentation to remove more than 50 % of the initial solids; subsequently, two systems were generated to evaluate the bubbling effect (CO2) in the precipitation of calcium carbonate (from the nixtamalization process itself). The first was through direct bubbling in the supernatant obtained from the sedimentation, and the second was with bubbling in a mixture of supernatant with residual sludge (from a food industry), which contained 28.8 g of volatile solids per liter.

In both systems the greatest efficiency occurred at 35 min of bubbling, with the sludge being 15 % higher (52.3 % efficiency). Subsequently, the extracts were placed in the reactor for anaerobic degradation with sludge (ratio of 1:0.4 v/v); in the first four stages of the process, the feed was adjusted to different volumetric organic loads (VOL) (1.8, 2.7, 1.5 and 0.9 g COD·L-1·d-1, respectively). In the last three stages the reactor was fed with the nejayote supernatant. The generation of methane in each stage was different (1.54, 3.42, ˂1.05, 1.25, 1.96, ˃1.52 and ˃1.52 L·L-1·d-1, respectively), directly depending on the initial VOL.

Finally, the process achieved the removal of more than 90 % of total organic matter, showing that when nejayote is subjected to a previous CO2 bubbling up to 90 % of the biogas produced is methanol. Based on the foregoing, Ferreira-Rolón et al. (2014) suggest a scale system to treat 3 m3 of nejayote per day, which promises 50 % recovery of solids and calcium sedimentation, as well as improving the methane generation (90 %) in the biogas. Given the results, the last two studies are useful for companies that might make use of the byproducts generated by the treatment, whose benefits are: 1) wastewater treatment through disposal of the effluent, and 2) remuneration for the generation of products of potential use.

Blanco-Gámez et al. (2008) isolated and characterized bacteria from a culture medium composed of nejayote. They demonstrated that the microorganisms present in the medium were gram-positive bacteria and had catalytic activity. In addition, the results showed that the isolated bacteria had 96 to 99 % similarity with Bacillus megaterium, which is of pharmaceutical importance because it produces the enzyme Penicillin G acylase with bio-catalyzing ability in the production of semisynthetic β-lactams (Nucci, Silva, Gomes, Giordano, & Cruz, 2005). These are used as antibiotics to eliminate gram-positive bacteria, interfering with the peptidoglycans that form the cell wall and inhibiting biosynthesis in it (Tortora-Gerard, Funke- Berdell, & Case-Christine, 2007; Voet & Voet, 2006), thereby combating various infections. In addition, costs generated by the input, in the implementation of synthetic media, could be minimized by using nejayote.

Niño-Medina et al. (2009) and Paz-Samaniego et al. (2015) extracted the solids from nejayote to evaluate AX compounds and polyphenols present in the residue. Paz-Samaniego et al. (2015) varied the nixtamalization time to evaluate its effect on the production of the components of interest. Although they used similar methodologies, Niño-Medina et al. (2009) obtained higher yield values (81 % AX) and 20 to 30 times more ferulic acid (Table 5).

Table 5 Arabinoxylans in nejayote gum.

| Compound type | Component | Content | |

|---|---|---|---|

| Niño-Medina et al. (2009) | Paz-Samaniego et al. (2015) | ||

| Arabinoxylans | Arabinose (g·100 g-1 AX) | 32.00 | 0.9* 0.5** |

| Xilose (g·100 g-1 AX) | 49.00 | ||

| Polyphenols | Ferulic acid (µg·mg-1 AX) | 0.23 | 0.012* 0.008** |

| Diferulic acid (µg·mg-1 AX) | 0.58 | -- | |

| Triferulic acid (µg·mg-1 AX) | 0.30 | -- | |

AX: arabinoxylans

*Result for 24-hour alkaline hydrolysis

**Result for 4-hour alkaline hydrolysis

The variation in results in the two reports is related to the quality of the raw materials (maize and alkaline agent) used in nixtamalization and to the conditions under which the process was carried out. However, because of the functional characteristics possessed by the AX, they are considered important for the food industry as stabilizing agents since they provide viscosity, texture and structure to bakery products (Matos-Chamorro & Chambilla-Mamani, 2010). In addition, the feruloylated AX are an important source of antioxidants and dietary fiber, not only relevant in the making of bread and beer, but also in the pharmaceutical industry that has demonstrated the link between antioxidants and chronic diseases (Niño-Medina et al., 2010).

Gutiérrez-Uribe, Rojas-García, García-Lara, and Serna- Saldívar (2010) and Rojas-García, García-Lara, Serna- Saldívar, and Gutiérrez-Uribe (2012) extracted phenolic compounds of nejayote from six varieties of maize (blue maize [BLU], high-carotenoid maize [HCA], normal white maize [NWH], normal yellow maize [NYE], quality protein maize [QPM] and red maize [RED]). Both studies used the same nixtamalization parameters; however, Gutiérrez-Uribe et al. (2010) suggest that the QPM alkaline broth presents a higher total polyphenols content (650 mg GAE·100 g-1), whereas Rojas-García et al. (2012) place the RED extract (87.98 mg GAE·g-1) in this category. On the other hand, ferulic acid is more present in the QPM extract (3,539.2 mg·100 g-1 and 388.38 mg·g-1, respectively, in each study). The results suggest variation in the characteristics of the grain itself relative to the place of cultivation and the purity of the alkali used in nixtamalization. The latter is directly related to hydrolysis efficiency of the maize components (Pappa, Palacios, & Bressani, 2010).

Sanchez-Gonzalez et al. (2011) isolated two microorganisms from nejayote (NJY2 and NJY4), which by their morphology and physiological characteristics proved to be a species of Bacillus. When comparing their genome with various species, they had almost 100 % similarity with Bacillus flexus, facultative alkaliphilic salt tolerant microorganisms. Subsequently, they studied strain NJY2 and found that it had xylanolytic capacity, since by sequencing 10 families of glycohydrolases they identified endo-1,4- β-xylanase and esterase enzymes; the latter only acted at pH above neutrality, specifically in ferulic acid or some other esters. In addition, they determined that the calcium from the nixtamalization process increased the production of esterases by strain NJY2.

Both endo-1,4-β-xylanase and esterase are important in the paper industry since together they remove up to 95 % of the lignin in wood, which provides the final physical characteristics to paper (Ponce-Noyola & Pérez-Avalos, 2002). Also, in the food industry they are involved in clarifying juices and wines (Ponce-Noyola & Pérez-Avalos, 2002), obtaining flavorings (vanillin) from ferulic acid (Sánchez-González et al., 2011), and improving the texture and flavor of bakery products (Ponce-Noyola & Pérez-Avalos, 2002)

Ramírez-Romero, Reyes-Velazquez, and Cruz-Guerrero (2013) used nejayote from three different maize mills as a culture medium for lactic acid bacteria (Lactobacillus rhamnosus, Lactobacillus casei and Lactobacillus helveticus) to generate probiotics with production of bacteriocins. They fermented 50 mL of the supernatant of each extract for 48 h at 37 °C. They evaluated bactericidal activity with Echerichia coli and Listeria innocua, which were cultured individually in the supernatant of the fermentation for 3 h, and at 37 °C and 150 rpm. They observed that the strains grew mainly in nejayote with reducing sugars, protein and carbohydrates (1.12, 17.6 and 86.39 %, respectively). The bacterium with the strongest inhibitory action against E. coli (10 %) and L. innocua (13 %) was L. helveticus, which they attributed to the bacteriocins developed in the strains. Thus, the study generated an alternative use of nejayote as a growth and development medium for microorganisms with biological capacity as an antimicrobial barrier at digestive tract level.

Ayala-Soto, Serna-Saldívar, García-Lara, and Pérez- Carrillo (2014) assessed the hydroxycinnamic acids, sugar composition and antioxidant capacity of arabinoxylans (AX) extracted from different maize sources: maize fiber, insect-resistant maize pericarp, insect-susceptible maize pericarp and nejayote. The highest AX yield was with maize fiber (20.9 %), with 2 % more than nejayote. With regard to sugar content, the nejayote showed the highest concentration of glucose and galactose (3.79 and 4.97 g·100 g-1 AX, respectively). The insect-resistant maize pericarp presented the highest total polyphenol content (350 mg GAE·100 g-1), 42 % more than nejayote, concentration of identified hydroxycinnamic acids (1.89 μg·mg-1 AX) and antioxidant capacity (6 mM TE·100 g-1); this last element is 50 % higher than the nejayote. The foregoing indicates a direct relationship between these compounds.

The previous research shows the potential of the waste, since various AX sources are used for the making of maize-based food products; however, nejayote is an unappreciated byproduct, without treatment and without apparent commercial value. However, phenolic compounds are considered to be high value-added substances and part of dietary fiber, and are also valued for their prebiotic property and their participation as immunomodulators against degenerative diseases such as cancer (Mendis & Simsek, 2014).

Acosta-Estrada et al. (2014) used the solids contained in the effluent (11.68 g·L-1) and wheat gluten (4:1 ratio) to make bakery products. They noted that the sensory and nutritional characteristics improved in comparison with bread without the nejayote additive. This suggests that nejayote solids can be incorporated into bread without affecting its acceptability and adding an important source of dietary fiber, calcium and antioxidants. In this regard, the use of nejayote solids as an additive in the food industry is worthy of consideration, not only in baking but also in products that would benefit from raising their fiber content. In medicine they can help reduce cardiovascular diseases and prevent several types of cancer thanks to the antioxidant capacity of ferulic acid (Abbas, Sabir, Ahmad, Boligon, & Athayde, 2014).

Castro-Muñoz, Barragán-Huerta, and Yáñez-Fernández (2016) evaluated the antioxidant activity with 2,2-diphenyl-1-picrylhydrazyl from the extract obtained from the "Integrated Membrane System" (Figure 4) by fractionating the nejayote (Castro-Muñoz & Yanez- Fernandez, 2015). The result is expressed as micromoles Trolox equivalents per liter of extract (TEAC). The antioxidant activity increased 105.26 % at the end of the separation from that determined at the start (0.76 TEAC); they attributed this to the molecular weight cut-off of the membranes. Each stage allowed the removal of organic matter of various sizes and the permeate of compounds weighing less than 1 kDa, such as the polyphenols. Antioxidants are considered secondary metabolites of plant species, they are related to the elimination of free radicals by acting as reducing agents or by inducing the generation of reducing enzymes and they participate in anti-mutagenic activities in mammals (López-Martínez et al., 2008). The recovery of these molecules can benefit the food industry (as a nutraceutical agent) or the pharmaceutical sector.

Figure 4 Integrated membrane system used for the fractionation of nejayote (adapted from Castro-Muñoz & Yánez-Fernández, 2015).

The current problem

Treatments applied to the effluent, generated as a byproduct of a traditional process in Mexico, largely diminish its polluting effect by considerably reducing the pH, total organic carbon, total solids and COD.

The use of different methodologies to treat nejayote helps protect the environment by recovering components that can be reused in the same treatment system (reuse of the calcium components) or in different processes, as well as in the obtaining of value-added products (Castro-Muñoz, Orozco-Álvarez, & Yáñez-Fernández, 2015c; Galanakis, Castro-Muñoz, Cassano, & Conidi, 2016).

The quality of the extract is directly related to the initial properties of the raw materials (maize, water and calcium hydroxide) and the conditions of the nixtamalization processes (Trejo-González, Feria-Morales, & Wild- Altamirano, 1982). The alkali, temperature and mixing time are some of the parameters that interact with the inputs, resulting in extracts with a higher content of components (Escalante-Aburto et al., 2013; Fernández- Muñoz et al., 2006; Ruiz-Gutiérrez et al., 2010).

On the other hand, the purity percentage of the components obtained from nejayote depends directly on the methods used to extract them, whether they are physical (centrifugation, evaporation, sedimentation or filtration), chemical (solvents) or biological (enzymes, microorganisms or reactors). Operating conditions during each process provide specific characteristics to the final extracts, which can be used by various areas in the food (human and animal), pharmaceutical and medical industries, as well as for construction or production of electric energy (Acosta-Estrada et al., 2014; Durán-of Bazúa et al., 2007; González et al., 2003).

Finally, the methodologies described provide alternatives to treat an industrial residue without any commercial value and generate products or obtain compounds with economic utility.

Conclusions

This review showed the state of the art of studies focused on the treatment of the byproduct of nixtamalization. Although it should be explored in greater depth, nejayote has been proposed as a raw material in the obtaining and development of products; it has also been used as a substrate in the culturing of different bacterial strains of biotechnological interest.

Based on the analysis, the methodologies shown prove to be viable to generate technological applications that help recover high added-value components, such as polyphenols, carbohydrates, sugars, gums and calcium components, of interest in the food, pharmaceutical and biotechnology areas. In addition, their incorporation as a raw material in the polymer industry could increase the degradation rate of plastic products.

Although the studies presented here allowed knowing the technologies used (fermentation, filtration, centrifugation and decantation) to treat nejayote in order to reduce its environmental impact, the biotechnological importance lies in bringing attention to the compounds that could be obtained. Therefore, the prospects for using nejayote depend on the employment of the extracted components (mainly polyphenolic), such as the production of food with high nutraceutical content (by providing antioxidant compounds) and the generation of new pharmaceutical formulations.

text in

text in