Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista mexicana de ciencias agrícolas

versión impresa ISSN 2007-0934

Rev. Mex. Cienc. Agríc vol.9 no.5 Texcoco jun./ago. 2018

https://doi.org/10.29312/remexca.v9i5.1503

Articles

Drying kinetics of Moringa oleifera

1Center of Research and Technological Development in Renewable Energies-University of Sciences and Arts of Chiapas. North-west Bypass num. 1150, building 24. University City, Tuxtla Gutiérrez, Chiapas, Mexico. CP. 29039. Tel. 6170440, ext. 4290. (vocky2731@gmail.com; edith.vigal@hotmail.com; juanamariajarquin@hotmail.com; pascual.lopez@unicach.mx; orlandolastre@yahoo.es).

Currently in several points of Mexico, as in the municipalities of Tuzantla, Mugica, Uruapan, Michoacan; Monterrey, Nuevo Leon, Torreon, Coahuila, Tuxtla Gutiérrez and Chiapa of Corzo, these last two in the state of Chiapas, there are plantations of Moringa oleifera trees for commercial purposes; however, producers have not found an adequate procedure that contributes to improving the final quality of said plant. The objective was to find a suitable drying process for this product, for which its kinetics of drying will be studied. The moringa was dried in a hybrid solar dryer at different temperatures (40 °C, 50 °C and 60 °C) during the month of May, recording the loss of mass and determining the free humidity for each temperature, through the balance Velab VE-24 analytical and Velab VE-50-5 thermo-balance. The curves were obtained from the analysis and processing of the experimental data through a program elaborated in Matlab and it was determined which of the selected mathematical models (Newton, Page, Henderson and Verma) was better adjusted to them. Determining that the Page model is the one that best describes the moringa's kinetics of drying. The diffusion coefficient and the activation energy were calculated for this case. Finally, the organoleptic quality of the product was evaluated by comparing it with other commercial samples of moringa, through the application of surveys. The drying curves show a decrease in the drying time when the temperature increases, resulting in a better quality of the dried product. Samples that were dried at 60 °C showed better characteristics of color, taste, smell and texture according to the organoleptic evaluation.

Keywords: drying kinetics; hybrid solar dryer; moringa

Actualmente en varios puntos de México, como en los municipios de Tuzantla, Múgica, Uruapan, Michoacán; Monterrey, Nuevo León, Torreón, Coahuila, Tuxtla Gutiérrez y Chiapa de Corzo, estos dos últimos en el estado de Chiapas, existen plantaciones de árboles de Moringa oleifera con fines comerciales; sin embargo, los productores no han encontrado un procedimiento adecuado que contribuya a mejorar la calidad final de dicha planta. El objetivo fue encontrar un proceso de secado adecuado para este producto, para lo cual se estudiará su cinética de secado. La moringa se secó en un secador solar híbrido a diferentes temperaturas (40 °C, 50 °C y 60 °C) durante el mes de mayo, registrando la pérdida de masa y determinando la humedad libre para cada temperatura, a través de la balanza analítica Velab VE-24 y termo-balanza Velab VE-50-5. Las curvas se obtuvieron del análisis y procesamiento de los datos experimentales a través de un programa elaborado en Matlab y se determinó cuál de los modelos matemáticos seleccionados (Newton, Page, Henderson y Verma) se ajustó mejor a ellos. Determinándose que el modelo Page, es el que mejor describe la cinética de secado de la moringa. Se calcularon par este caso el coeficiente de difusión y la energía de activación. Por último, se evaluó la calidad organoléptica del producto comparándolo con otras muestras comerciales de moringa, mediante la aplicación de encuestas. Las curvas de secado muestran una disminución del tiempo de secado cuando la temperatura aumenta, lo que resulta una mejor calidad del producto seco. Las muestras que se secaron a 60 °C mostraron tener mejores características de color, sabor, olor y textura de acuerdo con la evaluación organoléptica.

Palabras clave: cinética de secado; moringa; secador solar híbrido

Introduction

The Moringa oleifera is the most widely cultivated species of the moringa genus, being the only one of the genus of the family Moringaceae according to Quattrocchi (2000) is considered one of the most useful trees in the world, it can be used as food or for medicinal applications for being an important source of carotene, vitamin C, protein, iron, potassium, calcium and phosphorus. According to Olson (2011) said plant is commonly dried, crushed and stored without refrigeration for months without loss of nutritional values. With such a powerful nutritional value, these leaves could avoid the scourge of malnutrition and other related diseases (Mathur, 2005). Because of the benefits offered by moringa, its postharvest conservation is important through drying, which allows it to be commercialized in places where it is not cultivated.

Drying is one of the oldest techniques used for the conservation of food since the beginning of mankind since it provides the possibility of subsistence in times of lack Fito et al. (2001). Although natural drying is the most economical, it has some limitations. Under normal conditions, it takes two to three days; however, in times of low solar radiation and rainfall, the drying time is extended to 5 days or more, and the product can be negatively affected by biological agents. Due mainly to these disadvantages it is advisable to consider the use of solar dryers.

According to Heldman and Lund (2007), drying is defined as the removal of moisture due to the simultaneous transfer of heat and mass. Also, Sharma et al., (2003) point out that the kinetics of food drying is a complex phenomenon and requires reliable models to predict this process. According to Andrade et al. (2003) These models are useful tools to estimate the time necessary to reduce the water content of the product under different conditions and the ideal temperature, thus improving the efficiency of the process. Midilli et al. (2002) describe various mathematical models for the kinetics of drying agricultural products. So far, no drying kinetics studies of Moringa oleifera have been conducted, which is why this research focuses on the study of the drying kinetics of said plant.

Materials and methods

The leaves of Moringa oleifera were obtained from plantations of a hydroponic ranch located in the city of Chiapa of Corzo, Chiapas, which sells dry moringa capsules, subjecting said plant to a traditional or natural drying process.

After the plant was transferred to the laboratories of the Center for Research and Technological Development in Renewable Energies (CIDTER) of the University of Sciences and Arts of Chiapas (UNICACH), a microbiological selection of the leaves was carried out, washed, removed excess of water and finally submit them to the defoliation process. Trays of aluminum foil, tared on a Velab analytical balance, model VE-24, were made, in which the moringa leaves were weighed obtaining samples between 9 and 10 grams approximately, which were placed in the trays.

Drying equipment

The drying process was carried out in a hybrid solar dryer (Figure 1), which has the peculiarity of maintaining the temperature of the chamber constant. It presents for this a water heating system consisting of two heat pipe solar collectors, a thermo-tank, a heat exchanger placed inside the drying chamber and a pump that recirculates the water between the thermo-tank and the exchanger of heat. In addition, it has a backup wind generator to recharge a battery bank that is discharged through electrical resistances placed in the chamber. The camera also has a fan for air recirculation and an air extractor to remove humid air from inside the chamber to the environment.

Drying process

The dryer also has a data recording and control system where the values of temperature and humidity of the air in the chamber and the water temperature of the thermo-tank are monitored and recorded on an SD card. The experiments of the moringa leaves drying were carried out at 40 °C, 50 °C and 60 °C. To determine the initial moisture of the moringa sample, a Velab brand thermobalance model VE-50-5 was used.

Four samples of Moringa oleifera were prepared for each experiment. Said samples were placed inside the drying chamber (previously heated at constant study temperature). During the drying, the moringa mass variations were recorded every 30 min until it was minimal or null.

Determination of humidity and drying speed

To obtain the curves of drying and drying speed, the method of Geankoplis (1983) was used, determining the moisture content on a dry basis at each instant (Xt) according to equation (1).

Where: Mt= is the mass of the wet material in kg and Fs= is the mass of the dry product in kg, Xt= dry base moisture in kg of water kg of dry solid.

With the equilibrium moisture percent of the product (Xeq), the value of free moisture (X) in kg of free water/kg of dry solid for each value of Xt can be calculated by equation 2. This (X) is the moisture that the solid can lose after a time of contact with the air under the established conditions.

In relation to the above, the drying speed was calculated by means of equation (3), where: A= is the drying area in m2 and Fs= is the weight in kg of the dry solids.

Mathematical modeling of drying curves

For modeling the kinetics of Moringa oleifera, mathematical models were adjusted to the experimental data, being those of Newton, Page, Henderson and Verma (Table 1) the ones selected since they are the ones that most characterize the kinetics of drying of nutrimental plants and medicinal products (Correa et al., 2007).

Table 1 List of models used and their references.

| Model name | Model | Reference |

|---|---|---|

| Newton | Xa(t)=exp(-kt) | Mujumdar (1987) |

| Page | Xb(t)=exp(-ktn) | Diamante and Munro (1993) |

| Henderson | Xc(t)=a exp(-ktn) | Henderson and Pabis (1961) |

| Verma | Xe(t)=a exp(-kt)+(1-a) exp(-gt) | Verma et al. (1985) |

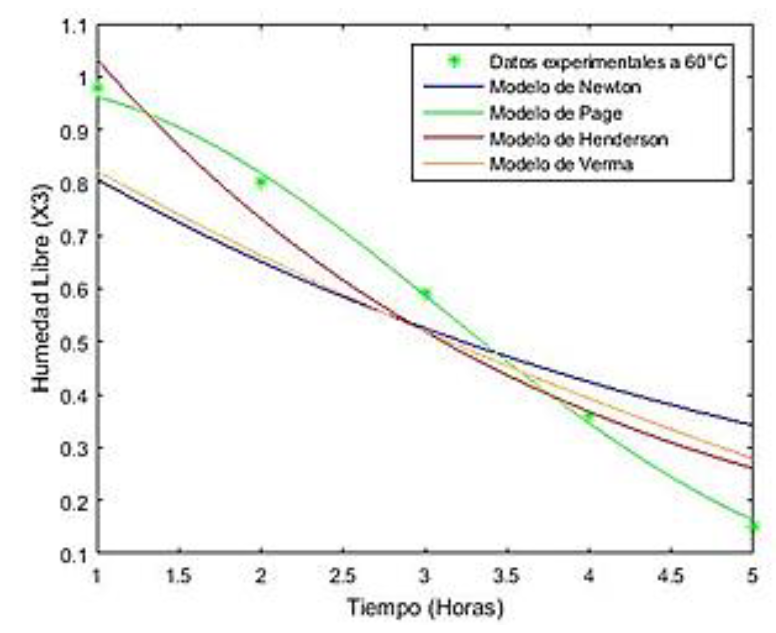

Using a program developed in Matlab, whose operation is described in Figure 2, allowed to find the model that best describes the behavior of its drying kinetics, using the correlation coefficient (R2) as the main criterion to select the best fit.

Determination of the diffusion coefficient (Def)

The diffusion coefficient (Def) is an effective diffusivity whose value is calculated through the mathematical model by adjusting the experimental values. It can be understood as the ease with which the water is removed from the material, this varies as the drying conditions change (temperature and air speed), it is not intrinsic to the material (Giraldo and Arévalo, 2010). The values of the diffusion coefficient were obtained through the logarithmic correlation of the experimental data (Ln(X)) and through the coefficients obtained from the best fitting model.

For the calculation of the effective diffusivity the Fick equation was used for laminar geometry in one direction.

Where: X= is the free moisture content, t is the time (h), x= is the characteristic dimension (m), Def = is the diffusion coefficient (m2 s-1).

According to Da Rocha et al., 2012 the solution of the Fick equation for the geometry of a moringa (sheet) and using eight series thermos is.

It was assumed that the first term of the sum is the only one that has significance, so for n= 0, the resulting equation looks like this:

By means of linear regression, the values of the parameters associated with the best adjustment curve are obtained, for the experimental data of free moisture X. The variables X and t present an exponential dependence, it is necessary to adjust it as follows.

By means of a linear transformation, applying Neperian logarithms a linear equation is obtained:

By analogy to the equation of a line y= A+Bx you have to:

Activation energy

The activation energy represents the energy required to initiate the diffusion of moisture during drying and gives an indication of the influence of temperature on the process, which can be described by the equation (10) of Arrhenius.

In which 𝐸𝑎 is the activation energy (m2 s-1), T is the absolute temperature of the drying air (K) Do is the Arrhenius factor m2 s-1 and R is the universal gas constant (8.314 kJ mol-1).

By means of the exponential regression, the activation energy is obtained as follows.

By analogy to the equation of the line Y=A+BX we obtain that:

Where: A represents the intercept and B the slope of the linear equation 𝑌=A+BX. To obtain the activation energy, the Ln(Def) was determined and the relation of the Arrhenius type Ln(Def) to the inverse of the absolute temperature of the drying air 1 000/T was plotted, using the values of the slope (B) obtained from said graph.

Descriptive sensory evaluation of moringa

As this is a new product, the level of preference and acceptability was evaluated using this method because it is easy and quick to process and analyze. For which there are 50 individuals to establish not only the difference between samples but the magnitude of it. These surveys allowed to determine the level of acceptability in taste, texture, smell and color of the samples. (Liria, 2007). All this in collaboration with the School of Nutrition of UNICACH.

Results and discussion

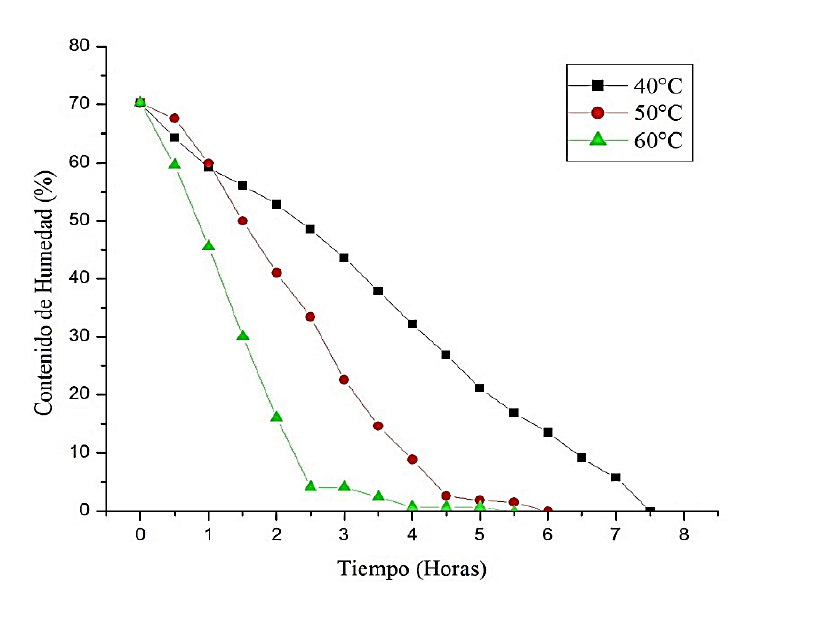

The Moringa oleifera presented an initial humidity of 70.3%. In the Table 2 shows the drying time and free humidity for the study temperatures. These results coincide with the relationship between high temperatures and shorter drying times.

Table 2 Drying time and free humidity of the moringa for the three temperatures.

| Drying temperature (oC) | Drying time (h) | Humidity of free (kg of water/kg of dry solids) |

|---|---|---|

| 40 | 6:30 | 0.13 |

| 50 | 4:00 | 0.02 |

| 60 | 2:15 | 0.12 |

Figures 3 and 4 show the curves of variation of humidity percent and drying speed for the three study temperatures with respect to time.

As a result of the modeling of the experimental data, Table 3 shows the coefficients obtained from each of the models used, as well as the correlation coefficient. As it is observed the model that was more adjusted to the experimental data was the Page model with an average correlation coefficient for the three temperatures of R2= 0.9957, this is verified in the graphs described in figures 5, 6 and 7, followed by the model of Verma, Henderson and Newton in that order. Therefore, the Page model will be used for the determination of the diffusion coefficient and the activation energy.

Table 3 Coefficients by mathematical models according to the experimental data.

| Model and equation |

40 °C | 50 °C | 60 °C | |||||

|---|---|---|---|---|---|---|---|---|

| Coefficients | R2 | Coefficients | R2 | Coefficients | R2 | |||

| Newton | k= 0.0952 | 0.8704 | k= 0.1561 | 0.8234 | k= 0.2147 | 0.7798 | ||

| Page | k= 0.01201 n= 1.94 | 0.9946 | k= 0.01911 n= 0.03818 | 0.995 | k= 0.03818 n= 2.399 | 0.9439 | ||

| Henderson | k= 0.1235 a= 1.244 | 0.9385 | k= 0.2227 a= 1.369 | 0.9337 | k= 0.3445 a= 1.45 | 0.9439 | ||

| Verma | k= 0.244 a= -36.47 g= 0.2362 | 0.9819 | k= 0.4186 a= -49.15 g= 0.4075 | 0.9779 | k= 0.6805 a= -14.28 g= 0.6174 | 0.7798 | ||

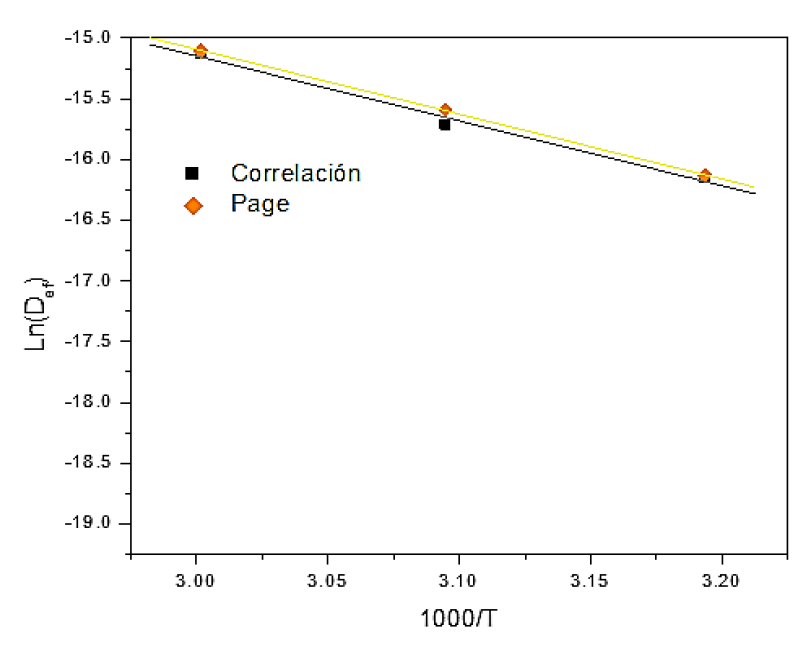

As can be seen in Table 4, there is a similarity between the values of the diffusion coefficient calculated from the Page model and those obtained from the logarithmic correlation of the temperatures of 40, 50 and 60 °C. It can also be noted that for higher drying temperatures the drying speeds are higher, thus, the increase in temperature favored the mass transfer and as a consequence the increase of the diffusion coefficient.

Table 4 Diffusion coefficients (Def), obtained for the Ln(X) and for the page model.

| Temperature (°C) | (Def) | |

|---|---|---|

| Ln (X) | Page | |

| 40 | 9.68678E-08 | 9.8894E-08 |

| 50 | 1.5008E-07 | 1.6966E-07 |

| 60 | 2.69933E-07 | 2.7581E-07 |

For the activation energy for the page model, it is very similar to the experimental data, so it is stated that it is the best fit model (Table 5).

Table 5 Activation energy for the page model and the logarithmic correlation.

| Model | Pending (B) | Intercept (A) | Do = exp (A) | Ea= -B*(kJ mol-1) |

|---|---|---|---|---|

| Correlation o Ln(X) |

-5.33607 | 0.86084 | 2.365146583 | 44.36408598 |

| Page | -5.35133 | 0.96307 | 2.619726702 | 44.49095762 |

The energy needed to start the moringa drying process is in the range from 44.36 to 44.49 kJ mol-1. A high activation energy corresponds to a reaction speed very sensitive to temperature (the Arrhenius representation has a large slope) and vice versa, a small activation energy corresponds to a reaction speed relatively insensitive to changes in temperature (Figure 8).

Table 6 shows a comparison of the diffusion coefficient obtained in this experiment with moringa with those reported in studies of similar plants.

Table 6 Comparison of diffusion coefficient and activation energy for various products.

| Mint (Mentha crispa L.) Park et al. (2002) |

Epazote (Dysphania ambrosioides) Kane et al. (2008) |

Thyme (Thymus) Da Rocha et al. (2012) |

Moringa | ||||

|---|---|---|---|---|---|---|---|

| Temp | Def (m2 s-1) | Temp | Def (m2 s-1) | Temp | Def (m2 s-1) | Temp | Def (m2 s-1) |

| 40 °C | 9.281E-13 - 1.125E-12 |

- | - | 40°C | 7.760E-12 | 40 °C | 4.8677E-08 |

| 50 °C | 2.261E-12 - 2.295E-12 |

50 °C | 3.7116E-09 - 4.598E-09 |

50°C | 2.089E-11 | 50 °C | 7.7453E-07 |

| - | - | 60 °C | 5.4772E-09 - 1.044E-0 |

60°C | 5.626E-11 | 60 °C | 1.5474E-07 |

Sensitive evaluation

For the organoleptic evaluation, the samples were numbered as follows: 1, dried at 40 °C; 2, dried at 50 °C; 3, dried at 60 °C and 4, commercial product of the Rancho of Chiapas of Corzo that dries traditionally; the results of said evaluation are shown in Table 7. The novel of liking was evaluated integrally, or the evaluated senses are summarized in expectation or disagreement with two intermediate terms as shown in the Table 7.

Table 7 Evaluation of the organoleptic taste of Moringa oleifera samples.

| Samples | Pleasure evaluation | |||

|---|---|---|---|---|

| Greater pleasure | Moderate pleasure | Moderate displeasure | Greater displeasure | |

| Sample 1 | 8 | 6 | 27 | 8 |

| Sample 2 | 6 | 26 | 8 | 4 |

| Sample 3 | 30 | 11 | 2 | 3 |

| Sample 4 | 6 | 7 | 13 | 35 |

The sample dried at 60 °C obtained the highest figures of pleasure because it presented the highest number of respondents who rated it with a high level of complete satisfaction in each item evaluated (18% for odor, 74% for color, 56% for texture and 52% for flavor) and in addition said sample was preferred over all others by 60% of the respondents. Finally, the sample number 3 (dried at 60 °C) is the best in terms of drying speed because it was the one that presented less time until reaching equilibrium moisture. In organoleptic terms, it presented the best evaluations in each of the items evaluated by the respondents.

Conclusions

It can be concluded that both in the kinetics of drying and in the organoleptic evaluation, the optimum drying temperature for the Moringa oleifera is at 60 °C, presenting a drying time of two hours, the Page model being the one that best describes the process; with a diffusion coefficient of 1.54745E-08 and an activation energy (Ea) whose value is in a range of 44.36 - 44.49 kJ mol-1. Regarding the organoleptic evaluation, the sample dried at 60 °C obtained the highest levels of taste in terms of smell, color, texture and flavor, and was also preferred over all other samples by more than 60% of the respondents.

Literatura citada

Andrade, E. T.; Borém, F. M. e Hardoim, P. R. 2003. Cinética de secagem do café cereja, bóia e cereja desmucilado, emquatro diferentes tipos de terreiros. Rev. Bras. Armazenamento. 1(7):37-43. [ Links ]

Corrêa, P. C.; Resende, O.; Martinazzo, A. P.; Goneli, A. L. D. e Botelho, F. M. 2007.Modelagem matemática para a descrição do processo de secagem do feijão (Phaseolus vulgaris L.) em camadas delgadas. Eng. Agr. 27(1):501-507. [ Links ]

Da Rocha, R. P.; Melo, D. C. E.; Corbín, B. J.; Berbert, A. P.; Donzeles, L. M. S. e Tabar, A. J. 2012. Drying kinetics of thyme. Rev. Bras. Eng. Agríc. Amb. 16(6):675-683. [ Links ]

Diamante, L. M. and Munro, P. A. 1993. Mathematical modelling of the thin layer solar drying of sweet potato slices. Solar Energy. 51(4):271-276. [ Links ]

Fito, P.; Chiralt, A.; Barat, J. M.; Andrés, A.; Martínez-Monzó, J. and Martínez-Navarrete, N. 2001. Vacuum impregnation for development of new dehydrated products. J. Food Eng. 49(4):297-302. [ Links ]

Geankoplis, C. J. 1983. Drying of process materials; transport processes and unit operations. Allyn and Bacon Inc. 2th. Boston, Massachusetts. 855 p. [ Links ]

Giraldo, A. y Arévalo, A. 2010. Datos experimentales de la cinética del secado y del modelo matemático para la pulpa de cupuaçu. Rev. Bras. Ciênc. Tecnol. Alim. 30(1):179-182. [ Links ]

Heldman, Daryl B. Dennis R. Lund, Christina Sabliov. 2006. Handbook of Food Engineering. Second Edition. CRC Press. Taylos & Francis Group. Boca Raton, Florida: 756 -810 pp. [ Links ]

Kane, C. S. E.; Jamali, A.; Kouhila, M.; Mimet, A. and Ahachad, M. 2008. Single-layer drying behavior of mexican tea leaves (Chenopodium ambrosioides) in a convective solar dryer and mathematical modeling. Chem. Eng. Comm. 195(7):787-802. [ Links ]

Liria M. R. 2007. Guía para la evaluación sensorial de alimentos. Instituto de Investigación Nutricional. Lima, Perú. 18-30 pp. [ Links ]

Mathur, S. B. 2005. Moringa book. Treesforlife. St. Louis, United States. 36 p. [ Links ]

Midilli, A.; Kucuk, H. and Vapar, Z. 2002. A new model for single-layer drying. Drying Technol. 20(7):1503-1513. [ Links ]

Mujumdar, A. S. 1987. Handbook of industrial drying. New York, United States. 437-562 pp. [ Links ]

Olson, M. E. y Fahey, J. W. 2011. Moringa oleifera: un árbol multiusos para las zonas tropicales secas. Revista mexicana de biodiversidad. 82(4):1071-1082. [ Links ]

Park, K. J.; Vohnikova, Z. and Brod, F. P. R. 2002. Evaluation of drying parameters and desorption isotherms of garden mint leaves (Mentha crispa L.). J. Food Eng . 51(3):193-199. [ Links ]

Quattrocchi, U. 2006. CRC world dictionary of plant names: common names, scientific names, eponyms, synonyms, and etymology. CRC Press. Boca Raton, Florida. 2408 p. [ Links ]

Sharma, G. P.; Prasad, S. and Datta, A. K. 2003. Drying kinetics of garlic cloves under convective drying conditions. J. Food Sci. Technol. 40(1):45-51. [ Links ]

Verma L. R.; Bucklin, R. A.; Endan, J. B. and Wratten, F. T. 1985. Effects of drying air parameters on rice drying models. Transaction of the ASAE. 28(1):296-301. [ Links ]

Received: February 2018; Accepted: April 2018

texto en

texto en