Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Revista mexicana de ciencias agrícolas

versão impressa ISSN 2007-0934

Rev. Mex. Cienc. Agríc vol.8 no.5 Texcoco Jun./Ago. 2017

https://doi.org/10.29312/remexca.v8i5.110

Articles

Experimental plantation of nopal for evaluation of fertilization and mucilage extraction systems

1Instituto Politécnico Nacional. Anillo Periférico Sur núm. 4863. Ampliación Tepepan, Xochimilco, Ciudad de México. CP. 16020 (sgaliciav@ipn.mx; lesliemhc@gmail.com).

2Universidad Autónoma Chapingo. Carretera México-Texcoco km 38.5. Texcoco, Estado de México. CP. 56230 (horacioa@correo.chapingo.mx).

3Instituto Politécnico Nacional. Hornos núm. 1003, Col. Noche Buena, Santa Cruz Xoxocotlán, Oaxaca. CP. 71230 (laquino@ipn.mx; hsernaa@ipn.mx).

This paper analyzes aspects related to the cultivation of nopal in the Milpa Alta Delegation in México City. First a comparative study of treatment types for nopal fertilization was carried out, which was carried out through an experimental process where yields and characteristics with different fertilizers were analyzed, which allowed to identify a system based on leachate as an alternative with greater efficiency. On the other hand, a methodology was established for the extraction of nopal mucilage through selection, drying and grinding to elaborate an additive for laboratory test that allowed to estimate sugars content and acidity level. In order to carry out the sampling process, an experimental plot was build that allowed to cultivate the nopal with the climatic conditions and soil properties of the region, as well as in different fertilization modalities to evaluate yields and quality.

Keywords: compost; fertilization; substrates

El presente artículo analiza aspectos referentes al cultivo de nopal en la Delegación Milpa Alta de la Ciudad de México. En primera instancia se efectúa un estudio comparativo de tipos de tratamiento para la fertilización del nopal, el cual se realizó mediante un proceso experimental donde se analizaron rendimientos y características con diferentes fertilizantes, que permitió identificar un sistema a base de lixiviados como una alternativa con mayor eficiencia. Por otro lado, se estableció una metodología para la extracción del mucílago de nopal a través de la selección, secado y molienda para elaborar un aditivo que permitió estimar el contenido de azucares y nivel de acidez en laboratorio. En una parcela experimental se llevó a cabo el proceso de muestreo que permitió cultivar el nopal con las condiciones climatológicas y propiedades del suelo de la región, así como en diferentes modalidades de fertilización para evaluar rendimientos y calidad.

Palabras claves: composta; fertilización; sustratos

Introduction

Nopal (Opuntia ficus)

Nopal (Opuntia ficus) is a plant of the Cactaceae family native to the American continent and characterized by a green color, presence of thorns and a branched structure whose extension can reach up to 5 meters high. Nearly 300 species of the genus Opuntia are known. However, there are only 10 or 12 species so far used by man, whether for fruit production and nopalitos for human consumption, forage or cochineal to obtain dye. Succulent and articulated stems or cladodes, commonly called penca, have ovoid or elongated racket shape, reaching 60-70 cm in length, depending on the moisture and available nutrients (Sudzuki et al., 1993).

When its measures are about 10-12 cm they are tender and can be consumed as vegetables. In México the nopal is an element present in the national symbolism whose representation dates back from pre-hispanic cultures being part of various mythologies (Chávez-Moreno et al., 2009). There is evidence on the knowledge, use and consumption of nopal by the first settlers of México, for example, in the excavations of Tamaulipas and Tehuacán, Puebla there were found fossilized seeds, tuna shells and nopal fibers with an antiquity of seven thousand years (Saenz, 2006).

In Mexico, Opuntia ficus-indica is the cultivated species of major commercial importance for the production of nopalito (Pimienta, 1997). Within Mexico’s gastronomy the consumption of nopal is a daily custom due to the benefits related to its consumption. The nopal has proven to be a source of manganese in the diet as well as an efficient source of minerals with 13% of the daily value, values increase with the maturity degree of the plant (Hernández-Urbiola et al., 2011). Also it is known that nopal consumption is a source of digestive fiber and its nutritional value can help in treating diabetes and hyperglycemia (Bacardi-Gascon et al., 2007).

The nopal cultivation in Mexico

The nopal cultivation in México is based on a traditional system and a micro tunnels system. The traditional system has planting densities of 15 000 to 40 000 plants per hectare by planting the mature pencas (2 to 3 years old) in rows at a distance of 30 to 40 cm between plants and 80 to 100 cm between rows. The plants height goes from 1 to 1.5 m. On the other hand, the micro tunnel system employs planting densities of 120 000 to 160 000 plants per hectare using beds of 1.2 to 2 m wide and 40 to 47 m long with a separation of 1 to 1.5 m (Flores-Valdéz, 2003). The micro tunnels system involves to cover the plantations which increases yields in cold climates. Yields in the traditional system vary from 30 to 80 t ha-1 (Pimienta, 1997), while in the intensive system, 179-263 t ha-1 have been recorded (Blanco-Macías et al., 2002).

The traditional system uses cattle manure as a fertilizer (over 100 t ha-1) every two or three years, which is complemented by mineral fertilizers such as urea or ammonium sulfate. In contrast the micro tunnels system uses cattle manure, nitrogen and phosphorus in proportions of 100 to 200 t ha-1, 100 to 200 kg ha-1 and 80 to 100 kg ha-1, respectively (Pimienta, 1997; Flores-Valdez, 1999).

Commercial plantations of nopal in México are located in regions with an average rainfall of 600 to 800 mm in the summer (Orona-Castillo et al., 2004), and harvesting is performed mostly manually using knives to cut the base of the penca (Cantwell, 1999). The cutting of the plant and the fruit must be carried out under suitable climatic conditions in order to avoid a high acidity content, the harvest should also be performed when the plant has reached a length of 20-25 cm and weigh about 90 to 100 g (FAO-OMS, 1993). Cladodes are classified as small when they have an average length of 12 cm or less, and as large when they reach 30 cm. The final use of the plant depends on its characteristics based on its quality, the commercialization can be done for direct consumption or destined to the elaboration of minimally processed nopal (Rodríguez-Felix, 2002). The criterion used to separate the nopalitos in the different quality degrees is based on its appearance, mainly the presence of defects in shape and color and mechanical damage. The classification is based on the size (length) of the nopalito, establishing five categories. These include cladodes from 9 cm up to 30 cm in length (FAO-OMS, 1993). In order for the vegetable nopal to be commercialized in international markets, compliance with additional quality standards is required in order to generate an adequate degree of competitiveness in contrast to other higher consumption vegetables (Caplan, 1995).

In regional terms, the Milpa Alta delegation in Mexico City ranks as the main producer of vegetable nopal with an annual average of 350 000 t and an average annual yield of 90 t ha-1 (SAGARPA, 2016). Regarding to the marketing and transportation of nopal in Milpa Alta, two alternatives are shown. The nopal for local consumption is sold in baskets weighing no more than 5 kg on the other hand, for consumption outside the region the nopal is marketed in bales of 1 m in diameter and 1.7 m in height containing approximately 3 000 pencas and weigh from 250 to 300 kg. Bales are transported to wholesale markets in México City. For markets distant from the production areas, they are packed in 20 kg wooden boxes or in carton boxes of 5 to 10 kg and transported in cooled trucks at 10 °C (Flores, 1992; Cantwell, 1999).

When the nopal reaches the commercialization stage, the period for consumption and expiration depends on variables such as the type of crop, procedure and characteristic of packaging, as well as temperature and humidity in storage (Nerd et al., 1997). Cladodes that show a damage in its base must be marketed in a short time and avoid storage or transport to distant markets since a loss by rots is generated up to 53% (Ramayo et al., 1978). The damage to the base is mainly caused by the harvest technique, which when performed manually involves a high risk of affecting the quality of the crop (Rodríguez-Felix and Villegas-Ochoa, 1997). Consequently, it is possible to have a high amount of product (nopal) that does not meet the quality standards necessary to be marketed in the different consumer markets, a situation that implies the searching for an alternative to better use the cladodium.

Nopal mucilage

On the other hand, it is known that mucilage is a byproduct obtained from cladodes of nopal, commonly referred to as polysaccharide pectin, it is a characteristic of the cactus family members. This compound is found in cladodes, skin and pulp of the fruit, although in different proportions (Medina-Torres et al.,2003). The chemical composition of Ofi nopal mucilage, has been the subject of several studies, Cardenas et al. (1997) found that the mucilage was a neutral polysaccharide containing arabinose, rhamnose, galactose and xylose. Furthermore, Paulsen and Lund (1979) reported that Opuntia ficus-indica extract was a mixture of a neutral glucan, glycoproteins and an acid polysaccharide made of L- arabinose, D-galactose, L-rhamnose, D-xylose and D-galacturonic acid. According to Trachtenberg and Mayer (1981), mucilage is a polysaccharide, containing 10% uronic acid, arabinose, galactose, rhamnose and xylose.

The composition of nopal mucilage was quite similar to Madjdoub et al. (2001) composed mainly of L-arabinose, D-galactose, D-xylose and 19.4% of uronic acid. McGarvie and Parolis (1981) found that the nopal mucilage is composed of a family of highly branched polysaccharides by a structure of α-D-galacturonic acid units attached 1-2 to units of β-L-rhamnose linked 1-4 with branching at C-4, galactose oligosaccharide branches which carry L-arabinose and D-xylose as substituents.

Use and application of nopal mucilage

Nowadays, nopal mucilage finds multiple applications in fields such as the food, cosmetics and pharmaceutical, construction and environmental industries, among others, which arise as research on its properties advances. The application of by-products that use mucilage as the main component has demonstrated practical results in different industries. Nopal mucilage has been used in aspects of environmental conservation as an element for the treatment of leachates in landfills Castellanos et al. (2012), also in the food industry nopal mucilage has been used to achieve a browning during banana dehydration Aquino et al. (2009) as well as to accelerate the enzymatic activity in apples (Martínez, 2012). Another application of the nopal mucilage can be seen as a fiber reinforcer used for packaging made from biopolymers (Rivera, 2015). However, an application that has gained importance for the nopal mucilage, is its use in the construction industry. The mucilage, given its characteristics as a thickening or modifying polysaccharide, makes it possible to increase the plasticity degree, as well as the decrease in the permeability of liquids in cement and lime pastes, as well as the property to form films (Muñoz, 2016).

Materials and methods

Experimental nopal cultivation

The cladodium cultivation process was carried out under the climatic conditions and with the soil characteristics of the region in order to establish a representative model of the nopal produced in the entire Milpa Alta delegation. The cultivation activities were carried out by means of a programmed control of fertilization using different products to be able to identify a greater yield according to the type of fertilization system. For the nopal production process, five types of treatment were determined: manure, compost, chemical fertilizer, leachate and water; a) the treatment is placed in the middle of the rows and these are those who receive such treatment directly; b) the chemical fertilizer, corresponds to the mara Yara Mix + urea, applied in the soil; and c) the leachate to be applied in the row 10 and 11 is divided into two, since the row 10 is applied to the soil and in the row 11 is foliarly applied. (Figure 1).

Mucilage characterization

Of the types of treatment used, two were selected: compost and manure, because these two types of fertilization systems are currently used in the region, leachate and chemical fertilizer are not generally applied. The obtained mucilage must be representative of the nopal produced in the region and grown under the same conditions performed by farmers of Milpa Alta (Figure 2-15).

Figure 2 Pruning of the remains of nopal pencas in order to establish an adequate space to proceed with the nopal sowing.

Figure 3 Determination of the area destined for the experimental plot in San Lorenzo Tlacoyucan, Milpa Alta delegation of 500 m2.

Figure 8 Harvesting by manual cutting. The last proportion was used for the mucilage extraction process.

Figure 10 The selected nopales underwent a process of manual cutting to reduce its volume to samples of 1 cm3.

Figure 11 The mixture of nopal and water was subjected to a heating process using thermoline laboratory equipment in order to reach an optimum temperatura for the use of the carbohydrates in the mixture.

Figure 12 The cactus and water mixture was subjected to a heating process using thermoline laboratory equipment in order to reach an optimum temperature for the use of the mixture carbohydrates.

Figure 13 Temperature monitoring was performed until reaching 50 °C (Hanna thermocouple), for one hour, to avoid reduction of viscosity and functionality in the mucilage.

Figure 14 Separation process by liquid decantation by density. When the separation process was carried out, it was also carried out a filtering process with a 500 microns mesh to remove residues.

Results and discussion

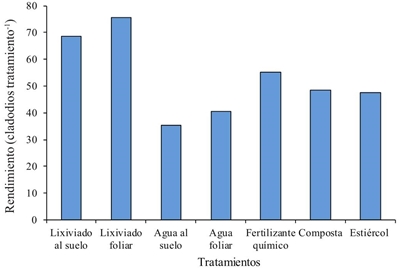

During the cultivation process, no evidence was shown to establish a significant difference between the yields of the cladodes depending on the treatment type, however, there was a slight variation in the number of obtained units (Figure 16).

As shown in Figure 16, leachate fertilization treatment type represented a higher yield of cladodes in contrast to other products, particularly the water-based treatment type resulted in low yields, whereas chemical fertilizer, compost and manure showed an average yield of 50.4 cladodes.

Regarding the physical characteristics of the nopal, the treatments used had no effect on the color parameters nor was there a significant variation in weight and size. Parameters such as acidity and pH were within the standard ranges for vegetable nopal cited by the literature (Rodríguez-Felix and Cantwell, 1988; Betancourt-Domínguez et al., 2006; Aguilar-Sánchez et al., 2007). Regarding Cladode texture, the values found were slightly lower than those reported in a similar study by Aguilar-Sánchez et al. (2007), which showed significant differences (p≤ 0.05) where the highest value was shown by ‘Copena F1' (15.08 Nw) and less firmness was obtained by ‘Oreja de elefante’ (8.14 Nw).

The few variations that occurred in the different types of treatments for the fertilization of the crop, resulted in a homogenization of the produced cladodium, which made it possible to cut and harvest the nopal to proceed with its selection and categorization and to perform mucilage extraction. It is important to note that the low variation in the nopal characteristics as a function of the treatment was expected so the cladodes used in the mucilage experiment were representative and with similar characteristics to those of the crops throughout the study region.

Regarding the mucilage yield and considering the same weight-volume ratio, no significant difference in yield was shown; however, regarding to the chemical parameters, a variation was observed. The mucilage obtained from the nopal fertilized with compost had a higher amount of both sugars and direct and total reducers, the pH is not as acidic as that found in other nopales ranging between 3 and 3.5 (Matsuhiro et al., 2005), the yield was 74% for nopal (compost) and 78% nopal (manure). Physically the compost nopal showed higher viscosity compared to manure nopal. The values previously mentioned, are shown in Table 1.

Discussion

First, in general it was possible to compare the yields and the quality of the final product by evaluating different fertilization systems, depending on the fact that the type of treatment that the crop receives is represented entirely by the direct application of fresh manure (Tavera-Cortés et al., 2014). This represents damage to the environment by the release of greenhouse gases (GHG) and above all it compromises the safety of the cladode and limits the consumer market due to the impossibility of certifying an organic production process. The results allowed to establish that, through the use of other fertilization systems, especially the leachate generated in a composting process, a slightly higher yield can be generated than that obtained with a manure treatment type.

It is important to note that the recommendation for the change in the fertilization system depends on the environmental benefits of reducing GHG emissions as well as the implementation of a composting process for self-generated organic wastes; however, it is recommended to perform a specialized study to accurately measure GHG emissions, as well as the different environmental impacts to generate more evidence to support the results of this research for a change in the treatment type.

On the other hand, the results obtained regarding the mucilage use, identified a methodology for its extraction, which, due to its simplified characteristics, can be applied by the nopal producers in the region. This would allow the creation of a new economic activity in the area focused on the extraction and exploitation of the mucilage, especially its commercialization to productive industries. Although when the obtained mucilage showed a greater sugars amount both direct and total reductants and a not so acidic pH, it is convenient to carry out a deep chemical characterization to determine the compounds present in the mucilages, together with a rheological characterization, using these parameters it will be possible to determine what other uses can be given to the obtained mucilage. Muñoz (2016) showed that aqueous solutions prepared with mature cladodium mucilages show highly elastic behavior at concentrations greater than 4% p/p, which leads to an increase in the viscosity and elasticity of elements that can be added to building materials. Therefore, the extraction and use of nopal mucilage in the Milpa Alta Delegation is an area of opportunity for the use of nopal, which, due to its quality characteristics, can not be marketed for direct consumption.

Conclusions

The research analyzes two important aspects in the cultivation of nopal, specifically in the Milpa Alta Delegation in México City. On one hand, different fertilization systems were evaluated, which allowed to conclude that a possible substitution of the current treatment type based on fresh manure for a compost leachate treatment that may have a slight increase in yield as well as environmental benefits. On the other hand, the research analyzes the use of nopal mucilage and it was possible to conclude that a methodology for its extraction and use can be carried out by the producers themselves, it was also possible to determine the general characteristics of the mucilage which can be evaluated as a byproduct in productive industries to improve construction materials.

Literatura citada

Aguilar, S. L.; Martínez, D. M. T.; Barrientos, P. A. F.; Aguilar, G. N. y Gallegos, V. C. 2007. Potencial de oscurecimiento enzimático de variedades de nopalitos. J. PACD. 9:165-184. [ Links ]

Aquino, L.; Rodríguez, J.; Méndez, L. y Torres, K. 2009. Inhibición del oscurecimiento con mucílago de nopal (Opuntia ficus indica) en el secado se plátano Roatan. Información Tecnológica. 20.4:15. [ Links ]

Bacardi, G. M.; Dueñas, M. D. and Jiménez, C. A. 2007. Lower ingeffecton postprandial glycemic response of nopales added to Mexicanbreakfasts. Diabetes Care. 30(5):1264-1265. [ Links ]

Betancourt, D. M. A.; Hernández, P. P.; García, S. A.; Cruz, H. F. and Paredes, L. O. 2006. Physico-chemical changes in cladodes (nopalitos) from cultivated and wild cacti (Opuntia spp.). Plant Foods for Human Nutrition. 61:115-119. [ Links ]

Blanco, M. F.; Valdez, C. R. and Ruiz, G. R. R. 2002. Intensive production of cactus pear under plastic tunnels. In: Nefzaoui, A. and Inglese, P. (Eds.). Proc. 4th International Congresson Cactus Pear and Cochineal. Oct. 22-28. Hammamet, Tunez. Acta Hort. 581:279-282. [ Links ]

Cantwell, M. 1999. Manejo postcosecha de tunas y nopalitos. In: Barbera, G.; Inglese, P. y Pimienta, E. (Eds.). 3 Agroecología, cultivo y usos del nopal. Estudio FAO Producción y Protección Vegetal, 132. Roma. 126-143 pp. [ Links ]

Caplan, K. 1995. Merchandising, distribution and marketing nopalitos and cactus pears. In: Proceedings of the First Annual Conference of the Professional Association for Cactus Development. San Antonio, Texas. USA. 46-47 pp. [ Links ]

Cárdenas, A.; Higuera, C. I. and Goycoolea, F. 1997. Rheology and agreggation of cactus (Opuntia ficus-indica) mucilage in solution. J. Profess. Assoc. Cactus Develop. 2:152-159. [ Links ]

Castellanos, M. C.; Becerra, N.; Carreño, L. and Páez, L. 2012. Comparativ estudy of the flocculantaction of Opuntia ficus indica Mucilage by two methods: coagulation and electrocoagulation in the leachates of pirgua landfill in tunja. Revista AIDIS de Ingeniería y Ciencias Ambientales: Investigación, desarrollo y práctica. 5(1):44-55. [ Links ]

Chavez, M. Ck.; Casas, A. and Tecante, A. 2009. The Opuntia (Cactaceae) and Dactylopius (Hemiptera: Dactylopiidae) in Mexico: a historical perspective of use, interaction and distribution. Bio. Conserv.18:3337-3355. [ Links ]

FAO-OMS. 1993. World wide codex standard for nopal. Codex Stan 185-1993. Codex alimentarius. Volume five B. Tropical fresh fruits and vegetables. Food and Agriculture Organization of the United Nations. World Health Organization. Roma. 85-93p. [ Links ]

Flores, A. 1992. Producción de vino y aguardiente de tuna, alternativa en el aprovechamiento del nopal. Ciencia y Desarrollo. 17:56-68. [ Links ]

Flores, V. C. A. 1999. Producción, industrialización y comercialización de nopalitos. In: Barbera, G., Inglese, P y Pimienta-Barrios, E. (eds.). Agroecología, cultivo y usos del nopal. Estudio FAO Producción y Protección Vegetal, 132. Roma. 97-105. [ Links ]

Flores, V. C. 2003. Importancia del nopal. In: Flores Valdéz, C. A. (Ed.). nopalitos y tunas, producción, comercialización, poscosecha e industrialización. 1ra Ed. Universidad Autónoma Chapingo, CIESTAAM. México.1-18 pp. [ Links ]

Hernández, U. M. I.; Pérez, T. E. and Rodríguez, G. M. E. 2011. Chemicalanalysis of nutritional content of pricklypads (Opuntia ficus indica) at variedages in anorganicharvest. Int. J. Environ. Res. Public Health. 8(5):1287-95. [ Links ]

Madjdoub, H.; Roudesli, S.; Picton, L.; Le C. D.; Muller, G. and Grisel, M. 2001. Prickly pear nopal spectin from Opuntia ficus-indica. Physico- chemicalstudy in dilute and semidilutesolutions.Carbohydrate Polymers. 46:69-79. [ Links ]

Martínez, A. 2012. Efecto de la aplicación de recubrimientos de nano emulsión-mucílago de nopal sobre la actividad enzimática de manzana fresca cortada. Tesis de Licenciatura. Universidad Nacional Autónoma de México (UNAM). México. 24-28 [ Links ]

Matsuhiro, B.; Lillo, L.; Saenz, C.; Urzu, Carlos and Zarate, O. 2005. Chemical characterization of the mucilage from fruits of Opuntia ficus indica. Carbohydrate Polymers. 63:263-267 p. [ Links ]

McGarvie, D. and Parolis, H. 1981. The acid-labile peripheral chains of the mucilage of Opuntia ficus indica. Carbohydrate Res. 94:57-65. [ Links ]

Medina, T. L.; Brito, De la F. E.; Torrestiana, S. B. and Alonso, S. 2003. Mechanical properties of gels formed by mixtures of mucilage gum (Opuntia ficus-indica) and carrageenans. Carbohydr. Polym. 52:143-150. [ Links ]

Muñoz, C. 2016. Caracterización reológica de mucílago de Opuntia ficus-indica en flujo cortante. Tesis de Maestría. Instituto Politécnico Nacional (IPN). México. 9-16 [ Links ]

Nerd, A.; Dumotier, M. and Mizrahi, Y. 1997. Properties and post harvest behaviour of the vegetable cactus nopal eacochenillifera. Postharv. Biol. Technol. 10:135-143. [ Links ]

Paulsen, B. S.; and Lund, S. P. 1979. Water soluble polysaccharides of Opuntia ficus indica. Phytochemistry.18:569-571. [ Links ]

Pimienta, E. 1997. El nopal en México y el mundo. In: cactáceas, suculentas mexicanas. CVS Publicaciones, México.87-95. [ Links ]

Orona, C. I.; Cueto, W. J. A.; Murillo, A. B.; Santamaría, C. J.; Flores, H. A.; Valdez, C. R.; García, H. J. L. y Troyo, D. E. 2004. Extracción nutrimental de nopal verdura bajo condiciones de riego por goteo. J. Profess. Assoc. Cactus Develop. 6:90-10. [ Links ]

Ramayo, R. L.; Saucedo, V. C. y Lakshminarayana, S. 1978. Prolongación de la vida de almacenamiento del nopal hortaliza (Opuntia inermis Coulter) por refrigeración. Chapingo, Nueva Época 10, México. 30-32 pp. [ Links ]

Rivera, J. 2015. Caracterización reológica de mucílago de Opuntia ficus-indica en flujo cortante. Tesis de Doctorado. Instituto Politécnico Nacional (IPN). México. 9-16. [ Links ]

Rodríguez, F. A. and Cantwell, M. 1988. Developmental changes in composition and quality of prickly pear cactus cladodes (nopalitos). Plant Foods for Human Nutrition. 38:83-93. [ Links ]

Rodríguez, F. A. 2002. Post harvest physiology and technology of cactus pear fruits and cactus leaves. Acta Hort. 581:191-199. [ Links ]

Rodríguez, F. A. and Villegas, O. M. 1997. Quality of cactus stems (Opuntia ficus-indica) duringlowtemperaturestorage. J. Profess. Assoc. Cactus Develop. 2:142-151. [ Links ]

Sáenz, C. 2006. Utilización agroindustrial del nopal. Boletín de servicios agrícolas de la FAO 162. Publicado por la Organización de las Naciones Unidas para la Agricultura y la Alimentación. Roma. 7-35 pp. [ Links ]

SAGARPA. (Secretaría de Agricultura Ganadería, Pesca y Alimentación) 2016. Cierre de la producción agrícola por cultivo. Servicio de Información Agroalimentaria y Pesquera. http://www.siap.gob.mx/cierre-de-la-produccion-agricola-por-cultivo/. [ Links ]

Sudzuki, F.; Muñoz, C. y Berger, H. 1993. El cultivo de la tuna (Cactus pear). Departamento de Reproducción Agrícola. Universidad de Chile. 40-42 [ Links ]

Tavera, C. M. E.; Escamilla, G. P. E.; Alvarado, R. H.; Salinas, C. E. and Galicia, V. S. 2014. Regional development model basedon organic production of nopal. Modern Econ. 5:239-249. [ Links ]

Trachtenberg, S. and Mayer, A. M. 1981. Composition and properties of Opuntia ficus indica. Phytochemistry. 20:2665-2668. [ Links ]

Received: June 2017; Accepted: August 2017

texto em

texto em