Introduction

Walnut is an important dry fruit of Juglans species and a source of healthy oil. The most important specie of Juglans is Juglans regia also known as Persian or English nut which is among the few useful plants that naturally grow both in Eastern and Western hemispheres of the earth [1]. Walnut contains significant amounts of antioxidants, omega (ω) 3 and ω-6 polyunsaturated fatty acids (PUFAs), vitamin E, minerals (Fe, Na, Ca, Mg, P), proteins and fibers [2]. Walnut oils are in a continuous interest in food industries because of their fatty acids profile, particularly the appropriate amounts of ω-3 and ω-6 PUFAs essential dietary fatty acids [3]. These fatty acids play a vital role in the prevention of depression as well as cerebral dementia in human being. The walnut oil consists of greater amount of oleic and linoleic acid in their composition [4]. Furthermore, walnut oil had been used extensively in the well-known Ayurvedic and Greek medicines as well as in the homeopathic and allopathic system of medicines for treating various ailments. The oil is also medicinally important as reported to possess strong hepatoprotective, antidepressant, antidiabetic as well as anti-inflammatory activities [5-8]. A well-known quinone; Juglone has been obtained which is a potent cytotoxic agent against various human tumor cell lines, especially human colon carcinoma [9]. Other isolated compounds include polyphenols (tellimagrandin I), tannins, vanillic and gallic acid, adenosine, flavones, and their derivatives. [10].

Pakistan is ranked eighteen in the world with total of 85,736 tons of walnut production [11]. The effect of various collections sites at different altitudes on physicochemical properties of nuts had been reported in literature [12,13]. It has been observed that altitude, rainfall, and temperature are important factors which effect the walnut properties and consequently change its various physicochemical properties. The altitude and temperature effects on cracking of walnut shell were observed by Koyuncu et al (2004) [14]. Since temperature changes with change in altitudes, therefore the walnuts oil extracted from sites with difference in altitudes will have different physicochemical properties. One basic reason for studying altitude effect is that plants consume different nutrients in presence of different amount of rainfall, temperature, and amount of sunlight, which are directly related to plant growth and fruits composition. The Northern areas of Pakistan are rich in walnut production due to the natural forests and having difference in ecology among these areas. Therefore, the aim of this study was to extract walnut oil from Juglandaceae regia L and to study the variations in their physicochemical properties; density, surface tension, viscosity, saponification values, acid value as well as GC/MS analysis of the oils. Olive oil is one of the best oils according to their important composition and health benefits. This oil has unique properties in reducing blood pressure and inflammation and can help in prevention of unwanted blood clotting. Olive oil has a relatively lower smoke point compared to other oils, so it is best for low and medium heat cooking and can use in development of different food products. Therefore, the physicochemical properties of extracted oils were also compared to the standard olive oil for better understanding of utilizing these oils in development of food and other products.

Experimental

Sample collection

The walnut samples were collected from local markets located in the six selected districts tabulated in Table 1. A global position system (GPS) was conducted to collect the absolute location of sample sites as shown Fig.1.

Table 1 Illustration of various physicochemical parameters obtained for all the walnut oil samples (A-F) compared to standard olive oil.

| Sample site | Altitude (m) | Sample name | Density (g/cm3) | Surface tension (N/m) | Viscosity (in centipoises) | Saponification values (mg KOH/g of oil) | Iodine values (g I2/100 g of oil) | Acid value (mg KOH per gram oil) |

|---|---|---|---|---|---|---|---|---|

| Upper Chitral | 1,494 | A | 0.984±0.03d | 35.44×10-3±1.04d | 17.5562±0.55c | 128.05±2.09b | 66.49±2.11d | 4.9±0.01c |

| Drosh | 1,359 | B | 0.994±0.01b | 40.62×10-3±1.79a | 16.8706±0.01d | 168.3±1.90a | 41.11±7.61e | 4.8±0.71c |

| Sheringal | 1,369 | C | 0.994±0.10b | 36.04×10-3±0.81c | 21.9143±0.71b | 88.15±0.96d | 28.42±0.12f | 4±0.01d |

| Kalam | 2,001 | D | 0.985±0.01c | 36.71×10-3±0.90c | 17.7437±0.73c | 112.2±1.76c | 70.87±0.77c | 5±0.81b |

| Madyan | 1,320 | E | 0.981±0.07e | 34.76×10-3±1.96e | 15.0595±0.65e | 84.15±3.71e | 104.56±2.91a | 3.5±0.01e |

| Shangla | 2,500 | F | 0.985±0.01c | 35.95×10-3±0.05d | 15.7163±0.90e | 112.2±0.88c | 28.42±3.00g | 3.9±0.31de |

| Olive oil | Standard | G | 0.990±0.01a | 38.43×10-3±0.78b | 39.994±0.16a | 56.1±0.19f | 91.87±0.77b | 6.7±0.66a |

Different letters (a-g) represent significant difference between same parameters of the different walnut oil samples.

Extraction of oil

The walnuts were peeled off (removed hardcover), weighed, and ground to powder using an electric blender. The powdered material was treated with n-hexane (w/v = 1:10) using a magnetic stirrer for 2 hours to obtain n-hexane extract. After filtration, the obtained filtrate was concentrated in a rotary evaporator at 40 °C for obtaining the oil and stored at 4°C for further experiments.

Determination of viscosity

Fixed volume of oil was subjected to determine its viscosity using the viscometer [15]. The time of flow was noted and viscosity was calculated by the following equation.

where tl = time flow of the given liquid oils, dl = density of the sample. dw =density of the reference value (water), tw = time flow of the reference value (water), and nw are constant and value is 0.8990 c.p.

Determination of surface tension

Surface tensions of the oils were determined by stalagmometry method. The following equation was used to determine the surface tension of the oils.

where, r1 = surface tension of the given sample, r2 = surface tension of the reference liquid d1 = density of the sample, d2 = density of the reference liquid (water), n2 = number of drops of water, n1 = number of drops of the sample.

Determination of density

A specific gravity bottle method was used to determine the oil density while following the below equation

where, m = mass of the sample, v = volume of the bottle.

Determination of acid value

A known quantity of oil sample was taken and mixed with a 10 to 12 mL mixture of methanol/chloroform solution followed by the addition of 0.5 g charcoal. The mixture was kept overnight. A clear layer of lipid was collected from the mixture. Afterward, 2-3 drops of phenolphthalein indicator were added and titrated against 0.01 N KOH solution. The volume of the solution was noted at the point of color change and repeated the same procedure for three times. The following equation was used to calculate the acid [16].

where, X = Volume of KOH used for the sample, Y =Volume of KOH used for the blank.

Determination of saponification value

Oil samples were mixed with 30 mL ethanol and 25 mL of 0.5 N KOH. The mixture was heated for 30 min and then cooled to 25 °C. Few drops of phenolphthalein were added and titrated the mixture against 0.5 N H2SO4 till the endpoint reached (color change to red). The volume of titrated solution upon which the color changed was noted and the same was done with the blank sample. The saponification value was calculated with the following equation [16].

where, X = Volume of H2SO4 used for the sample, Y =Volume of H2SO4 used for the blank.

Determination of iodine value

Oil samples were dissolved in 20 mL of CCl4 and then Wijis reagent (25 mL) was added. This mixture was left in dark for 30 min, followed by titration against 0.1 N Na₂S₂O•5H₂O. At the point when the color change to yellow 1 mL of starch solution was added to bring blue color. The titration was repeated for the mixture till the color disappeared and the volume of 0.1 N Na2S2O3•5H2O was noted. The same procedure was repeated for the blank sample. The following equation was used to calculate the iodine value [16].

where, X = Volume of Na2S2O3•5H2O used for the blank, Y = Volume of Na2S2O3•5H2O used for the sample.

Gas Chromatography (GC)

An “Agilent USB-39376752 gas chromatograph (Agilent Technologies, Palo Palo Alto, CA, USA) with HHP-5MS 5 % phenyl methylsiloxane capillary column (30 m) (0.25 mm × 0.25 μm) film thickness; Restek, Bellefonte, PA) equipped with an FID detector”, career gas “helium” was used for GC analysis. The temperature was kept dynamic as the oven initial temperature retained at 70 ºC for 1 minute, proceeded by the increasing rate of 6 ºC/min to 180 ºC for 5 minutes and finally at 5 ºC to 280 ºC for 20 minutes (injector/detector set in the range of 220-290 ºC). The flow of helium was maintained at 1mL/min while the injection mood of samples (1/1000 in pentane, v/v) was maintained in a split less mood.

Gas Chromatography and Mass Spectrometry (GC/MS) analysis

GC/MS analysis of samples was processed using an Agilent USB-393752 gas chromatograph (Agilent Technologies, Palo Alto, CA, USA) with an HHP-5MS 5 % phenylmethyl siloxane capillary column (30 m × 0.25 mm × 0.25 μm film thickness; Restek, Bellefonte, PA) outfitted with an Agilent HP-5973 mass selective detector in the electron impact mode (Ionization energy: 70 eV) working under the same experimental conditions as described for GC.

Identification of components

The individual compounds were identified using extensive comparative analysis with the spectral data retained in the system library on the same conditions. A comparison of the mass fragmentation pattern confirmed the assignments with our data [15].

Statistical analysis

All the experiments were carried out in triplicate while the data was analyzed through one-way ANOVA. SAS 8.1 software (SAS Institute Inc., NC, USA) was used in calculating Duncan multiple range test P < 0.05 to which the means were compared.

Results and discussion

The densities measured at room temperature for all the samples as compared to the density of olive oil (0.990 g/cm3) have been provided in Table 1. The data suggest that amongst all, B and C showed higher densities i.e. 0.994 and 0.994 g/cm3 than all the samples while lower density values were obtained for samples A, D, E, and F (0.984, 0.985, 0.981, 0.985 g/cm3) respectively. It has been observed that the density of edible oils is dependent on their fatty acid composition, minor components as well as temperature [17]. As specified in literature [17,18] the density of edible oils decreases with an increase in temperature and has been well established for all the studied oils. The lower values of densities alternatively show more unsaturation probably because of omega 6 fatty acids while the increased values are indicative of higher saturation of fatty acid contents as well as extra polymerization in the oils [19]. Our results show an almost similar pattern of densities values obtained for different edible oils at room temperatures, such as corn oil, mustered oil soybean oils except for peanut oil which shows relatively lower density values [20]. In the current studies, the walnut oil of Madyan (E) has the lowest density as compared to standard olive oil while the samples obtained from Kalam and Upper Chitral also showed lower densities. Drawing inference from the data, the walnut oils of the areas of swat (excluding Shangla), as well as the Upper Chitral region, contain more unsaturated fatty acids thus have better quality for further application in food industries.

The surface tension was measured at room temperature for all the samples and was compared to the standard olive oil, enlisted in Table 1. The data revealed that that amongst all, sample B showed a higher value of surface tension; 40.62×10-3 N/m while all the other samples showed lower surface tension values (A= 35.44×10-3 ,36.04×10-3, 36.71×10-3, 34.76×10-3and 35.95×10-3 N/m) compared to olive oil (38.43×10-3 N/m). The lowest value was observed for the walnut oil sample E obtained from the Madyan area. It has been observed that the larger values of surface tension are related to the more cohesive forces of attraction between the oil molecules at the surface. The lower values of surface tensions for oils are due to the weak London forces of attraction amongst their molecules. The lower values of surface tension alternatively provide more surface area for better chemical reactions or any other processes when commercially used hence improve the volubility of the oils [21].

Viscosities of all the samples were measured according to standard protocols and have been provided in Table 1. According to the results, all the oil samples showed lower viscosities at room temperature as compared to the standard, olive oil (39.9944 cp). The highest viscosity value was obtained for sample C; 21.9143 cp while the lowest value was obtained for sample E; 15.0595 cp. All the other samples showed viscosity values between 15 to 17 cp respectively. There are two ways for measuring the viscosity of oils, absolute viscosity, and kinetic viscosity. The absolute viscosity is the resistance to flow due to internal friction while the kinetic viscosity of an oil is its resistance to flow due to gravity [22]. The absolute viscosity is important because it is needed in measuring the oil flow rates, heat unit operations such as heat exchange, freezing points, sterilization, and other properties. Viscosity also depends upon temperature, as an increase in temperature decrease viscosity [23]. It has been observed that the oils having greater viscosities values have a greater composition of saturated fatty acids (above 16 %) while the low viscosity values indirectly suggest that the oils are enriched in unsaturated fatty acids. Viscosity also depends upon the chain length of fatty acids [19]. Our findings are similar as reported earlier in literature [23] where they compared rice bran oil with walnut in which the walnut oil showed the lowest viscosity at room temperature [24]. The sample E from the Madyan area showed the lowest viscosity value as compared to others, indicative of more unsaturation in its composition; hence justifying good quality amongst all.

The saponification values were measured at room temperature for all the samples as compared with standard olive oil, enlisted in Table 1. The saponification value of olive oil was obtained as 56.1 mg KOH/g. All the walnut oil sample showed higher values; A=128.05; B=168.3; C= 88.15; D=112.2; E= 84.15 and F= 112.2mg KOH/g of oil respectively. The more promising value was obtained for sample E (Madyan) which was close enough to the standard saponification value. The saponification value is the number of milligrams of potassium hydroxide required to saponify or neutralize the fatty acids present in one gram of the oil. It is a measurement of the average molecular weight (chain length) of all the fatty acids (free or combined) present in oils. The triglyceride with a high value of saponification is considered to make better quality soaps than those with low saponification values. The presence of long-chain fatty acids (usually in fats) imparts low saponification values because they have a fewer number of carboxylic function group per unit mass of the oil as compared to short-chain fatty acid [25]. Our results indicate that sample E may contain high molecular weights (large chain) fatty acids hence having lower values while the others may contain a high proportion of low molecular weight (small chains) fatty acids as triglycerides and exhibiting larger saponification values. In a previous study, low saponification values were recorded for almond seed oil in comparison with the APCC and Codex Alimentarius [26]. However, a higher saponification value (200 mg/KOH/g) shows a higher percentage of low molecular weight fatty acid Furthermore, such values also indicate that this oil is not suited for the production of soap or any other cosmetic products, while such oil may be used as the essential fatty acid source for human diet [27].

The iodine value was measured as grams of iodine required to neutralize 100 g of oil at room temperature for all the samples as compared to the standard olive oil and provided in Table 1. The data revealed that that amongst all, sample E showed a higher iodine value; 104.56 as compared to all the other samples including olive oil (91.87). The other samples showed lower iodine values (A= 66.49, B= 41.11, C=28.42, D=70.87 and F= 28.42 g I2/100 g of oil). The iodine value equal to the number of grams of iodine required to saturate the fatty acid present in 100 g of the oil. The oils rich in saturated fatty acid have low iodine value, while oil rich in unsaturated fatty acid show higher iodine values [28]. Iodine monochloride (Wijs reagent) in glacial acetic acid reacts with an unsaturated bond to produce a di-halogenated single bond. After the reaction is completed, the amount of iodine that has reacted is determined by adding a solution of potassium iodide to the reaction product. This causes the remaining Iodine monochloride to form molecular iodine. The liberated iodine is then titrated with a standard solution of 0.2M sodium thiosulphate. Starch is used as the indicator for this reaction where the liberated iodine reacts with starch to give the purple-colored product (endpoint). The iodine value is a vital characteristic of oil as it indicates the proportion of unsaturated fatty acid present. The higher the iodine number, the more C=C bond is present in the oil [29]. It has been reported that oil with low iodine value improves the stability and good yield of the liquid oil [30]. High iodine value justifies the utilization of the oil in soap and shampoo production [31]. In the above sample, sample E is of higher iodine value so sample E justifies its utilization in soap and shampoo production. Iodine value or number is also useful as a guide to check adulteration of oil and also as a process control of oil.

The acid values were obtained as milligrams of KOH required to neutralize 1 g of oil at room temperature for all the samples as compared to the standard olive oil and provided in Table 1. The data revealed that that amongst all, sample E showed a lower acid value (3.5) as compared to all the other samples, while the acid value obtained for olive oil was 6.7. The other samples also showed lower acid values (A= 4.9, B= 4.8, C=4, D=5, and F= 3.9 mg KOH /1 g of oil). Higher acid values describe the higher contents of free fatty acids (FFAs) in a sample. Also, the higher the acid values, the higher are the deterioration or rancidity of the oils. As the rancidity increases, the oil achieves a foul smell along with a sour test. The cause of rancidity is the hydrolytic oxidative cleavage of the triglycerides causing the formation of free fatty acids [32]. The acid value also measures the degree to which lipases break down triglycerides in the oil. Rancidity is followed by the formation of FFAs and so acid value or FFA measure is used as a means of knowing the quality and edibility of oil [33]. The acid value of oils indicates the amount of free fatty acid present in the oil. It determines the purity of oils. The higher the values, the lower the possibility of the oils being used for cooking purposes. It was observed that higher and lower acid values obtained for Jui coconut oil and Fresh soybean oil were 18.04 and 0.36, respectively. Higher values indicate that triglycerides of oil are converted into fatty acids and glycerol which cause the rancidity of the oil [34]. Our results suggest that the acid values for all the walnut oil samples are lower which means that the oil contains less amount of FFAs as well as is less likely to deteriorate (longer shelf life). Amongst all, the sample from Madyan possesses lower acid values, hence bears the best quality.

Fatty acid composition of sample E

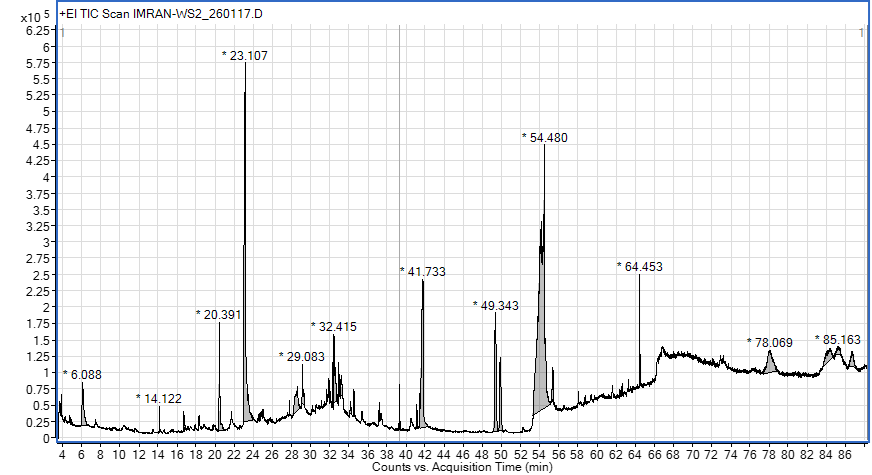

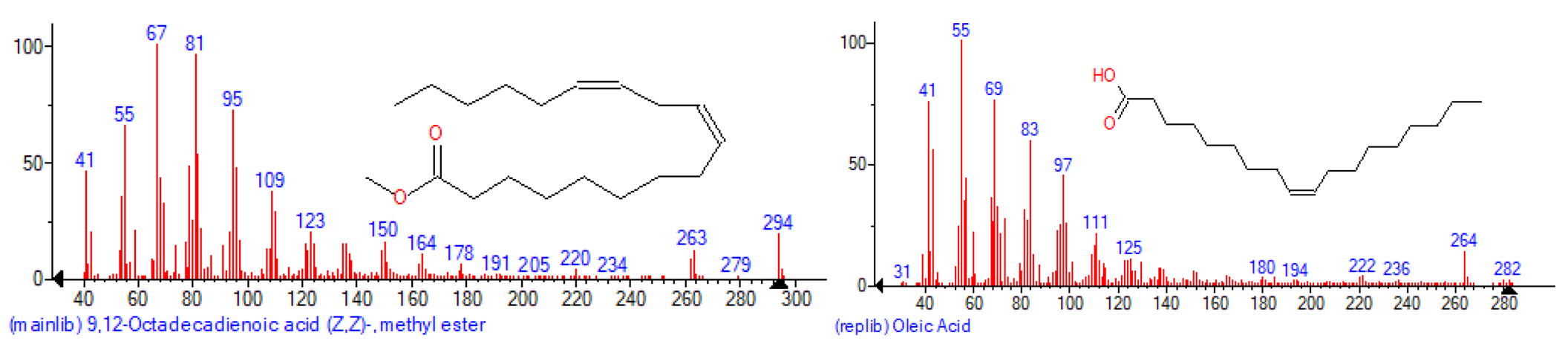

The walnut oil obtained from sample E showed promising physicochemical properties earlier was subjected to combined Gas Chromatography-Mass Spectrometry (GC-MS) to assess the fatty acid contents (Fig. 2 and Fig. 3). A total of 23 peaks was recorded by Gas Chromatography (GC), which were analyzed and quantified. Of the total, identification of individual peaks and their resolutions were obtained by comparison of their retention indexes with the system GC-MS library. These findings have been summarized in Table 2. Apart from other components of the least interest, the major fatty acid found was Oleic Acid (41.55 %) while Linoleic acid methyl ester was detected in 9.1 % quantity.

Fig. 2 Total Ion Chromatogram obtained for sample E walnut oil. *Note: the RT index at 49- and 54 minutes show peaks for linoleic acid methyl ester and oleic acid respectively.

Fig. 3 Mass fragmentation pattern of linoleic acid methyl ester and oleic acid in GC/MS of sample E oil.

Table 2 Percentage composition of the walnut oil obtained from sample E (Madyan) obtained by GC-MS.

| Compound | Molecular Formula | RT (Retention Time) | Area Sum % |

|---|---|---|---|

| Dimethoxybicyclo [3.3.1]nona-2,4-dione | C11H16O4 | 14.12 | 0.37 |

| 2-Furancarboxaldehyde, 5-(hydroxymethyl)- | C6H6O3 | 23.11 | 14.24 |

| 3(2H)-furan-3-one | C6H8O4 | 20.39 | 2.85 |

| Guanosine | C10H13N5O5 | 28.53 | 2.2 |

| 1,1'-Biphenyl, 3,4-diethyl- | C16H18 | 32.41 | 2.69 |

| Estra-1,3,5(10)-trien-17β-ol | C18H24O | 41.73 | 8.75 |

| Linoleic acid methyl ester | C19H34O2 | 49.34 | 9.01 |

| Oleic Acid | C18H32O2 | 54.48 | 41.45 |

| Others (unidentified) | 17.84 |

Overall, the walnut oil of sample E was enriched in oleic acid and linoleic acid which affects its physicochemical properties such as density, viscosity, iodine value, etc. These fatty acids have never been detected in any such quantities earlier up to the best of our knowledge. Other oxygenated hydrocarbons or their derivatives were found in relatively small quantities. The variation in the fatty acids may be due to the difference in altitude and area. Also, the quality and quantity of oleic acid and linoleic acid vary with the difference in chemo and genotype of the species, the methods of extraction as well [35]. In this study, all the oil samples show higher saponification values particularly sample B, which indicates their application in cosmetic industries. However, such oil may not be suitable for cooking purposes. According to the quality standards set by the Federation of Oilseeds, the standard olive oil comprises of 71 % oleic acid and 9 % linoleic acid [35] which is very close to the composition of sample E, walnut oil of Madyan area, hence proved to be of best quality amongst all the other samples for food product development. Anther probable cause of the differences between sample E and all others in their properties including chemical composition may be due to the difference in forest types, soil nature, average rainfall and temperature however, the discussion of these parameters are beyond the scope of our studies.

nueva página del texto (beta)

nueva página del texto (beta)