Introduction

The consumption of vegetables, such as fresh tomato and tomato products, is inversely related to the development of some types of cancer and plasma lipid peroxidation, this is due to its content of bioactive compounds. Tomatoes (Solanum lycopersicum) are rich in lycopene and other carotenoids, flavonoids, vitamin C, K1, B2, and B9, and minerals such as potassium, copper, iron, and phosphorous among many other active compounds [1]. The phenolic compounds present in tomatoes can act synergistically with lycopene in preventing cell damage [2]. The concentration of these substances is higher in the skin and seeds and lower in the pulp of the fruit, which is the main ingredient of tomato-based products [3]. The applied technological processes as well as plant variety, cultivation, and harvesting conditions can significantly affect the content and composition of phenolics in tomato fruit and tomato-based products [1,3]. Tomato processing is accompanied by the generation of tons of organic by-products or wastes that remain in excellent condition and contain high amounts of bioactive compounds. Currently, the food industry has opted for the use of organic by-products in food processing to take advantage of substances and ingredients with added nutritional contributions and to produce functional foods. In the food industry, tomato products, such as purees, pasta, or tomato juice, and thermal treatments such as pasteurization are applied, but this treatment causes changes in the contents of bioactive compounds in the food. The use of microwaves has been proposed as an alternative to preserving both thermolabile compounds and organoleptic characteristics due to the shorter time required for processing [4]. Microwaves interact with ions and polar molecules of water, which causes an alteration in the magnetic field and friction between molecules, which results in direct heating of the food [5], increasing the microbiological safety and maintaining the general quality of the products. The main advantage of microwave treatment is that during processing, the volumetric heat generated in the food significantly reduces the heating time and can reach high enough temperatures to inactivate pathogenic microorganisms. For tomato products, the benefit of microwave heat treatment in tomato sauce has been reported: when subjected to pasteurization at 915 MHz with powers of 1.2 - 4.8 kW, the inhibition of E. coli, S. Typhimurium, and L. monocytogenes is achieved [6]. On the other hand, it is important to highlight that according to data from the FAO, Mexico is the 9th largest producer and the largest exporter of tomatoes worldwide. The Agrifood and Fisheries Information Service (SIAP) reports that tomato production in Mexico during the 2020/2021 season was 3.03 million tons, while for the 2021/22 season it is estimated to reach 3.72 million tons. Agroindustrial waste generated by this industry and others have caused environmental problems, so there is a growing interest in implementing processes that allow efficient and comprehensive use of waste. Considering that Mexico is one of the main producers worldwide, tomatoes of national origin were used in this study and give added value to the residues of this industry. Taking into account the above, the objective of the present work, was to prepare tomato puree with the addition of skin and seed residues, and the content of antioxidants at each stage of the process was determined. The effect of microwave treatment as a preservation method for storage was evaluated since the quantification of the main bioactive compounds has not been reported even for the pasteurization of tomato puree. To assess the effect of microwaves on the organoleptic properties of tomato purees, a sensory evaluation of the processed products was also carried out. A comparative study of the elaboration of tomato puree was carried out between the method used in the industry and the one developed at the laboratory level. This with the purpose of evaluating the effects of the heat treatments applied in each one of them also comparing with the microwave treatment.

Methodology

Raw material

Samples of tomatoes (Solanum lycopersicum) of the saladette variety (50 kg), from the state of San Luis Potosí (ejido of Vanegas), were collected and selected according to the parameters established by Mexican Standard [7]. The preparation of tomato purees was carried out at the laboratory and pilot plant levels. The applied procedure is the one normally used in the industry, separating the skin and seeds that in this work were not thrown away but were used as an additive to the tomato puree. The seeds and the skin were perfectly ground to obtain a homogeneous pure.

The heat treatments applied in the industry for the preparation of tomato purees, paste or juice, generate changes in the content of bioactive compounds in the food. In the present work, a comparative study was carried out using both the method applied in the industry (at the pilot plant level) and at the laboratory level. The use of microwaves as an alternative for conservation is also proposed, in order to preserve the organoleptic characteristics and thermolabile compounds since less time is used in the process.

Preparation of the puree at the laboratory level

Tomato puree

A sample of ten kilograms of tomatoes was chopped and scalded at 95 °C for 60 seconds, to separate the skin and seeds, and the flesh was then liquefied and then pulped. The juice obtained in the pulping was treated at 85 °C until 10 °Brix; 1 % of salt was added, and the puree was mixed and packed. Subsequently, the product obtained was packaged in 200 mg glass jars to be supplemented, pasteurized, and processed by microwave. A total of 20 bottles with products were obtained.

Tomato powder

Tomato seeds and skin obtained in the previous stage were dried in an oven at 90 °C for 3 hours. They are subsequently ground in a nutribullet processor and sieved with mesh. No. 10.

Tomato puree supplemented

To obtain the supplemented puree, the powder from the previously pulverized and dried skin and seeds, was added in an amount of 6 % to a batch of the tomato puree obtained in a) (corresponding to 6 % of the initial weight of the raw material calculated on a wet basis [8]. Subsequently, the samples were packed in glass jars with a capacity of 200 g (20 jars).

Microwave treatment

The methodology used was proposed by Lau and Tang [9]. A batch of 4 bottles with the puree obtained in a), were subjected to microwave treatment: one-third of each jar was covered with aluminum foil to generate uniform heating of the food, and the jars were then treated in a conventional microwave oven at a frequency of 2,450 MHz for 30 seconds and a power of 750 W. Then, the jars were placed in containers with water at 40 °C and moved to a container with water at 10 °C to reduce the temperature. This procedure was also applied to the samples of pure supplemented obtained in c) and was repeated until a total of 16 flasks were obtained for subsequent tests. For comparative purposes, a batch of flasks of the obtained puree was subjected to the pasteurization process under the conditions used in the industry.

Conventional pasteurization

A batch of 9 bottles with the puree (supplemented and no supplemented) underwent conventional pasteurization. A stainless-steel electric autoclave Polinox, AUVV-1 trade, was used. The process was carried out with steam heating at 90 °C for 15 minutes. After the heat treatment, the containers were gradually cooled by placing them in a bowl with water at 10 °C until the temperature was reduced. This procedure was repeated 2 times to obtain 18 bottles for subsequent tests.

Preparation of the puree at the pilot plant level

The preparation of tomato purees at the pilot plant level was carried out in the Department of Biochemical Engineering at ENCB. The processing began with the slicing of 32 kg of saladette tomatoes in a hammer mill; the juice was obtained in a pulper, separating the skin and seeds; evaporation was then carried out to obtain concentrated puree, which was packaged and sterilized. Due to the conditions existing in the pilot plant equipment, instead of pasteurization, sterilization of the bottles was performed in an electric autoclave at 121 °C. In a 200 g jar with tomato puree, copper thermocouples of 1/2 and 1/3 were placed to record the temperature. The lethality value (L) was recorded every 30 s with the help of the 1/3 thermocouple and the lethality table for microorganisms of z = 18 °F, adding these values until obtaining an F0 value of 0.20 min.

After the heat treatment, the autoclave was gradually cooled by emptying the hot water and filling the chamber with water at 20 °C until the temperature was reduced. A batch of 9 bottles of 200 g of concentrated tomato puree was treated in the microwave in batches following the procedure performed at the laboratory level. A yield of 43 % was obtained at the end of the processing, which was close to that indicated by different authors [10].

Physicochemical parameters

The tomato purees were analyzed directly to determine the humidity and density [11]. For the determination of soluble solids and pH [7], purees were filtered. The acidity percentage [7] was calculated with Equation 1:

where V1 = mL of NaOH used in the titration (mL), N = ormlity of the NaOH solution (meq/mL), P eq. = equivalent weight of citric acid (0.064 g/meq), m = mass of the wet base sample (g).

Methanolic extract

A 1g sample was weighed, mixed with 10 mL of a methanol/water solution at an 80:20 ratio [10], and then sonicated for 10 minutes (Ultrasonic cleaner sonicator, Brenson 3210) and kept under stirring for 2 hours at room temperature. The solution was then filtered.

Total phenolic compounds (TPC)

The determination of TPC was carried out according to the method described by [12] with modifications. The total phenolic concentration was obtained by comparison with the standard curve of gallic acid (y = 0.004x + 0.045, R² = 0.9992), expressing the results as equivalent milligrams of gallic acid (GAE) per kilogram of the sample.

Total flavonoids (TF)

The method used was that reported by Bahorun et al. [13], which is based on the binding of the displacement reagent (AlCl3) with the flavonoid molecule producing a chelate formation, which generates the displacement of the absorption wavelength . Total flavonoid concentrations were obtained by comparison with the quercetin calibration curve (y = 0.0081x + 0.0141, R² = 0.9994), and the results were expressed as equivalent mg of quercetin per kg of sample.

Antioxidant capacity (AC)

The reducing power of the samples was determined by the method described by Brand-Williams et al., [14] for inhibition of the radical 2,2-diphenyl-1-picrylhydrazyl (DPPH). The percentage of inhibition of the sample corresponds to the amount of DPPH radical neutralized by the extract at a particular concentration, determined using Equation 2, where A=control absorbance and A1=sample absorbance at 515 nm:

The antioxidant capacity is expressed as millimoles of TE (Trolox equivalents) per kg of sample, using a Trolox calibration curve and the percent inhibition of the samples (y = 0.098x + 4.584, R² = 0.9968).

Quantification of lycopene

The method suggested by Fish et al. [15]: a 0.3 g sample was collected in a light-protected bottle and supplemented with 20 mL of a solution of hexane, ethanol, and acetone at a 2:1:1 ratio and was then stirred for 15 minutes at room temperature. Then, 5 mL of distilled water was added and stirred for a further 5 minutes to allow the separation of non-polar and polar phases. Finally, the supernatant was removed, and the absorbance of the non-polar phase was measured (hexane) in a 1 cm quartz cell at 503 nm in a UV/vis spectrophotometer, using hexane as a blank. The amount of lycopene was estimated, taking into account the molar extinction coefficient (ε) 17.2 ×104/M cm of lycopene in hexane at 503 nm, and the concentration was calculated using Equation 3:

where x = amount of hexane in the extraction (mL), y = weight of the sample (g), A503 = absorbance of the non- polar phase of the sample, and 3.12 = extinction coefficient derived from the conversion to mg/kg in wet base.

Kinetic study

Bioactive degradation kinetics in pasteurized tomato purees and microwave treatment were carried out for 90 days in a controlled temperature room (25 °C). Samples were taken every 15 days and bioactive compounds were analyzed with the methods described above (samples contained in separate bottles in duplicate). Compound degradation was calculated using the standard first-order kinetic equation [16]:

where, C = concentration of the bioactive compound (mg / kg) at one time, t = storage time (days), Co = initial concentration (day 0) of the compound (mg / kg), k = reaction rate constant (days).

Identification of individual compounds by HPLC

The method reported by Nicoletti et al., (2007) [17] was used with some modifications. Samples were obtained by solid-phase extraction (SPE) on SEP-PAK C18 columns. An Agilent Technologies high-resolution liquid chromatography (HPLC), in reversed-phase with diode array (PDA), and a UV/vis detector were used. The separation was carried out in a LiCro-Chart reversed-phase column (Merk, Darmstadt) RP-18, C18 250 × 4 mm, PI 5 μm, which was maintained at 25 ± 1 °C, the flow of the mobile phase was 1 mL/min, and the injection volume was 20 μL. A multistage gradient method was used, consisting of a mixture of 0.5 % formic acid in water (Phase A) and acetonitrile (Phase B). Readings were obtained at 280, 306, 320, and 370 nm, which are the maximum wavelengths of naringenin, resveratrol, chlorogenic acid, rutin, and quercetin, respectively. The standards used were Sigma grade ≥ 95 % (HPLC). A mixture of individual standards in methanol was injected, achieving the separation of each peak in the chromatogram.

Microbiological analysis

Diacetyl or 2,3-butonodione is a metabolic product indicative of microbial action by fermentation of sugars by yeasts and bacteria in fruit products [18]. The analysis is based on the detection of a dark, purple- colored substance, by reacting diacetyl with creatinine in the presence of naphthol. The absorbance was measured in a UV / vis spectrophotometer at 545 nm, using distilled water treated in the same way as the blank. The diacetyl content was determined by comparing the diacetyl concentration calibration curve. On the other hand, the molds and yeast accounts were carried out following the Official Mexican Standard [7]. Half-milliliter aliquots of the prepared dilutions (10-1 to 10-3) were seeded in duplicate in acidified dextrose potato agar by the extension sowing technique. The boxes were incubated at 25 ± 1 °C for five days after which developed colonies were counted, and colony-forming units (CFU) were calculated.

Shelf life

The physicochemical, antioxidant, and microbiological properties of tomato purees were determined for 90 days at room temperature (25 °C) in low-light conditions, recording the values of the samples contained in independent bottles every 15 days in duplicate. The bottles were analyzed to evaluate the shelf-life and were made in triplicate.

Sensory evaluation

The sensory evaluation was carried out with 20 untrained panelists to detect the differences and characteristics of the different tomato purees made. The amount of sample was 30 mL at a temperature of 25 °C. Two tests were carried out. The discriminative test was the comparison of pairs. The characteristics evaluated were flavor, color, and aroma. The descriptive test applied was the attribute scale, which consisted of presenting three samples to the panelists: 1) microwave-treated tomato puree, 2) tomato puree supplemented with seed and skin powder and microwave-treated and 3) commercial tomato puree. The attributes evaluated on a graphic scale were texture and flavor. The graphic flavor scale is represented by the extremes slightly astringent to extremely astringent, while the texture of the samples is represented by the extremes slightly creamy to extremely grainy.

Color determination

The color was evaluated with a Hunter Lab ColorFlex EZ colorimeter using the CIELab system, which allows the mathematical determination of any color by chromaticity coordinates [19]. The colorimeter calibration uses a black and white standard. Measurements were made using 50 g of each sample and were compared with a control (standard), which was the raw material before processing (saladette tomato variety).

Statistical analysis

The statistical analysis of the data was carried out using the Minitab 16.1.0, 2010 program. The data are reported as mean ± standard deviation, of an average of six repetitions. One-way analysis of variance (ANOVA) was performed using Tukey's method, using 95 % confidence to determine significant differences in the comparison of results.

To compare the effect of each processing stage during the preparation of tomato purees, a matrix was built with each group of variables and principal component analysis (PCA) was used as the ordering method, using the Minitab 16.1.0 program, 2010. Principal component analysis (PCA) is a statistical technique that seeks to synthesize information by reducing the number of variables that explain a phenomenon without this reduction causing a significant loss of information. The main components or factors are a linear combination of the original variables and meet the condition of being independent of each other, that is, each one of the components will explain the variability of a certain number of the original variables and the variability that it is not capable of explaining will be explained by the next main factor and so on.

Results and discussion

Physicochemical parameters

Table 1 shows the results of the physicochemical parameters and antioxidant contents of tomato purees obtained at the sampling points during processing and of the final products at the laboratory level. The soluble solids value of fresh saladette tomatoes was within the range of 4.4 - 4.9 reported by Echarrys and Ramírez [20] for different tomato varieties from Venezuela. During the processing of tomato purees, from the concentrate stage, the soluble solids increased significantly, due to the evaporation of tomato juice, which suggests the accumulation of sugars during processing and heat treatment [21]. The pH value obtained from the fresh fruit coincided with that reported by Rodríguez et al. [3] for tomatoes of different varieties from Mexico. The pH decreased during processing until reaching an average value of 3.98, similar to the changes reported by other authors for tomato sauces and purees [19]. The titratable acidity in fresh tomato was higher than the value reported by Rodríguez et al. [3] of 0.28 % for saladette variety tomatoes from the state of San Luis Potosí. The difference may be due to the state of maturity of the fruit since the acidity in the fruit decreases significantly as the ripening state progresses as a consequence of the degradation of polymeric carbohydrates (starch, peptic substances, and hemicellulose), increasing the accumulation of monosaccharides [21]. The tomato purees presented acid values which are close to those reported for different tomato products at 1 - 2 % (ketchup, pasta, and tomato juice) [19]. The relative density of the fresh fruit, coinciding with the densities reported in different tomato varieties (saladette, cherry, and ball) in Mexico [3]. Alterations in the relative density were generated in the processing stages until values of 1,062 and 1,100 for the tomato purees were achieved; these differences were a consequence of the concentration of soluble solids in the food. The moisture content of the whole fresh fruit was similar to that reported by Muñoz de Chávez et al. [22] for tomatoes of different varieties. In general, the fruit has 94 % of water, which can vary according to the cultivation conditions, degree of maturity, and type of the fruit, while the tomato purees presented moisture contents between 85.9 and 88.6 %, with a decrease between 5 and 10% compared to fresh fruit, which is due to the various processes applied, such as concentration, and the addition of solutes, such as salt [21]. The values of the physicochemical parameters obtained from the different tomato purees (Table 1) are within the intervals established by the Mexican Standard for packed tomato puree [7] (NMX-F-033-1982), which specifies that the puree must have a soluble solids content greater than 10° Brix, a pH of 4 to 4.5 and a maximum of 1.0 % titratable acidity expressed in citric acid. The tomato puree supplemented with the seeds and skin of the fruit showed lower acidity, higher amounts of soluble solids and relative density, and lower % moisture than the non-supplemented puree. Conventional pasteurization and microwave treatment of tomato purees showed no significant difference (p> 0.05) in physicochemical properties. Several authors have pointed out that microwave treatment does not affect pH parameters and soluble solids in food [23,24].

Table 1 Physicochemical parameters and antioxidant properties of sampling points and tomato purees samples*.

| Sample | (°Brix) | pH | Acidity (% cítric acid) | Relative density | Moisture (%) | Phenolic compounds (mgGAE/kg) | Total Flavonoids (mgQE/kg) | Antioxidant capacity (mmol TE/kg) | Lycopen (mg/kg) wb | |

|---|---|---|---|---|---|---|---|---|---|---|

| Processing stages | Fresh fruit | 4.48 ± 0.02f | 4.36 ± 0.0b | 0.398 ± 0.00f | 1.026 ± 0.003c | 94.36 ± 1.02a | 180.9 ± 15.57d | 131 ± 5d | 1.009 ± 0.057f | 77.68 ± 2.0c |

| Scalding | 4.50 ± 0.00f | 4.40 ± 0.0a | 0.554 ± 0.006e | 1.034 ± 0.005c | 93.33 ± 0.57a | 206.6 ± 18.48d | 129.71 ± 4.2d | 1.629 ± 0.041d | ND | |

| Concentrated | 10.0 ± 0.00e | 4.00 ± 0.0c | 0.786 ± 0.005d | 1.052 ± 0.002b | 89.76 ± 0.75b | 411.9 ± 7.52c | 172.92 ± 1.9c | 1.527 ± 0.043e | ND | |

| Salad | 10.5 ± 0.00d | 3.98 ± 0.0c | 0.799 ± 0.00c | 1.053 ± 0.00b | 89.30 ± 0.80b | 440.5 ± 18.3c | 172.30 ± 2.9c | 1.5 ± 0.09e | ND | |

| Added | 13.00 ± 0.01b | 3.99 ± 0.02c | 0.887 ± 0.01b | 1.092 ± 0.010a | 87.29 ± 0.52c,d | 512.43 ± 6.13b | 192.26 ± 2.12a | 1.855 ± 0.034b | ND | |

| Concentrated puree | Conventional Pasteurization | 11.02 ± 0.10c | 4.00 ± 0.05c | 0.968 ± 0.007a | 1.062 ± 0.00b | 88.40 ± 0.22b,c | 520.7 ± 4.22b | 186.7 ± 2.56b | 1.811 ± 0.04c | 95.26 ± 1.8b |

| Microwave treatment | 11.25 ± 0.24c | 3.96 ± 0.05c | 0.963 ± 0.003a | 1.064 ± 0.003b | 88.60 ± 0.38b,c | 513.5 ± 2.81b | 185.8 ± 2.46b | 1.765 ± 0.024c | 94.95 ± 1.3b | |

| Added puree | Conventional Pasteurization | 13.20 ± 0.15a | 3.99 ± 0.01c | 0.888 ± 0.003b | 1.100 ± 0.003a | 85.9 ± 0.23d | 592.43 ± 4.22a | 196.99 ± 0.71a | 2.121 ± 0.019a | 104.13 ± 2.3a |

| Microwave treatment | 13.25 ± 0.04a | 3.98 ± 0.01c | 0.891 ± 0.00b | 1.099 ± 0.006a | 86.1 ± 0.27d | 607.07 ± 4.22a | 196.99 ± 0.71a | 2.083 ± 0.013a | 104.45 ± 1.7a |

*Mean ± standard deviation, n=6. Results expressed on a wet basis. ND, No detected; mg GAE/kg, galic acid mg equivalents/kg; mg QE/kg, Quercetin mg equivalents/kg; mmolTE/kg, trolox milimols equivalents /kg. a,b,c,d,e,f Different letters in each column indicate significant difference (p < 0.05).

Total phenolic compounds (TPC)

The values obtained from the studied samples at laboratory level are presented in Table 1, expressed in mg GAE/kg. The initial results of concentrated tomato purees (with seeds and skin removed), pasteurized and treated with microwaves, were lower than tomato puree supplemented with seeds and skin of the fruit, which represents an increase between 13.77 and 18.34 %. The fresh fruit and the scalding sample did not show a significant difference between TPC values since scalding destroys the enzymes responsible for the loss of color, reduces the load of microorganisms present in the raw material, and softens the tomatoes to facilitate pulp extraction and is achieved with steam heating for 60 seconds; thus, this procedure did not affect the TPC. For the fresh fruit, the TPC value was comparable to that reported by Toor and Savage [25], who analyzed the phenolic contents in different varieties of tomatoes grown in New Zealand, reporting values between 157-201.4 mg GAE/kg wb (wet basis). There was a significant difference in the TPC between the concentrated tomato juice and the fresh fruit, which was due to the increase of the °Brix, the elimination of water, and the heat treatment with temperatures of 85-90 °C after the concentration process. There was no significant difference after adding salt to the product, indicating that sodium chloride does not influence the total contents of phenolic compounds in the food. A pronounced increase in total phenolic compounds was observed during the processing stages in the samples with different heat treatments. These results are comparable with the work of several authors [10], who reported increases in the contents of phenolic compounds during the processing of tomato products using conventional treatments. No significant differences were found in the concentrations of total phenols in tomato purees subjected to conventional pasteurization and by microwave; however, a slight increase in the puree supplemented with seeds and skin in the microwave-treated fruit could be observed (Table 1). In products pasteurized by microwaves, significant advantages have been found concerning the contents of total phenolic compounds in the food [23,26], such as the significant reductions in heating time and high temperatures, which allow similar phenolic contents of compounds to be obtained compared to conventional pasteurization.

Total flavonoids

Table 1 shows the total flavonoid content as equivalent milligrams of quercetin per kilogram of sample web (mg QE/kg). The value of fresh fruit was similar to that reported by Lenucci et al. [27], who reported 74 -198 mg QE/kg wb for different varieties of tomatoes grown in Italy. The composition of antioxidant compounds varies considerably according to the genetic variety, maturity, and growing conditions of the fruit [21]. The concentrated tomato juice revealed a significant difference (p < 0.05) between the values for the fresh and scalding fruit, which was due to the heating and evaporation of the water. The samples after the salting process showed no difference (p > 0.05) from concentrated tomato juice. The initial values of total flavonoids in concentrated tomato purees were higher than those obtained by Kamiloglu et al. [28], who reported values of 84 mg/Kg wb for tomato puree with 12 °Brix and 42 mg QE/kg wb in fresh tomato. After performing the heat treatments, a significant increase (p < 0.05) in the total flavonoid content in the different final products was observed, ranging from 41.98 - 50.30 % compared to the fresh fruit (wb). This increase is because heating causes the release of flavonoids in the food due to the breakdown of cellular constituents, such as vacuoles, which serve as storage for these secondary metabolites [29]. These results agree with Kamiloglu et al. [28], who reported an increase in the bioavailability of naringenin (a more abundant flavanone in this vegetal) after subjecting fresh tomatoes to cooking, and this increase is because the mechanical and thermal treatments provide the energy needed to break the interactions between molecules, therefore improving the bioavailability of flavonoids. Tomato purees supplemented with seeds and skin showed increases in flavonoid concentration ranging from 5.46 - 5.81 % in comparison with concentrated purees. Toor and Savage [30] pointed out that organic wastes generated in the production of tomato products present high concentrations of flavonoids, mainly rutin and naringenin, with total flavonoid values ranging between 98 - 137 mg QE/kg wb for seeds and between 220 - 240 mg QE/kg wb for the skin of tomatoes grown in New Zealand. In Mexico, Rodríguez et al. [3] reported rutin contents of 1165.8 µg/kg in the skin and 147.8 µg/kg wb in seeds, as well as quercetin contents of 111.8 µg/kg in the skin and 501 µg/kg wb in seeds of saladette tomatoes from the state of San Luis Potosí. The total flavonoid content in microwave-treated tomato purees did not show a significant difference (p > 0.05) compared to those that were conventionally pasteurized, in agreement with the report by Igual et al. [31], who evaluated the total flavonoid content of grapefruit juice treated by microwaves and found no significant difference in the initial flavonoid values with conventional pasteurization; thus, the use of microwaves is a preservation method that generates better retention of individual flavonoids, representing a good alternative to conventional pasteurization.

Antioxidant capacity (AC)

The results obtained for AC are presented in Table 1 and are expressed as equivalent millimoles of Trolox (TE) per kg of the sample (mmol TE/kg). Initial values in concentrated tomato purees were within the range of 1.09- 1.79 mmol TE/kg reported by Podsedek et al., [32] for different tomato products. Tomato purees supplemented with seeds and skin showed increases in AC between 17.11 and 18.01 % compared to concentrated purees. The AC of the hydrophilic extracts of the fresh fruit is mainly due to the compounds contained in the seeds and skin of the fruit [30].

Lycopene

The lycopene contents in the different stages of processing of the tomato purees (scalding, concentrated, salted, and supplemented) were similar to those of the fresh fruit. Therefore, in Table 1, only the results obtained in the raw material and the final products are shown. The main carotenoid in tomatoes is lycopene, which represents 80 % of the total carotenoids, followed by β-carotene, lutein, and cis-lycopene [32]. The lycopene concentration in the saladette tomato was within the range of 18.2 - 80.5 mg/kg reported by Odriozola et al. [33] for different tomato varieties grown in Spain. The lycopene contents in fresh tomatoes reported in the literature vary considerably due to different techniques in fertilization, harvest time, and selected variety but are usually between 20 - 160 mg/kg wb [28]. In concentrated tomato purees, the amount of lycopene obtained is comparable to that reported by Xianquan et al. [34] for different tomato products: tomato sauce (62 mg/kg wb), tomato soup (79.9 mg/kg wb), and ketchup (99 - 134.4 mg/kg wb). An increase in lycopene concentration in the final products in comparison to the fresh fruit was obtained (Table 1). Shi et al. [35] reported that during heat treatment, several factors affect the lycopene content in food, such as the higher extraction of this compound from the matrix, since heating can break the cell wall and release more lycopene content from the tomato matrix, mainly in the form of trans isomers, which is the predominant form of lycopene in tomatoes (94 - 96%). Xianquan et al. [34] reported that during the processing of tomato products, there are two changes in lycopene: 1) isomerization of certain trans- lycopene forms to mono-cis or poly-cis forms, and 2) oxidation of the molecule, which will depend on the time of exposure to processing (cooking, drying and/or heating). In contrast to β-carotene, lycopene remains relatively resistant to cis-conversion during the processing of tomato products. The carotenoids present in tomato products are more bioavailable than those present in fresh fruit; in fact, heat treatment may be responsible for increasing the in vivo bioavailability of carotenoids [34].

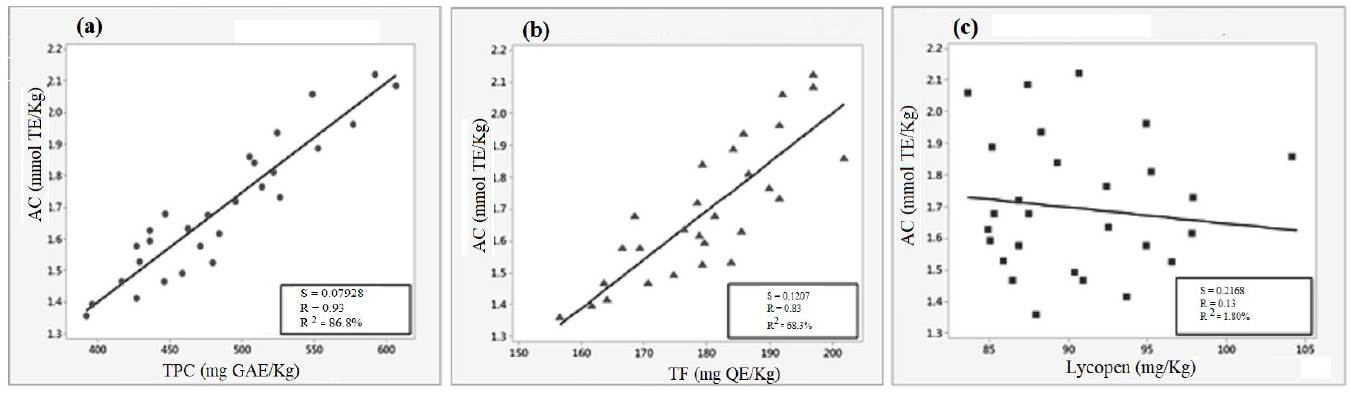

Relationship between antioxidant capacity (AC) and the content of phenolic compounds

Fig. 1(a, b, c) shows the relationship obtained between the content of bioactive compounds and the antioxidant capacity of the samples under study. (a) The relationship between AC and the content of phenolic compounds was statistically significant (R = 0.93) (p < 0.05), with a coefficient of determination greater than 70 % (R2 = 86.3 %), suggesting that these compounds contribute significantly to antioxidant activity in tomato puree samples. This result coincides with that reported by Podsedek et al. [32], who obtained a positive correlation (R = 0.94) between the antioxidant activity and the total phenolic compounds present in the hydrophilic fractions (phenolic compounds and vitamin C) of different tomato products. (b) The antioxidant activity and flavonoid content (p <0.05) had a positive correlation (R = 0.83), with the coefficient of 2 factors also contribute to AC. Slimestad and Verheul [3 products is provided by phenolic compounds, whi antioxidants, such as phenolic acids and stilbenes, whic lycopene content and antioxidant capacity was not stati the variables was < 0.70 (R = 0.13), indicating that ther in the samples was evaluated by the hydrophilic fractio evaluated in this fraction; therefore, a way to assess th technique of quantification of antioxidant activity with and lipophilic extractions. Therefore, phenolic compo hydrophilic fraction of food. As several authors have pointed out, vitamin C could be related to the AC; however, in tomato products, ascorbic acid is affected by heat treatment, with losses of 60 - 96 % reported [37,38].

Shelf life

Slight variations in the physicochemical parameters of the different tomato purees evaluated during storage were observed concerning their initial values; however, after 90 days, the physicochemical results were within the intervals established by the Mexican Standard [6] (NMX-F-033-1982). By decreasing the °Brix (from 11.02 ± 0.10 to 10.78 ± 0.05), the relative density (from 1,062 ± 0.001 to 1,010 ± 0.002) and the titratable acidity decreased (from 0.96 ± 0.05 to 0.89 ± 0.06 % of citric acid). This may be due to the reactions of solute interactions with the matrix and their stability at room temperature. The pH value remained almost constant during the 90 days (it varied from 3.96 to 4.03); likewise, due to the tightness of the bottles, the humidity values did not show a significant difference (p> 0.05). For the purees supplemented with the seed and skin powder, phase separation in the food was observed after day 45, which caused a decrease of °Brix; this separation is due to the presence of occluded air and the size of the particles that comprise the supplement powder, since the larger the diameter of the particles, the less they can be held in the fluid column, meaning that they tend to fall due to the effects of gravity. The physicochemical parameters define the state of food quality (normal, decomposing, adulterated, etc.) and serve to make decisions about handling and processing conditions; they are also related to the stability of bioactive compounds in products derived from vegetables. In the bioactive compounds , a significant decrease in total phenols (p <0.05) was observed during the 90- day shelf life (Fig. 2(A)), with percentages of degradation of 18.95 % for pasteurized tomato purees and 22.90 % for microwave-treated purees; these results coincide with that reported by Yilmaz and Karadeniz, [39] who found a 22.48 % decrease in total phenols present in quince nectar stored for 9 months at 20 °C. They also found that at higher storage temperatures, the degradation of phenolic compounds was higher. Total flavonoids (Figure 2B) decreased significantly (p < 0.05) during the storage time. For pasteurized tomato purees, the degradation was 12-14.37 % over the 90 days, while for microwaved purees, the decrease was 15.71-15.48 %. It has been reported that the content of polyphenols such as quercetin decreases significantly during storage because quercetin is a flavonoid with potent antioxidant activity; therefore, it is more easily oxidized, unlike rutin, in which the 3-hydroxyl group of the C ring is occupied by sugar fractions, which makes it more stable [38]. During storage, the enzyme peroxidase can be involved in the oxidative relationships of the phenolic compounds that are capable of interacting with oxygenated reactive compounds, transferring one or two hydrogen atoms to these compounds, and generating quinones. During shelf storage, glycosylated flavonoids and phenolic acids are more stable against oxidation than aglycones, probably due to the blockage of the 3-hydroxyl group in the C ring of its chemical structure [38]. Flavonoids are phenolic compounds present in fruits and vegetables. Their relevance is justified not only by the quality of food in terms of its visual appearance and taste but also from the point of view of health since they are related to the prevention of degenerative diseases [31]. Among the main flavonoids present in tomato products are quercetin, rutin, and naringenin. Light, temperature, and oxygen are the main factors related to the loss of lycopene during storage [35]. In the present study, a loss of 10.52 - 16.97 % of the lycopene content was obtained during the 90 days of storage at room temperature (Fig. 2(C)). The antioxidant capacity decreased significantly (p < 0.05) (Fig. 2(D)), with reductions of 23.80 % for pasteurized tomato purees and 26.83% for microwave-treated samples. This decrease is due to the decreases in antioxidant compounds, such as total phenols and flavonoids, present in the samples.

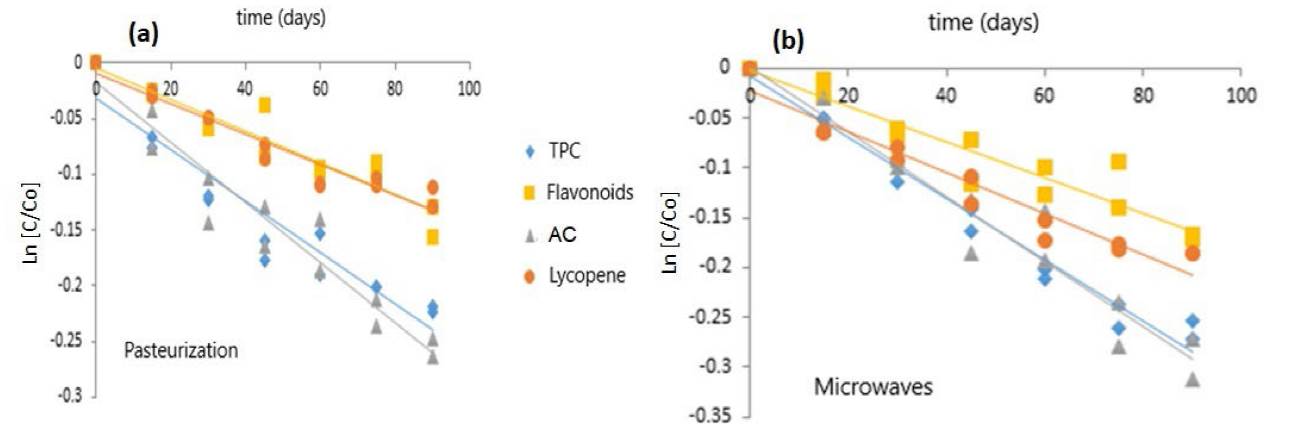

Kinetics study

The kinetics of the bioactive compounds for 90 days at room temperature are presented in Fig. 3(a) and (b), and they were adjusted to the first-order kinetics model since coefficients of determination (R2) ≥ 90 % were obtained. Table 2 shows the kinetic parameters of reaction rate (k), half-life (t 1/2), and coefficient of determination of R2 for the bioactive compounds of processed tomato purees. In each of the bioactive compounds, the coefficient of reaction speed was higher in tomato purees treated by microwaves since this treatment generates direct heating of the food and reaches higher temperatures in less time; thus, the reaction speed can be related to the most pronounced damage produced in the food cells when subjected to this heat treatment [5]. The most labile bioactive compounds were total phenols, with a higher reaction rate and a shorter half-life (223 -301 days) compared to total flavonoids (385 - 495 days) and lycopene (330 - 495 days). The antioxidant capacity presented similar behavior to total phenols since the hydrophilic fraction used to determine the antioxidant capacity in tomato purees is mainly composed of phenols and ascorbic acid, which is known to be a thermolabile compound. Total flavonoids were less susceptible to degradation, since, during storage and heat treatment, most of these compounds are glycosylated and, therefore, generate more stable molecules [31]. The degradation rate constant k of the analyzed components was similar in the applied treatments (pasteurization and microwave). On the other hand, the half-life obtained by microwave was slightly lower than that obtained by the pasteurization process. This may be because the pasteurization treatment was at a higher temperature, which could cause greater stability of the sample tomato components like lycopene.

Fig. 3 (a) Bioactive degradation kinetics in pasteurized tomato purees, (b) Microwave treated, Average ± standard deviation, n = 6. Results expressed on a wet basis (wb).

Table 2 First-order kinetics parameters of tomato puree bioactive compound during storage (90 days, 25 °C).

| Bioactive compound | Conventionally pasteurized tomato purees | Microwave treated tomato purees | ||||

|---|---|---|---|---|---|---|

| k (días-1) | t1/2 (días) | R2(%) | k (días-1) | t1/2 (días) | R2(%) | |

| Total phenolic compounds | 0.0023 | 301.36 | 91.09 | 0.0031 | 223.59 | 97.69 |

| Total Flavonoids | 0.0014 | 495.10 | 90.29 | 0.0018 | 385.08 | 90.95 |

| Antioxidant activity | 0.0027 | 256.72 | 93.73 | 0.0033 | 210.04 | 94.98 |

| Lycopen | 0.0014 | 495.10 | 93.78 | 0.0021 | 330.07 | 93.83 |

K, Reaction rate coefficient in days t1/2, Half-life; R2 , Determination coefficient adjusted to percentage

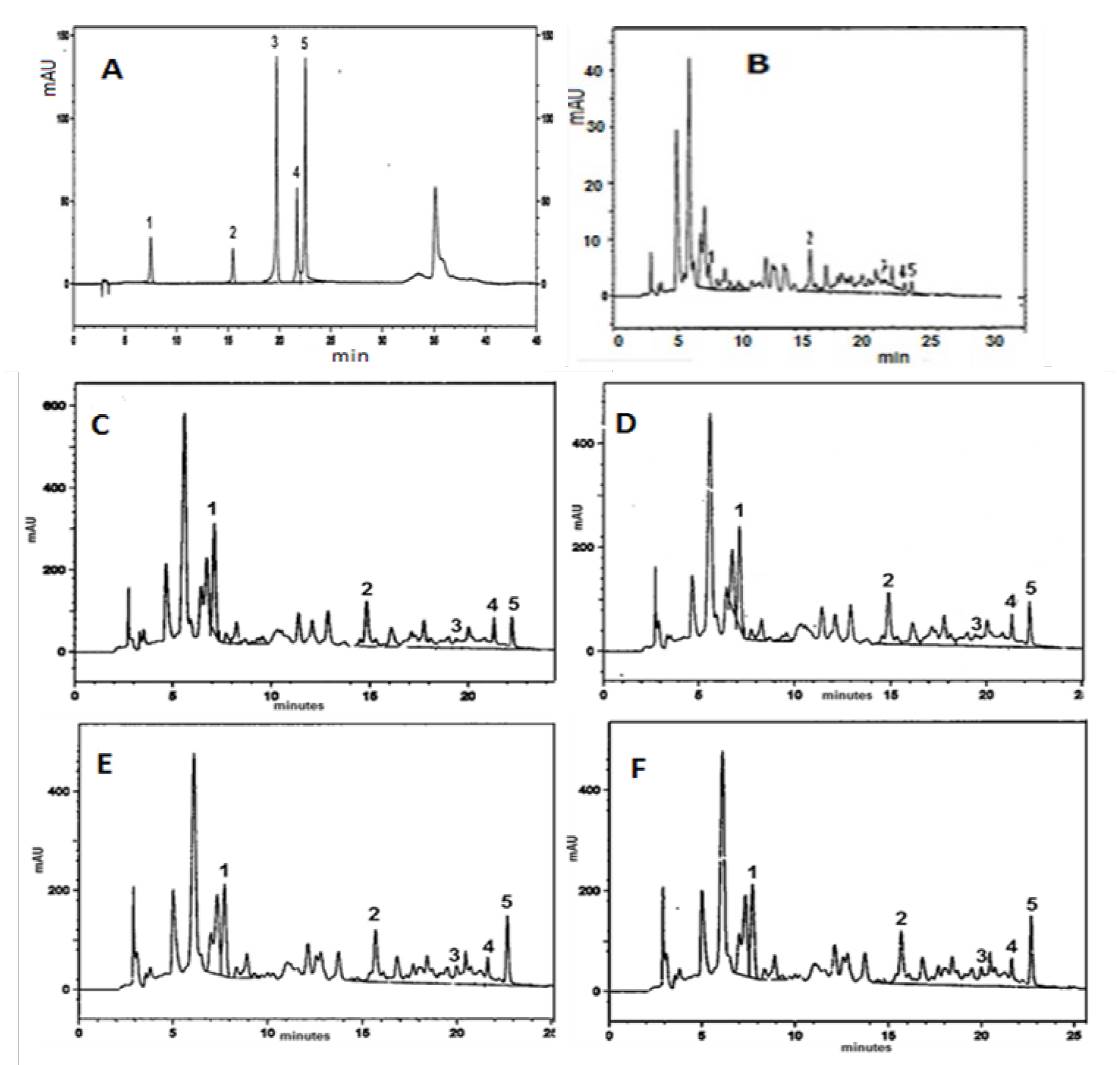

Individual phenolic compounds

The chromatograms are summarized and shown in Table 3 and Fig. 4. In all the samples analyzed, the five selected phenolic compounds were identified, with rutin being the most concentrated, in agreement with that reported by various authors [36,38]. In general, the contents of all the phenolic compounds analyzed increased considerably when applying any of the different heat treatments, with similar values between the different techniques (pasteurization and microwave) compared to the values obtained for fresh tomatoes. The use of microwaves was a better alternative to conventional pasteurization due to the retention of all the bioactive compounds analyzed in the different samples and the shorter time spent treating the tomato products.

Table 3 Phenolic compounds in saladette tomato and tomato puree expressed on a dry basis (mg/kg db).

| Chloragenic acid | Rutin | Resveratrol | Quercetin | Naringenin | ||

|---|---|---|---|---|---|---|

| Fresh fruit | tomato | 128.85 ± 14.27 | 277.45 ± 13.04 | 4.58 ± 0.00 | 7.34 ± 3.37 | 9.33 ± 0.39 |

| oncentrated puree | Conventional Pasteurization. | 143.36 ± 7.74 | 202.99 ± 5.98 | 6.29 ± 0.06 | 42.92 ± 4.48 | 19.78 ± 0.53 |

| Microwave | 150.20 ± 6.34 | 226.77 ± 8.28 | 6.96 ± 0.12 | 47.90 ± 5.83 | 21.81 ± 0.57 | |

| Added puree | Pasteurization | 166.73 ± 7.92 | 190.79 ± 0.28 | 10.36 ± 0.48 | 75.62 ± 2.49 | 27.59 ± 1.64 |

| Microwave treatment | 155.73 ± 8.70 | 169.55 ± 5.68 | 12.15 ± 0.72 | 73.69 ± 6.80 | 27.03 ± 1.87 | |

*Mean ± standard deviation

Fig. 4 HPLC chromatograms at 280 nm: (A) Standards: 1: chlorogenic acid; 2: routine; 3: resveratrol; 4: quercetin; 5: naringenin. (B) Fresh tomato, (C) Pasteurized concentrated tomato puree, (D) Microwave treated concentrated tomato puree, (E) Pasteurized added tomato puree, (F) Microwave treated added tomato puree.

Microbiological activity

The determinations of the diacetyl concentration in tomato purees were made for 90 days at room temperature. The initial values (day 0) of diacetyl concentration in tomato purees subjected to conventional pasteurization and microwaves did not present a significant difference (p> 0.05). Both heat treatments achieved similar microbial inactivation. After day 45 of storage, an exponential increase in the diacetyl concentration was found in the different purees treated by both thermal methods. Despite the increase in diacetyl concentration, at the end of the 90-day storage, the values were within the permissible diacetyl content for processed products, which varies from 0.6 to 6 ppm depending on the desired specifications [40]. On the other hand , the mold and yeast count in all samples contained in independent bottles and analyzed every 15 days were negative (< 1 CFU/mL), while the positive control that was obtained with a sample of tomato puree without heat treatment and stored for 15 days at 25 °C presented 15 CFU/mL. Therefore, with microwave heat treatment, inhibition of the growth of microorganisms was comparable to the efficiency of conventional heat treatment was achieved. The preservative effect of the microwaves and the bactericidal effect they produce are functions of the heat that is generated; that is, the microwaves themselves do not give rise to any type of inactivation of foodborne microorganisms, but, in reality, it is the heat produced by the excitation of the product’s molecules that produces the destruction. Several studies have reported the kinetics of destruction of microorganisms such as Saccharomyces cerevisiae, Lactobacillus Plantarum, and Escherichia coli, as well as the inactivation of enzymes (pectin methyl esterase, lipoxygenase, and lipases) under a continuous flow of microwave heating (915 MHz and 2450 MHz), and it has proven to be more efficient than conventional pasteurization [41].

Sensory evaluation

The sensory evaluation was assessed by means of tests (discriminative and descriptive) and by the quantitative determination of color (CIELab). The evaluation of the tomato purees carried out by the panelists, of which 92% agreed on the following results: the microwave-treated tomato puree presented a less acidic taste, a more intense red color, and a pleasant aroma compared to the pasteurized tomato puree. This agrees with the result of physicochemical tests where no significant difference was found in the titratable acidity content in the different thermal treatments; however, a difference in acidity was noticeable for the panelists, who commented that the microwave-treated puree had a less acidic and more pleasant taste. This difference may be because microwaves tend to better preserve the thermolabile and volatile compounds of foods due to their rapid heating and protect the natural pigments from degradation than those that are treated by prolonged heat treatments [42]. In the descriptive analysis (Scale of attributes), the tomato puree supplemented with skin and seeds was evaluated as having a highly astringent flavor compared to the concentrated tomato puree and the commercial one, which resulted in a medium astringent flavor. This is because the seeds and skin contain a greater amount of polyphenols, such as phenolic acids, which tend to confer more astringent and acidic flavors to food. The tomato puree supplemented with skin and seeds was evaluated as having a similar sensation of texture to the concentrated tomato puree may be because of the homogeneity of the seed and skin powder, which was vigorously ground and filtered. The commercial tomato puree presented 4° Brix, while the purees processed in the present work presented between 10 - 13 °Brix, which could be the reason for the differences found in the consistency of the evaluated products. At the industrial level, the skin and seeds of the fruit are discarded because it is thought that they can confer an undesirable texture and a strange flavor to the final product. According to the individual values of L, a, b, of the CIELab system, the tomato puree supplemented with seeds and skin of the fruit treated by microwaves had a color profile similar to that of fresh tomatoes.

Color determination

The determination of color was carried out in the saladette tomato purees added with the skin and seeds of the fruit and in the fresh fruit. Color variation was analyzed when applying heat treatments: conventional pasteurization and microwave treatment. The results of the values of "L", "a" and "b" of the CIELab system and the total color difference (ΔE*) compared to the fresh tomato (standard) are shown in Table 4. The value of "L" for the fresh tomato was higher than that of the samples with thermal treatment, which indicates greater luminosity than the thermally processed products. Regarding the "a" value, it has been pointed out that the red color of tomatoes is due to the presence of the carotenoid, lycopene; in ripe tomatoes, lycopene is responsible for 90% of the pigment, a correlation of 0.887 has been shown between the a/b value and the amount of lycopene present in tomato products [19], therefore that the higher values in the fresh fruit and in the puree treated by microwaves, may indicate greater retention of the bioactive compound in the food, compared to the puree subjected to conventional pasteurization. The results obtained from the “b” value, for fresh tomato and purees, indicate that the color of the products tends to degrade a little towards orange as the value increases. In general, the total color difference value (ΔE*) was less than 3.0 for the two different tomato purees added and subjected to different heat treatments, this indicates that color variations compared to fresh tomato are not perceptible for the average human eye. According to the individual values of L, a, b, from the CIELab system, the tomato puree added with seeds and skin of the fruit treated by microwaves presented a color profile more similar to that of fresh tomatoes than conventionally pasteurized tomato puree. This result coincides with what was reported by Sun et al. [43], who found better color retention in microwave-treated vegetables compared to vegetables subjected to conventional heat treatments (sterilization and pasteurization); on the other hand, Benlloch-Tinoco et al. [42] worked with kiwi puree at different microwave powers and heating times, pointing out that the color of the food tends to degrade with longer times of exposure to heat. Microwave heating is 3-5 times faster than conventional heating; therefore it has the potential to improve product quality by reducing heat exposure time [43].

Table 4 Color values for fresh tomato and tomato puree added with seeds and skin.

| Sample | L | A | b | ΔE* |

|---|---|---|---|---|

| Fresh tomato | 32.5 ± 0.4 | 37.2 ± 0.5 | 28.5 ± 0.4 | - |

| Tomato puree added conventional pasteurization | 31.2 ± 0.5 | 36.6 ± 0.2 | 30.0 ± 0.2 | 2.20 |

| Tomato puree added microwave treatment | 31.1 ± 0.9 | 36.8 ± 0.3 | 29.7 ± 0.3 | 2.17 |

ΔE* value compared to fresh tomato

Results in the pilot plant

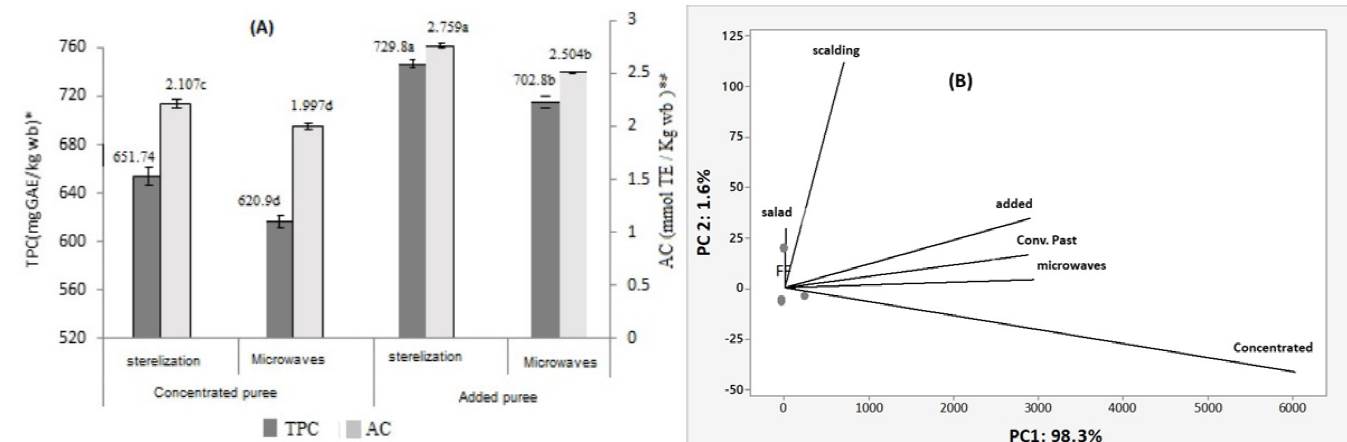

The results for the bioactive compounds obtained in the tomato puree processed in the pilot plant are presented in Fig. 5(A). The total phenolic concentrations achieved with the laboratory and pilot plant equipment showed statistically significant differences (p <0.05). At the pilot plant level, a higher value of total phenols was obtained in the final product, with the same observed during all processing stages, with results in wet basis (wb) (concentrate: 450.7 mg GAE/kg, salty: 459 mg GAE/kg, supplemented: 582.2 mg GAE/kg), compared to those obtained at the laboratory level (Table 1). Similar results were obtained for antioxidant activity at the pilot plant level (concentrate: 1,688 mmol TE/kg, salty: 1,685 mmol TE/kg, supplemented: 2,005 mmol TE/kg) and at the laboratory level (Table 1). The difference between the equipment used is mainly due to the greater evaporation capacity, homogeneous heating, and higher temperature (> 121 °C) reached in the equipment used in the pilot plant. Prolonged heating can cause greater damage to the cell and therefore generate the greatest release of bioactive compounds from the matrix [44]. Graziani et al. [45] reported that during intense heating, the formation of non-enzymatic darkening compounds, which have antioxidant properties and can balance the decrease of natural antioxidants, such as carotenoids and ascorbic acid, in the food is promoted, which may be the reason whereby the values of antioxidant properties are higher in mashes subjected to sterilization compared to those treated by microwaves.

Fig. 5 (A) Total phenolic compounds (TPC) and Antioxidant Capacity (AC) in tomato purees made in pilot plant. mean ± standard deviation, n=6. *mg galic acid equivalents/kg sample wb; **mmol Trolox equivalents/kg sample wb. a,b,c,d Different letters indicate significant difference (p < 0.05). (B) Analysis of main components (PCA) of the processing stages.

Microwave treatment at the industrial level involves heating the food in a continuous flow, which generates advantages over batch treatments, with increased productivity, ease of cleaning, and automation [9], [46]. As has been shown in several investigations, tomato consumption is encouraged for the prevention of chronic illnesses like diabetes, cardiovascular diseases, and others, due specifically to its mineral and vitamin content [47].

Understanding how processing affects the natural source is extremely important since each stage of the process can modify the composition, content, and type of antioxidants present. The present paper provides an overview of one of the uses of the tomato produced in Mexico and proposes an alternative to include the skin and seeds in the processing, thus valuing the secondary and waste fractions of the tomato. The remains from the industry of processed tomato products give rise to other by-products with added value [48].

Influence of the processing stages on antioxidant properties

Fig. 5(B) shows the vector graph based on their correlation with the two main variability factors. During the preparation of tomato puree, each stage could influence the chemical composition and the final characteristics of the product. Principal component analysis (PCA) was used to reduce the number of variables and detect relationships between each stage of the process during the preparation of tomato purees, analyzing the contents of total phenolic compounds, total flavonoids, AC, lycopene, and soluble solids. The first main component (PC1) explained 98.3 % of the total variation of the data; this component indicates the predominant processing stages in the preparation of tomato purees, and it corresponds to the heat treatments applied. The greatest variation in bioactive compounds occurred during the concentration stage of tomato juice (75.5 %), which generated an increase in the content of bioactive compounds. The second component explains 1.6 % of the total variability of the data and is strongly related to the scalding stage (86.8 %) and to a lesser extent to the stages of supplementation (26.6 %) and salting (22.7 %); this variability is due to the mechanical action during the slicing of the fruits (scalding) and to the agitation during salting. In Fig. 5(A), it is possible to interpret the distances between the points in terms of similarity, as observed in conventional pasteurization and microwave treatment. Both treatments generated comparable retention of antioxidant compounds; however, the microwave treatment used less time for exposure of the food to heat, which is an advantage over pasteurization [23].

The purpose of the comparative study of heat treatments in pilot plant and laboratory was to determine the stage in which the bioactive compounds undergo changes in their concentration, and it was verified that it was in the concentration stage and heat treatments. In addition, the samples added with tomato seeds and skin increased the antioxidant capacity of the samples as well as the sterilization that was used in the pilot plant.

Conclusions

The PCA analysis showed that the processing stages that affect the polyphenolic content in the elaboration of tomato purees corresponded to the heat treatments appliednd and the concentration stage. The greatest increasein bioactive compounds occurred during the concentration stage of tomato juice. The microwave treatment of tomato products represents an alternative to conventional pasteurization since it uses less treatment time and preserves bioactive and thermolabile compounds; the puree presents a less acidic taste, more intense red color, and pleasant aroma, with a similar sensation in the texture compared to pasteurized tomato puree. In addition to the above, microwaves inhibit the growth of microorganisms that could alter the quality of food. At the pilot plant level, the sterilized products had a higher concentration of antioxidants compared to those treated by microwaves. The tomato puree supplemented (with the skin and seeds of the same fruit) and treated by microwaves can be considered potentially functional since it features higher concentrations of bioactives.The remains from the industry of processed tomato products (including peel and seeds) give rise to other by-products with added value.

nueva página del texto (beta)

nueva página del texto (beta)