1. Introduction

The globalization process that is taking place worldwide requires companies to put in place new strategies to adapt their competitiveness to international standards to affirm their persistence in the global market. In this new scenario, the business competitiveness strengthens not only through the "classic leverage" of cost reduction but also by pursuing an organizational approach that promotes innovation and maintains competitiveness in the future. In this context, appropriate maintenance management of physical assets assumes increasingly significant importance for business results. Efficient maintenance management, by preventing breakdowns, positively impacts the factors that affect competitiveness in terms of safety and environmental issues. However, not all companies, even those defined as "intensive assets", are conscious of this opportunity. The reason lies in an organizational culture that remains anchored to a traditional maintenance approach, essentially a repair, without making it evolve towards a more complex activity. Through prevention actions along the whole life cycle of the equipment and the pursuit of continuous improvement, the maintenance can give value to the company business in a broader systemic perspective. According to the new demands that arise mainly from the evolution of the social context, where an increasingly important is attributed to safety, quality of life and respect for the environment, the maintenance system has revised necessary its strategies. Hence, over the years, the maintenance paradigm is changing, and now industrial maintenance has become a strategic factor in ensuring industrial systems' productivity (Gallab et al., 2017; Sharma et al., 2011). Maintenance has evolved to meet the needs of the current business trends. In today's technological era, maintenance is of utmost importance, and businesses are approaching its evolution in digital transformation.

Considering the dynamics of maintenance management and the range of opportunities arising from Industry 4.0, the study finds the current relationship between maintenance and Industry 4.0 and contrasts many stands. The goal is to analyse state-of-the-art maintenance in an industrial context and understand how maintenance is evolved to meet its requirements to identify "Maintenance 4.0" regarding crucial aspects and future trends. While the Industry 4.0 keyword dates back to 2011 (Kagermann et al., 2013), the first papers dealing with maintenance in smart factories were published in 2015, and the last report on maintenance in smart factories was published in 2020.

Indeed, the nine pillars of Industry 4.0 (Vaidya et al., 2018) are very beneficial in maintenance, significantly augmented reality (Bousdekis et al., 2021). Augmented reality applications have shown great relevance in terms of quality control and supervision, assembly, maintenance, and safety activities. For this reason, it has become very applied in manufacturing companies (Bottani & Vignali, 2018).

Augmented Reality (AR) provides a seamless interface that mixes the real and virtual world to improve collaboration between humans and intelligent environments (Mourtzis, Vlachou et al., 2017) and has become an innovative and effective solution for solving many critical issues to assist and improve maintenance processes before implementation (Nee et al., 2012).

The paper is structured as follows: Section 2 explains the research methodology. Section 3 is devoted to the review results, followed by Section 4, which presents authorship and collaboration. And finally, a conclusion is provided in Section 5.

2. Research methodology

2.1. Databases, keywords, inclusion criteria

The research methodology we used is a systematic literature review as it is a routine test of the current state of knowledge regarding a given topic. A systematic literature review structure is systematic in collecting and synthesising literature, and it is straightforward and reproducible in presenting findings (Rhoades, 2011).

This study focuses on literature review thanks to the search using the Scopus database (http://www.scopus.com/).

The first step of a systematic literature review is defining the strategy of locating, selecting and including the studies. In this paper, a computerised search was made using the Scopus database (http://www.scopus.com/) to identify relevant studies.

The research was performed by making queries on Scopus with the general keywords or topics most frequently used in the peer-reviewed literature: “Maintenance”, “Industry 4.0”, “Augmented Reality”, “Maintenance 4.0”.

The research uses the following strings:

• Query 1: “Maintenance” and “Industry 4.0” in tiles-abstracts-keywords and “Augmented Reality” in all the databases.

• This search query identifies 112 documents.

• The publication timespan was limited to be between 2015 and 2020.

• The studies were also limited to the English language.

• Only scientific articles and reviews are considered (f.e. conference papers were excluded).

• Due to the application of these limitations, the result consists of 38 documents.

• Query 2: “Maintenance” and “Augmented Reality” in tiles-abstracts-keywords.

• This search query identifies 948 documents.

• Timespan was limited to be between 2015 and 2020.

• The studies were limited to the English language.

• Only scientific articles and reviews are taken into account.

• Due to the application of these limitations, the result consists of 151 documents.

• Query 3: “Maintenance 4.0” in tiles-abstracts-keywords.

• This search query identifies 30 documents.

• Due to the application of that limitation, the result consists of 25 documents.

The hunt from which a total of 218 papers were selected was narrowed down to 198 papers without duplicates. During which we omitted articles that turn out to be preliminary conference papers or articles that were erroneously listed as journal papers in the science databases. Other papers from the inquiry were omitted for not having any author name. The entire collection of 197 papers is documented in Table 1.

2.2. Classification

The emphasis of this paper is the substance of 197 science study papers examined:

1. Applications papers (92): papers whose main aim is to develop and test new ideas and applications in the real world or laboratory.

2. Review papers (33): papers whose main aim is to conduct a literature review, study state of the art, and make a methodological analysis.

3. Conceptual papers (72): papers whose main aim is not to develop new solutions but to analyse some specific aspect or problems of Maintenance 4.0 and A.R. solution in this field.

The whole sample of papers reviewed and analysed have been reported in Table 1 (in Appendix). Each paper has been matched to the type of article to which it refers.

3. Review results

First of all, paragraph 3.1 is reported geographical statistics and the publication trend in time for the whole sample of papers. Then in paragraph 3.2 and subsections 3.2.1, 3.2.2, 3.2.3, the three groups of papers are analysed separately, highlighting the main points of interest of the most relevant and cited papers through citation analysis. The analysed studies suggested highlighting two parameters related to the keywords found in the articles, called "Frequency" and "Persistence". The first one shows the number of articles in which a specific keyword appears. The "second one" is used to highlight the number of years since an argument is introduced as a keyword, and so it shows the keyword's importance in time. The keywords study is conducted, exporting them automatically from Scopus research to Excel with the "Export" function.

3.1. Trend of publication in time

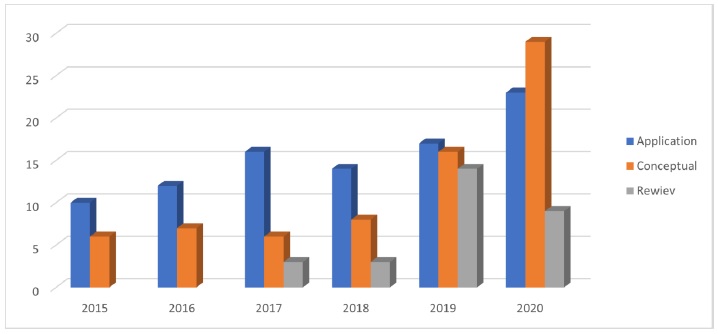

The three categories of papers are in this paragraph shown based on publication year (Fig.1). This analysis aims to put in evidence more attention during the year to “Maintenance 4.0” and “Augmented Reality” themes. The publication period is the same as the preliminary research and goes from 2015 to 2020. As we can see in this figure, there are only 16 publications related to the topic in the first year of study (2015), while in the last one (2020), the number of papers reaches a peak of 61. The most significant increase of publication occurred between 2018 and 2019 (22), and it shows that after an almost constant trend in the first three years, between 2019 and 2020, the “Maintenance 4.0” topic aroused a consistent interest with 108 total publications.

Fig. 2 divides the total number of publications per year in "application", "conceptual", and “review” groups. First, it shows that "review" papers are the least published during the all-time span, with a total of 29 articles. Simple discoveries on a particular topic may only be made after several scientific articles by various scientists have been written.

The total number of publications of “conceptual” and “application” papers is close: 72 vs 92; it is very interesting to put in evidence that only in the last year (2020) “conceptual” papers with 29 publications overcome “application” papers with 23 publications. The development of “conceptual” and “application” papers is motivated by the widespread diffusion in the recent years of “Industry 4.0” instruments in the maintenance sector (Fig 1, Fig 2).

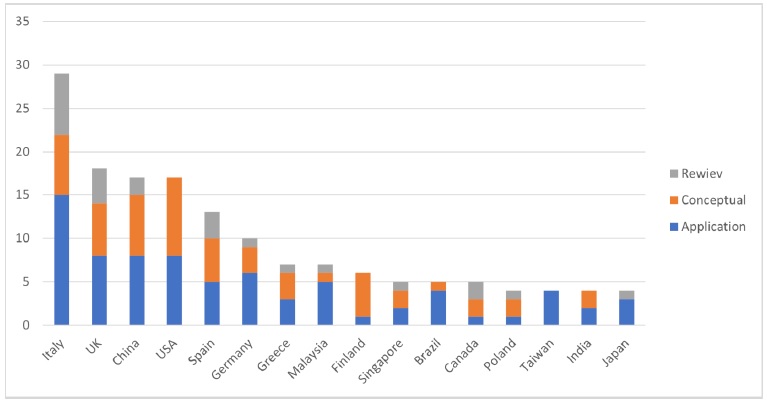

A geographical distribution analysis of the studies is shown in Fig 2. It could be exciting to understand in which country the "Maintenance 4.0" argument is developing. The country of the papers was assigned, taking into account the nationality of the first author, which is a very common approach in review studies (e.g., (Gao et al., 2017). The figure shows that most of the studies comes from Italy (23 papers: 15,02%), UK (18 papers: 9,32%), China (17 papers: 8,8%), USA (1 papers: 8,8%), Spain (13 papers: 6,73%) and Germany (10 papers: 5,18%). This result is due to industries adopting this new kind of maintenance in these countries for the first time. A consideration that could be done for the leading country, Italy, is that there are no differences between the number of “conceptual” and “review papers” (7), while “application” papers reach a peak of 15 papers. Finally, many countries have carried out very few (i.e., one or two) studies, demonstrating that this technology is still in its early adoption stage.

3.2. Paper categories

This paragraph is extrapolating the main point of interest of the whole sample of papers, divided into three groups. In Tab. 2.1, 2.2, 2.3, the relevance of the papers is shown through a citation analysis that sorts review, conceptual and application papers in order of total citations and citations per year. Citations per year also highlight new papers that have less chance of being cited (Table 2.1, Table 2.2., Table 2.3).

Table 2.1 Citation analysis for “review” papers.

| Paper | Citations | Citations/Year |

| (Palmarini et al., 2018) | 163 | 55,4 |

| (Younes et al., 2017) | 52 | 13 |

| (Bottani & Vignali, 2018) | 42 | 21 |

| (Gattullo, et al., 2019) | 40 | 20 |

| (Cimino et al., 2019) | 27 | 13,5 |

| (Fernández del Amo et al., 2020) | 18 | 6 |

| (JasiulewicZ-Kaczmarek & Gola, 2019) | 15 | 7,5 |

| (Bousdekis et al., 2021) | 1 | 1 |

| (Bottani & Vignali, 2018) | 76 | 25,3 |

Table 2.2 Citation analysis for “conceptual” papers.

| Paper | Citations | Citations/Year |

| (Gavish et al., 2015) | 206 | 34,3 |

| (Roy et al., 2016) | 123 | 24,6 |

| (Aromaa & Väänänen, 2016) | 68 | 13,6 |

| (Uva et al., 2017) | 53 | 17,6 |

| (Fantini et al., 2020) | 51 | 51 |

| (Elia et al., 2016) | 48 | 9,6 |

| (Jetter et al., 2018) | 35 | 11,6 |

| (Poushneh, 2018) | 31 | 10,3 |

| (Vaidya et al., 2018) | 274 | 91,3 |

| (Gallab et al., 2017) | 12 | 3 |

Table 2.3 Citation analysis for “application” papers.

| Paper | Citations | Citations/Year |

| (Chen et al., 2016) | 57 | 11,4 |

| (Mourtzis, Zogopoulos, & Vlachou,2017) | 56 | 14 |

| (Plopski et al., 2015) | 53 | 8,83 |

| (Masoni et al., 2017) | 52 | 13 |

| (Chicchi Giglioli et al., 2015) | 43 | 7,16 |

| (Lima et al., 2017) | 40 | 10 |

| (Neges et al., 2017) | 40 | 10 |

| (Fernández-Caramés et al., 2018) | 38 | 12,6 |

| (Mourtzis, Vlachou et al., 2017) | 68 | 17 |

| (Nee et al., 2012) | 348 | 38,6 |

3.2.1. Review papers

The 29 review articles’ overarching aim is to summarize the recent literature surrounding Maintenance 4.0 and the AR-enabled consequences of Industry 4.0.

Previous works of Damiani et al. (2018) which are not present in the sample of papers, want to highlight the importance of AR technology in the whole Industrial 4.0 system, while Mourtzis, Vlachou et al. (2017) indicate that own maintenance together with Virtual Training is the main application areas.

Instead, Palmarini et al. (2018) propose a “systematic review of augmented reality applications in maintenance", showing that AR's current field in maintenance is Mechanical maintenance, Plant maintenance, Consumer Technology, and the Aviation Industry. Techniques and technology related to A.R. in the maintenance field are also studied by Fernández del Amo et al. (2018) through an important literature review for knowledge transfer in maintenance application.

Very interesting and new application papers in this area are the studies conducted by Tanaka et al. (2019) that studied 3D CAD Models for VR/AR viewing during the bridge maintenance process and the practical augmented reality-assisted maintenance system for adaptive user support proposed by Siew et al. (2019).

An important research methodology towards Augmented Reality manuals for industry 4.0 is provided by Gattullo et al. (2019). Bottani and Vignali (2018) propose a review of the last decade of “Augmented reality technology in the manufacturing industry”, indicating among the other things that new technologies as a 3D scanner, holographic display, and connected mobile devices are moreover utilised in the manufacturing industry and so in the maintenance field.

An overview of maintenance evolution through Industry 4.0 technologies, also called Maintenance 4.0, is analysed by new review papers like Silvestri et al. (2020), and JasiulewicZ-Kaczmarek and Gola (2019), which is highlighted the progressive evolution and the actual way to do maintenance during the fourth industrial revolution.

3.2.2. Conceptual papers

As a result of the research, 72 articles are conceptual that want to describe general aspects, problems, and solutions of Maintenance 4.0. and of AR technologies in the industrial manufacturing field. Conceptual papers are in the Tab. 3.2 classified in order of total citation and of citation per year to highlight its scientific relevance. Uva et al. (2017) published a critical practical paper, which draws a literature review, tests and business experience feedback to A.R. technologies used in the potential smart factories. This paper presents an evaluation of the efficiency of conveying technical instructions with this SAR prototype and shows the improvement of operators' efficiency.

Fantini et al. (2020) and Jetter et al. (2018) propose manuscripts on the increasing transition of manufacturing companies to the Industry 4.0 concept and the various AR technologies developed in the maintenance sector. These papers could be very interesting in how these topics are becoming fundamental targets, making the industrial manufacturing sector competitive during the year.

“Maintenance 4.0: Intelligent and Predictive Maintenance System Architecture” suggested by Cachada et al. (2018) illustrate the growing value of maintenance as a part of the manufacturing methods. The paper looks at why maintenance is abandoning its traditional strategy and is now focusing on utilising a predictive and constructive approach (Condition-based Maintenance). The application of such techniques includes a well- structured infrastructure that can be enhanced by using the Internet of Things (IoT), artificial intelligence, and cloud computing.

In this paper Chahada et al outline the design of an insightful and predictive maintenance framework consistent with the ideals of Industry 4.0. It is an advanced and online review of the collected data for the earlier prediction of system defects and assists technicians through repair interventions by offering directed intelligent decision support. Ceruti et al. (2019) look at how Business 4.0 principles will enhance the condition of maintenance. The conference will concentrate on developing AR and Additive Manufacturing (AM) technology, which will help sustain and develop goods. The proposed AR/AM systems are proposed as feasible tools in aviation maintenance. The sources Jasiulewicz-Kaczmarek et al. (2020) or allow fascinating proposals that should be further researched. Both papers address the various methods of current maintenance. The first viewpoint in this paper is the historical perspective, and evolution has been described in the approach to maintenance in light of manufacturing engineering growth. The following viewpoint explores the topic of data- driven maintenance and the historical development of maintenance data. The third viewpoint explores the need for maintenance in the sense of sustainable growth and prospective prospects to use data-driven maintenance technologies to apply the fiscal, environmental and social challenges of sustainable production.

3.2.3. Applications papers

Maintenance 4.0 uses advanced technologies for predictive analysis and provides decisions based on feasibility. Research has shown that the topic is currently used in a wide range of applications, and it will undoubtedly be a source of further applications in the future. It is often linked to augmented reality (AR). Masoni et al. (2017) affirm that augmented reality allows operators to view information necessary for direct execution in the work area without the need to refer to paper-based manuals. Moreover, AR could be helpful in the training field, allowing technicians, even the most inexperienced, to improve without an actual waste of material.

In general, Maintenance 4.0 behaves like preventive maintenance to avoid the occurrence of problems that could lead to damages or risks. For this reason, it obtains a vast number of consents in many fields of application. In order to demonstrate the effectiveness of this method, three practical examples are shown below in which this type of technology is used, namely that railway, naval and aeronautic fields.

The railway field must be taken into account that the railway is a highly complex system. In fact, from a technological point of view, it is made up of a set of physical elements that interact. Therefore, different internal or external factors could compromise the work.

In addition to that, the railway services must be able to respect time and spaces punctually and reliably. According to Kans et al. (2016), Maintenance 4.0 allows an advanced traffic management system thanks to a program that manages a large amount of data and information. It also gives a more accurate assessment of the vehicle's health, allowing it to extend the life of components. Indeed, this methodology's advantage in this context is an improvement in operations in all fields thanks to the further implementation of advanced systems (for example, the RFID technology that allows to analyse and view train data for maintenance planning economic).

Regarding the naval application fields, Kandemir & Celik (2020) state a Property Management System (PMS) that is used to plan times and hourly maintenance activities to prevent possible risks that can lead to failures. Thanks to the use of cloud-based sensors that allow monitoring and preventing failures related to phenomena such as vibrations or temperature near the critical parts of the ship.

Finally, regarding the aeronautical field, Industry 4.0 introduces several key technologies (such as networking, availability of big data and networks of micro-sensors connected) which, besides being suitable in factories, are also very useful in aeronautics. Ceruti et al. (2019) affirm that support local monitoring strategies in real- time, efficient big data management algorithms (Analytics) is necessary. This gives the possibility to collect data from millions of sensors (e.g., Bragg fibers included in composite structures) to find faster crack propagation.

3.3. Keywords analysis

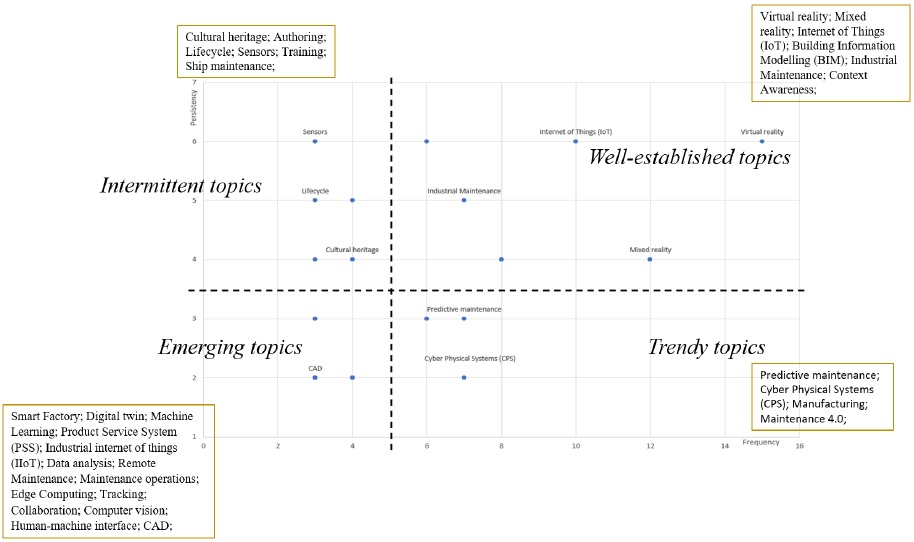

The study of the authors’ keywords for a selection of all items produced a total of 589 distinct terms. Not all papers use the appropriate author keywords’ and were therefore omitted from the study. It is essential to remember that a wide range of keywords related to virtual reality, industry 4.0 and maintenance were also omitted from Scopus's search question. Obviously, these keywords have a more prominent presence, and they could theoretically be the study's findings. The data showed that writers prefer to use these keywords to convey the same idea through articles. According to Bottani and Vignali (2018), the keywords are gathered manually to evaluate related and dissimilar Keyword classes. In Table 3, only 20 keywords are listed to avoid bias, such as over- reporting trivial keywords. Frequency and longevity keywords will be displayed in colour (Figure 3).

Table 3 Keywords analysis.

| Keyword | Frequency | Persistence | Min Year | Max Year |

| Virtual reality | 15 | 6 | 2015 | 2020 |

| Mixed reality | 12 | 4 | 2017 | 2020 |

| Internet of Things (IoT) | 10 | 6 | 2015 | 2020 |

| Building Information Modelling (BIM) | 8 | 4 | 2017 | 2020 |

| Predictive maintenance | 7 | 3 | 2018 | 2020 |

| Cyber-Physical Systems (CPS) | 7 | 2 | 2019 | 2020 |

| Industrial maintenance | 7 | 5 | 2016 | 2020 |

| Context Awareness | 6 | 6 | 2015 | 2020 |

| Manufacturing | 6 | 3 | 2017 | 2019 |

| Maintenance 4.0 | 6 | 3 | 2018 | 2020 |

| Smart Factory | 4 | 2 | 2019 | 2020 |

| Cultural heritage | 4 | 4 | 2017 | 2020 |

| Digital twin | 4 | 2 | 2019 | 2020 |

| Authoring | 4 | 5 | 2015 | 2019 |

| Machine Learning | 4 | 2 | 2019 | 2020 |

| Product Service System (PSS) | 3 | 3 | 2018 | 2020 |

| Lifecycle | 3 | 5 | 2016 | 2020 |

| Sensors | 3 | 6 | 2015 | 2020 |

| Industrial internet of things (IIoT) | 3 | 3 | 2018 | 2020 |

| Training | 3 | 4 | 2017 | 2020 |

| Data analysis | 3 | 3 | 2018 | 2020 |

| Remote Maintenance | 3 | 2 | 2017 | 2018 |

| Maintenance operations | 3 | 2 | 2019 | 2020 |

| Ship maintenance | 3 | 6 | 2015 | 2020 |

| Edge Computing | 3 | 2 | 2019 | 2020 |

| Tracking | 3 | 3 | 2017 | 2019 |

| Collaboration | 3 | 2 | 2019 | 2020 |

| Computer vision | 3 | 2 | 2019 | 2020 |

| Human-machine interface | 3 | 2 | 2019 | 2020 |

| CAD | 3 | 2 | 2019 | 2020 |

The upper-right quarter of diagram 3 reflects the category of old or repeated keywords used as a number. According to Bottani and Vignali (2018), study subjects that have been researched so much that they are deemed "well-established". The top-left quarter of search results concerning keywords emerged more than 2.5 years ago. This quarter contains subjects that are already being discussed yet that are still requiring further study. The bottom-left quarter is given recent keywords depending on their level of use. The contemporary subjects discussed in this essay could well vanish early, or they could become "trendy" in the years to come. The bottom-right quarter comprises just certain subjects that tend to be very promising important keywords used, as shown in Table. Sought out phrases such as "Predictive maintenance", "CPS", "Manufacturing", and "Maintenance 4.0" are frequently researched.

4. Authorship and collaboration

More than 700 scholars made over 200 contributions to the researched papers. Table 4 reports the number of authors per article and indicates that a paper can be published by a single (one) author or even more than 5 authors (Table 4).

Table 4 Number of Authors per paper.

| Num. of Authors | Paper | Percentage |

| One Author | 15 | 7,772020725 |

| Two Authors | 27 | 13,98963731 |

| T Three Authors | 44 | 22,79792746 |

| Four Authors | 31 | 16,06217617 |

| Five Authors | 40 | 20,7253886 |

| More than five | 36 | 18,65284974 |

| Total | 193 |

Three authors wrote forty-four papers, followed by 40 partnerships linked to five authors, followed by 36 papers written by more than five authors, followed by 31 collaborations written by four authors, followed by 27 papers written by two authors (13.98 percent). The increased number of researchers involved in the Maintenance 4.0 area and the fact that the research sector is multidisciplinary has inspired the collaborators.

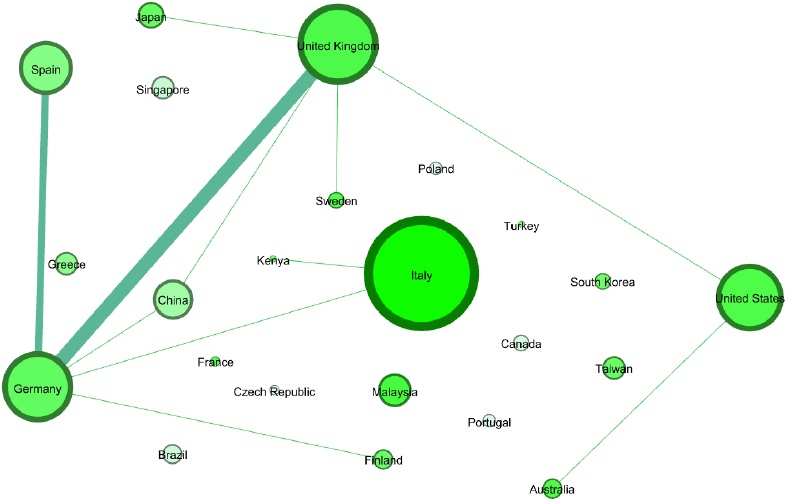

It is found by the data gathered from the foreign partnerships, stated in Figure 4. Gephi was used to generate a graph consisting of nodes. In this article, the countries are represented by their country code, which highlights the number of writers from that country. Although European countries like Italy, the United Kingdom, Germany, and Spain lead with research articles, China and the United States are still contributing. Remind the reader that the interactions between the countries and the degree of cooperation indicate the partnerships' importance. In addition to these most significant nation partnerships, nations like the U.K., Germany, and Spain are now collaborating together.

Gephi (https://gephi.org/) is a graphic representation tool, but it always returns a graph; it is therefore composed of nodes and arcs to which a personal interpretation must be attributed. It is useful for some descriptive statistics.The collaboration between authors from different countries shows the collectivity of science, both in terms of knowledge and in terms of resources.

With Gephi, a graph is represented, consisting of arcs and nodes. Consequently, in order to build it, it is necessary to import a table from Excel constructed as follows: Two columns are represented where the first column corresponds to the origin nodes and the second column to the target nodes. The arcs of the graph will be represented by the software itself, in this case representative of the collaboration between countries. Gephi will combine all the collaborations, represent through links the existing collaborations, and highlight the most frequent collaborations with ever thicker lines.

5. Conclusions

The research aim was to create an overview of the existing repair expertise and analyse the art's general state. Three separate search questions culminated in the discovery of 214 peer-reviewed articles conducted from 2015 to 2020. These studies centred on Industry 4.0 and maintenance/augmented reality. These articles have been categorized into the study paper (33), implementation paper (92), and development of a thesis (72). The entire collection of papers was analyzed concerning their year of publishing and where they were written. Subsequently, the reviews were independently reviewed, and philosophical and implementation papers were analyzed using a keyword scan to define the major topics discussed and their degree of dissemination in the science community. For each type of literature, a review was performed on the number of times the article has been referenced. Finally, after having dealt with three general forms, an additional study was carried out on the keywords, assessing the most relevant keywords' occurrence and durability, and another focused on the authorship. After that, it can be easily shown how the curiosity in the implementation of 4.0 and other innovations is growing gap In this subject, the capacity is severely limited as it has not yet been fully established. In reality, considering the diversified applications of this subject, it is difficult to define a specific sector that will profit from this topic the most. Furthermore, several experiments tend to have been conducted only in the laboratory, without applying this technology in a real setting, so further study is required to improve the applicability in less explored areas.

nueva página del texto (beta)

nueva página del texto (beta)