1. INTRODUCTION

The evolution of fibre reinforced composite-based producís is becoming a trend in engineering application. Natural fibres have unique role in the ecological cycle, and their natural abundance, plentiful supply and relative cheapness are matched by the ease and readiness with which these resources can be swiftly replenished. Such materials can therefore provide a compatible and competent alternative reinforcing material in composite production.

Studies on natural fibres show that these materials exhibited lower durability and lower strength compared to glass fibres, however, low specific gravity resulted in a higher specific strength and stiffness than glass fibres, which is considered as benefits especially in parts designed for bending stiffness.

However, Rowell, Sanadi, Caulfield, and Cobson (1997) reported that the efficiency of the natural fibre-based composites depends on the fibre-matrix interface and the ability to transfer stress from the matrix to the fibre, they went further to note that the main obstacles in the use of natural fibres have been the poor compatibility between the fibres and the matrix that may lead to micro-cracking of the composite and degradation of mechanical properties. Various treatments have been used to improve the matrix-fibre adhesión in natural fibre reinforced composites. Numerous findings show that alkaline treatment leads to formation of high amounts of voids and rougher surfaces, while silane treatment further improves the interfacial adhesión and mechanical properties of the composites .

Additionally, Rowell, Han, and Rowell (2001) reported that the performance of a given fiber used in a given application depends on several factors including chemical composition, physical properties, the interaction of a fiber within the composite matrix, and how that fiber or fibre-matrix performs under a given set of environmental conditions. In order to expand the use of agro-fibers for composites, it is essential that information is available on fiber characteristics and the factors which effect performance of that fiber. This is necessary for the development of a detailed data base of chemical and physical properties of the vast variety of natural fibers that are potentially available in the world. It is also necessary to understand the factors which affect the performance of a given fiber in a given application.

In general, engineering properties of natural fibre reinforced composites lay emphasis on stiffness, low density, dimensional stability and strength, of which stiffness plays dominance especially in the áreas of structural application. Apart from the characteristic of low cost, acceptable specific strength, biodegradability and renewability, it is essential therefore, that the elastic property of reinforcing fibres are known, even for failure prediction purposes.

Wambua, Ivens, and Verpoest (2003), in their work noted that the tensile modulus, impact strength and the ultimate tensile stress of kenaf reinforced polypropylene composites were found to increase with increasing fibre weight fraction. Vannan and Vizhian (2014) found in their work that, as short basalt fiber content was increased from 2.5% to 10% by wt. %, an improvement in Young's modulus of 13.26% has been observed and that optical microscopy was used to examine the general microstructure and fiber distribution in the composite produced, including the use of Scanning Electron Microscope (SEM) to observe and understand the failure mechanism of the fractured surface. Research attempts have been made to improve the elastic behaviour of natural fibres by adopting appropriate fibre treatment process including improved processing techniques to eliminate, or at best reduce the processing-induced flaws.

One of the most important properties of natural fibres is their elastic behavior which is well documented. Other research findings show that most natural fibres elongate substantially when subjected to tensile stress.

Research attempts have been made to improve the elastic behaviour of natural fibres by adopting appropriate fibre treatment process including improved processing techniques to eliminate, or at best reduce the processing-induced flaws. One of the most important properties of natural fibres is their elastic behavior which is well documented. In general, most natural fibres elongate substantially when subjected to tensile stress leading to high strain valúes, including the exhibition of modérate degrees of elasticity and plasticity.

In the context of utilization of oil palm trunk fibres for studies, the following findings were noted. It was found that oil palm trunk fibres contain large amount of lignin, including very porous and lacuna-like cross-section with varying diameters, whose factors affect their mechanical properties, such as high ductility, but have lower tensile strength than most other natural plant fibres was reported (Sreekala, Kumaran, & Thomas, 1997).

The effects of both particle size and filler loading in oil palm frond polypropylene matrix, especially on the significant difference at 95 % confident level in the tested samples for flexural Modulus of Rigidity (MOR), flexural Modulus of Elasticity (MOE), tensile strength, tensile modulus, elongation at break, and water absorption behavior was worked-on by who reported that largest size showed the best mechanical properties among the others, contradicted the previous reports on wood particle thermoplastic composite.

Hashim et al. (2011) reported on the modulus of rupture, infernal bond strength, water absorption and thickness swelling of the boards of particle boards made from oil palm trunk.

Their result showed that moduli of rupture of the samples increased with increasing press temperature, even without satisfying the standard valúes, while attaining the satisfactory valúes for all three temperature levéis.

Anyakora and Abubakre (2011) reported that the composites of oil palm empty fruit bunch, another part of oil palm tree, exhibited improved impact strength properties from 10% fiber content to 60% fiber content after which problems of poor wetting set-in, the findings of Ahmad, Saman, and Tahir (2010) reported that the compressive, tensile and flexural strength properties of the concrete improved by the addition of 1% oil palm trunk fibre which acted as crack arrester, that the low dosage of oil palm trunk fibre improves the resistant against NaOH and NaCl attack but concrete with high dosage of oil palm trunk fibre have good resistance against the HC1.

Findings by Ventura, Morón, and Ardanuy (2014) showed that the alkaline treatment oil palm frond fibers was effective for increasing the wettability of the fibers leading to composites with a good-balanced between lightness 2014 and toughness for potential applications in packaging or automotive industries.

It was obvious that most researches concentrated on the effect of fibre loading and surface treatment, but little and apparent lack of information on the effect of microstructural analysis on the elastic properties of oil palm trunk composites.

Notwithstanding the inherent justification of alkaline and silane treatment of oil palm trunk for improved mechanical properties, the establishment of relationship between the micro-structure and elastic properties of oil palm trunk fibre will stimulate further work in natural fibre utilization, especially for the purpose of using suitable fibre type, treatment method and processing procedures for any desired composite application, even for mechanical property tailoring and behavioural predictive purposes.

2. MATERIALS AND METHODS

2.1 MATERIALS

The oil palm fibres were obtained from trunks of mature and fruited plants with known age, and used within two weeks of felling. These extracts were processed at the Pulp and Paper section of Federal Institute for Industrial Research, (FURO) Oshodi, Lagos, Nigeria into tangled mass of varying diameters of 0.45mm - 0.81mm and lengths of 12.00mm - 36.90mm.

The Polymer used was Siropol 7440 un-saturated polyester resin purchased from Dickson Chemicals Ltd, Lagos, Nigeria with specific gravity of 1.04, viscosity of 0.24 Pa.s at 25°C. Other chemicals used were; cobalt in styrene, diglycidylethers and phenylsilane procured from Zayo - Sigma Chemicals Limited, Jos, Nigeria.

A two-part mould facility (mild steel flat 4mm thick sheet) - of 150mm x 150mm with active surfaces ground, pre-designed cavity of 5mm depth, with clamping bolts in place, fabricated at the Dantata & Sawoe Mechanical Workshop, Abuja, was adopted in the production of test specimen plates.

Other equipment used were Universal Testing Machine, Instron, Model 3369, Compact Scale (Model -FEJ, Capacity - 1500g, 1500A) and EVO/MA 10 Scanning Electron Microscope by JPEG SmartSEM software, of 5 nanometer resolution, installed at Shetsco Science and Technology Complex, Gwagwalada, Abuja, Nigeria.

2.2 METHODS

The oil palm trunk fibre was processed using the method by Anyakora and Abubakre (2011). The collected trunks of oil palm fibres were extracted by chemico-mechanical process. The process involved the impregnation of sample with solution of sodium hydroxide and sodium sulfide and conversión of the softened sample into fibre by mechanical action, followed by thorough washing, screening and drying. The extracted fibres were separated, re-washed and dried in the forced-air circulation type oven. The fibres were subsequently weighed and percentage yield determined.

The process adopted in this work was the silane treatment preceded by the sodium hydroxide treatment. Known weights of extracted oil palm trunk fibres were soaked in prepared known volume of 0.5 mol/litre of NaOH for 2 hours. The producís were removed and washed with distilled water before air-drying. Subsequent processes included soaking the surface-treated fibres in 2% phenlysilane solution for 24 hours. Subsequently, the product was removed, dried at 60°C and stored in specimen bag ready for use.

The production of test specimen panels was carried out in compliance with the relevant test standard for reinforced plastics - BS ISO 1268-3:2000 produced following the method by Anyakora and Abubakre (2011) as follows; oil palm trunk fibres were cut and weighed on a calibrated compact scale. The recorded weights of fibres were manually placed in the mould facility already prepared while ensuring that no material was lost in the process. Since the fibres are of tangled mass, arrangement of angle did not have a preferred orientation, thus, the composites in this work were considered as randomly oriented. Subsequently, polyester mix was prepared using 100 mi of unsaturated polyester resin and 1 mi of accelerator plus 1 mi of hardener (which was previously determined to the best curing needed for the fibres). The polyester mix was weighed on calibrated compact scale. Two sets of matrix systems were prepared; one set each for the treated fibre, and other for the un-treated fibre composite preparation. Using the known 10% to 70% by weight of the treated and untreated fibres, corresponding 90% to 30% by weight of the matrix system sets were prepared. The polyester resin mix was poured into the mould cavity containing tangled fibre mass fully laid in the cavity cleaned and pre-placed with aluminum foil. The top mould was subsequently placed and clamping bolts fully secured. The mould containing the un-cured composite was placed in an oven operated at 110°C, and removed after 30 minutes, and allowed to cool to room temperature before placing in humidity controlled bag.

The production of test specimen panels was carried out in compliance with the relevant test standard for reinforced plastics - BS ISO 1268-3:2000 produced following the method by Anyakora and Abubakre (2011) as follows; oil palm trunk fibres were cut and weighed on a calibrated compact scale. The recorded weights of fibres were manually placed in the mould facility already prepared while ensuring that no material was lost in the process. Since the fibres are of tangled mass, arrangement of angle did not have a preferred orientation, thus, the composites in this work were considered as randomly oriented. Subsequently, polyester mix was prepared using 100 mi of unsaturated polyester resin and 1 mi of accelerator plus 1 mi of hardener (which was previously determined to the best curing needed for the fibres). The polyester mix was weighed on calibrated compact scale. Two sets of matrix systems were prepared; one set each for the treated fibre, and other for the un-treated fibre composite preparation.

Using the known 10% to 70% by weight of the treated and untreated fibres, corresponding 90% to 30% by weight of the matrix system sets were prepared. The polyester resin mix was poured into the mould cavity containing tangled fibre mass fully laid in the cavity cleaned and pre-placed with aluminum foil. The top mould was subsequently placed and clamping bolts fully secured. The mould containing the un-cured composite was placed in an oven operated at 110°C, and removed after 30 minutes, and allowed to cool to room temperature before placing in humidity controlled bag.

3. RESULTS AND DISCUSSION

3.1 THE ELASTIC PROPERTIES

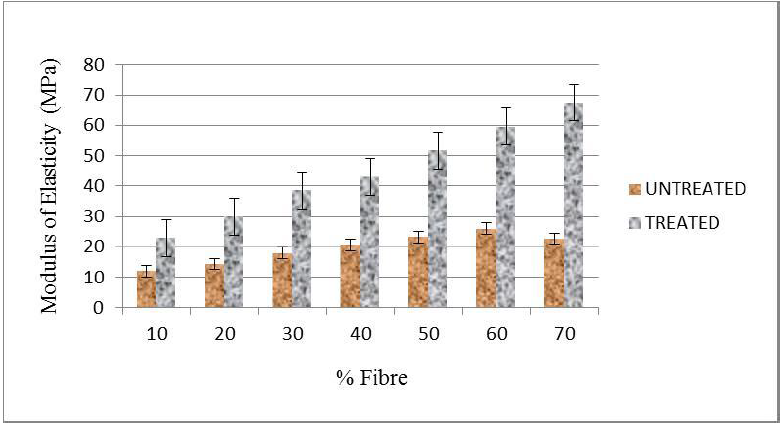

The MOE properties of the composites were measured and the results are represented in Figure 1.

It was observed that the treated oil palm trunk treated composites exhibited outstanding MOE valúes showing the positive effect of surface treatment for achieving improved elastic properties. Although there was remarkable and continuous increment in the MOE of treated oil palm trunk fibre composites, the trend was similar to the valúes of MOE for untreated composites till 60wt. % fibre content before subsequent drop. This was different from the findings of Keramat, Jahromi, Jafari, Mohtasebi, and Rafiee, (2008) - which the modulus of elasticity increased with increasing fibre content. This could be ascribed to fabrication defect and the unstable morphology of oil palm fibre.

Other corroborated findings include the consideration of large amounts of lignin contained in oil palm fibres, with very porous and lacuna-like cross-section of varying diameters, that affect their mechanical properties, such as high ductility, but have lower tensile strength than most other natural plant fibres reported by Sreekala et al.. (1997), including the moduli of elasticity of treated fibre reinforced plastics generally improving with increased fibre content in the composite.

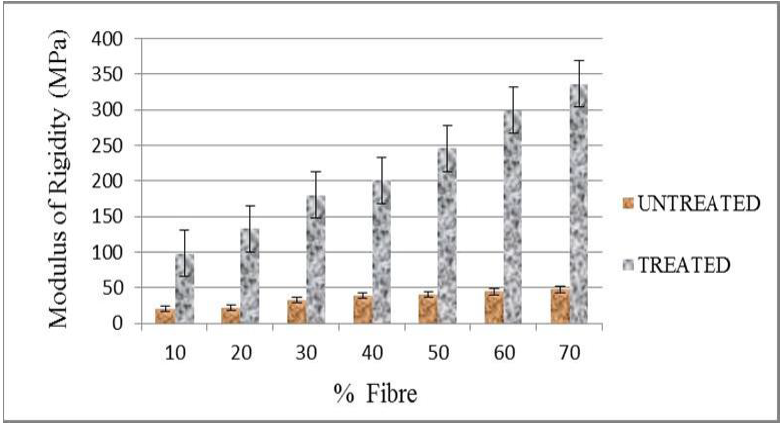

The MOR properties of the composites were measured and the results are represented in Figure 2.

From the results shown in Figure 2, it was obvious of very outstanding valúes of Modulus of Rigidity even higher than observed in the MOE. Surprisingly, there was no drop in MOR after 60wt. % fibre content as in the MOE results. It was obvious that the issue of unstable morphology of oil palm trunk fibre superseded the suggested fabrication defect.

3.2 MICROSTRUCTURAL ANALYSIS OF COMPOSITES

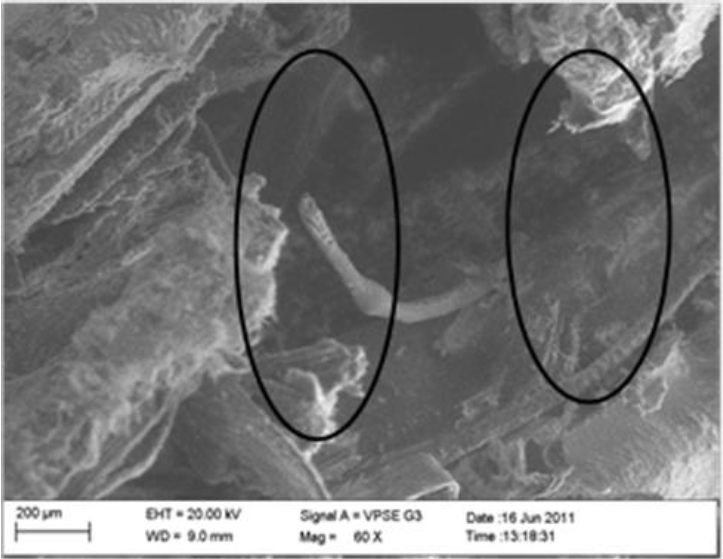

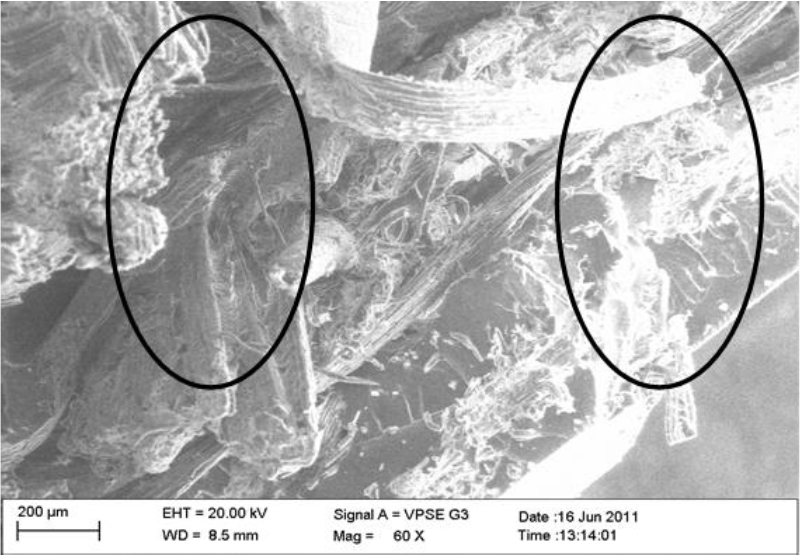

The SEM analyses of fractured surfaces after tensile loading of the composites are represented in Figures 3 and 4

Fig. 3 SEM micrograph of untreated oil palm trunk fibre reinforced polyester composite showing fibre peeling and pulí out at 70wt. % fibre content.

Fig. 4 SEM micrograph of treated oil palm trunk fibre reinforced polyester composite showing the tensile fractured surfaces at 7üwt. % fibre content.

From the scanned electrón microscopy, an indication of uneven mixing of the fibre surfaces with protrusions and small voids were observed in both the untreated and fractured treated natural fibre composites showed that the composites failed by a combination of fibre fracture and fibre pull-out indicating that fibre fracture was a major mechanism in the strength of composite. The results of the fractured surfaces showed that the reinforcing fibres were damaged during stress loading suggesting that the mechanism of fracture was dependent on the fibre type, fibre strength and void content of the sample.

4. CONCLUSION

Based on the results, it was deduced that MOE and MOR properties showed increasing trend as the fibre was increased. The essence of improving the matrix-fibre adhesión through surface treatment was achieved in the outstanding elastic properties of composites of oil palm trunk fibres composites. Addftionally, it was concluded that there was a drop in the MOE of both the untreated and treated composites after 60wt. % fibre content. The SEM results showed that the pattern of failure of the composites were consistent with previous studies inferring that the elastic properties of investigated oil palm trunk fibre composites were dependent largely on the microstructural factors.

Inference was therefore made that, knowledge of effect of fibre loading, alkaline and silane treatment processes and established relationship between the micro-structure and elastic properties were desirable in the utilization of oil palm trunk fibre composite for a desired engineering application.

CONFLICT OF INTEREST

The authors have no conflicts of interest to declare.

text new page (beta)

text new page (beta)