Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Tecnología y ciencias del agua

versión On-line ISSN 2007-2422

Tecnol. cienc. agua vol.9 no.2 Jiutepec mar./abr. 2018 Epub 24-Nov-2020

https://doi.org/10.24850/j-tyca-2018-02-04

Articles

Methane recovery and reduction of greenhouse gas emissions: WWTP Nuevo Laredo, Tamaulipas, Mexico

1El Colegio de la Frontera Norte (Colef), Monterrey, México, iaguilar@colef.mx

2Egresada del Programa de Maestría en Gestión Integral del Agua de El Colegio de la Frontera Norte (Colef), Monterrey, México, pablancojara@gmail.com

In this paper, we studied energy recovery from anaerobic digestion of sewage sludge in Waste Water Treatment Plants (WWTP), as a mechanism to reduce Greenhouse Gas (GHG) emissions and improve energy efficiency. We analyzed the case of the International Wastewater Treatment Plant at Nuevo Laredo (WWTP-NL), which is considered energy efficient and produces good quality sewage sludge. We utilized a benchmarking approach based on a multiparametric model with six key variables to evaluate the energy use efficiency of the WWTP-NL. The prospective electric energy production was estimated based on the potential amount of methane recovered. Then, we compared baseline and projected GHG emissions. For this purpose, we used the Clean Development Mechanism (CDM) methodology to project the recovery of biogas in wastewater by introducing an anaerobic treatment system for sludge treatment. The main findings of this prospective exercise are that the implementation of an energy recovery project in the WWTP-NL would: reduce the plant’s GHG by 21%; supply 14% of the energy required by the plant; and improve the energy efficiency of the plant by 2%. Specific technical, legal and economic feasibility studies are required for the practical implementation of this theoretical energy WWTP recovery project; nonetheless, this exercise shows that the project would generate clear environmental benefits.

Keywords Wastewater treatment; sewage sludge; methane recovery; energy use efficiency; GHG emissions

En este trabajo se examina la recuperación de energía de lodos de aguas residuales, mediante el aprovechamiento del metano generado en procesos anaerobios, como un mecanismo para reducir las emisiones de gases de efecto invernadero (GEI). Se estudia la Planta Internacional de Tratamiento de Aguas Residuales de Nuevo Laredo, Tamaulipas (PTAR-NL), cuya capacidad de diseño, nivel de eficiencia energética actual y calidad final de lodos hace relevante un ejercicio prospectivo. Para evaluar la eficiencia energética de la planta se utiliza un enfoque benchmarking con seis características clave en el uso de energía; se estima la producción potencial de energía eléctrica teórica a partir del metano potencialmente capturado, y se realiza un ejercicio de apreciación ex-ante de emisiones de GEI para proyectos de mecanismos de desarrollo limpio (MDL) en PTAR. Los resultados más importantes son: a) que el aprovechamiento de lodos para la generación de energía en PTAR-NL disminuiría las emisiones de GEI por el tratamiento de lodos en 21%; b) la generación de energía eléctrica mediante recuperación de metano aportaría el 14% de la energía requerida por la planta, y c) además, la eficiencia energética de la planta mejora en 2%. Para la implementación de recuperación de metano en PTARs aeróbicas con tratamiento de lodos en condiciones anaeróbicas se requiere de estudios específicos de factibilidad técnica, legal y económica; sin embargo, este ejercicio muestra relevantes beneficios ambientales en su implementación.

Palabras clave tratamiento de aguas residuales; lodos residuales; recuperación de metano; eficiencia energética; emisiones GEI

Introduction

The 2017 United Nations World Water Development Report states that better management of wastewater involves not only its decontamination but most importantly, wastewater reuse and recovery of byproducts such as sludge (WWAP, 2017). Nevertheless, in Mexico as well as other countries, treated wastewater is discharged into ecosystems while, in the best case, wastewater sludge is disposed of in sanitary landfills. The so-called linear approach to sanitation contributes to a lack of nutrients and energy as well as the environmental pollution resulting from the treatment, operation and use of nonrenewable energy. Water and sludge contain energy and nutrients that can be recovered for use (Tabasová, Kropác, Kermes, Nemet, & Stehlík, 2012). One benefit of recovering energy from sewage sludge is the reduction in the emissions of methane (CH4). Methane has 25 times more capacity for trapping heat in the atmosphere as compared to carbon dioxide (CO2), and is an important precursor of tropospheric ozone (Noyola, Paredes, Morgan-Sagastume, & Guerec, 2016). In Mexico, 30% of the Wastewater Treatment Plants (WWTP) use activated sludge treatment technologies, and represent 61% of the installed capacity for treatment (Conagua, 2014). WWTP with activated sludge treatment technology might recuperate energy from sludge through anaerobic digestion and partially self-provide the energy requirements, with the subsequent money savings.

Northern Mexico is a region with a higher percentage of wastewater treatment (Peña de la, Ducci, & Zamora, 2013), however only a few cities in the region sell treated wastewater for industrial use, including for the irrigation of municipal green areas or golf courses. Generally, wastewater sludge is considered residue and is usually dumped into sanitary fills. In Mexico, final disposal of wastewater sludge must comply with at least two Official Mexican Norms (NOM-004-SEMARNAT-2002 and NOM-083-SEMARNAT-2003): one specifies the maximum limits of pollutants and the quality of sludge required for potential uses and final disposal; the other defines the criteria for the design of sanitary landfills for urban solid waste, including their construction, operations, monitoring and closing.

The management, treatment and disposal of municipal wastewater increases GHG emissions due to the decomposition of organic matter and their associated treatment process (Noyola, Morgan-Sagastume, & Güereca, 2013; Noyola, et al. 2016). Anaerobic wastewater treatment technologies can be a source of CH4 and nitrous oxide (N2O) emissions when energy is not recovered, while WWTP that use aerobic treatment contribute to indirect emissions due to their high energy consumption. Consequently, treatment selection has important consequences for GHG emissions (Noyola et al., 2016). WWTP have an estimated share of about 5% of the total worldwide CH4 emissions, and this is expected to increase up to approximately 28% for the period 2005 to 2030, from 477 to 609 million metric tons of equivalent carbon dioxide (EPA, 2012).

For the period 1990 to 2010, methane gas emissions from municipal wastewater treatment increased 126.6% in Mexico, from 3 948.2 to 8 946.5 gigagrams of equivalent CO2, with a 4.2% of average annual increase (Semarnat-INECC, 2012). This increase in emissions was partially due to a Mexican policy that promoted and funded treatment infrastructure for municipal and industrial wastewater, resulting in a two-fold increase in the volume of treated wastewater for the period 2000-2012 (Peña de la et al., 2013). In 2010, there were 2 186 functioning WWTP in Mexico, and the more common treatment technologies for wastewater treatment were waste stabilization ponds (35%) and activated sludge (30%) (Conagua, 2011). By the end of 2014, the number of WWTP increased to 2 337, with a total installed treatment capacity of 151 883.43 l/s and a treated volume of 111 253.51 l/s, or the equivalent of 52.7% of total collected wastewater (Conagua, 2014). By 2030, the amount of methane emissions from wastewater treatment in Mexico is expected to be 58.1 MtCO2e (EPA, 2012). Given this situation, a change is needed from a linear wastewater management approach to a more integrative approach, which should include not only reusing treated wastewater but also treated sludge (Limón, 2013). Since 2008, the Mexican National Water Commission has promoted the reuse of treated wastewater. To this end, two Official Mexican Norms on artificial recharge of aquifers using treated wastewater have been published (NOM-015-Conagua-2007 and NOM-014-Conagua-2003) (Peña de la et al., 2013).

Regarding sewage sludge, this must be stabilized before disposal in order to reduce foul odors and health risks. It must also be dehydrated to reduce its volume. Sewage sludge treatment processes vary according to their source and type of water use, wastewater treatment and disposal method (Ramírez, Cardoso, & Moeller, 2009). Activated sludge treatment requires electrical energy to transfer oxygen to water and microorganisms, utilizing electromechanical equipment (mechanical air diffusers, compressors). In the aerobic process, 65% of the energy produced by microbial metabolisms is transformed into sludge, while 35% dissipates through the release of energy (Noyola et al., 2013). There are several alternatives for reusing stabilized sludge, for example, it can be used as fertilizers by composting or as a source of energy by recovering methane using diverse methods (Tabasová et al., 2012; Lazarova, Peregrina, & Pascal, 2012). The latter option might improve the energy efficiency of WWTP and reduce methane emissions.

A direct way to recover methane gas in WWTP is to use anaerobic digestion processes for wastewater treatment. Another option is to replace aerobic treatment of sludge with anaerobic treatment. Sewage sludge has a high organic content which is suitable for anaerobic digestion. Anaerobic digestion is a biological process by which sewage sludge, through the action of a group of bacteria and in the absence of oxygen, is broken down into biogas and a mixture of mineral products (Bachmann, Jansen, Baxter, Bochmann, & Montpart, 2015). The final product of this process is a biogas composed mainly of CH4 (between 60 and 70%), CO2 (approx. 30%), N2 and O2 (about 3% each). The best option would be to use direct anaerobic treatment for wastewater, because it has greater digestibility and a high content of primary sludge as compared to activated sludge; however, replacing infrastructure would be too costly. In Mexico, only two WWTP utilize anaerobic digestion technology for wastewater treatment and obtain biogas for power generation: “El Ahogado”, a WWTP located in the Guadalajara metropolitan area, in Jalisco, with an installed capacity of up to 2.25 cubic meters per second, and which generates up to 78% of the energy required for the plant by using anaerobic digestion; and “San Pedro Mártir,” a WWTP located in the Querétaro metropolitan area (ZMQ), with a dual process, and which has a processing capacity of 0.75 cubic meters per second and generates 69% of the required energy for the functioning of the plant. Another WWTP, “Atotonilco,” which is still under construction, will use anaerobic digestion for the cogeneration of thermal and electric energy. Atotonilco is planned to have a capacity to treat 23 m3/s during the dry season and 60% of the wastewater generated in the valley of Mexico, and to generate about 60% of the energy required for its operation by recovering methane gas (Peña de la et al., 2013).

Recent papers in the specialized literature on wastewater management suggest that a scenario that combines aerobic with anaerobic technologies is a better option than aerobic technology alone for the onsite cogeneration of electricity. Combining treatment technologies might reduce emissions by as much as 27% by 2030 (Noyola et al., 2016). Two WWTP in Mexico that currently use anaerobic digestion for the treatment of sludge are the WWTP of the city of La Paz, Baja California Sur, and the city of Culiacan, Sinaloa. These plants use a portion of the generated methane gas as fuel to heat the digesters, and the rest of the gas is burned.

Anaerobic sewage sludge treatment and the capture of biogas would make possible to supply the total energy demand of the digester and a portion of the power demanded by the aeration system, for WWTP that utilize aerobic wastewater treatment. In addition, heat energy can be generated and used to heat the digester up to its operating temperature. With the use of appropriate heat exchangers, up to 7 400 kJ/h of heat per kW can be recovered and fed to the generator (Nolasco, 2010). Furthermore, the electricity generated by methane gas recovery can be considered carbon neutral since it is generated in the natural carbon cycle (Wiser, Schettler; & Willis, 2010; Jorgensen, 2009).

This paper examines the potential of methane gas recovery for energy generation in the International Wastewater Treatment Plant of Nuevo Laredo, Tamaulipas, Mexico (WWTP-NL), an energy efficient plant which generates good quality biosolids (see Table I). This alternative would contribute to further reducing direct and indirect emissions from the WWTP as compared to a scenario of biogas burned off in open flame, which is considered a good practice by the Intergovernmental Panel on Climate Change (IPCC). It is also a viable alternative to operating WWTP with aerobic treatment or without sewage sludge treatment, instead of replacing aerobic with anaerobic wastewater treatment. This paper proposes:

To evaluate the energy efficiency of the WWTP-NL and its energy potential by recovering methane gas;

To calculate the energy savings in the WWTP-NL generated by replacing external energy with energy from a methane gas recovery project;

To estimate the potential reduction in GHG emissions from the WWTP-NL as a result of the recovery of methane gas.

The WWTP-NL is located on the right side of the Rio Grande River in the municipality of Nuevo Laredo, in the northern portion of the state of Tamaulipas. The WWTP-NL is a secondary aerobic treatment plant with oxidation ponds, and a design capacity to treat 1 360 l/s of urban wastewater. The wastewater from the city of Nuevo Laredo is mainly of domestic and commercial origin; this is important because wastewater containing low discharges from industry decreases the variability in the characteristics of the sewage sludge.

The following paragraphs describe the wastewater treatment processes at the WWTP-NL (see Figure 1). Raw wastewater comes from two collectors, known as “El Ribereño” and “El Coyote.” It arrives by gravity to two sumps which have three submersible pumps for sewage sludge pumping, with a maximum capacity of 600 l/s each. In 2013, only one of these sump pumps was put into operation, sending an average flow of wastewater from between 850 to 910 l/s to the treatment system (Blanco, 2014). This average flow was maintained at these levels in 2016. After two siftings, the residual water reaches two Vortex-type grit chambers where inorganic sands are separated for disposal in tanks and containers.

Pretreated wastewater arrives by gravity to the oxidation ponds. The WWTP-NL has six carousel-type oxidation ponds for extended aeration, each one is 98.6m long, 38.4m wide and 6.7m high, each with a single hydraulic capacity of 850.7 17. In 2013, only four of the six ponds were in operation since the WWTP-NL was operating at 67% of its design capacity.

The effluents from the oxidation ponds pass by gravity to the distribution box to feed the secondary clarifiers. The clarification system comprises four circular concrete tanks 50.00 meters in diameter and 4.00m high, with a chute for the effluent measuring 47.8m in diameter and 6.35m deep. In 2013, only two of the four tanks were operating.

The recirculation pumping station consists of six horizontal centrifugal pumps and is used to send the activated sludge to the aeration tank (return sludge). In 2013, only one pump was operating to provide service to the two clarifiers in operation.

The chlorination is carried out in a chlorine contact tank divided into two sections, each measuring 32.7m in length, 14m wide and 3.6m deep. Two chlorine evaporators are utilized, each with a capacity of 6 000 lb/day. The chlorine evaporators send chlorine gas through pipelines up to two chlorinators. Finally, the residual water already treated and disinfected is discharged into the “El Coyote” stream in the Rio Grande flood zone. Occasionally, the WWTP-NL sends treated water to the pumping station to be reused in watering gardens, cleaning the plant, and irrigating green areas in the "Countryside" Golf Club in Nuevo Laredo. However, most of the effluent from the WWTP-NL is discharged into a Rio Grande flood zone, which is an international water body, and therefore it must comply with standards established by the International Boundary and Water Commission (IBWC), United States-Mexico division.

Figure 1 Process diagram of the WWTP-NL. Source: Prepared by the authors based on Watergy México A. C. and BECC (2014).

In accordance with the operating instructions manual for the WWTP-NL, it was designed to generate 28 l/s of sewage sludge when working at 100% capacity. The sludge treatment process is described below.

Sludge from secondary clarifiers is pumped to a rectangular tank of reinforced concrete that has a volume of 2 937m3 and is ventilated by means of three rotary blowers and fine bubble diffusers located at the bottom of the tank. In the stabilization tank, sludge is thickened to 1%, in about 24 hrs. Once stabilized, three positive displacement pumps transport the sludge to drying beds for final disposal. In 2013, only one displacement pump was used and it worked only 12 hrs/day every two days. Eighty reinforced concrete tanks with sand and gravel filter beds are located at the end of the sludge treatment. Each one is 15m wide, 35m long and 0.5m deep. These drying beds remove excess moisture from the sludge for later disposal as waste at a confinement site. The WWTP-NL generates 10 ton/day of sludge that is classified as excellent quality, or class "A", in compliance with the NOM-004-SEMARNAT-2002, so it can be reused even for uses with direct contact with people (see Table 1). Twelve percent of the treated sludge is used as compost locally. The main disadvantage in the use of compost is that it must be transported to the place of use, generating GHG emissions by transport. Since the main economic activities in Nuevo Laredo are trade and services, the use of biosolids as compost on a larger scale would require transporting the material to agricultural areas located at a greater distance, which would generate GHG emissions.

Table 1 Parameters of the sludge at the WWTP-NL, march 2013. Source: Prepared by the authors based on data provided by the laboratory of the WWTP-NL.

| Parameter | Result | NOM-004-SEMARNAT-2002 Excellent Sludge | Units |

|---|---|---|---|

| Arsenic | < 5.0 | 41 | Mg/Kg |

| Cadmium | <2.0 | 39 | Mg/Kg |

| Copper | 117.1 | 1500 | Mg/Kg |

| Fecal coliforms | <300 | 1000 ˂ | NMP/gBS |

| Total Chromium | 21.02 | 1200 | Mg/Kg |

| Helminth eggs | 0 | 1 ˂ | Eggs/gBS |

| Mercury | 0.65 | 17 | Mg/Kg |

| Nickel | 13.6 | 420 | Mg/Kg |

| Lead | 28.8 | 300 | Mg/Kg |

| Salmonella spp | <3 | 3 ˂ | NMP/gBS |

| Zinc | 633.6 | 2800 | Mg/Kg |

Materials and methods

The analysis of the WWTP-NL includes three components: an assessment of the efficiency of the plant; the estimation of potential energy recovering from anaerobic processes and its effect on the WWTP-NL energy efficiency; and the reduction of GHG emissions which is estimated by comparing emissions at baseline and with the methane recovery project.

For the analysis of the energy efficiency of the WWTP-NL, we applied a benchmarking approach proposed by the American Water Works Association Research Foundation (Research Foundation, 2007). The AWWA Research Foundation study developed a multiparameter model that captures key external features for energy use in a WWTP. To develop this model, information on energy use and the descriptive characteristics of the required parameters were collected from a statistical sample of 266 WWTP in the United States. An econometric analysis evaluated the correlation of 32 parameters with the use of energy, trying to define the variables with the greatest weight. Finally, a model was defined that relates the use of energy, as the dependent variable, with six independent variables: average flow of influent, biochemical oxygen demand (BOD) in the influent, BOD in the effluent, the influent load factor, use of trickling filter, and removal of nutrients. The coefficients generated by this model are reported in Equation 1.

Where:

ln(Es) |

= expected average energy use; with a logarithmic transformation account for the range of variation in the size of the plants |

Iprom |

= average daily flow in the influent |

ICOD |

= COD in the influent |

ECOD |

= COD in the effluent |

IFC |

= Load Factor of influent (Iprom/Idiseño ×100) |

FP |

= Use of trickling filter (yes=1, no=0) |

RN |

= nutrient removal (RN yes=1, no=0) |

By applying the coefficients of the AWWA Research Foundation model (Equation (1)), the expected average energy use (ln(s)) can be estimated given the set of six parameters. The first step in this analysis is to calculate the total energy use by type of source (conversion to kBTU/year). A correcting factor for the source of energy adjusts for the losses based on their origin. The second step is to estimate the average energy use for a plant with similar characteristics. The score of the plant given its current use of energy (ln(EAS)) is obtained by applying a natural logarithm. To compare the energy use performance of the WWTP-NL with the performance of a typical plant from the sample in the original study (with similar characteristics), the difference between the score given the current use (ln(Eas)) and the estimated score (ln(s)) is calculated.

WhereE as = current energy use, adjusted by the factor of origin (in this case, electricity or methane gas) to convert the total amount of energy to British Thermal Units (BTU):

To compare the energy use performance (ln(Es)) of the WWTP-NL with the best observed use in the sample from the AWWA Research Foundation study, an adjustment factor (Fadj) is calculated by dividing the estimated score (prediction) by the average score of 17.8 (corresponding to the average score obtained in the AWWA Research Foundation study, 2007).

Now we apply the adjustment factor obtained to locate the current energy use on the distribution curve of the adjusted energy use (ln(Eadj)).

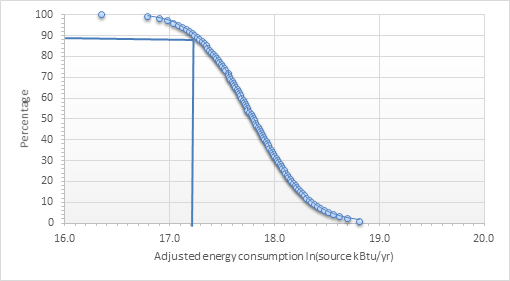

To assess baseline energy efficiency, we find the value of the adjusted energy use (ln(Eadj) according to the values presented as percentiles in Figure 2. The location on the curve indicates how close the observed energy use is to the best use of energy (better efficiency the closer the observed value gets to ascoreof 100).

Finally, to compare the WWTP-NL’s baseline performance in energy use with its potential performance with the methane gas recovery project, we apply Equation 2, now with the correction factor for two sources of energy: electricity (11.1Kbtu/kWh) imported into the system and power generated by biogas from methane (21.2 1Kbtu/m3). We apply the adjustment factor and find the new value in Figure 2. The improvement in energy efficiency with the methane gas recovery is estimated as the difference between the scores with and without the project, standardized with the estimated adjustment factor (Fadj)

Kinetic equations were used to predict the production of methane, assuming the use of simple complete-mix anaerobic digesters, single stage, with a mesophilic digestion process (Metcalf & Eddy Inc., Tchobanoglous, Stensel, Tsuchihashi, & Burton, 2014). This is the most common and easily operated digester, which reduces costs related to adaptation. In general, WWTP in Mexico operate at ambient temperature, which corresponds to the lowest level in the mesophilic range (30-38 C). Most anaerobic reactors operate under mesophilic conditions since they are more stable than those that operate in the thermophilic temperature range (Monroy, Fama, Meraz, Montoya, & Macarie, 2000). Digesters that operate in the thermophilic temperature range (50-570C) require larger amounts of energy, generate a supernatant with large amounts of dissolved solids, and produce foul odors (Appels, Baeyens, Degreve, & Dewil, 2008). In this work we do not consider some options that would improve the efficiency in biogas production; for example, pretreatment of sludge or a combination of sludge with fats or other materials.

To estimate the amount of production of methane gas we use Equations 5 and 6 (Metcalf & Eddy Inc. et al., 2014), and the variables described below:

Where:

V CH4 |

= Volume of methane (m3/d) produced under standard conditions |

S 0 |

= bCOD in the influent g/m3 |

S |

= bCOD in effluent g/m3 |

Q |

= sludge flow m3/d |

Px |

= net mass of solid biological synthesized per day kg/d |

The net mass of solid biological synthesized per day (Px) can be estimated with the following equation, used for high load biodigesters with a complete mixture (motorized shaker that allows a homogeneous mixture of sludge), without exhaust gas recirculation (Metcalf & Eddy Inc.et al., 2014):

Where:

Y |

= coefficient of performance, which is obtained from the combination of fermentation and methanogenesis processes |

Q |

= flow m3/d |

S 0 |

=bCOD in the influent g/m3 |

S |

= bCOD in effluent g/m3 |

B |

= Endogenous decay coefficient (fermentation, methanogenesis) |

STR |

= solids retention time, for digestion of high load range is 15 to 20 days, in practice (Metcalf & Eddy, Inc. et al., 2014). |

The typical values of the anaerobic reaction forY and bare: for the coefficient of performance (Y), a range of 0.05-0.10 g VSS/g bCOD; for the endogenous coefficient (b) the range is 0.02-0.04 g/g.d(Metcalf & Eddy Inc.et al., 2014; Appels et al., 2008).

As a third component, we used the methodology approved for Clean Development Mechanisms (CDM) projects for WWTP, AMS IIIH "Methane Recovery in Wastewater Treatment" (UNFCCC, 2014; Nolasco, 2010). This methodology compares the reduction in GHG emissions using the implementation of CDM projects with baseline GHG emissions. The AMS IIIH methodology includes procedures for the recovery of biogas from organic matter by means of various options. One of the CDM projects consists of replacing aerobic sludge treatment with an anaerobic system combined with gas recovery and either methane burning in flame or its use for electricity generation for the WWTP.

The baseline for this study is defined as "aerobic digestion of sludge generated in a WWTP with aerobic treatment.” Baseline emissions are those generated under the plant’s current operating conditions. The potential project is defined as "Implementation of an anaerobic digestion system with methane recovery" (methodology AMS-IIIH) of sludge generated by aerobic treatment of wastewater (Nolasco, 2010). The simplified calculation of baseline and project emissions is based on the following equations:

To estimate baseline emissions and emissions with the project we used the following equations (8 and 9):

Where:

QL |

= volume of sludge (t/year) |

DOC |

= content of organic matter in the sewage sludge (0.05 for domestic mud) |

MCF S |

= methane correction factor for the sludge treatment system |

DOCF |

= fraction of organic content (DOC) that is transformed into biogas (0.5) |

F |

= fraction of methane in the biogas: 0.7 |

UF |

= correction factor for uncertainty (0.94) |

GWP CH4 |

= methane global warming potential (21 kgCO2e/kgCH4) |

L |

= fraction of biogas that is lost in the system for capture of the electric current, distribution and consumption (suggested value 0.2) |

EG |

= energy surplus (energy recovery - consumption of the project), which replaces the use of fossil fuels or electricity (MWh/year). |

EC |

= WWTP Energy consumption in the form of electricity (MWh/year) |

EF |

= emission factor of the electrical grid (tCO2e/Mwh) |

To estimate the potential for electrical power generation, we assume the use of an internal gas combustion engine. Internal combustion engines offer the advantage of low emission of oxides of nitrogen in compliance with the regulations for emissions to the atmosphere. The efficiencies of the various internal combustion engines that use gas to generate electrical energy range between 30 and 42% (Wiseret al., 2010). For this study, we assumed a parameter of efficiency of 35%. It should be noted that the real operation of a gas recovery project must consider scenarios involving maximum and minimum power generation in order to reduce risks and increase the efficiency of the process.

This study focuses on the reduction of GHG emissions related to the management of sludge, the most important of which is methane. Therefore, the environmental impacts and energy uses that are relevant to the work are limited to treatment processes and utilization of sludge, and we do not use methodologies with broader purposes, such as a life cycle analysis, which would require evaluating the whole sanitation process including all the inputs and outputs of the systems to be evaluated and all vectors involved (air, water, soil).

Results and discussion

Energy efficiency assessment

The WWTP-NL records a monthly average consumption of 677 696 kWh for its operations, equivalent to an annual consumption of 8 356 132 kWh/year. The energy consumption per process area can be seen in Table 2. The pumping station consumes the greatest percentage of electrical energy (46%). The oxidation ponds consume 37%, which is the area with the second highest consumption.

The energy use score for the WWTP-NL was calculated based on the AWWA Research Foundation benchmarking approach. For its current energy use, the WWTP-NL score is obtained by performing the following calculations (Equation (2)):

Eu |

= Energy required KWh/year=8132 356kWh/year |

FS |

= factor of origin of the energy= 11.1 kbtu/kWh |

Eas |

= ∑ Eu (FS)= 8 132 356KWh/year (11.1Kbtu/KWh)= 90 269 151.6 kbtu/year |

Ln(Eas) |

= ln(90 269 151.6 kbtu/year)= 18.32 |

Table 2 Monthly average energy consumption by the wwtp-nl by process area. Source: Prepared by the authors with data provided by Comapa Nuevo Laredo, Coordination of Treatment Plants.

| Process area | Energy expenditure (KWh) | Average percentage |

|---|---|---|

| Pump station | 313428 | 46 |

| Screening and grit | 12912 | 2 |

| Oxidation ponds | 251864 | 37 |

| Clarifiers | 1666 | 0.25 |

| Return of Sludge | 32600 | 5 |

| Chlorination | 24763 | 4 |

| Sludge tank | 14949 | 2 |

| General Areas | 25514 | 4 |

We applied the coefficients in the measurement of the AWWA Research Foundation model (Equation 1) and data to the characteristics of the WWTP-NL in order to assess the difference between the score with the current use (ln(Eas)) and the estimated use (ln(Es)). The daily influent average for 2016 in the WWTP-NL was 19.73 mgal/d; the average BOD in the influent was 232.00 mg/l and the average BOD per day in the effluent was 3,175 mg/l; the influent load factor was calculated using the ratio between average influent 864.66 l/s for 2016 and the influent design capability of the WWTP-NL (1 360 l/s). In this case, trickling filter or removal of nutrients were not included in the processes of the WWTP.

Table 3 Values of the parameters for the generation of biogas in WWTP-NL. Source: Prepared by the authors with data obtained in the plant (Coordination of Treatment Plants, Comapa NL) and parameters from Metcalf & Eddy, Inc. et al., 2014.

| Parameter | Symbol | Value | Units |

|---|---|---|---|

| bCOD in the influent | So | 232.00 | Mg/l |

| bCOD in effluent | S | 3,175 | Mg/l |

| Flow of sewage sludge | Q | 74 706.62 | M3/d |

| Coefficient of performance | Y | 0.08 | gVSS/g bCOD |

| Endogenous coefficient | b | 0.03 | 1/d |

| Sludge retention time | SRT | 16 | d |

| Average conversion factor of methane at 350C | 0.40 |

Note:VSS= volatile suspended solids; bCOD = Chemical Oxygen Demand biodegradable.

By applying equation (1):

The baseline score of the plant calculated above (ln (Eas= 18.32) is lower than the average score obtained for the sample with similar characteristics in the benchmarkingstudy (18.83). This result is important as it indicates that, comparatively, the WWTP-NL can be considered as efficient.

To perform the graphical analysis of the energy performance of the WWTP-NL, the baseline score is located on the distribution curve of the adjusted energy use. This location on the distribution curve indicates how close the WWTP-NL performance comes to the best energy use of similar plants in the AWWA Research Foundation study sample. First, we calculate the adjustment factor (Fadj) with the result of current energy use (equation (2)):

An adjusted energy consumption score of 17.32 is located approximately at the 87th percentile of the curve (Figure 2). One way to interpret this result is that the WWTP-NL is located in the group of 13% of the sample plants that are similar to the WWTP-NL with less energy use. This result suggests that the WWTP-NL is efficient in their energy consumption at baseline.

Figure 2 Adjusted energy consumption in the WWTP-NL with methane recovery. Source: Prepared by the authors, adapted from AWWA Research Foundation (2007).

In our assessment, we assume the use of 100% of the sludge obtained from the WWTP-NL processes for energy generation. The process of anaerobic digestion can be fed with a mixture of primary and secondary sludge, in addition to fat trapped in the filters or grease traps at the entrance to the plant. The latter two options are not considered in our estimates. To assess the biogas potential, the use of a high-speed, one-stage anaerobic digester is assumed. We know that the plant’s average monthly flow of waste water is 864.66 l/s, equivalent to 74 706.62 m3/d. To estimate the chemical oxygen demand (COD) load in the influent, we already know its daily average BOD (232.00 g/m3); and in the primary clarifier a BOD removal of 35% and 60% of removal of total suspended solids (TSS) are assumed.

For the estimation of the potential amount of biogas, we used Equations (5) and (6) and the parameters and data in Table 3, in addition to the estimated bCOD in the influent and effluent. First, the mass of biological solid synthesized daily is estimated using Equation 6. The endogenous coefficient (b) considered for a complete-mix digester is 0.03. The hydraulic retention time of the sewage sludge (STR) is a parameter that sets the time that the sludge remains in the anaerobic digestion reactor and with which microorganisms can transform organic matter into a gas. Very short periods of time produce incomplete degradation and less amount of gas is generated. Under mesophilic temperature conditions, average operation of 35C, at least 10 retention days are estimated (Metcalf & Eddy, Inc.et al., 2014); although in practice a range of 16 to 25 days is recommended (Bachmann et al., 2015). For this exercise, we used the criterion of 16 days. The net mass of biosolids synthesized daily, in kilograms per day (Px), was obtained by applying these parameters to the equation (6):

To estimate the production of methane gas we use Equation 5. The average conversion factor for methane production at an average temperature of 35 °C is 0.40 (Metcalf & Eddy Inc. et al., 2014).

We estimate a production of 815 m3of methane gas for the WWTP-NL. After estimating the amount of methane gas that can potentially be generated, the amount of theoretical energy needs to be estimated. To do this we calculate the volume of biogas generated, assuming a content of 70 per cent of methane:

To estimate the theoretical energy per day, a higher calorific value of 27.8MJ/m3 or 7.72kWh/m3 is assumed (Ríos & Kaltschmitt, 2016) based on the content of methane (70%). With these data we obtain the theoretical energy per day:

The next step is to estimate the potential electrical energy derived from the biogas. For this purpose, the use of a gas internal combustion engine with a parameter of efficiency of 35% is assumed. Metcalf & Eddy, Inc. et al. (2014)report an efficiency range of 37 to 42% for an internal combustion engine, however, other publications (IDAE, 2007; IIE, 2012) report lower efficiency (30-42%); therefore, a conservative approach of 35% was used.

The amount of electrical energy that can potentially be achieved using methane generated by the WWTP-NL sludge is 1 248 132kWh/year. With the project, the recovered energy would replace electrical energy that is currently imported into the treatment system. To estimate the amount of energy that would still be necessary to import, we simply subtract the energy that can be generated with the project from the electrical energy used without the project.

The amount of energy that is replaced is equivalent to 14 % of the energy used by the WWTP-NL. To put it in context, recommendations from an energy efficiency audit of the WWTP-NL in 2013 would achieved an energy savings in the range of 8.98 to 9.49% (Watergy Mexico A. C. and BECC, 2014).

Now, we analyze the change in energy efficiency of the WWTP-NL with the methane gas recovery project. Energy consumption with the project is composed of imported electricity and electricity generated by biogas. The correction factors are 11.1Kbtu/kWh for electrical energy and 21.2 1Kbtu/m3 for the energy from biogas. Applying these parameters, we obtain the adjusted energy consumption with the project:

Afterward, we estimate the efficiency with the methane gas project. The new score of the plant with its current energy use ln(EAS) is normalized using the adjustment factor estimated above (Fadj)=1.05786.

This new estimate of efficiency with the project generates a score of 17.27, which is less than the 17.32 without project. This new adjusted score changes the location of the adjusted energy consumption (Figure 2) from the 87th percentile without the project to the 89th percentile with the project. The energy efficiency of the WWTP-NL improves approximately 2% with the methane gas recovery project. Although this seems to be a marginal improvement, it should be recalled that the WWTP-NL without the project is efficient when compared to most of the similar WWTP in the United States. The following section analyzes the benefit in terms of GHG emissions reduction.

Reduction in methane gas emissions

To estimate the potential reduction in methane gas emissions, we simply compared the baseline emissions with the WWTP-NL emissions corresponding to the methane gas recovery project. We used Equations 8 and 9with the following parameters, taken from Nolasco (2010).

QL |

=2 629.34 tons/year of sludge |

DOC |

= 0.05 for domestic sludge. |

MCFS |

= methane correction factor for the disposal of sludge (0.4) for an overloaded aerobic treatment plant |

DOC F |

= fraction of organic content (DOC) that is transformed into biogas (0.5) |

F |

= fraction of methane in the biogas (0.7) |

UF |

= correction factor for uncertainty (0.94 ) |

GWP CH4 |

= global warming potential of methane 21 kgCO2/kgCH4 |

EF |

= emission factor of the electricity grid (0.466tonCO2/MW) |

L |

= fraction of biogas is lost = 0.2 recommended |

By replacing these parameters in Equation 8, we obtain a baseline emissions (GHG) for the WWTP-NL of 4 136 tons of carbon dioxide equivalent emissions per year.

This result does not include GHG emissions for the transportation of sewage sludge. However, just for reference, according toChacón, Giner, Vázquez, Maldonado and Lindquist (2010), the GHG emissions from transport in Tamaulipas were 3.32 million metric tons of carbon dioxide, with an increase to 3.92 millions of metric tons in 2015.

The generation of electricity through methane recovery with the methane gas recovery project (as previously estimated) is 1 248 132 KWh/year.Using this information in the Equation 9, GHG emissions with the project are estimated (PE):

This represents a reduction of 21 %, without compromising the quality of the effluent from the WWTP-NL.

Conclusion

This paper shows how the recovery of sludge can be useful not only to replace imported electric energy, with the consequent economic savings, but also to reduce methane gas emissions. The use of sewage sludge for the generation of biogas in the WWTP-NL would reduce the volume of organic matter up to 50%, equivalent to a total reduction of dry matter of 25 to 33%. The biogas is used for the generation of electrical energy, replacing 14 % of electrical energy imports. This shift results in a savings by reducing consumption of electrical energy obtained from the Federal Electricity Commission (CFE) network. If we combine the cost savings in power consumption with the energy input from methane recovery, the WWTP-NL would be much more efficient in terms of energy. In addition, the energy efficiency of the plant would improve by 2% directly from the new composition of energy sources (electricity and biogas). This improvement in efficiency is relevant because the WWTP-NL, with its current use of energy, is regarded as efficient compared to other WWTP in Mexico and the United States with similar operational characteristics. The results also show that the implementation of a methane gas recovery project at the WWTP-NL would reduce GHG emissions by 21%, which implies a relevant environmental benefit. This work does not include economic variables, but considering the environmental and energy benefits that the methane gas recovery project would provide, it is reasonable to think that it would be economically viable.

Referencias

Appels, L., Baeyens, J., Degreve, J., & Dewil, R. (2008). Principles and potential of the anaerobic digestion of waste-activated sludge. Progress in Energy and Combustion Science, 34(6), 755-781. [ Links ]

American Water Works Association, AWWA Research Foundation. (2007). Energy index development for Benchmarking water and wastewater Utilities. Recuperado de http://www.waterrf.org/Pages/Projects.aspx?PID=3009 [ Links ]

Bachmann, N., Jansen, J., Baxter, D., Bochmann, G., & Montpart, N. (2015). Sustainable biogas production in municipal wastewater treatment plants. Recuperado de http://www.iea-biogas.net/files/daten-redaktion/download/Technical%20Brochures/Wastewater_biogas_grey_web-1.pdf [ Links ]

Blanco, J. P. (2014). Aprovechamiento de lodos residuales para cerrar el ciclo urbano del agua, mejorar la eficiencia energética y reducir los GEI: caso de la PITAR Nuevo Laredo (tesis de maestría). El Colegio de la Frontera Norte, Monterrey, México. [ Links ]

Chacón, D., Giner, M. E., Vázquez, M., Roe, S. M., Maldonado, J. A., Lindquist, H., Strode, B., Anderson, R., Quiroz, C., & Schreiber, J. (2010). Emisiones de gases de efecto invernadero en Tamaulipas y proyecciones de casos de referencia 1990-2025. Recuperado de http://www.cocef.org/uploads/files/inventario_emisiones_gei_tamaulipas_junio_2010.pdf [ Links ]

Comisión Nacional del Agua, Conagua. (2011). Inventario nacional de plantas municipales de potabilización y de tratamiento de aguas residuales en operación. Recuperado de http://www.conagua.gob.mx/CONAGUA07/Publicaciones/Publicaciones/SGAPDS-INVENTRIO%202011%20FINAL.pdf [ Links ]

Comisión Nacional del Agua, Conagua . (2014). Inventario nacional de plantas municipales de potabilización y de tratamiento de aguas residuales en operación. Recuperado de http://www.conagua.gob.mx/CONAGUA07/Publicaciones/Publicaciones/Inventario_Nacional_Plantas1.pdf [ Links ]

Environmental Protection Agency, EPA. (2012). Global anthropogenic Non-CO 2 greenhouse gas emissions: 1990-2030 (Report EPA 430R-12-006). Recuperado de https://www.epa.gov/sites/production/files/2016-05/documents/epa_global_nonco2_projections_dec2012.pdf [ Links ]

Instituto de Investigaciones Eléctricas, IIE. (2012). Guía de usuario. Generación de electricidad mediante residuos sólidos urbanos. Temixco, México: Instituto de Investigaciones Eléctricas. [ Links ]

Instituto para la Diversificación y Ahorro de la Energía, IDAE. (2007). Biomasa. Digestores anaerobios. Recuperado de http://www.idae.es/uploads/documentos/documentos_10737_Biomasa_digestores_07_a996b846.pdf [ Links ]

Jorgensen, P. J. (2009). Biogas, green energy. Process-Design-Energy supply-Environment. Recuperado de http://lemvigbiogas.com/BiogasPJJuk.pdf [ Links ]

Lazarova, V., Peregrina, C., & Pascal, D. (2012). Towards energy self-sufficiency of wastewater treatment. In: Water. Energy interactions in water reuse (pp. 87-126). Lazarova, V., Choo, K.-H., & Cornel, P. (eds.). London: IWA Publishing. [ Links ]

Limón, J. G. (2013). Los lodos de las plantas de tratamiento de aguas residuales, ¿problema o recurso? Trabajo de ingreso del autor como miembro de la Academia de Ingeniería. Academia de Ingeniería, A. C., Guadalajara, México. [ Links ]

Meda, A., Lensh, D., Schaum, Ch., & Cornel, P. (2012). Energy and water: Relations and recovery potential. In: Water. Energy interactions in water reuse (pp. 21-35). Lazarova, V., Choo, K.-H., & Cornel, P. (eds.). London: International Water Association, IWA Publishing. [ Links ]

Metcalf & Eddy Inc., Tchobanoglous, G., Stensel, H. D., Tsuchihashi, R., & Burton, R. (2014). Wastewater engineering treatment and resource recovery (5th ed.). London: McGraw Hill Higher Education. [ Links ]

Monroy, O., Fama, G., Meraz, M., Montoya, L., & Macarie, H. (2000). Anaerobic digestion for wastewater treatment in México: State of the technology. Water Resources, 34(6), 1803-1816. [ Links ]

Nolasco, D. A. (2010). Desarrollo de proyectos MDL en plantas de tratamiento de aguas residuales (nota técnica). Washington, DC: Banco Interamericano de Desarrollo, Sector de Infraestructura y Medio Ambiente. [ Links ]

Noyola, A., Morgan-Sagastume, J. M., & Güereca, L. P. (2013). Selección de tecnologías para el tratamiento de aguas residuales municipales. Guía de apoyo para ciudades pequeñas y medianas. México, DF: Universidad Nacional Autónoma de México, Instituto de Ingeniería. [ Links ]

Noyola, A., Paredes, M. G., Morgan-Sagastume, J. M., & Güereca, L. P. (2016). Reduction of greenhouse gas emissions from municipal wastewater treatment in Mexico based on technology selection. Clean Soil Air Water, 44(9), 1091-1098. DOI: 10.1002/clen.201500084 [ Links ]

Peña de la, M. E., Ducci, J., & Zamora, V. (2013). Tratamiento de aguas residuales en México (Nota Técnica IDB-TN-521). Recuperado de http://services.iadb.org/wmsfiles/products/Publications/37783778.pdf [ Links ]

Programa Mundial de Evaluación de los Recursos Hídricos de las Naciones Unidas, WWAP. (2017). Informe Mundial de las Naciones Unidas sobre el Desarrollo de los Recursos Hídricos 2017. Aguas residuales: El recurso desaprovechado. Recuperado de http://unesdoc.unesco.org/images/0024/002476/247647S.pdf [ Links ]

Ramírez, E., Cardoso, L., & Moeller, G. (2009). Operación y mantenimiento de plantas de tratamiento de lodos activados. Material tecnodidáctico (7ª ed.). Moeller, G. et al. (eds.). Jiutepec, México: Secretaría de Medio Ambiente y Recursos Naturales-Instituto Mexicano de Tecnología del Agua. [ Links ]

Ríos, M., & Kaltschmitt, M. (2016). Electricity generation potential from biogas produced from organic waste in Mexico. Renewable and Sustainable Energy Reviews, 54, 384-395. [ Links ]

Secretaría de Medio Ambiente y Recursos Naturales- Instituto Nacional de Ecología y Cambio Climático, Semarnat-INECC. (2012). México. Quinta Comunicación Nacional ante la Convención Marco de las Naciones Unidas sobre el Cambio Climático. Recuperado de http://unfccc.int/resource/docs/natc/mexnc5s.pdf [ Links ]

Tabasová, A., Kropác, J., Kermes, V., Nemet, A., & Stehlík, P. (2012). Waste-to-energy technologies: Impact on environment. Energy, 44(1), 146-155. [ Links ]

United Nations Framework Convention on Climate Change, UNFCCC. (2014). Clean development mechanism CDM methodology booklet (6th ed.). Recuperado de https://cdm.unfccc.int/methodologies/ [ Links ]

Watergy México, A. C. , & Comisión de Cooperación Ecológica Fronteriza, COCEF. (2014). Auditoría de eficiencia energética en estaciones de bombeo y plantas potabilizadoras en el sistema municipal de agua y saneamiento de Nuevo Laredo, Tamaulipas. Informe Final. México, DF: Watergy México A. C., Comisión de Cooperación Ecológica Fronteriza, COCEF. [ Links ]

Wiser, J. R., Schettler, J. W., & Willis, J. L. (December, 2010). Evaluation of combined heat and power technologies for wastewater treatment facilities. Recuperado de https://www.cwwga.org/documentlibrary/121_EvaluationCHPTechnologiespreliminary[1].pdf [ Links ]

Received: May 16, 2017; Accepted: September 07, 2017

texto en

texto en