Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Revista mexicana de ciencias agrícolas

versão impressa ISSN 2007-0934

Rev. Mex. Cienc. Agríc vol.8 no.5 Texcoco Jun./Ago. 2017

https://doi.org/10.29312/remexca.v8i5.108

Articles

Greenhouse prototype with bamboo frame: materials selection, design and environmental impact

1Universidad Autónoma de San Luis Potosí-Facultad de Agronomía y Veterinaria. Carretera San Luis-Matehuala km 14.5. Soledad de Graciano Sánchez, San Luis Potosí, México. (mauricio.romero@uaslp.mx; lio34@hotmail.com; federico.villarreal@uaslp.mx; jorge.alcala@uaslp.mx).

2Universidad Autónoma de San Luis Potosí-Facultad de Ingeniería. Dr. Manuel Nava núm. 8. Zona Universitaria Poniente, San Luis Potosí, San Luis Potosí, México. CP. 78290. (angel.cardenas@uaslp.mx).

This paper aims to develop a production alternative in protected crops for resource-poor farmers in México. The objectives were: i) determining the resilience of bamboo culms of four species: Bambusa oldhamii Munro, Bambusa vulgaris var. vulgaris Schrad, Bambusa vulgaris ‘Striata’ y Gigantochloa verticillata Willd.; ii) design a greenhouse prototype for arid zones with bamboo culms; and iii) to estimate the environmental impact in relation to involved CO2. The results of compressive strength show that species were statistically equal, as well as between the lower, middle and upper sections of the culms; the average values ranged from 645 kg cm-2 to 952.31 kg cm-2. Regarding to bending, no significant difference was found between species, only in sections; it is observed that bending decreases towards the top of the culms in the four species; the found average values ranged from 850.17 kg cm-2 to 1 927.63 kg cm-2. Regarding the tensión the difference was only between sections of the stems in B. vulgaris var. vulgaris, in this species the lower section averaged 1023 kg cm-2 and the top 727 kg cm-2. Using resistance data and agronomic characteristics desirable for greenhouses in arid zones, the structural design was determined using STAAD.Pro®V8i software. The prototype’s construction specifications are exposed to detail so that it can be reproduced without complications by producers. Finally an environmental benefit is estimated in emissions of CO2 of 2847 kg in greenhouse construction of 135 m2 compared to one of the same area made out of steel.

Keywords: Bambusa spp.; arid zones; culms; materials resistance; protected crops

El presente trabajo pretende desarrollar una alternativa de producción en cultivos protegidos a productores de escasos recursos de México. Los objetivos fueron: i) determinar la capacidad de resistencia de culmos de bambú de cuatro especies: Bambusa oldhamii Munro, Bambusa vulgaris var. vulgaris Schrad, Bambusa vulgaris ‘Striata’ y Gigantochloa verticillata Willd.; ii) diseñar un prototipo de invernadero para zonas áridas con culmos de bambú; y iii) estimar el impacto ambiental en relación al CO2 involucrado. Los resultados de resistencia a la compresión muestran que las especies fueron estadística iguales, así como entre las secciones inferior, media y superior de los culmos; los valores promedios oscilaron de 645 kg cm-2 a 952.31 kg cm-2. En flexión no se encontró diferencia significativa entre especies, solo en las secciones; se observa que la flexión disminuye hacia la parte superior de los culmos en las cuatro especies; los valores promedios encontrados oscilaron de 850.17 kg cm-2 a 1 927.63 kg cm-2. En tensión la diferencia fue solo entre las secciones de los tallos en B. vulgaris var. vulgaris, en esta especie la sección inferior promedió 1 023 kg cm-2 y la superior 727 kg cm-2. Con los datos de resistencia y características agronómicas deseables para invernaderos de zonas áridas se determinó el diseño estructural con el uso del software STAAD.Pro®V8i. Las especificaciones de construcción del prototipo se exponen a detalle a manera de que pueda reproducirse sin complicaciones por parte de los productores. Finalmente se estima un beneficio ambiental en emisiones de CO2 de 2 847 kg en la construcción del invernadero de 135 m2 en relación a uno de misma área construido de acero.

Palabras clave: Bambusa spp.; culmos; cultivos protegidos; resistencia de materiales; zonas áridas

Introduction

The current demand for food in the world and the need to conserve natural resources guied the science and technology community to seek strategies for sustainable farming, that is: economically profitable, socially just and environmentally friendly.

Greenhouse production is a sound strategy that has proven productive in the world, with yields far above from what has been achieved in the open and reducing weather damage. However, acquiring a medium technology greenhouse is unlikely to low-input producers (82% of producers in México according to Villa, 2011). Prices vary from 30 to 50 dollars per square meter, initial investment that can not be covered by this group of producers either with their own resources or through government support. They resign themselves to continue their traditional production systems, exposed to unpredictable meteorological events.

The main structural material used in greenhouses, steel, has two serious drawbacks to be used by the indicated producers, these are: 1) its price, which has reached historical highs in recent years and represents 80% of the total investment of a greenhouse (Moreno et al., 2011); and 2) environmental, it is estimated that for every ton of steel produced, 1.7 t of CO2 on average are emitted into the atmosphere, which is one of the main greenhouse gases. Besides, the iron and steel industry is attributed to being responsible for 4 to 5% of the total world CO2 emissions (World Steel Association, 2008).

As an alternative to steel, as structural material in greenhouses, there are bamboo plants culms. These have shown qualities for these purposes worldwide, such as:high strength combined with low density and high elasticity

(Xiaobo, 2004; Ubolsook and Thepa, 2011; Gutu, 2013). Moreover, its cultivation leads to environmental benefits such as soil conservation, erosion control, water regulation, contribution of organic matter and to biodiversity. It is also considered as the timber plant with the fastest growing in the world and one of the plant species with the highest rate of CO2 sequestration in the world (Cárdenas, 2011; Sharma et al., 2014). Castaneda et al. (2005) estimated the annual average carbon accumulation on a bamboo plantation in 12.98 t ha-1 with 50% of carbon concentration in plant tissue.

Another important advantage of bamboo culms is its permanent availability through cultivation which can be set on the producer’s plot. In the state of San Luis Potosí, México, several species of bamboo are grown in the tropical region known as Huasteca. Where bamboo has shown an excellent adaptation, the plants reach up to more than 16 m high and 10 cm thick. Bamboo was introduced more than 10 years ago, but still no information has been reported about its mechanical properties, which are necessary for the structural design of a greenhouse.

Natural materials for structural use in greenhouses is nothing new. In this regard we can recall, as an example, the horticultural region of Almeria, Spain, which in the early 60’s designed Almería type greenhouses. The structures were made of wooden posts, which have gradually stepped to greenhouses with steel structures, counting till the date with over than 37 000 ha (Valera et al., 2014).

Based on the above, and as a proposal for a model of sustainable rural production for low-income producers in México, this paper was made with the following objectives: i) determining the compressive strength, bending and tension of bamboo culms of four species; ii) design a greenhouse prototype for arid areas; and iii) estimate the environmental impact in relation to CO2 involved.

Material and methods

Resistance tests

Evaluated culms belong to four species of bamboo plants grown in the Huasteca region of the state of San Luis Potosi, Mexico: Bambusa oldhamii Munro, Bambusa vulgaris var. vulgaris Schrad, Bambusa vulgaris ‘Striata’and Gigantochloa verticillata Willd. The collection site belongs to the experimental agricultural field of the National Institute of Forestry, Agriculture and Livestock Research (INIFAP), located in the municipality of Huehuetlán, San Luis Potosí, México, located at 21º 28’ 43” north latitude and 98º 58’ 30’ west longitude with an altitude of 92 m. In the Köppen’s classification the climate is called Cfga (humid temperate climate without dry season, average annual temperature of 23 °C and annual precipitation of 1 800 mm) (Pineda, 2005). Plant materials were established 10 years ago from the state of Veracruz, México.

Three culms per plant of three years of age were collected, with heights of more than 12 m and thicknesses between 8-9 cm. These were cut to the first six meters from the base to facilitate transportation, the apical part was discarded and allowed to air in the shade and room temperature.

The resistance properties were determined 160 days after collection of the culms. For this, the culms were previously divided into three sections of equal size: basal, median and superior (2 m each).

Resistance tests were performed for compression flexion and tension. These properties are required for the design of structures such as greenhouses. Due to the lack of a specific construction standard with bamboo in Mexico, it was taken as reference the Colombian technical standard NTC-5525 2007, test methods to determine the physical and mechanical properties of Guadua angustifolia Kunth., of the Colombian Institute of Technical and Certification Standards, based on norm ISO 22157 (2004) Bamboo: determination of physical and mechanical properties.

The test specimens for the compressive strength test were prepared according to the aforementioned Colombian standard NTC 5525, without knots, with a length equal to the external diameter and its ends with flat surfaces and at right angles to the length. The probe was positioned in such a way that the center of the press head was located in the center of the cross section of the specimen.

The specimens for the flexural strength tests were mounted with a length between the supports centers of 30 times the outside diameter, with a variable number of knots per specimen. Mounting culms for bending had four points, applying the load of the centers of the frames of the charging device at two points in the middle third of the distance between the supports. Stubbing culms was avoided using a plate and metal support of 15 cm long.

The test specimens for tensile strength tests parallel to the fibers were prepared with a total length of 60 cm, in the middle of which was left a test portion of a rectangular cross-section measuring 2.5 cm wide and 10 cm length independently of wall thickness. For mounting the specimen in the testing machine a distance of 30 cm between the end catchers was established.

Each test was repeated three times for each section of the culm (low, medium and high) for each species, giving a total of 36 measurements.The mechanical tests were performed in the mechanics laboratory of soils and materials of the Faculty of Engineering of the Autonomous University of San Luis Potosí. The compression tests were carried out on an AUTOMAX 5 press and the bending and tensioning tests on a Forney universal test machine.

The obtained data were statistically analyzed by analysis of variance and comparison of means to see if there are differences between sections of the culms (low, medium and high), as well as among the four tested species, the Tukey’s test with a confidence level of 5% was used. Both were conducted with the experimental designs software FAUANL package Version 1.1 (Olivares, 2012).

Greenhouse agronomic and structural design

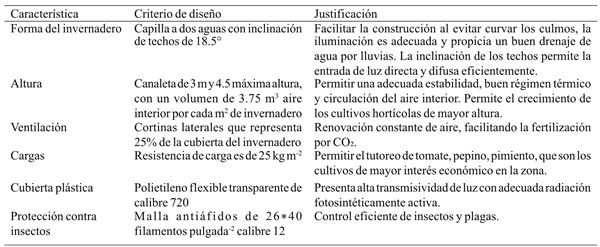

The prototype was thought to be built in the center of protected agriculture from the Faculty of Agriculture of the Autonomous University of San Luis Potosí, México.The location is 320 km east of the collection site (Huehuetlán, SLP), with geographic coordinates 22° 09’ 00” north latitude and 100° 59’ 00” west longitude with a height of 1 874 masl. Due to the semiarid climate of the place, the greenhouse design was based on this climate. For this purpose the literature was consulted to determine the desirable characteristics of a greenhouse for semiarid áreas in México: Matallana and Montero (1995); Castellanos (2004); Sánchez del Castillo (2007); Muñoz (2009). The characteristics to define for the agronomic greenhouse design were: shape, height, ventilation, live and dead loads for tutoring, cover features and physical barrier to pests.

Based on the resistance values and the agronomic design defined above, and the maximum wind speed (110 km h-1), ideas of basic structural frameworks were proposed in order to favor such conditions. These models were captured using the STAAD.Pro®V8i software, which is widely used in three-dimensional structural analysis designed with an open architecture for static and dynamic analysis of concrete, steel, aluminum, and wood structures, in bridges, buildings, towers, stadiums, etc. (Zertuche and Hernández, 2014). Using this software the behavior of structures under extreme conditions were simulated and maximum efforts were calculated at different critical points of the structure to verify that they were within safety margins. Finally the best model was chosen for its simplicity and structural stability.

The design of the foundation was based on the Building Regulations for the Distrito Federal (GODF, 2004), which specifies the design strength to limit state failure and specified resistance factors to both the structure and its foundation resist shear forces, twisting moments of mezzanine and earthquake-induced turning moments combined with those corresponding to other stresses and affected by the corresponding load factor.

Estimation of involved CO 2

CO2 emission of that would be generated by steel production for the construction of a greenhouse with dimensions and characteristics equivalent to those of the bamboo prototype was estimated. Based on the recommendation of the Mexican standard for the design and construction of greenhouses NMX-E-255-CNCP (DOF, 2008), which mentions the compliance of 5 to 6 kg of steel per m2 of the greenhouse. Furthermore CO2 emissions of steel manufacture were considered, which is 1 700 kg CO2 for 1 000 kg Steel (WSA, 2008).

Likewise, CO2 sequestered in biomass of bamboo culms was estimated by calculating the total of the structure once built dry weight. Three representative samples of each species were previously oven dried with forced air at 65°C to constant weight. The weight obtained was multiplied by the factor of 0.5 whereas 50% of the plant biomass is composed of carbón (Brown, 2002; Castañeda et al., 2005).

Results and discussion

Resistance tests

Compression. The information is important in the structural design of the greenhouse because of the constant effort that the columns are subjected to due to the weight of the structure, the dead and live loads. Dead loads are represented by the elements that remain hanging from the structure for a period longer than 30 days (eg. the crop). The live loads correspond to elements that remain hanging from the structure of the greenhouse for periods of less than 30 days.

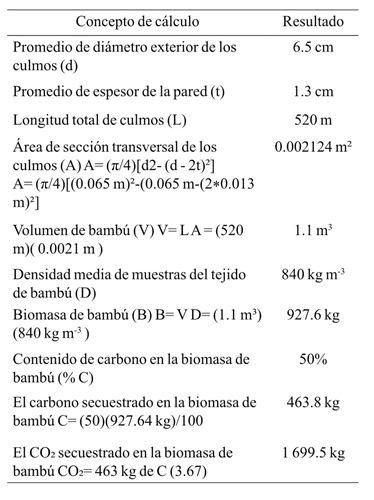

The results obtained in tests conducted with the Automax 5 brand press indicate that there is no statistical difference in terms of compressive strength between sections and between species, found average values ranged from 645 kg cm-2 a 952.31 kg cm-2 (Figure 1a and 1b). Xiaobo (2004) reported similar results in stress tests performed in bamboo of Phyllostachys pubescens species, analysis of variance revealed no significant difference between different bamboo heights in maximum compressive stress to the longitudinal direction with 865.73 kg cm-2 average in culm of three years old.

Figure 1 Resistance test results, a) compression between culm sections by species; b) compression between species by section; c) bending between culm sections by species; d) bending between species by section; e) tension between culm sections by species; and f) tension between species by section. Bars represent averages and standard error obtained from three replicates, different letters indicate significant difference between sections and species (p≤ 0.05, Tukey test).

Flexure. The information is useful in the structural design of the greenhouse because the most significant force exerting an effort on the structure of the greenhouse is due to the wind. This type of pressure exerts a bending stress on the columns. The columns of the walls, especially those facing the dominant direction of the wind, must be able to withstand the maximum pressure that can exist under the most adverse scenario. The spacing between columns must be such that the pressure exerted by the wind does not exceed the permissible stresses of the material used as the structure of the greenhouse, this option can be used to compensate for the differences in strength encountered between sections.

The results obtained in tests with universal testing machine Forney brand indicate significant difference between sections where the bending decreases toward the top of the culms in the four species. In the case of B. vulgaris ‘Striata’, the difference of the lower section is almost doublé compared to the upper section: 1 878 kg cm-2 and 978 kg cm2, respectively (Figure 1c). Between species a difference is observed in the lower section with the smaller value shown by B. oldhami. In the upper section also differences are observed, where B. oldhami and Bambusa vulgaris ‘Striata’were the species that showed lower resistance (Figure 1d). Xiaobo (2004) reported similar results on the effect of the location of the vertical sample along the bamboo culm, which was not significant on flexural strength, with an average of 1 574.4 kg cm-2 in three years culms of the Phyllostachys pubescens species.

Tension. The information will be useful in the greenhouse design because the wind, in addition to exerting a pressure effort on the columns of the greenhouse, also produces significant suction forces. It is very common for walls and ceilings that are not facing the prevailing wind directions to be subjected to suction efforts.

The results obtained in tests with universal testing machine Forney brand indicate significant differences between the three sections of the stems in the species B. vulgaris var. vulgaris, the ratio is that at higher stem height the lower the flexural strength, lower section averaged 1 023 kg cm-2 and the top 727 kg cm-2 (Figure 1e).

Based on the above data and in order to continue with the design and construction of the greenhouse the B. oldhami species was chosen, since it showed resistance values similar to other species and for being the most widely available in the collection area. In addition, this species has shown great adaptation even in other geographical areas of lower rainfall and temperatures in the state of San Luis Potosí.

Agronomic greenhouse design

The criteria for agronomic design were made taking into account the recommendations of Matallana and Montero (1995); Castellanos (2004); Sánchez del Castillo (2007); Muñoz (2009). Table 1 shows the criteria.

Greenhouse structural design

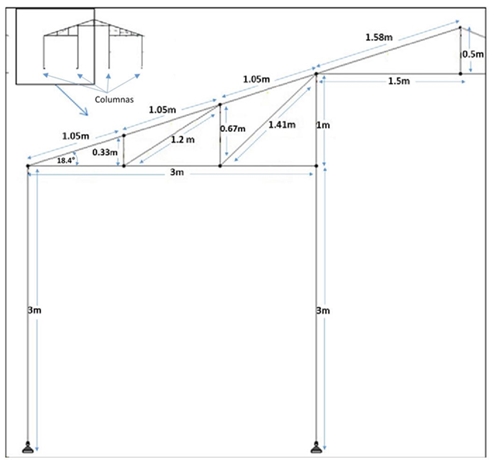

The desing proposed for the basic structural framework is shown in Figure 2, which arises from STAAD.Pro®V8i software. The design integrates the features and specifications resulting from the resistance of culms of B. oldhami and agronomic design. Each frame is supported on four columns with a 3 m gap between them, each consisting of two bamboo culms. The geometric shape is two-water with an inclination angle of 18.5°. The three sections were structured, at its top (3 to 4.5 m) in a triangular shape in order to increase the resistance and stability of the greenhouse.

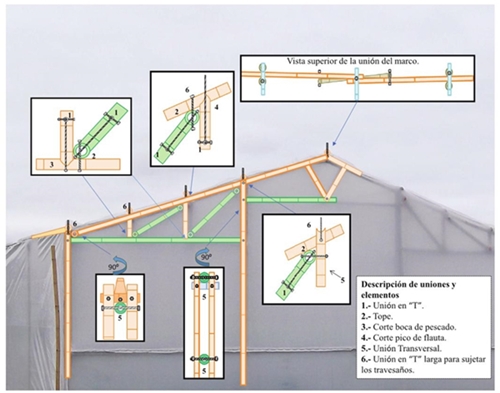

Joints and joint elements of the structural frame are illustrated in Figure 3. The main connection piece between culms is the threaded rod of galvanized steel 3/8 with 3/8 washers welded at one end and fastened with a screw (under “T”), or in some cases only with screws at both ends. For 90° joints a “fish mouth” type cut was held. For joints smaller than 90° a “slant” type cut was made. The stops are bamboo pieces of 8 cm thick that are used to connect bamboo pieces with 45° angle. Figure 3 also shows in a perspective of 90°rotation the detail of the joints of the columns carrying two culms, there is a transverse connection at the height of the channel in the first column, and two in the second column to join a crossbar and a spar.

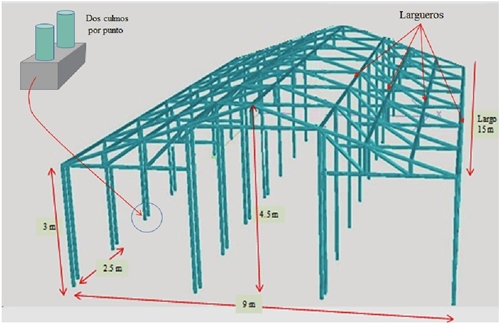

The basic structural framework can be repeated indefinitely to extend the greenhouse (if desired), longitudinally, transversely or both. In this paper, for experimental purposes, the prototype was defined in longitudinal shape at 15 m. For this, seven structural frames were required, which were joined at the top by nine 15-meter stiles. The total area of greenhouse prototype is 135 m-2 with a 3 m height at the cannel and 4.5 m total height (Figure 4). For the placement of the plastic of the greenhouse, a profile and fastener wire were placed in zig-zag form in the outer contours that joined to the culms by “butterfly” type screws.

The arrangement of the pads for the greenhouse foundation is shown in Figure 5, with a total of 28 elements. The foundation model has a depth of 55 cm, which is calculated according to the depth where the solid subsoil was found where the greenhouse construction is planned. In each pad, it is projected to place two bamboo poles mounted on a number 4 rod with a concrete filling for fixing and clamping.

Environmental benefit of using bamboo

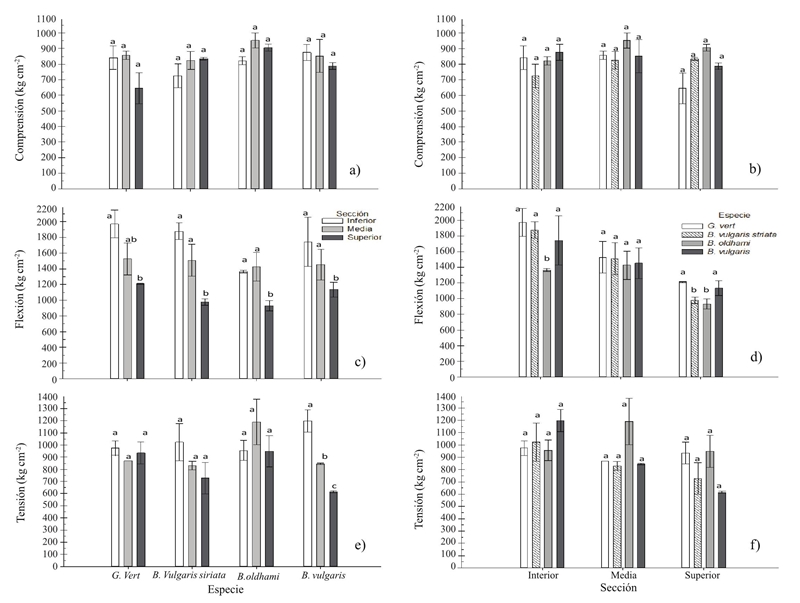

The procedure used to calculate the carbon released in steelmaking is shown in Table 2, where the use of 5 to 6 kg of steel per m2 of greenhouse is considered, according to the norm NMX-E-255-CNCP (DOF, 2008). In this case it is estimated a total of 1 147.5 kg of CO2 emissions by the steel used in a greenhouse with the dimensions of the bamboo prototype. On the other hand, the procedure used to calculate the carbon sequestrated in the bamboo biomass is shown in Table 3.

Table 2 Calculation memory of CO2 emissions released into the atmosphere during the production of steel.

The estimated value is 463.8 kg of C and 1 699.5 kg of CO2. Summing up the amount of CO2 that would remain fixed in the structural bamboo biomass plus that which would stop being dumped into the atmosphere during steel production for an equivalent structure, the environmental benefit of using a bamboo structure instead of a steel one can be estimated in 2 847 kg of CO2.

The foregoing without considering other environmental benefits not evaluated in this work, such as CO2 which remain fixed in the ground where bamboo grows, amount that according to FAO (2002), might be significant. The bamboos not only store carbon in foliar biomass, but also contribute to the existing ground biomass through their root systems and the contribution of waste to the soil (branches and leaves) and thus, soils are the largest carbon reservoir of the terrestrial cycle of this element.

45 months after the design and construction of the greenhouse prototype with bamboo structure, this has remained stable and firm. The maintenance work has been reduced to adjustments of fastening screws and varnishing with castor oil. It is considered that the plastic cover has contributed to reduce the wear of the culms by avoiding contact with rainwater and reduce the incidence of UV rays, both considered agents with degradation power of natural materials.

Conclusions

The compressive strength of bamboo culms of the four species are statistically equal, the same happened between the lower, middle and upper sections; the average values ranged from 645 kg cm-2 to 952.31 kg cm-2. In bending, no significant difference was found between species, only in the sections, it is observed that bending decreases towards the top of the culms in the four species; the found average values ranged from 850.17 kg cm-2 to 1 927.63 kg cm-2. Tension showed significant differences only between stems sections in B. vulgaris var. vulgaris, in this species the lower section averaged 1 023 kg cm-2 and the top 727 kg cm-2. Using resistance data and agronomic characteristics desirable for greenhouses in arid áreas a structural design was determined using STAAD.Pro®V8i software. Construction specifications of the prototype are exposed to detail so that they can be reproduced without complications by producers. Finally an environmental benefit is estimated in CO2 emissions of 2 847 kg in greenhouse construction of 135 m2 compared to one of the same area constructed out of steel.

Literatura citada

Brown, S. 2002. Measuring, monitoring and verification of carbon benefits for forest-based projects. Phil. Trans. Roy. Soc. Lond. 360: 1669-1683. [ Links ]

Cárdenas, L. M. 2011. Bambú. In Bambú. Sánchez- Vidiella, A. Editorial FKG. 383 p. [ Links ]

Castellanos, J. Z. 2004. Manual de producción hortícola en invernadero. 2da . Edición. INTAGRI, S. C. México. 469 p. [ Links ]

Castañeda, M. A. J.; Vargas, H. A.; Gómez, G. J.; Valdez, H. H. y Vaquera, H. H. 2005. Acumulación de carbono en la biomasa aérea de una plantación de Bambusa oldhamii. Agrociencia. 39:107-116. [ Links ]

DOF (Diario Oficial de la Federación). 2008. Norma Mexicana NMX-E-255-CNCP-2008, invernaderos de cubiertas plásticas. Diseño y construcción - especificaciones. México. [ Links ]

FAO (Organización de las Naciones Unidad para la Agricultura y la Alimentación). 2002. Captura de carbono en los suelos para un mejor manejo de la tierra. Informes sobre recursos mundiales de suelos No 96. Roma, Italia. 70 p. [ Links ]

GODF (Gaceta Oficial del Distrito Federal). 2004. Reglamento de construcciones para el Distrito Federal. 29 de enero del 2004, ciudad de México. México. 43 p. [ Links ]

Gutu, T. 2013. A study on the mechanical strength properties of bamboo to enhance its deversification on its utilization. Int. J. Inno. Technol. Exp. Eng. 2(5):2278-3075. [ Links ]

ISO (International Organization for Standardization). 2004. International Standard ISO 22157-1:2004 (E). Bamboo determination of physical and mechanical properties. 314-319 pp. [ Links ]

Matallana, G. A. y Montero, J. I. 1995. Invernaderos: diseño, construcción y ambientación. 2a Edición. Mundi-Prensa. España. 209 p. [ Links ]

Moreno, R. A.; Aguilar, J. y Luévano, G. 2011. Características de la agricultura protegida y su entorno en México. Revista Mexicana de Agronegocios. 15(29):763-774. [ Links ]

Muñoz, R. J. J. 2009. Estructuras de invernaderos y cubiertas de protección. J. Z. Castellanos (Ed.). In: manual de producción hortícola en invernadero. INTAGRI, México. 21-41 pp. [ Links ]

Olivares, S. E. 2012. Paquete de diseños experimentales. FAUANL, Versión 1.1. Facultad de Agronomía Universidad Autónoma de Nuevo León. Marín, N. L., México. [ Links ]

Pineda, M. L. F. 2005. Descripción del clima y modelación numérica de fenómenos meteorológicos en San Luis Potosí. Tesis de Posgrado en Ciencias Aplicadas. Instituto Potosino de Investigación Científica y Tecnológica. San Luis Potosí. 55 p. [ Links ]

Sánchez, del C. F. 2007. Diseño agronómico de invernaderos. In: Memorias V Simposio internacional de producción de cultivos en invernaderos. Universidad Autónoma de Nuevo León , San Nicolás de las Garza, Nuevo León, México. 31 p. [ Links ]

Sharma, P.; Dhanwantri, K. and Mehta, S. 2014. Bamboo as building material. International Journal of Civil Engineering Research. 5(3):249-254. [ Links ]

Ubolsook, P. and Thepa, S. 2011. Structural analysis of bamboo trusses structure in greenhouse. Second international conference on environmental science and technology IPCBEE. IACSIT Press, Singapore. 6:228-232. [ Links ]

Valera, M. D. L.; Belmonte, U. L. J.; Molina, A. F. D. y López, M. A. 2014. Los invernaderos de Almería, análisis de su tecnología y rentabilidad. In: memorias I seminario técnico agronómico. Universidad de Almería. CAJAMAR. Almería, España. 504 p. [ Links ]

Villa, I. M. R. 2011. ¿Qué hacemos con el campo mexicano? Segunda edición, Editor Colegio de Postgraduados. 434 p. [ Links ]

Xiaobo, L. 2004. Physical, chemical, and mechanical properties of bamboo and its utilization potential for fiberboard manufacturing. Thesis submitted to the graduate faculty of the Louisiana State University and Agriculture and Mechanical College The School of Renewable Natural Resources. 68 p. [ Links ]

WSA (World Steel Association). 2008. Informe de sustentabilidad de la industria siderúrgica mundial 2008. Editado por World Steel Association, Bruselas, Bélgica. 9-10 pp. [ Links ]

Zertuche, H. A. y Hernández, S. R. 2014. Manual Staad.Prov8i. Primera edición, Tomo I. Instituto Tecnológico de Nuevo Laredo. México. 725 p. [ Links ]

Received: June 2017; Accepted: August 2017

texto em

texto em