Introduction

Construction and manufacturing industries of wood articles require information on the moduli of elasticity and rigidity in order to improve the design and the quality of wood products (Köhler, Sørensen, & Faber, 2007; Olsson & Källsner, 2013). Knowledge of the moduli of elasticity and rigidity of wood is of great importance in decision making related to the use of natural resources, and in the engineering, construction and architecture areas. The moduli are also important for the manufacture of wooden musical instruments (Brémaud, Gril, & Thibaut, 2011). Similarly, in different engineering specialties and materials sciences, the elastic parameters are necessary for the modeling of the mechanical behavior of the wood through the finite element method (Mackerle, 2005; Tankut, Tankut, & Zor, 2014) and for the analysis through artificial neural networks (Tiryaki & Hamzaçebi, 2014).

In the case of the mechanical behavior of the wood in static conditions, the determination of the moduli of elasticity and rigidity are derived from the stress-deformation relation (Adamopoulos & Passialis, 2010). When the parameters are derived from dynamic tests, the experimental parameters to be determined in the test pieces are the frequency (Yoshihara, 2012a) or the speed of the wavelength (Keunecke, Sonderegger, Pereteanu, Lüthi, & Niemz, 2007). The experimental results are pondered by the density of the wood, its temperature, the content of humidity at the moment of the test (Gorišek & Straže, 2013; Hernández, Passarini, & Koubaa, 2014) and by the anisotropy directions in which the test pieces were aligned (Brémaud et al., 2011).

Regarding the modulus of rigidity, some authors such as Naruse (2003); Keunecke et al. (2007); Yoshihara (2012b); Ozyhar, Hering, Sanabria, and Niemz (2013); Kránitz, Deublein, and Niemz (2014); Nadir, Nagarajan, and Midhun (2014) and Sotomayor (2015) have reported data from several types of wood. The information on the modulus of elasticity determined through non-destructive methods and quality indexes of Mexican wood is lacking, with the exception of Sotomayor-Castellanos, Guridi- Gómez, and García-Moreno (2010). It is also worth noting the absence of derived data from mechanical tests that could be applied in the study of the behavior of wood products functioning in dynamic conditions or for seismic design purposes for wood structures.

The modulus of rigidity is useful for the calculation of elements and connections where deformations outside the plane appear, caused by cutting efforts. For example, for beams that work with bending and torsion, as well as in connections between structural elements in buildings and wood items. Similarly, wood sawmills usually produce parallelepipeds for structural use, cut in the radial-tangential plane with at least two of its faces showing longitudinal-tangential planes. In this manner, when the wood is in service, it works as a beam bending or as a resistant element in products comprised of wood, the modulus of rigidity for the longitudinal-tangential plane is the parameter required for design and calculation.

The objective of this research was to determine the modulus of rigidity for the longitudinal-tangential plane of seven species of Mexican wood, performing torsional vibration tests. The species studied were: Enterolobium cyclocarpum (Jacq.) Griseb., Tabebuia donnell-smithii Rose, Tabebuia rosea (Bertol.) DC., Swietenia humilis Zucc., Lysiloma acapulcensis (Kunth) Benth., Cordia elaeagnoides A. DC. and Tabebuia chrysantha (Jacq.) G. Nicholson.

Materials and methods

Study material

The experimental material was comprised of wood from seven Mexican species. The wood was collected from a sawmill located in the municipality of Arteaga, Michoacán. The species were identified through the observation of their macroscopic anatomical characteristics in the Laboratorio de Mecánica de la Madera of the Facultad de Ingeniería en Tecnología de la Madera in the Universidad Michoacana de San Nicolás de Hidalgo. The wood was stored in a conditioning chamber for six months at 20 °C with a relative air humidity of 65 %, until reaching a humidity content consistent with the wood. From the pieces of cut wood, 20 test pieces of each species were cut at random with the following dimensions: 0.07 m x 0.07 m x 0.01 m in the longitudinal (L), tangential (T) and radial (R) directions, respectively. The test pieces were elaborated with sapwood and it was ensured that they were free of growth and heartwood anomalies.

Experimental design

The experiment was designed following the recommendations of Gutiérrez and de la Vara (2012). The response variables were density and the modulus of rigidity. The species were considered the variation factor. The tests were done on 20 replicas (test pieces) of each species, with a total of 140 samples observed for each one of the two response variables.

Prior to the dynamic tests, the dimensions and mass of the test pieces were measured. The humidity content was calculated in accordance to ISO 13061-1:2014 (International Organization for Standardization [ISO], 2014), using five complementary test pieces for each studied species. The density (ρ) was calculated with the relation between the mass and the volume of the test pieces, measured at the time of the test.

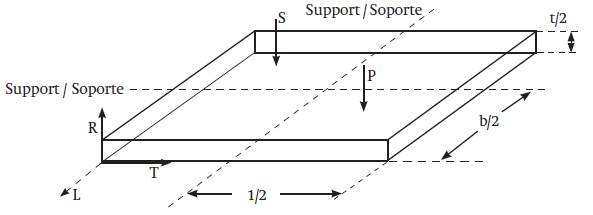

The torsional vibration tests were done based on the protocol recommended by the ASTM C1259- 14 (American Society for Testing and Materials [ASTM International], 2014). The test piece was placed on isolated supports among the test pieces, forming a cross. The test piece was placed in the radial direction, perpendicularly to the longitudinal direction in the tangential-radial plane, which caused torsional vibrations in the plane corresponding to the longitudinal and tangential directions; this was done so that the calculated modulus of rigidity corresponded to the longitudinal-tangential plane, in accordance to the elastic model of wood proposed by Sotomayor-Castellanos and Hernández-Maldonado (2012). These authors published modulus of rigidity values for the different orthotropic planes of the elastic model of wood based on prediction equations, employing the density of the wood with 12 % humidity as a reference parameter. The methodology proposed in this investigation employs test pieces with small dimensions and only requires the torsional natural frequency as an experimentally measured parameter.

According to the ASTM E1876-01 (ASTM International, 2001), an impact was applied to each one of the 20 test pieces of each species, using one steel sphere of 0.005 m in diameter adhered to an elastic rope of 0.01 m in length and 0.002 m in thickness and 0.007 m in width. The impact was applied to the P point of the test piece surface, located in the intersection of 0.25 width b and 0.26 length l of each specimen (Figure 1). The movement of the test piece in the s point was recorded with a Grindosonic® (MKS model, Belgium) device in a symmetrical position with regards to the impact point. The reading of the electric movement sensor is transformed into an electrical signal, which in turn, is converted into the natural frequency f of the system, with a reading accuracy of 0.005 %.

Figure 1 Diagram of the torsional vibration tests. P: position to expand the impact, s: position to measure the natural frequency, R: radial direction (t = thickness), T: tangential direction (l = length), L: longitudinal direction (b = width). Adapted from the ASTM C1259 (ASTM International, 2014).

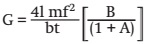

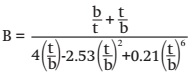

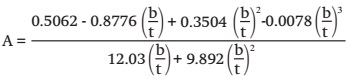

The dynamic modulus of rigidity of wood through torsional vibrations was calculated with the following formula (ASTM International, 2014):

In which:

where:

G = |

Dynamic modulus of rigidity (Pa = N·m-2) |

f = |

Natural resonance frequency (Hz) |

m = |

Mass of the test piece (g) |

l = |

Length of the test piece (tangential direction) (m) |

t = |

Thickness of the test piece (radial direction) (m) |

b = |

Width of the test piece (longitudinal direction) (m) |

A and B = |

Geometric adjustment factors |

Statistical analysis

Normality tests were performed, calculating the degree of the underpinning and the slant, in order to confirm that the data of the samples came from normal distributions. After verifying the normality of the data, a descriptive analysis was done calculating the means, standard deviation and coefficient of variation for the density, frequency and modulus of rigidity values. Finally, the lineal regression between the density of the wood as an explicative variable of the modulus of rigidity variable was calculated. The statistical calculations were done with the Statgraphics® (Statpoint Technologies, Inc., 2006) program.

Results and discussion

The average humidity content of the wood was 11.5 %. Table

1 shows the densities, natural frequencies and moduli of rigidity for the

longitudinal tangential plane of the seven types of wood studied. The statistics

presented for each species are: arithmetic mean (

Table 1 Densities, natural frequencies and dynamic modulus of rigidity of the seven Mexican species of wood being studied.

| Species | Descriptive statistics | ρ (kg·m-3) | f (Hz) | GLT (MPa) |

|---|---|---|---|---|

| 506 | 2,277 | 695 | ||

| Enterolobium cyclocarpum (Jacq.) Griseb. | σ | 80.20 | 80.20 | 48.30 |

| CV | 15.86 | 3.52 | 6.95 | |

| 496 | 2,556 | 870 | ||

| Tabebuia donnell-smithii Rose | σ | 40.70 | 175.11 | 172.75 |

| CV | 8.20 | 6.85 | 19.85 | |

| 592 | 2,367 | 879 | ||

| Tabebuia rosea (Bertol.) DC. | σ | 20.98 | 74.25 | 55.27 |

| CV | 3.55 | 3.14 | 6.29 | |

| 662 | 2,409 | 1,019 | ||

| Swietenia humilis Zucc. | σ | 12.69 | 82.68 | 65.67 |

| CV | 1.92 | 3.43 | 6.45 | |

| 716 | 2,643 | 1,328 | ||

| Lysiloma acapulcensis (Kunth) Benth. | σ | 25.39 | 94.14 | 124.52 |

| CV | 3.55 | 3.56 | 9.38 | |

| 1,135 | 2,676 | 2,157 | ||

| Cordia elaeagnoides A. DC. | σ | 30.67 | 77.05 | 142.53 |

| CV | 2.70 | 2.88 | 6.61 | |

| 1,274 | 2,881 | 2,807 | ||

| Tabebuia chrysantha (Jacq.) G. Nicholson | σ | 24.91 | 91.36 | 216.09 |

| CV | 1.95 | 3.17 | 7.70 |

ρ: Density; f: natural frequency; GLT: dynamic modulus of rigidity in the longitudinal-tangential plane;

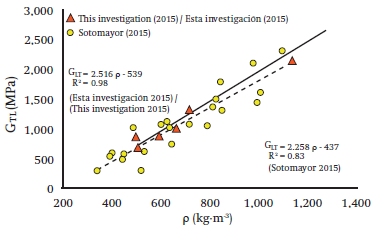

The magnitudes and the CV of the density of the types of wood studied were similar to the results of vibration tests in transversal bending of 23 analyzed species (sixspecies coincide in this investigation) by Sotomayor (2015). Figure 2 graphically compares the results of both studies. Similarly, it is confirmed that the density is a predictor of the modulus of rigidity with a determination coefficient (R2) of 0.98 for the results of this investigation and of 0.83 for those of Sotomayor (2015). The data of the modulus of rigidity for the longitudinal-tangential plane reported by Sotomayor (2015) come from tests were bars with a length of 0.5 m and a transversal section of 0.05 m x 0.05 m were used, for species with densities in an interval of 338 kg·m-3 and 1,147 kg·m-3 and a humidity content of 11.5 %.

Figure 2 Dynamic modulus of rigidity in the longitudinal-tangential plane (GTL) in function of the density (ρ) of the wood. Comparison of results of this investigation (2015) and those of Sotomayor (2015).

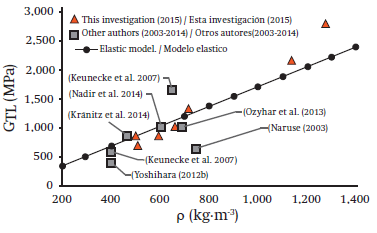

The torsional natural frequency increases when the density of the wood increases. Natural frequency is a predictor of the dynamic modulus of rigidity with a correlation of GLT = 3.41ρ - 7,288 and R2 = 0.81. The GLT values of the seven Mexican species are similar to the moduli of rigidity for the longitudinal-tangential plane determined by the authors: Naruse (2003), Keunecke et al. (2007), Yoshihara (2012b), Ozyhar et al. (2013), Kránitz et al. (2014), Nadir et al. (2014) and Sotomayor (2015), for woods with densities and humidity contents similar to the ones determined in this study. Figure 3 presents a graphic comparison between the GLT determined in these studies. In regards to the information on moduli of rigidity derived from static tests, Naruse (2003) used cut tests and determined the moduli of rigidity of Fagus crenata Blume wood with a density of 740 kg·m-3 and a humidity content of 8 %; his results were: GLR = 980 MPa, GLT = 637 MPa and GRT = 196 MPa, where the sub-indexes indicate the planes formed by the radial (R), tangential (T) and longitudinal (L) directions of the wood. Yoshihara (2012b) used asymmetric bending tests in wood plaques of Picea sitchensis Carr. with a width of 0.006 m, a density of 400 kg·m-3 and 12 % humidity, and determined a GLT of 400 MPa. On the other hand, Nadir et al. (2014) used compression and cut tests and determined the moduli of rigidity of the Hevea brasiliensis Muell. Arg. wood with a density of 605 kg·m-3 and humidity of 10 %. The anisotropy relation for the different moduli was: GLR = 1,070 MPa, GLT = 1,008 MPa and GRT = 256 MPa. Regarding the dynamic test data, Keunecke et al. (2007) used ultrasound and determined the moduli of rigidity for the Taxus baccata L. and Picea abies L. Karst. wood with densities of 650 kg·m-3 and 400 kg·m-3, respectively, and humidity contents of 11 and 12 %, respectively. The results obtained in the T. baccata wood were: GLR = 1,740 MPa, GLT = 1,650 MPa, GRT = 368 MPa; and in the case of P. abies: GLR = 617 MPa, GLT = 587 MPa and GRT = 53 MPa. Ozyhar et al. (2013) also used ultrasound waves and determined the modulus of rigidity of Fagus sylvatica L. wood with a density of 689 kg·m-3 and 9.6 % humidity. The moduli of rigidity obtained were: GLR = 1,370 MPa, GLT = 1,010 MPa and GRT = 430 MPa. On the other hand, Kránitz et al. (2014) used ultrasound for the determination of the modulus of elasticity of P. abies wood with a density of 465 kg·m-3 and 12 % humidity, and obtained GLR = 926 MPa, GLT = 863 MPa and GRT = 107 MPa.

Figure 3 Dynamic modulus of rigidity in the longitudinal-tangential plane (GTL) in function of the density (ρ) of the wood. Comparison of results between the elastic model of wood (Sotomayor- Castellanos & Hernández-Maldonado, 2012), information from this investigation (2015) and the results from other authors (2003-2014).

In this study, E. cyclocarpum presented the lowest value for the modulus of rigidity (695 MPa) and T. chrysantha presented the highest (2,807 MPa). The values of the moduli of rigidity fluctuated around the line of prediction proposed by the elastic model of wood (GLT = 1,708ρ) by Sotomayor-Castellanos and Hernández- Maldonado (2012).

Conclusions

The modulus of rigidity for the longitudinal-tangential plane of the species studied, obtained from the torsional vibrations method, were proportional to the density of the wood and to the natural frequency of the test pieces. The magnitudes of the average values of the dynamic modulus of rigidity of the Mexican wood are similar to the results obtained by other investigators for foreign species and using different types of tests. The tests are fast and it is easy to locate the test pieces due to their small dimensions, in the orthotropic directions of the wood. This would facilitate the determination of the modulus of rigidity of the GLR and GRT planes by cutting the test pieces in the appropriate directions. The results, comparable with those of authors that use different configurations and requests, suggest that the method of torsional vibrations could be useful for the mechanical characterization of Mexican wood. The method requires few materials and the realization of the dynamic tests is quick, qualities that make this a low cost technique for the dynamic characterization of the mechanical behavior of wood.

texto en

texto en