1. Introduction

One of the simplest and most direct applications of solar energy is the solar still. Desalination via solar energy is a practical solution to produce potable water especially in remote areas that experience a scarcity of potable water and where sunlight is available, (Alawee, 2015). In recent years, many researchers have used fins in various ways to enhance the productivity of solar stills. The use of fins is one of the passive methods that are widely used in engineering disciplines to enhance the heat transfer process between surfaces and surrounding fluids. Fins are concerned with energy transitions that require heat movement.

Velmurugan, Deenadayalan et al. (2008) showed that when fins are integrated to still basins, the productivity of solar stills is enhanced to approximately 53% higher than that of conventional stills. Velmurugan, Gopalakrishnan et al. (2008) also compared the ordinary basin of conventional solar stills with three other types of solar still basins. The first basin contains wicks, whereas the second and third ones are sponge and fin basins, respectively. The comparison showed that productivity increases by 45.5%, 29.6% and 15.3% when fins, wick and sponges are used, respectively.

Omara et al. (2011) examined the productivity of solar stills integrated with the absorber plate of gilled and corrugated distilled bases under Egyptian weather conditions. The researcher found that the productivity of this type of solar still increases by approximately 21%-40% in comparison with the conventional absorption plate. Alawee, Dhahad et al. (2021) , Alawee, Dhahad, and Mohammad, (2021) experimentally studied the performance of solar stills integrated with inclined perforated and non- perforated rectangular fins. Results showed that the productivity increases by approximately 16%-54% by using a finned plate instead of a flat conventional absorption plate.

Many researchers have studied various factors that enhance the productivity and efficiency of conventional solar stills. Yeo et al. (2019) investigated the influence of different heat sources on the performance of the hybrid multiple-effect diffusion solar still (HMED) and revealed that HMED solar still increase productivity by (5.3%-17.6%) compared with conventional solar stills. Al-Hussaini and Smith (1995) used vacuum technology inside solar stills and revealed that applying vacuum inside solar stills increases water productivity by approximately 100%. Jubran et al. (2000) numerically studied a solar still with a multistage evacuation process. Their solar still was built from three insulated stages positioned on top of each other. A perfect sealing was used between the various stages such that the water vapour that evaporated within the boiling process can only move through a limited orifice connecting the two stages. They found that the still can generate up to 9 kg/m2/day with an acceptable distillation efficiency of 87%. Nafey et al. (2002) examined the effect of using a bored plate floating on the water in the distilling tank on the productivity of stills and found that 15%−40% improvement in productivity can be achieved in comparison with a conventional solar still. Al-Hinai et al. (2002) conducted a parametric study to investigate a double-effect solar still and compared it with a single-effect solar still. They used a shallow water basin with asphalt coating. An average annual energy that equals to 4.15 and 6 kg/m2/day was produced for the single- and double-effect stills, respectively. Rajaseenivasan and Murugavel (2013) theoretically studied the effect of adding extra basins to a solar still with a single basin on productivity. The results showed that the modified solar still has a productivity that is 85% higher than that of a single basin under the same circumstances. Tiris et al. (1998) integrated a flat plate collector with a single-basin still and found that productivity increases by 45.5% compared with the conventional solar still. Tanaka and Nakatake (2006) conducted a theoretical study to examine different basin types in a solar still with external and internal reflectors. They found that the solar still with external and internal reflectors yields 48% higher productivity compared with that of the conventional solar still. Abdullah et al. (2019) conducted an experiment using a rotating drum inside the basin still to increase the evaporative surface area and decrease the thickness of the saline water film. They found out that 350% increase in the distillate output of the solar still can be achieved by utilising this technique. Alawee, Mohammed, Dhahad et al. (2021) tested performance and the productivity for the solar still with novel designs. They reported that the distillate output of the solar stills were 1.5-.4.8 kg/m2. Alawee et al. (2015) conducted an experimental study to augment the efficiency of a conventional solar still. The results showed that the modified solar still produces 18%-24% distillation, which is greater than that of a conventional one for similar basin conditions.

The above studies have revealed that an increase in the basin area of a solar still leads to an acceptable enhancement in the productivity of the still. However, to the best knowledge of the authors, the use of perforated inclined fins to extend the basin surface area has yet to be investigated. Therefore, the present experimental and theoretical work aims to investigate the augmentation in the thermal performance of a solar still by integrating perforated fins inclined by 45° at the basin plate under Iraqi climate conditions.

2. Experimental setup and procedure

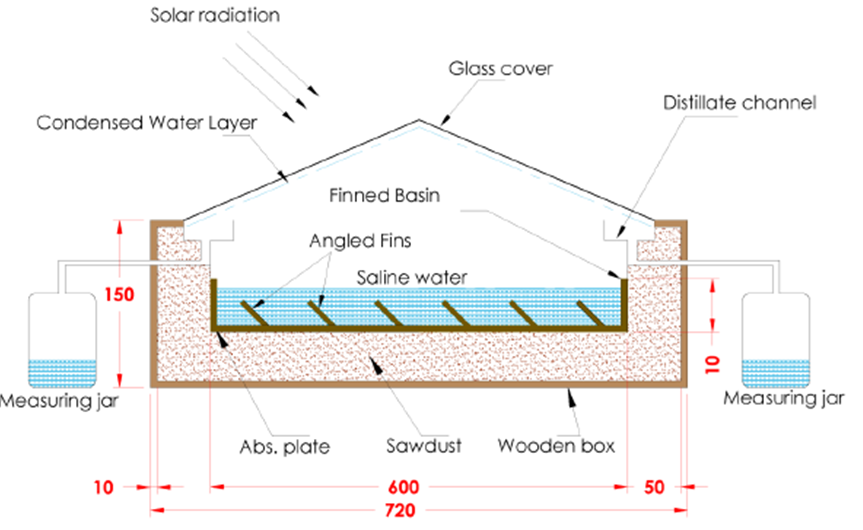

For the purpose of performance comparison, two types of single-effect single-slope solar stills were designed, built and investigated under the circumstances of Baghdad (Figure 1). The first solar still is a conventional one, whereas the second is integrated with perforated inclined fins at the basin plate.

2.1. Conventional solar still

The conventional solar still system illustrated in Figure 2 consists of the following parts: a feeding water tank, a distillation basin, a measuring jar and a pipe network. The basin of the solar still was made of galvanized iron with a thickness of 2 mm and a basin area of 0.75 m2 (1.25 m × 0.60 m); the height of the side wall is 40 cm. The still base and the interior of the side walls were painted with a matte black paint to increase absorption. The solar still was positioned within a wooden container with a thickness of 2 cm, and the space between the still walls and the wooden box was filled with sawdust to minimize thermal losses. A 4 mm-thick glass panel was used to cover the solar still from the top, and it was fixed at a 30° angle with the horizontal. The glass cover was securely fastened using silicone rubber to prevent vapour from leaking out. The solar still was routed to the south geographical location to obtain maximum solar radiation throughout the year. A 40 L storage tank was used to feed the still. Condensed water flowed down through glass cover into a collection canal and was stored in a storage bottle.

2.2. Solar still with perforated rectangular inclined fins

The use of fins in distilled bases increases its surface area, thus increasing the heat transfer between the water and the still base. The increased heat transfer increases water temperature, thereby leading to an increase in the difference between the temperature of the water and that of the glass cover. Consequently, productivity is increased. In this study, inclined perforated rectangular fins were integrated at the basin of the still. The use of inclined perforated fins has several advantages, namely, increase in external surface area, increase in heat transfer with the inner area of the perforated plate and increase in the absorption of solar radiation.

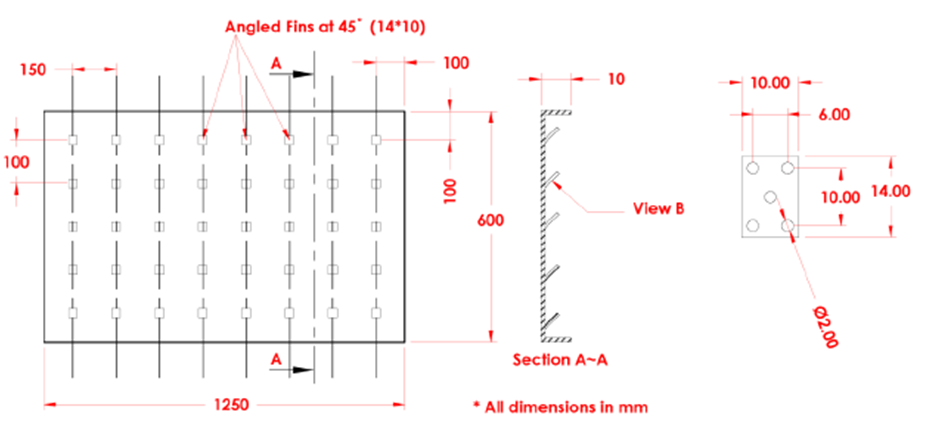

Solar stills with perforated inclined fins are shown in Figure 3. Finned and conventional stills have similar dimensions and external designs. The only difference lies in the absorber plates, where they are perforated finned and not flat. The finned absorber plate is made of galvanised iron and manufactured by a computer numerical control milling machine. The breadth, thickness and length of the fins used in this study were 14, 10 and 2 mm, respectively. The pitches between two neighbouring fins were taken as 100 and 150 mm in the longitudinal and transverse directions, respectively. The dimensions and other details of the finned basin are shown in Figure 4.

The water depth in the basin was maintained at 10 mm, and the plate fins were tilted at an angle of 45°. A pyrometer was used to measure the flux density of the solar radiation in the desired location. Copper-constantan thermocouples were used to measure the water temperature inside the distillation basin. However, ambient temperature was measured by using a mercury thermometer. The quantity of collected water was measured by using a 5 L measuring beaker.

The finned solar still with perforated inclined fins was tested and compared with a conventional solar still. In all the experiments, the hourly recorded variables are as follows: solar radiation intensity, average water temperature in the distillation basin, glass cover temperature and ambient air temperature.

Many parameters were measured to assess the thermal performance of the solar stills used. The temperature of the basin water was measured using a T-type thermocouple (copper-constantan) (±0.2 C) connected to digital thermometer. Solar intensity was measured using a solarimeter (0-2500 W/m2) with an accuracy of ±2 W/m2. Ambient temperature was measured manually with a mercury thermometer. The distillate output was measured using a 2,000 mL beaker (with an accuracy of 3 mL). The total uncertainty in the current experimental measurements was calculated using the method proposed by Kline and McClintock (1953) and found to be within ±8%.

3. Mathematical Model

Figure 2 displays the schemas for the various heat transfer modes in the double-slope solar still. Such types are convection, heat, and evaporation. The conventional still and finned mathematical models are based on the energy balances of the glass, basin water and basin. The following premises are considered in the determination of equations for the energy balance.

- There is no leakage from the two solar stills.

- The heat that the glass surface absorbs is equal to the heat that the vapour rejects; therefore, all vapours are converted into distilled water.

- No heat losses from the basin to the air (or such losses are insignificant).

- The temperature gradients along the depth of the water and the glass cover thickness are negligible.

The energy balance is explained as follows based on the above.

The energy obtained from the glass cover includes the energy absorbed from the sun (ITαg) and the energy transfer from the basin water across evaporation (qe,wg), convection (qc,wg), and radiation (qr,wg). This obtained energy would partially raise the temperature of the glass (MgCp,g/dt), and partially pass it by convection (qc,wa) and radiation(qr,wa). The glass cover's energy balance can be the following (Appadurai & Velmurugan, 2015):

Evaporative, convective and radiative energy between water and glass is given as follows:

In the above,

Here, p w is the partial water vapor pressure at the (Tb), and p g is partial water vapor pressure at the (Tg) (in Pa).

In addition,

The transfer of energy by convection and radiation between glass and air are given as:

where

3.2. Water basin

The energy absorbed in the basin water are transferred partly in to the basin (qc,w-b), and mirrored in part to the glass cover by evaporation (qe,w-g), convection (qc,w-g), and radiation (qr,w-g). The residual energy would increase the temperature of the basin water by Mw dT/dt . The water basin's energy balance is shown as follows

The heat transfer by convection between the basin and water is given as follows:

The coefficient of convective heat transfer between the basin and water, (hc,bw), is 135 W/m2 K .

3.3. The basin

The solar intensity (α b I t ) increases the energy of the basin absorber layer. This extracted energy is equal to the amount of the energy produced from the basin and the energy lost by the air and water convection. The equation of energy balance for the basin is as follows:

The heat transfer by convection between the basin and air is given as follows:

Here, the value of Ub is [29,31] 14 W/m2 K.

3.4. Condensate flow rate calculation

The amount of water condensed (productivity) can be estimated as follows (Zurigat & Abu-Arabi, 2004):

In the above, hfg is latent heat of vaporisation, and the values are calculated as follows:

Initially, the time period was supposed as 5 s, and the temperatures of the glass, water, and basin were considered as the ambient temperature. The engineering equation solver program was used to solve Eqs. 1, 12 and 14 to predict variations in glass (dTg), saline water (dTw) and basin temperature (dTb). Experimentally determined solar intensity values and ambient temperatures were used for the respective hour and day. The parameter was redefined for the next step. Table 1 describes the physical input parameters used for the mathematical modelling.

Table 1 Physical input parameters used for mathematical modeling.

| Parameters | Value |

| Mass of glass, |

10.0 kg |

| Specific heat of glass, |

800 J/kg K |

| Area of glass, |

0.86 m2 |

| Absorptivity of glass, |

0.0475 |

| Emissivities of water, |

0.96 |

| Emissivities of glass, |

0.88 |

| Mass of water, |

7.50 kg without fins 6.94 kg basin with fins |

| Specific heat of water, |

4187 J/kg °C |

| Absorptivity of water, |

0.05 |

| Area of water, |

0.75 m2 without fins 0.69 basin with fins |

| Mass of basin, |

5.2 kg without fins 6.3 kg basin with fins |

| Specific heat of basin, |

473 J/kg °C |

| Absorptivity of basin, |

0.95 |

| Area of the basin plate, |

0.75 m2 without fins 0.58 m2 with fins |

4. Results and Discussion

To investigate the influence of finned absorber plate on the enhancement of the still productivity, perforated rectangular inclined fins were attached to the base of the still. Their results were compared with the results of the conventional solar still. Initially, the water depth inside the distillation basin was fixed to 1 cm for both two stills. The experiments were conducted at different days between February and May from 8 am to 5 pm.

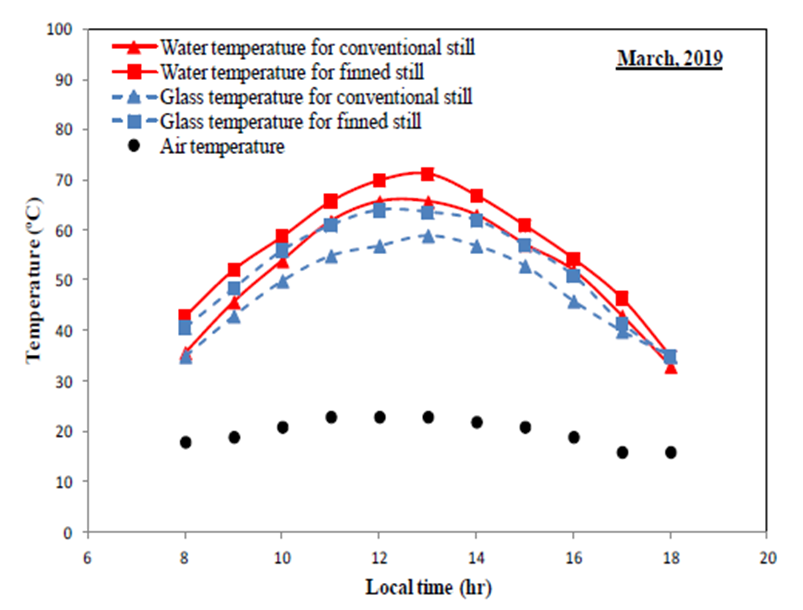

Figure 5 display the hourly alteration of the solar irradiance between February and May. In these figures, the test days were divided into four categories, according to the monthly radiation level. The first is for days with average radiation of approximately 271 W/m2 (February), the second for 382 W/m2 (March), the third for 504 W/m2 (April), and the forth for 650 W/m2 (May). Solar irradiance begins to rise in the morning, attains the maximum value in the afternoon and then commences reduction after 1 p.m. The maximum value recorded was 860 W/m2 for 21 May 2019. The hourly alteration of the solar basin water temperature, glass temperature and ambient air are displayed in Figures 6, 7, 8 and 9 for an average of three test days in each month. These figures illustrate the experimental hourly variations of the water basin, glass and air temperatures in the conventional solar still and finned solar still. The trend of temperatures for all solar stills was found similar. Temperatures of basin water are observed to be the highest followed by glass temperature in order. The temperature rises during the daytime up to the maximum nearly at 1.00 p.m. It was noticed that the lowest measured temperature in the water basin was found in the conventional solar still while the higher temperature was found in the finned basin solar still was used. For two stills, the maximum temperature of the water is during the month of May as the solar intensity is higher.

Figure 6 Experimental variation of different hourly temperatures for conventional and finned solar stills

Figure 7 Experimental variation of different hourly temperatures for conventional and finned solar stills for March.

Figure 8 Experimental variation of different hourly temperatures for conventional and finned solar stills for April.

Figure 9 Experimental variation of different hourly temperatures for conventional and finned solar stills for May.

The maximum water temperature in the distillation basin was measured and found to be 70.0 ˚C and 74.6 ˚C for conventional and finned solar stills, respectively during the month of May 2019, as shown in these figures.

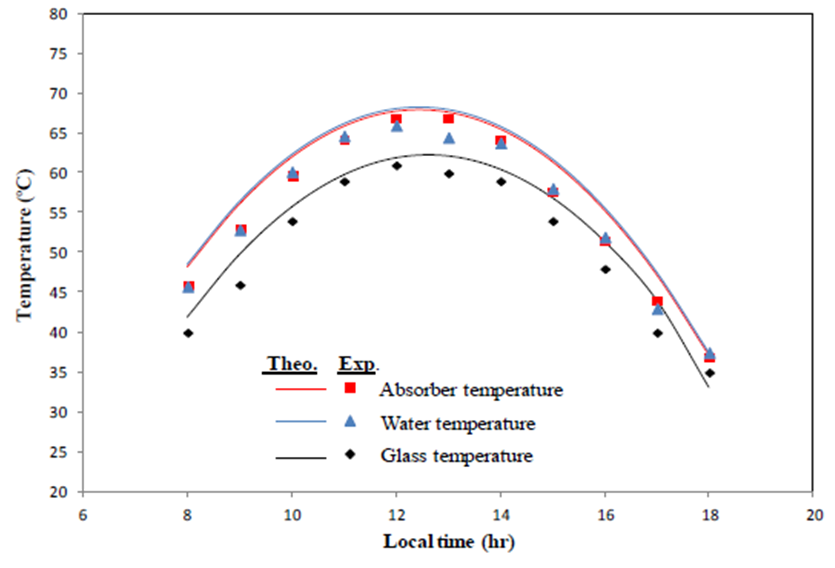

The increase in the water temperature can be attributed to improvement made to the thermal performance of the finned basin solar still. Also, the water temperature is significantly affected by coupling perforated inclined fins with the solar still absorber. Moreover, the still with perforated inclined fin absorbers provides an absorber temperature larger than that of the conventional still. This result was expected because the use of inclined fins increases the surface area of the absorber plate. Thus, the rate of heat absorbed by the finned absorber is increased owing to the increase in the surface exchange. Hence, the absorber’s temperature is increased. Figure 10 depicts the measured temperatures compared with the predictions temperatures using the mathematical model. It can be observed that both experimental and mathematical results show the same trend in temperature rise and decrease with respect to time. The average difference between the mathematical and experimental results was found to be 9% for water temperature and 12% for glass temperature.

Figure 10 Comparison of measured temperatures with predicted temperatures from a mathematical model for conventional and finned solar stills for May.

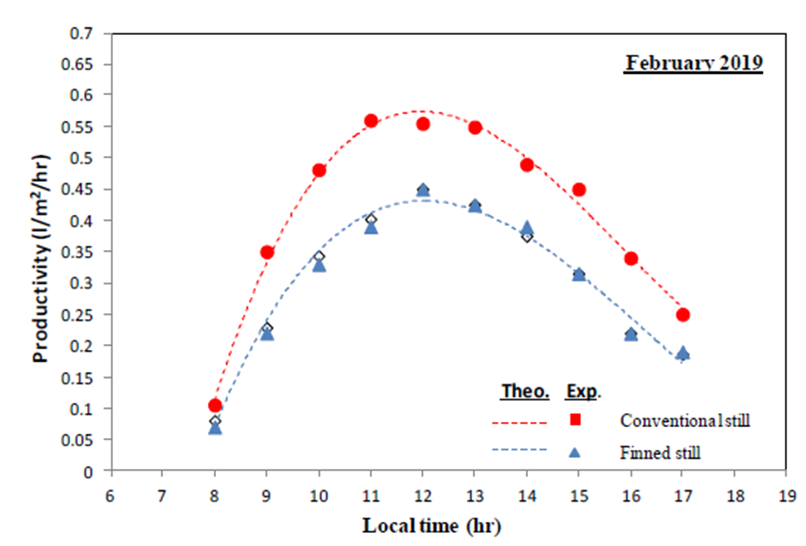

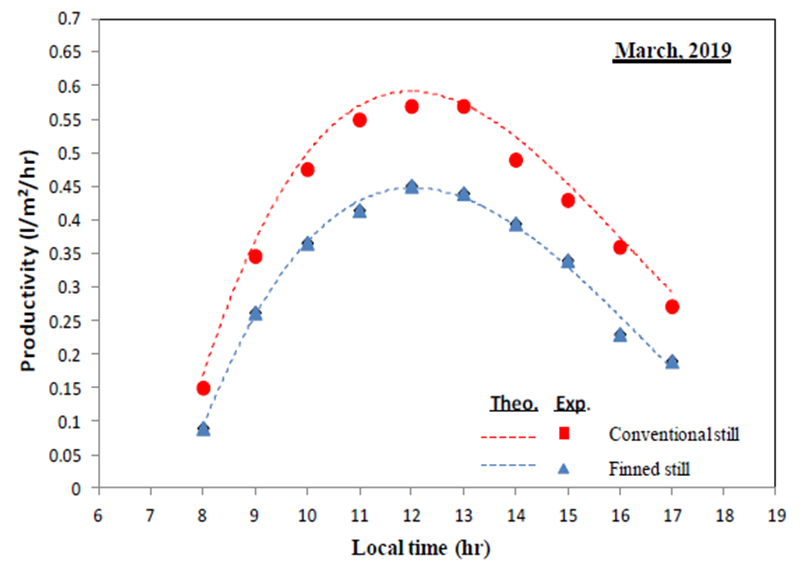

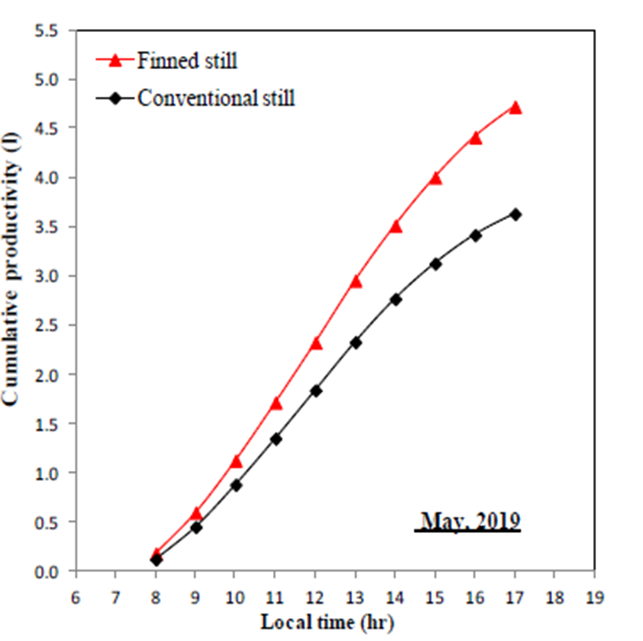

The empirical and mathematical hourly productivity of the two solar stills (for all the test months) is presented in Figures 11, 12, 13 and 14. The average hourly productivity yields as a function of solar intensity. Productivity is low during hours of low radiation (in the morning hours) and reaches the maximum during hours of high radiation, i.e. afternoon hours. The greatest hourly productivity is found to be achieved at 1 p.m. for the two stills. This result is due to the solar radiation that reaches its peak value between 1-2 p.m. at the chosen location.

It can be observed that the yield during the month of May is higher to that of other months (February, April and March), as the different between glass temperature and basin water temperature that is highest during this month. Furthermore, the productivity of the solar still with inclined fins during daytime is higher than that of the conventional solar still. The average hourly yield of the conventional and finned solar stills is 380 and 439 mL/m2h, respectively, on May.

The maximum hourly distillate output of the conventional and finned basin solar stills is 490 and 641 mL/m2, respectively. The solar still with elevated basin improved the hourly productivity. This is because the condensation surface area of the finned basin solar still is greater than that in the conventional solar still. Hence, the rate of vaporization was increased and rate of condensation was increased. The average difference between the theoretical and experimental results was found to be 6-7% for total water productivity.

Figure 15 presents the cumulative water output (in mL) against time in a day from 8 am to 5 p.m. As shown in Figures, the maximum values of the daily productivity are found at the month of February for both solar stills. The productivity values of conventional solar still are 3.02, 3.17, 3.39 and 3.63 l/m2, for months of February, March, April and May, respectively. Similarly, the productivity values of solar still with perforated inclined fins are 4.13, 4.51, 4.41 and 4.72 l/m2, for months of February, March, April and May, respectively.

Figure 15 Variation of cumulative productivity from conventional and finned solar stills for February, March, April and May

The perforated inclined fins attached to the base of the solar still have a significant effect on increasing the productivity of the distilled water; this effect is attributed to the high absorption of the solar radiation incident on them. The solar still with perforated inclined fins yields an average of 28% increase in the amount of produced distilled water in comparison with a conventional still. This increase is due to the fins’ inclination angle, which is perfect for solar ray absorption during winter in the Iraqi region.

During the time when fins are used, the surface area of the absorber plate increased, and the preheating time for the saline water decreased. Thus, productivity increased. The improvement in the performance of the elevated solar still is inferred to be in between 30%-36.5%. Moreover, the yield for several typical days (3 clear days) in the months of February, March, April and May was approximately 4.13-4.72 l/day.

The solar still performance is usually evaluated by its thermal efficiency. Table 2 summarizes the thermal efficiencies of the finned still compared with the conventional still. As observed from the Table 2, the efficiency of the finned still was higher than that of the conventional still. The thermal efficiency is evaluated using the following formula (Essa et al., 2021):

Table 2 Average thermal efficiency of tested solar stills during tested months.

| Average efficiency | Still with non-perforated fin | Still with perforated fin | Conventional still |

| Feb., 2019 | 38.5 | 43 | 34 |

| Mar., 2019 | 38 | 41.5 | 34.5 |

| Apr., 2019 | 37.7 | 41 | 34.5 |

| May, 2019 | 37.2 | 40.5 | 34 |

| June, 2019 | 36.2 | 38 | 34.5 |

| July, 2019 | 36.5 | 38.5 | 35 |

| Aug., 2019 | 37.2 | 39 | 35.5 |

where

Besides, the vaporization latent heat is defined by:

Table 2 shows that the thermal efficiency of the conventional distiller ranged from 34% to 35.5%. In addition, the efficiency of the solar still with finned with non- perforated fin ranged from 36.2% to 38.5% while the efficiency of the solar still with finned with perforated fin ranged from 38% to 43%, depending on the month.

5. Conclusions

The key findings of this study are as follows:

1. The daily fresh water yield of a conventional solar still can be enhanced by using perforated inclined fins that are integrated at the basin plate.

2. The daytime productivity of the solar still with perforated inclined fins was found higher than that of the conventional solar still, due to improve the thermal performance of the finned basin solar still.

3. The accumulated productivity values of the conventional solar still are 3.02, 3.17, 3.39, and 3.63 l /m2 for the months of February, March, April, and May, respectively. While, the productivity values of the finned solar still are 4.13, 4.51, 4.41, and 4.72 L/m2 for the same previous months.

4. The solar still with perforated inclined fins gives an average of 33.2% increase in the amount of distilled water produced in comparison with that of a conventional still.

nueva página del texto (beta)

nueva página del texto (beta)