Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Nova scientia

versión On-line ISSN 2007-0705

Nova scientia vol.6 no.11 León abr. 2014

Ciencias naturales e ingenierías

Study of Space Charge in SC Shield / XLPE Interface and Mid-Voltage Cable Perfomance

Estudio de la carga de espacio en la interface capa semiconductora/XLPE y la eficiencia en cables de media tensión

Idalberto Tamayo Ávila1, José Manuel Nieto Jalil2, Jorge Viteri1, Juan Belana3 y José Antonio Diego3

1 Universidad Tecnológica Equinoccial, Facultad de Ciencias de la Ingeniería, Campus Occidental. Quito, Ecuador.

2 Departamento de ingeniería y Arquitectura, Instituto Tecnológico y de Estudios Superior de Monterrey Campus Sonora Norte, México. E-mail: jnietoj@itesm.mx.

3 Departament Física i Enginyeria Nuclear, Universitat Politécnica de Catalunya, España.

Recepción: 13-03-2013

Aceptación: 26-06-2013

Resumen

Se estudiaron tres cables experimentales de media tensión: C2, C3 y C4; con aislamiento de polietileno reticulado (XLPE) denominados: Medio, Alto y Bajo en los test de perforación con tensiones sobre 150 kV. Los tres cables han sido medidos sistemáticamente mediante las técnicas del Pulso Electroacústico (PEA) y de las Corrientes de Despolarización Estimuladas Térmicamente (TSDC) usando un voltaje de polarización de 120 kV en muestras tal y como se reciben, tratadas térmicamente a 90 ºC y 120 ºC durante 672 horas. Las medidas de carga interna en el cable C4 son de un orden del doble que en los cables C2 y C3. El fenómeno de carga interfacial ha sido estudiado por espectroscopia infrarroja mediante la técnica de Reflectancia Total Atenuada (ATR) y muestra que hay componentes que migran, se difunden y se trasportan desde la capa semiconductora externa hacia el aislamiento de polietileno reticulado durante el tratamiento térmico del cable.

Las medidas por PEA usando un campo eléctrico de 120 KV/mm muestran la formación y propagación de paquetes de carga de espacio desde el semiconductor (SC) hacia el aislamiento. Estos resultados son coherentes con las medidas mediante TSDC que muestran diferencias entre las áreas bajo la curva de corriente en función de la temperatura para los tres cables C2, C3 y C4 que es el resultado de la carga acumulada. Para resumir, la combinación de las mediciones PEA, TSDC y ATR son herramientas útiles para la comprensión de los procesos de relajación de carga de espacio y la eficiencia de los cables con aislamiento de XLPE.

Palabras clave: Carga de espacio, polietileno reticulado (XLPE), Corrientes de Despolarización Estimuladas Térmicamente (TSDC), Pulso Electroacústico (PEA), Reflectancia Total Atenuada (ATR).

Abstract

Three experimental mid-voltage cables , C 2, C3 and C4 with cross-linked polyethylene (XLPE) isolation, rated respectively as Medium, High and Low in perforation tests over 150KV, are studied. All these cables have been systematically measured by Electroacoustic Pulse (PEA) and Thermally Stimulated with Depolarization Currents (TSDC), using 120KV of polarization voltage in samples as received, annealed at 90kV and 120oC up to 672 hours. Measured internal charge of cable C4 at least doubles that of cables C2 and C3. The interfacial phenomenon has been studied by Infrared spectroscopy measurements Attenuated total reflectance (ATR) that show chemical components that migrate, spread, and transport from the external semiconductor layer to the cross-linked polyethene isolation during the thermic treatment of the cable.

The PEA measurements using  electric field showed the formation and propagation of space charge packet from SC to isolation. These results are coherent with TSDC measurements that also show differences in the areas under the curve of current as a function of temperature for each cable type C 2, C3and C 4. This is a result of the amount of charge accumulated. To sum up, combination of PEA, TSDC and ATR measurements is a useful tool in understanding charge relaxation processes and XLPE cable performance.

electric field showed the formation and propagation of space charge packet from SC to isolation. These results are coherent with TSDC measurements that also show differences in the areas under the curve of current as a function of temperature for each cable type C 2, C3and C 4. This is a result of the amount of charge accumulated. To sum up, combination of PEA, TSDC and ATR measurements is a useful tool in understanding charge relaxation processes and XLPE cable performance.

Keywords: Space charge, crosslinked polyethylene (XLPE), Thermally Stimulated Depolarization Currents (TSDC), Electroacouscic Pulse (PEA), Attenuated Total Reflectance (ATR).

Introduction

The presence of space charge in XLPE in dielectrics material not only affects the value of its electric field and its conductive properties but also plays an important role in aging processes (Dissado, 1998). From an applied point of view, for mid-voltage cable, the study of space charge formation and relaxation processes is especially interesting as they condition cable lifetime. Polyethylene (PE) is a linear semi-crystalline non polar polymer that is used in such cable insulation and the conduction processes observed can be associated with free charge (Tamayo, 2003). In industrial applications, PE is commonly cross-linked (XLPE) by the addition of some chemical additives (cross-linking agents) and heating, up to a temperature higher than 200oC to produce a vulcanization reaction. This process introduces several cross-linking by products that influence materials' conductive properties.

The development of new techniques for determining space charge profiles in insulators (Sessler, 1999) has renewed the interest in the study of space charge in dielectric materials in recent years. These studies have shown that the formation of space charge profiles in XLPE, used in cable insulation, is greatly influenced by several factors, including the cross-linking byproducts, antioxidants, oxidation of the material, temperature, electrode type, and other circumstances of the manufacturing process that must be taken into account (Hozumi, 1996; Bambery, 1996; and Suzuoky I et al, 1991).

Previous works showed that cable semiconducting shields (SC) play an important role in charge trapping processes in XLPE. The charge that arises was previously trapped in defects that diffuse from the SC layers. Infrared spectroscopy (IR) analysis showed that this diffusion of defects into the XLPE bulk takes place in a continuous way when the sample is annealed at temperatures above 80oC (Tamayo et al, 2004). Diffused defects act as traps for the charge that is injected from the electrodes if a polarizing electric field is present. There are numerous works dealing with the formation and propagation of space charge packet in the XLPE bulk, the influence of antioxidant(Kon et al, 1999), by-products cross-linked, acetophenone concentration (Tamayo, 2011). In our case we have focused our work on studying the interface and chemistry influence because in other works it has been shown that the external interface is more significant than the internal interface (Vissouvanadin et al, 2009). In this work, three experimental cables supplied by General Cable S.A., each one with quite different perforation test results, are systematically measured.

The main goal to achieve is to obtain a correlation between cable characteristics and measured results. Following this purpose, several samples were annealed at Ta = 90oC and Ta = 120oC for different times ta between 0 and 672 hours, and the charge distribution profile and the diffusion of chemical components from the semiconducting external shield into the XLPE isolation is measured. In the PEA measures, the charge accumulated near outer semiconducting electrode is related with the charge obtained by TSCD. Finally, we have obtained by PEA technique that the chemical composition of the semiconductor shield affect the formation of space charge packet and you propagation velocity in Low Density Polyethylene LDPE. The anterior results they are in accordance with the perforation test on C 2, C3 and C 4 cables.

Experimental

Samples

Cable samples were supplied by General Cable S.A Figure 1 and consisted of a cylindrical insulating XLPE (3) layer with 8.00mm and 13.00mm of inner and outer radius, respectively. The samples had two 0.60mm thick semiconductor shields based on EVA and Carbon Black (2,4) in contact with the inner and external surfaces of XLPE. The aluminium conductor (1) has been used as a positive electrode, while outer semiconductor (4) as a negative electrode, the copper screen (5) and the PVC cover (6) were removed during the sample manufacturing.

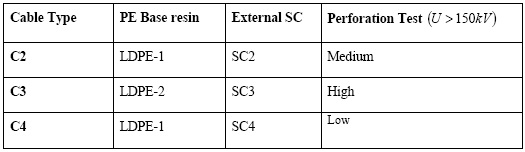

Three experimental cables (C 2, C3 and C 4) were prepared using different PE crosslinking agent base resin (PE1, PE2) and different external semiconducting shields (SC1, SC2). Cables were evaluated by perforation tests at General Cable S.A., delivering quite different results. The following table summarizes each cable properties.

Charge distribution measurements in cables and LDPE films in touch with the semiconductor shields C 2, C3 and C 4.

Charge distribution measurements were performed by the Pulsed Electro-Acoustic method (PEA). In this technique a pulsed electric field of 450 V amplitude and 80ns length is applied to the sample inducing the oscillation of space charge present through the material. The resulting pressure wave, related to the space charge distribution, is recorded as a function of time. More detailed explanation of this technique can be found in excellent treatises [8]. The PEA experimental set-up used in this work was commercial PEA equipment "Techimp PEA cable system". A "Spellman SL10" 130kV high voltage power supply was used to polarize cable samples, and data was recorded by means of a "Tektronix TDS 5032" digital oscilloscope. The measuring procedure consisted on a 2 hours polarization time (tp) at room temperature, and 120kV applied voltage (VP). Charge distribution was measured continuously during polarization and 30 minutes more after removing the electric field. Samples consisted in 1.5m long cable sections conveniently arranged for measurements. The total measuring section length was 10cm.

Samples of LDPE of 0.150mm thick were taken and dried during 24 hours under vacuum at room temperature, then the samples of the outer semiconductor 12mm in diameter in the cables C2, C3and C4 were cut and used as electrodes during the measurement through the technical PEA applying an electric field of  , and an amplitude pulse of 300V and 40ns length.

, and an amplitude pulse of 300V and 40ns length.

TSDC measurements

The samples that were polarized during the measurements, using the PEA technique, were cut without altering the zone where there were PEA measures and got the download details TSDC technique from 50 up to 120oC at a speed of global warming of  in system prepared conveniently to obtain the intensity of the download stream as a function of temperature. The area under the curve Intensity vs Temperature is the amount of charge involved in the depolarization current.

in system prepared conveniently to obtain the intensity of the download stream as a function of temperature. The area under the curve Intensity vs Temperature is the amount of charge involved in the depolarization current.

ATR measurements

Attenuated Total Reflectance (ATR) measurements were performed with a 'Nicolet 510M spectrometer of germanium optical in samples of outer semiconductors C2 , C3 and C4 of 12mm diameter. In XLPE sheets, circular samples 0.250mm thick were cut directly from the original cable with mechanical methods. We also analyzed the LDPE film circular samples on diameter 12mm and 0.150mmthick in contact with the outer semiconductor shield C2 , C3 and C4 cables during the PEA measurements with field  .

.

Results and discussion

PEA measurement as received cables

The Figure 2 show measurements of received cables at 0.50mm depth in XLPE insulating from the outer semiconductor shield. We can observe clear differences between them. Cable C4 shows much higher internal charge than the other two cables. However, cable C3 that performs better than C2 in perforation tests, shows higher internal charge as well. In all cases a distribution of trapped charge, injected from the external semiconductor electrode, can be observed.

Space charge packed-lite in LDPE films in touch with the cables C2, C3 and C4 semiconductor shields

In figure 3, the formation and propagation of the packed space charge from SC to LDPE films 0.150mm thickness can be observed. The results are according to the tests perforation. The semiconductor SC3 has a lower contribution to the formation of packages and the intensity is smaller than in SC2 and SC4. In LDPE films in touch with the SC4 the propagation speed of the packed is in order to  while in two other cases is

while in two other cases is  .

.

PEA and TSDC measurement in cables annealed at 90oC.

With the goal of clarifying the results obtained in the measures technique on the cable C3 , we have proceeded to study using the thermal aging in the cable samples because of the perforation test we carried at 90o C temperature. In figure 4b) the PEA measurements in cables annealed 672 hours at 90o C let you set that the C4 cable has more charge accumulated in comparison with C3 and C2. These results are consistent with the findings by TSDC (figure 5b). We can observe that the three cables, also after annealing internal charge distribution in all cables, follow similar relation as in the received samples but with less internal charge (figure 4a) and a decrease of the charge with the PEA measurements. However, in C3 there is still more charge accumulated than in cable C2.

PEA and TSDC measurement in cables annealed at 120 °c.

To speed up the effect of the temperature we proceeded to anneal the cables for 672 hours at 120 °C and repeat the measures by PEA and TSDC. In figures 4c) and 5c) we finally see that cable C3 has less charge than cables C 2 and C 4. While the charge in cable C3 tend to decrease, in cables C2 and C4 it tends to increase. The above associates the differences in the process of cross-linking these cables.

ATR spectra in xlpe layer in touch with the semiconductor C 2, C3 and C 4.

In figure 6a) we show the spectra ATR for the layer of XLPE in contact with the semiconductor screens of cables 2, 3 and 4 without heat treatment. We can clearly see that in the XLPE cables 2 and 4 there is band absorption from1557, 1638, 1742, 3300 cm-1 that is not of the XLPE. The bands1557, 1638 and 3300cm 1 are of the azodicarbonamide ADA, and the band 1742cm-1 corresponds to the Ethylene Vinyl Acetate EVA.

Figure 6b) shows the spectra ATR of layer of XLPE in contact with the semiconductor cables annealed during 672 hours at 90oC. We see a decrease in the absorption bands and if you are annealed for 672 hours to 120oC figure 6c) notes further declines.

The azodicarbonamide (C2H4O2N4) is a strong organic foaming agent of heat decomposition type. The decomposition temperature range is small. This product can be decomposed into N2, CO, CO2, used as a foaming agent for producing several foamed plastics.

The presence of the absorption bands of azodiacarbonamide that are detected in the polyethen isolation XLPE are the consequence of the diffusion process from the semiconductor layer, meaning that the azodiacarbonamide is in the external semiconductor layer in the XLPE during the process of fabrication of the cable in that itself it reaches temperatures higher than 200 °C during the reaction of vulcanization.

The decrease of the intensity of the bands of absorptions with the heat treatment of the samples to 90o C and 120o C seems to be related with the decomposition of the azodicarbonamide that contributes with the space charge input on the interface which it has been detected by PEA and TSDC explained previously.

Conclusions

We believe that the presence of azodicarbonamide on the external semiconductor facilitates the transport of electrical charge toward the isolation of XLPE. During the manufacturing process of the cable there is dissemination of azodicarbonamide toward the external surface of the XLPE, creating a porous structure and defects that serve as centers of accumulation of charge.

The heat treatment of the cable to 90 oC and 120 oC causes a decrease in the amount of azodicarbonamide in the outer layer of the isolation of XLPE either by decomposition or by a new broadcast toward the inner layers.

In the external interface there is a more significant presence of charge and is due to the external semiconductor shield structures. It has to be manipulated and flexible for their application, and the additives are necessary. The semiconductor shield of the cable C3 does not have azodicarbonamide; this contribution had an improved performance before the perforation test.

We initially detected more charge by means of the techniques PEA and TSDC, but the heat treatment improved the behavior with regard to the cables C 2 and C 4. This may be due to the fact that the cable C3 contains a resin commercial basis (LDPE-2) different from C2 and C 4. The influence of temperature can cause a higher degree of cross-linking and the elimination of by-products of the reaction of reticulated.

References

Bambery, K.R and Fleming. R. J. The temperature dependence of space charge accumulation in cross-linked polyethylene. IEEE. 1996. Pp 16-21. [ Links ]

Chen Fu, M. (2003) Space charge measurement in polymer insulated power cables using flat ground electrode PEA system, IEE Proceedings Science Measurement and Technology, Vol.150, Iss.2, pp.89. [ Links ]

Dissado, L.A (1998). What role played by space charge on the breakdown an ageing of polymers. Proceedings of the 3rd International Conference on Electric Charge in Solid Insulators, Société Française du Vide, Tours, France, pp 141-150. [ Links ]

Hozumi, N. Space Charge Behavior in Electrical Insultaion Under High Fieds.IEEE 1996 pp 3-8. [ Links ]

Kon H, Suzuoky Y, MIzutani T ; Suzuki T. Study os Space Charge Behaviour in Polyethylene for Power Cable Insulation by Laser-induced pressure-pulse Technique- Effects of Antioxidants. Trans IEE Japan, BcVol 114-A pp 243.251, 1999. [ Links ]

Sessler G.M. (1999). Electrets, 3rd éd.; Gerhard-Multhaupt, R., Ed.; Laplacian: Morgan Hill, CA, Vol. 2, Chapter 10, pp 41-80. [ Links ]

Suzuoky, Y; Furuta T; Yamada H. Han S.O, Mizutani T. Study of space charge in polyethylene by Direct probing Effects of Oxidation. IEEE Transactions on Electrical Insulation. Vol 26 No 6, 1991. Pp 1073-1079. [ Links ]

Tamayo Idalberto, Belana J., Cañadas J.C., Diego J.A., Mudarra M. , Sellarás J. (2003) Thermally Stimulated Depolarization Currents of Crosslinked Polyethylene Relaxations in the Fusion Range of Temperatures". J Polym Sci Part B: Polym. Phys, 41, 1412-1421. [ Links ]

Tamayo Idalberto, Belana J., Diego J. A., Cañadas J. C., Mudarra M., Sellarès J. (2004). Space Charge Studies of Crosslinked Polyethylene Midvoltage Cable Insulation by Thermally Stimulated Depolarization Current, Infrared/Fourier Transform Infrared, and Scanning Electron Microscopy. J. Polym. Sci. Part B: Polym. Phys., vol. 42, pp. 4164-4174. [ Links ]

Tamayo Idalberto, Diego J. A., Orrit J.(2007) Space Charge Measurements in XLPE Insulated Mid-Voltage Cable: Correlation whit Cable Performance". JICABLE 2007, SEE, Versailles, France. pp 331-336. [ Links ]

Tamayo Idalberto, Ôrrit J., Diego J.A.,Belana J and Cañadas J. (2011) Influence of EVA-carbon Black based SC-shield in Free Charge Genertation and Propagation in LDPE. 14th International Symposium on Electrets. Montpellier. France pp 97-98. [ Links ]

Vissouvanadin B., Le Roy, Teyssedre S, Laurent G., Denizet C., Mammeri I., Poisson M. (2009). Impact of conditioning on space charge formation in XLPE under DC electrical stress. Properties and Applications of Dielectric Materials. ICPADM 2009. IEEE 9th International Conference on the, On page(s): 961 - 964, Volume: Issue: 19-23. [ Links ]