Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Tecnología y ciencias del agua

versión On-line ISSN 2007-2422

Tecnol. cienc. agua vol.10 no.2 Jiutepec mar./abr. 2019 Epub 21-Abr-2021

https://doi.org/10.24850/j-tyca-2019-02-03

Articles

Biological treatment of wastewater denitrification using a biofilm reactor with rice husk as an energy source

1Escuela Politécnica Nacional, Quito, Ecuador, joseph.sanchezb@epn.edu.ec

2Escuela Politécnica Nacional, Quito, Ecuador, marcelo.munoz@epn.edu.ec

3Escuela Politécnica Nacional, Quito, Ecuador, maria.aldas@epn.edu.ec

Two systems of biological treatment of denitrification in wastewater were evaluated, using anaerobic biofilm reactors with different external energy source. The first system used methanol as carbon source (conventional system) and the second, rice husk substrate, both operated with hydraulic retention times of 2.38, 5.56, 6.67, and 8.33 hours, with a nitrate feed of 40 mg NO 3 − / L. The system with rice husk substrate had greater efficiency in the removal of nitrates, with 97.58%, while the system with methanol has an efficiency of 93.46%, for the same time of retention. The two systems have a similar behavior in the removal of organic load, with a maximum efficiency of 94%. The concentration of biomass in the reactor with rice husk substrate is 14 286 mg/l, being higher than that of the reactor with methanol, which is 10 220 mg/l. The coefficient of biomass production, Y, is 0.007 and 0.0045 for the reactor with methanol and with rice husk, respectively, which indicates a low generation of sludge.

Keywords denitrification; rice husk; biofilm; biological treatment of wastewater; methanol; cleaner production

Se evaluaron dos sistemas de tratamiento biológico de desnitrificación en aguas residuales utilizando reactores anaerobios de biopelícula con diferente fuente externa de energía. El primer sistema empleó metanol como fuente de carbono (sistema convencional) y, el segundo, sustrato de cáscara de arroz; ambos operaron con tiempos de retención hidráulicos de 2.38, 5.56, 6.67, y 8.33 horas, con una alimentación de nitratos de 40 mg NO 3- /l. El sistema con sustrato de cáscara de arroz tuvo mayor eficiencia en la remoción de nitratos, con 97.58%, mientras que el sistema con metanol tiene una eficiencia de 93.46%, para el mismo tiempo de retención. Los dos sistemas tienen un comportamiento similar en la remoción de carga orgánica, con una eficiencia máxima de 94%. La concentración de biomasa en el reactor con sustrato de cáscara de arroz es 14 286 mg/l, siendo mayor a la del reactor con metanol, que es de 10 220 mg/l. El coeficiente de producción de biomasa, Y, es de 0.007, y de 0.0045 para el reactor con metanol y con cáscara de arroz, respectivamente, lo que indica una baja generación de lodo.

Palabras clave desnitrificación; cáscara de arroz; biopelícula; tratamiento biológico de aguas residuales; metanol; producción más limpia

Introduction

The industrialization and large-scale production have incorporated a high concentration of nitrates in the water resource, degrading its quality and therefore human health (OMS, 2003).

The purification treatments that currently exist are classified as physical-chemical and biological, but the problem of physical-chemical treatment is the transformation of contaminants into more or less harmful ones; while biological treatments degrade the pollutant in its basic components helping to close life cycles of the elements (Pozo, 2008).

In Ecuador, tertiary wastewater treatments have not been developed, due to the lack of importance in the research. Ecuador has replicated models studied in other countries without considering the context of existing and useful raw materials in the country, which makes the applicability of these technologies are very expensive. (Gervacio, 2007).

The technology that makes use of anaerobic biofilm reactors currently works with methanol as a source of energy for biological development, as well as, for the degradation of nitrates. Methanol is an expensive compound and its large-scale application, makes it a product that is difficult to handle; limiting the applicability of these purification systems in Ecuador (Ávila, Razo, & Gómez, 2003).

As an alternative to the use of chemical substances mentioned above, the use of natural materials such as wood chips, sawdust, straw, cotton, corn cobs, seaweed, bark, etc. appears. Because of their low cost, availability and proven efficiency, they are being investigated in the process of nitrate removal (Wang & Chu, 2016).

If it is not considered to evaluate the behavior of existing materials in Ecuador's internal production for the contribution of energy in the tertiary treatments of biofilm reactors for denitrification, no more economical and applicable technologies will be created in the country and the rates of diseases produced by a high concentration of nitrates in the water will not decrease; for example, the number of newborns suffering from "blue baby" disease, a product of the interaction of nitrates with hemoglobin, has increased the death rate in newborns; in addition, cases of disorders have been identified in pregnant women when they ingest high amounts of nitrates, mainly malformations that affect the central nervous system, muscle or bone (OMS, 2003).

The high concentration of nitrates in water produce the eutrophication of hydric resources, as a result of anthropic action the level of quality of life will decrease in rivers, lakes, estuaries, etc. (Romero, 2010), if the research find materials that substitute methanol, contributing the amount of energy appropriate to the biological technologies of wastewater treatment, the costs involved in tertiary treatment will decrease and its applicability in the Ecuadorian context will be a fact; decreasing and eliminating the diseases produced by the interaction between the human and the nitrate concentration; this will strengthen the integral management of the hydric resource.

In view of the above, this research proposes to apply the theory of clean production (Rojas & Leopoldo, 2012), using waste from industry, in order to being a source of energy in wastewater treatment processes with high nitrate content; specifically, the rice husk, a residue of the rice industry in Ecuador was used as an energy source in the microbiological processes of water purification.

The scope of the research is to determine the removal of high concentrations of nitrates, by comparative evaluation of the denitrification process between a system of an anaerobic biofilm reactor with external source of rice husk carbon, and a system by an anaerobic biofilm reactor with external carbon source of methanol. The reactors were evaluated on laboratory models.

The aim is to substitute methanol, which acts as a conventional external energy source for the denitrification process, in order to provide an economically feasible and applicable alternative in the tertiary treatment of water purification in the Ecuadorian context.

Materials and methods

Two similar biological reactors models were built, differing in the carbon source that was added to produce the denitrification process, one of the systems worked with methanol, and the other with rice husk as organic source of energy.

The simultaneous operation of these two models, allowed to evaluate the functioning, development and efficiency of the denitrification process. The reactors models built in the laboratory were designed with a volume of 1 L, this value considered the maximum flow used in the present study, and that is directly related to the retention time referred by literature (Antoine, 1974).

Fine gravel (5-10 mm) was used to distribute the flow of the aqueous solution inside the reactors, as well as the container of the carbonaceous material (rice husk), enough to cover a height of 3.5 cm. The material that was used as a support medium for the biomass was polyethylene terephthalate in square units of 2 cm on each side, polyethylene terephthalate is an inert material.

The range of nitrate concentration in the water entering the system of 30 to 40 mg/L as a reference, this range corresponds to the level of nitrates present in the completely nitrified domestic wastewater (Cuevas & Tejero, 2007).

Sodium nitrate and potassium nitrate, were considered as alternatives of chemical compounds to be used to nitrify water (40 mg 𝑁𝑂 3 − /L). The most appropriate option was sodium nitrate, because it maintained the value of hydrogen potential higher than potassium nitrate, additionally, the amount of sodium nitrate per liter of water required to nitrify it was lower.

The amount of methanol required to adequately perform the denitrification process was based on the laboratory studies that McCarty developed through an empirical equation that describes the general nitrate removal reaction (Metcalf & Eddy, 1972). Using the empirical equation, 0.028 ml of methanol was required per liter of fed water to the system so that the denitrification process was carried out properly.

The parameter of the Chemical Oxygen Demand (COD), derived from the methanol feed, allowed to modeling the amount of organic material in the denitrification system with external energy source of rice husk substrate. Tests that related the volume of the containers with the organic matter (rice husk) and the COD values were carried out. It was found that a volume of 3 liters of carbonaceous material has a COD value similar to the referencial 70 mg/L, which corresponds to the methanol solution with water.

The most important control parameters considered in the denitrification process were: temperature, nitrate concentration, chemical demand for soluble oxygen, hydrogen potential in both effluent and effluent, in addition the analysis of solids in the sludge resulting from the research (Suarez & Jácome, 2007), these will allow the development of a comparative analysis between the two models that have different external sources of carbon in their operation, as well as the efficiency obtained with each one of the laboratory models designed.

For physical and chemical parameters measurement in this work, the methods proposed by the American Public Health Association, the American Association of Water Works, and the Environmental Water Federation, "Standard Methods for Analysis of Water and Residual Water" (1999) were performed. A diagram of the installation of the two reactors is shown in Figure 1.

In Figure 1a), the anaerobic reactor scheme fed with methanol is observed, it was mixed with the water in the feed tank. The layer constituting the reactor support medium was contained in a volume of one liter, the fine gravel layer is not considered in the volume of the reactor.

For the operation of the anaerobic biofilm reactor with support medium and rice husk substrate as an external source of energy, which is observed in Figure 1b), it was necessary to implement a preliminary reactor vessel containing the carbonaceous material, the rice husk. This reactor was built with descending flow, maintaining the same characteristics of the anaerobic reactor with external source of methanol energy. Table 1 describes the construction characteristics of the reactors.

Table 1 Dimensions of the anaerobic reactors fed with methanol and with rice husk and the carbonaceus material container.

| Magnitude | Units | Reactor with methanol | Reactor with rice husk | Carbonaceus material container |

|---|---|---|---|---|

| Reactor diameter | cm | 12 | 12 | 14 |

| Fine gravel height | cm | 3.5 | - | 3.5 |

| Support medium height | cm | 8.9 | 8.9 | - |

| Carbonaceous material height | cm | - | - | 16 |

| Total reactor volume | L | 1 | 1 | 3 |

| Specific surface | m2/m3 | 960 | 1075.95 | - |

| Reactor useful volume | L | 0.91 | 0.91 | - |

The operating retention time for anaerobic reactors was the same for both systems. The variation of the hydraulic retention time was directly related to the feed flow. The range considered for the analysis was: retention time from 2.38 to 8.33 hours and a flow rate from 7 ml/min to 2 ml/min, this range was considered because at higher values of 7 ml/min the efficiency of the denitrification was zero, and the minimum flow rate reached with the peristaltic pump was 2 ml/min, values applied for a reactor volume of 1 L.

The period of operation was the duration in which the denitrification system worked at a same time of hydraulic retention and flow. At the start of the reactor, at the initial flow rate of 7 ml/min, the longest period was used, since it was expected that acclimatization and stabilization of the microorganisms to the new medium to carry out. In addition, samplings were obtained to determine the value of each parameter in periods of four hours (six analyzes per day). In Table 2, the retention times and the period of operation of the reactors are shown.

Results

Reactor with Methanol Substrate (R1)

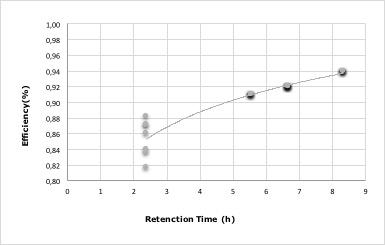

On average, the effluent nitrate concentration at a hydraulic retention time of 2.38 hours is 23.14 mg/L, with an average efficiency of 28.47%; and for a hydraulic retention time of 8.33 hours it was 2.21 mg 𝑁𝑂 3 − L, with an average removal efficiency of 93.46%. The present analysis has as reference level for drinking water, indicates by the Environmental Protection Agency (EPA), (10 mg/l) (EPA, 2012). Taking the reference level of the EPA for drinking water, the hydraulic retention times range from 6.67 hours, with an efficiency of 81.46%, the behavior of nitrate removal efficiency for R1 is shown in Figure 2 below.

As observed, for comply with the limit established by the EPA, an efficiency greater than 70% and a hydraulic retention time greater than 6 hours are required; in any case, if a greater nitrate removal is required, the value of the retention time must be increased, as well as the related parameters.

The denitrification efficiency curve was adjusted to a logarithmic equation, with the form:

As the nitrate removal efficiency was inversely proportional to the flow, the volumetric load is also proportional to the logarithmic curve, which can be seen in Figure 3.

The volumetric load parameter presented values of 0.086 to 0.30 kg

The volumetric load is inverse to the hydraulic retention time. The logarithmic curve that was generated is:

R1 also had satisfactory organic material removal efficiency values. The range of removal efficiencies of organic material were from 82% to 94%, at retention times of 2.38 hours to 8.33 hours respectively, with an average value of 91%, values that can be observed in Figure 4.

The percentages of organic matter removal are greater than those obtained in the removal of nitrates, so the effluent presents an acceptable quality in terms of COD concentration.

The logarithmic curve generated was as follows:

From the solids analysis, it was determined that 9.3 g of the sludge formed in the biofilm reactor with external carbon source corresponds to the biomass; 31% of the total solids are composed of volatile suspended solids, that is, the sludge is characterized by being a stable sludge. In Table 3, the values of the solids obtained are observed.

Table 3 Values for solids present in R1.

| Solids | Mass | Percentage |

|---|---|---|

| g | % | |

| Total suspended solids, SST | 29.7 | 100 |

| Fixed suspended solids, SSF | 20.4 | 69 |

| Volatile suspended solids, SSV | 9.3 | 31 |

From the obtained values, the following parameters were calculated:

It was determined by the expression:

This value means that 0.007 kg of biomass expressed as SSV is

developed for each kg of COD fed.

Organic Load-Specific Surface Ratio. The relation between the organic load and the specific surface, had the hydraulic retention time as main variable, which is related to the volumetric flow, and with the amount of organic matter fed to the anaerobic biofilm reactor, these data is observed in the Table 4, and were calculated by the expression:

Table 4 Relation Organic load vs. Specific surface depending on the retention time.

| Retention time | Flow | [DQO] prom. | Specific surface | Organic load / Specific surface |

|---|---|---|---|---|

| h | mL/min | mg/L | m2/m3 | kg/day.m2 |

| 2.38 | 7 | 72.79 | 960 | 0.000764 |

| 5.56 | 3 | 80.86 | 960 | 0.000364 |

| 6.67 | 2.5 | 76.55 | 960 | 0.000287 |

| 8.33 | 2 | 70.43 | 960 | 0.000211 |

Reactor with rice husk substrate (R2)

The range of nitrate removal efficiencies in the anaerobic biofilm reactor with external carbon source was from 20.28% to 97.58%, with hydraulic retention times of 2.38 and 8.33 hours respectively, with an average value of overall efficiency of 80.77%, which can be seen in Figure 5. From the hydraulic retention time of 5.56 hours, the maximum permissible level for drinking water of 10 mg/L, proposed by the EPA, was achieved (EPA, 2012).

The behavior of this reactor is similar to that of R1, since with hydraulic retention times of approximately 6 hours, an acceptable effluent is obtained according to the indicated limit.

The efficiency of nitrate removal in the reactor fed with rice husk obeyed a logarithmic curve, expressed as:

The levels of efficiency of removal of organic matter were in the range of 92% to 94%, with an average value of removal efficiencies of organic matter in general operation equal to 93%; being mostly constant due to the relation with the incoming COD, as shown in Table 5.

Table 5 Affluent and effluent average COD values, removal efficiency of organic matter and its relation to hydraulic retention time.

| Hydraulic Retention Time | DQO affluent | DQO affluent | Efficiency |

|---|---|---|---|

| h | mg DQO/L | mg DQO/L | % |

| 2.38 | 62 | 5 | 92 |

| 5.56 | 191 | 11 | 94 |

| 6.67 | 234 | 16.4 | 93 |

| 8.33 | 303 | 24 | 92 |

The range of the volumetric load in the operation of the anaerobic biofilm

reactor is 0.086 kg

The tendency that describes the behavior between the volumetric load and the efficiency of nitrate removal adjusted appropriately to a logarithmic curve:

From the analysis of solids, it is determined that 12.9 g of the sludge formed in the biofilm reactor with external carbon source corresponds to the biomass; 25% of the total solids is composed of volatile solids, that was, the sludge was characterized by its estability. In Table 6, the values of the solids obtained are observed.

Table 6 Values for solids present in R2.

| Solids | Mass | Percentage |

|---|---|---|

| g | % | |

| Total suspended solids, SST | 52.4 | 100 |

| Fixed suspended solids, SSF | 39.5 | 75 |

| Volatile suspended solids, SSV | 12.9 | 25 |

As in the previous case, with these values, the following parameters were calculated:

It is determined by the expression (4):

The reactor with external source of rice husk carbon generates, for each kg of COD fed, 0.0045 kg of biomass expressed as SSV.

Biomass concentration, calculated by equation (5):

These data are calculated from equation (5), and are shown in Table 7.

Table 7 Relationship Organic load vs. Specific surface depending on the retention time.

| Retention time | Flow | [DQO] main | Specific Surface | Organic load / Specific surface |

|---|---|---|---|---|

| h | ml/min | mg/L | m2/m3 | kg/day.m2 |

| 2.38 | 7 | 62 | 1075.95 | 0.00058 |

| 5.56 | 3 | 191 | 1075.95 | 0.00077 |

| 6.67 | 2.5 | 234 | 1075.95 | 0.00078 |

| 8.33 | 2 | 303 | 1075.95 | 0.00081 |

Discussion

From the observation of the obtained results, it was determined that the biological system of denitrification with carbon source of rice husk substrate complied with the reference level proposed by the United States Environmental Protection Agency of 10 mg/L of nitrates, from 5.56 hours of hydraulic retention time; while in the biological system with external methanol carbon supply this reference level is achieved from 6.67 hours, thus it can be said that in both reactors, an increase in the hydraulic retention time causes a greater efficiency in both the removal of nitrates as in the removal of organic matter (in values close to 99% and 94%, respectively), which has been corroborated in similar studies (Capodaglio, Hlavínek, & Raboni, 2016).

The biological system of denitrification with carbon source of rice husk presented greater efficiency in the removal of nitrates, in all hydraulic retention times analyzed, this is due to the presence of the carbonaceous material that is decomposed into smaller molecules that are later used by the denitrifying microorganisms (Wang & Chu, 2016). In addition, the rice husk provides an adequate surface for microorganisms to form a biofilm on it (Lu et al., 2017).

Both reactors worked with similar volumetric loads for each retention time, the loads were greater with shorter retention times, causing adequate conditions in the effluents obtained, thus, the biological system of denitrification with carbon source of rice husk substrate complies with the reference level proposed by the EPA, of 10 mg/L, when the optimum average nitrate volumetric load is equal to or less than 0.15 kg NO3 - /m3.day; while, in the biological system with external methanol carbon source, this reference level was achieved when the optimum average nitrate volumetric load was equal to or less than 0.13 kg NO3 -/m3.day.

The low sludge production (Y=0.007 and 0.0045) and the high concentration of biomass in the reactors (10220 and 14286 mg / L), for the reactor with methanol source and with source of rice husk substrate, respectively, are evidenced; the values of the biomass-organic load ratio indicate that the reactor with rice husk produced a lower quantity of sludge, these values are lower than those reported in the desnitrification process (0.054 and 0.12) in a biofilm reactor (Ambrosio & Tejero, 2000). In addition, it presented a greater amount of biomass, which is reflected in the efficiencies of organic matter removal, which are greater than those of the other system that works with methanol, indicating that with higher biomass generation, the treatment capacity of the system increases (Torresi et al., 2017). High removals, both of nitrates and organic matter, were achieved through the use of a low-cost energy source, which makes this system with rice husk as a viable technological alternative (Wang & Chu, 2016).

Conclusions

The biological systems studied reached adequate levels of efficiency in the denitrification process with external carbon source. Additionally, it was found that both systems reach high levels of organic material removal present in water.

It was found that shorter hydraulic retention times in the system with rice husk, higher efficiencies were obtained than in the biological denitrification system with methanol carbon source. On the other hand, it could be determined that the removal of nitrates was faster in the biological system fed with rice husk substrate, than that of the system that is fed with methanol, in addition, the volumetric load of nitrates is higher in the system biological fed with rice husk substrate, that the system that is fed with methanol.

It is important to highlight the low production of sludge and the high concentration of biomass in both reactors, aspects that influence the easy operation of the system. It was determined that the use of rice husk substrate as a source of energy or carbon in the biological denitrification system that was evaluated in this work, had the capacity to replace the carbon source or conventional external energy of methanol; because it had higher levels of efficiency in the removal of nitrates as well as the comparative advantages found in the present study.

Finally, due to the ease of handling, the low danger, low or no cost that represents the rice husk against methanol, it becomes an economical and safe alternative for its appropriate application in biological technologies of water treatment contaminated with nitrates.

Referencias

Ambrosio, M., & Tejero, I. (2000). Reducción simultánea de DBO(C), NH4+ y desnitrificación en un reactor de biopelícula. XXVII Congreso Interamericano de Engenharia Sanitária e Ambiental. Porto Alegre, Brasil. [ Links ]

Antoine, R. (1974). Nitrification of activated sludge effluent: BIO-SURF process. Water and Sewage, 11, 44. [ Links ]

Ávila, J., Razo, E., & Gómez, J. (2003). Avances en la eliminación biológica de nitrógeno, sulfuro y materia orgánica de aguas residuales. Revista Latinoamericana de biología. México, DF, México. [ Links ]

Capodaglio, A., Hlavínek, P., & Raboni, M. (2016). Advances in wastewater nitrogen removal by biological processes: State of the art review. Revista Ambiente & Agua, 11(2), 250-267. [ Links ]

Cuevas, G., & Tejero, I. (2007). Diseño, construcción y operación de un sistema con biopelículas para el tratamiento y reutilización de aguas residuales municipales. Tampico, México: Latin American and Caribbean Consortium of Engineering Institutions. [ Links ]

EPA, Environmental Protection Agency. (2012). Las preguntas comunes y sus respuestas sobre el nitrato y el agua potable. Yakima, USA: Environmental Protection Agency. [ Links ]

Gervacio, O. (2007). Desarrollo del sistema de desnitrificación a escala de laboratorio de muestras de aguas residuales de la empresa metropolitana de rastro de Quito usando como fuente de carbono el efluente de la primera separación de levadura de Levapan del Ecuador S.A. Quito: Escuela Politécnica Nacional. [ Links ]

Lu, Y., Zhang, X., Feng, L., Yang, G., Zheng, Z., Liu, J., & Mu, J. (August, 2017). Optimization of continuous-flow solid-phase denitrification via coupling carriers in enhancing simultaneous removal of nitrogen and organics for agricultural runoff purification. Biodegradation, 28(4), 275-285, DOI: 10.1007/s10532-017-9795-8 [ Links ]

Metcalf & Eddy. (1972). Wastewater engineering. McGraw-Hill Inc. Hong Kong: China. [ Links ]

OMS, Organización Mundial de la Salud. (2003). Nitrate and nitrite in drinking water. Documento de referencia para la elaboración de las Guías de la OMS para la calidad del agua potable. Ginebra, Suiza: Organización Mundial de la Salud. [ Links ]

Pozo, M. J. (2008). Proceso de nitrificación en reactores secuenciales discontinuos SBR (Sequencing Batch Reactor) con biomasa granula. Quito, Ecuador: Escuela Politécnica Nacional. [ Links ]

Rojas, R., & Leopoldo, M. (2012). Utilización de biosólidos para la recuperación energética en México. Producción + Limpia, 7(2), 74-94. [ Links ]

Romero, M. (2010). Proceso de eutrofización de afluentes y su prevención por medio de tratamiento de efluente. Revista Ingeniería Primero, (17), 67-74. [ Links ]

Suarez, J., & Jácome, A. (2007). Eliminación de nitrógeno de las aguas residuales. Procesos de nitrificación y desnitrificación. Coruña, España: Universidad de Coruña. [ Links ]

Torresi, E., Escolà, M., Polesel, F., Plósz, B., Christensson, M., & Bester, K. (Jan, 2017). Impact of external carbon dose on the removal of micropollutants using methanol and ethanol in post-denitrifying Moving Bed Biofilm Reactors. Water Research, 1, 108:95-105, DOI: 10.1016/j.watres.2016.10.068 [ Links ]

Wang, J., & Chu, L. (2016). Biological nitrate removal from water and wastewater by solid-phase denitrification process. Biotechnology Advances, 34(6), 1103-1112. [ Links ]

Received: August 04, 2017; Accepted: July 31, 2018

texto en

texto en