Introduction

Nowadays, an effort has been made to use biodegradable polymers for natural sources. Natural biopolymers come from four main sources: animal, seafood, agricultural and microbial [1].

Starch, is a polysaccharide that has been used as a raw material for production of biomaterials for applications in agriculture and food because of its low cost, availability, good tensile strength, and it is derived from a renewable resource [1), (2].

Triticale (X triticosecale Wittmack) is a cereal grain of selfing, obtained artificially by humans from crossing wheat with rye. Its name is a combination of prefix Tritico (derived from Triticum) and the suffix Secale, the genera of the botanical parent plants. This is a cereal that adapts to any climate even more than wheat. It has a high starch content between 57 % and 65 %, which gives it great potential for applications as forage and as a biomaterial [3],[4],[5].

Due to the agri-food potential of the triticale crop, INIA (Institute of Agricultural Research, Chile), through its regional research centers, has developed a series of new varieties of triticale, among them Aguacero, Faraón and Peteroa.

Many studies have been done related to starch quality determination [6]. However, for triticale starch, there are few information about rheological properties. Among new equipment for rheological characterization, Mixolab® has been used to determine the thermo-rheological properties of starches [7], replacing conventional instruments with the advantage of having information about protein weakening, starch gelatinization and retrogradation in only one test [8].

Different films based on thermoplastic starches such as corn [9], potato [10], cassava [11] and wheat [12], have been elaborated and characterized. However, other sources of starch different than foodstuffs have been sought. For example: banana [13], tapioca [14] or mango [15], among others. Triticale as a new source of starch could be a good alternative for film preparation. Morphological, crystalline structure and thermal properties for triticale starch films were characterized in a previous work [5]. However, thermo-rheological and mechanical properties were not evaluated.

The aim of this work was to evaluate the physico-chemical properties and thermo-rheological behavior of Aguacero, Faraón and Peteroa triticale starch varieties and to report mechanical properties of this starch as a new source for biodegradable polymeric films with potential applications in packaging.

Materials and methods

Triticale grains from Aguacero, Faraón and Peteroa varieties Downpour-INIA, were provided by INIA-Quilamapu, Chile. Glycerol was bought to Wrinkler.

Starch isolation

The extraction method using a pretreatment with temperature was used for starch isolation [16],[17],[18]. In brief: 300 g of starch was washed with cold water and mixed with 600 mL of water at 50 °C during 48 h with the incorporation of SO3 (0.2 %). Then, NaOH (0.2 %) was added at the end of the procedure. Water was discarded and triticale was blended in an Oster blender (model 972-55H) with additional water for 10 min. Then the mixture passed through a U.S. Standard sieve N°35 (500 μπι) and later through an ASTM-E11 sieve (125 μιη). After 12 h of sedimentation, the supernatant was removed and the sample was centrifuged using a Weisser Hettich model Eba-85 for 15 min at 3000 rpm. This procedure was repeated. The obtained starch was dry-oven in Memmeret Labtec oven at 50 °C for 24 h. Dry starch was blended again and finally, passed through the U.S. Standard sieve N° 35.

Blends and films elaboration

Thermoplastic starch (TPS) for each variety were elaborated for two starch/glycerol/water compositions: 50/25/25 and 50/35/15. TPS was prepared using a Cooler Mixer (LABTECH Engineering Company LTD, model LMX10-S-VSFI) during 3.9 min at 2800 rpm. Starch films were elaborated by casting method. Also, specimens (15 χ 2.5 χ 0.3 cm3) were hot pressed using a hydraulic press (LABTECH Engineering Company LTD, model LP20-B) at 120 oC for 10 min and 80 bars for the mechanical tests.

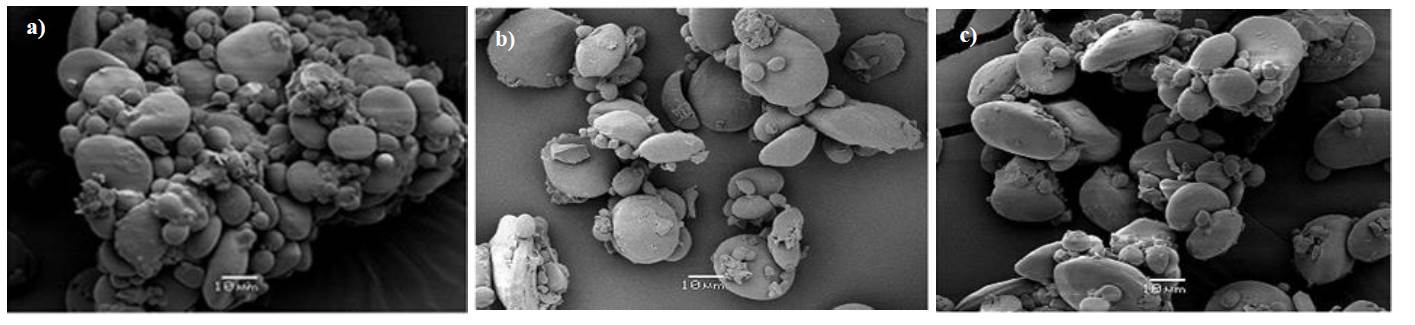

Granules morphology

The morphology of the three varieties of triticale was studied using a scanning electron microscope ETEC Autoscan. Samples were gold coated by the use of a sputtering. Size of the starch granules was determined from analysis of the microphotographs obtained using the program Image J version 1.46a.

Chemical analysis

Triticale starch varieties were evaluated for humidity by oven-drying at 50 °C for 48 h. The protein content was assessed using the Kjeldahl method (AOAC 2.057 method), lipids by the AOAC 7.062 method and total starch content of the flour by using the Megazyme Kit for total starch (AOAC 996.11). The amylose content was determined using the UNE-EN ISO 6647-1:2008 [19]. The data were reported as means ± SD (n = 3).

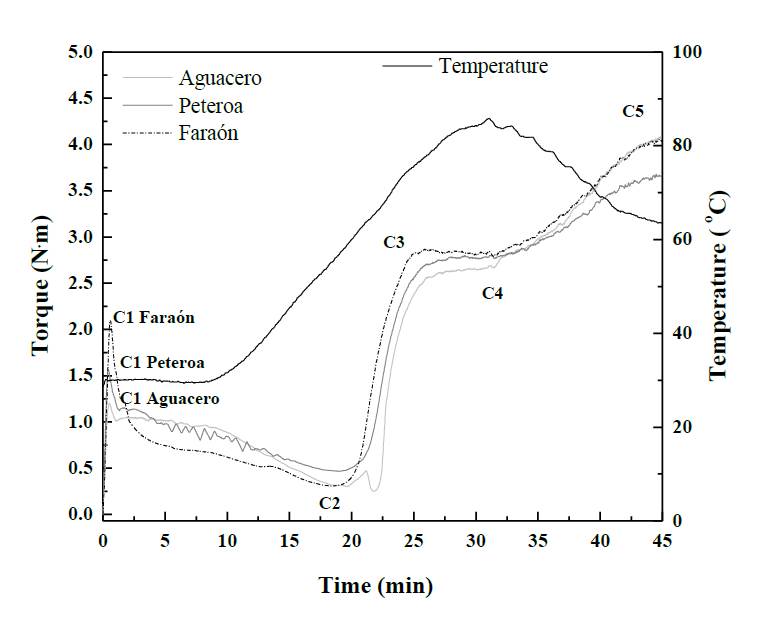

Thermo-rheological measurements

The thermo-rheological measurements were performed by placing 30 g of the sample into the Mixolab® bowl (Chopin Technologies, France) and then, mixing. Water for optimum consistency (1.1 Nm) was 65 %. The mixing speed was 80 rpm. The 1st stage corresponded to the initial mixing for 8 min at 30 °C. Temperature was increased at 4 °C/min from 30 °C to 60 °C (2nd stage). In the 3rd stage, the temperature was increased from 60 °C to 90 °C. Then, a holding period of 7 min at 90 °C was set (4th stage), followed by a temperature decrease of 4 °C/min until 50 °C, and 5 min holding time until the 5th stage. Total time analysis was 45 min. Each analysis was conducted in duplicate.

Results and discussion

Granules morphology

From Figure 1 the morphology of Faraón, Aguacero and Peteroa starch granules is observed, respectively. The micrographs of Faraón triticale (Figure 1a) shows small spherical and large oval granules. The average particle size diameter was 9 ± 2 μπι. (Figure 1b) shows microphotographs of Aguacero triticale starch. Large granules with mostly oval shape and smooth surface were observed. The average diameter was 16 ± 2 μπι. Finally, for Peteroa starch (Figure 1c), granules with uniform size and shape distribution with large granules are seen. Average diameter size was 14 ± 1 μπι.

Chemical analysis

The results for the chemical analysis of the three triticale varieties showed a starch content of the flour of 74.0 ± 2.0 %, 70.3 ± 1.1 % and 74.0 ± 1.6 %, for Aguacero, Faraón and Peteroa starches, respectively. Fras et al. [20] reported that the starch content of eight Polish winter hexaploid triticale varieties flours ranging from 68.2 to 77.5 %. Values obtained for the three triticale varieties are within this range.

The moisture content was lower for Aguacero (6.7 ± 3.2 %) followed by Peteroa (9.2 ± 4.3 %) and Faraón (11.7 ± 3.8 %) varieties compared with the value of 13.25 ± 0.02 °% (for Buck TK 25 variety) obtained by Aguirre et al. [4].

Protein content for the three varieties: Aguacero (4.1 ± 0.7 %), Faraón (5.2 ± 0.2 %) and Peteroa (6.3 ± 1.2 %) was lower compared to the values between 9.8 and 13.9 % reported by Fras et al. [20].

Lipids content were within the range (1-2.4 %) reported by Rakha et al. [21] for Sweden triticale varieties, being 2.0 ± 1.3 % for Aguacero, 0.9 ± 0.2 % for Faraón and 1.2 ± 0.5 % for Peteroa varieties studied.

Also, the amylose content were within the range reported in the literature, 13.8-32.6 [22] for 33rd ITSN and 33rd ITYN triticale varieties. Obtained values in this work were 21.8 ± 3.3 %, 20.7 ± 5.2 % and 20.3 ± 3.1 % for Aguacero, Faraón and Peteroa starches, respectively.

Thermo-rheological measurements

From Figure 2, Mixolab® curve for the three triticale starches varieties is shown. The main difference was found for C1 which is the initial maximum consistency (Nm) use to determine the water absorption. This torque value was higher for Faraón (2.10 N m), followed by Peteroa (1.55 Nm) and finally Aguacero (1.20 Nm). Flours with smaller particle size showed higher water absorption [23]. Faraón had the smaller granule size (see Figure 1) and the highest moisture content (11.7 ± 3.8 %) in agreement with the results for C1 values shown in Figure 2. On the other hand, the protein weakening range (C2-C1), the 3rd and 4th stages (swelling and gelatinization) and the 5th stage of retrogradation were similar for the three starches. The gelatinization temperature obtained were 82.2 °C for Faraón starch, followed by Peteroa (72.0 °C) and finally Aguacero (65.6 °C). Faraón starch showed a higher gelatinization temperature compared to the other starches. Gelatinization temperature is higher and had a broader range for starches with smaller granule size compared to starches with larger granule size. [24].

Mechanical tests

From Table 1, the mechanical properties of TPS starch films are shown. The main factors evaluated were the starch type and the concentration of plasticizer (glycerol and water) for the different compositions of starch/glycerol/water 50/25/25 and 50/35/15.

Table 1 Mechanical properties of TPS starch films

| Variety | Composition | E (MPa) | σβ (MPa) | Ɛβ (%) |

|---|---|---|---|---|

| Aguacero | 50/25/25 | 1.54 ± 1.12 | 0.04 ± 0.01 | 36.35 ± 14.41 |

| Aguacero | 50/35/15 | 0.54 ± 0.42t | 0.03 ± 0.01 | 41.21 ± 8.84 |

| Faraón | 50/25/25 | 1.90 ± 1.09 | 0.04 ± 0.02 | 34.69 ± 6.93 |

| Faraón | 50/35/15 | 0.67 ± 0.36t | 0.03 ± 0.01 | 37.94 ± 8.64 |

| Peteroa | 50/25/25 | 1.16 ± 0.38 | 0.06 ± 0.01 | 39.34 ± 7.39 |

| Peteroa | 50/35/15 | 0.37 ± 0.3!t | 0.02 ± 0.02 | 64.77 ± 14.14 |

Values correspond to the average of three repetitions ± the standard deviation. է Values are statistically different (p = 0.05).

In Table 1, it can be seen that the values of modulus of elasticity or Young's modulus (E), were higher for the films of composition 50/25/25, as well as tensile strength at break (σβ), while the percentage of elongation at break (Ɛβ) was higher for the films of 50/35/15 composition. This can be attributed to the higher glycerol content of these films, which acts as a plasticizing agent. Therefore, when the content of glycerol in the films is increased, the tensile strength decreases and the elongation at break increases, which indicates that the increase in the amount of plasticizer reduces the intermolecular forces making the material more flexible [25].

Moreover, the final mechanical properties of the films are the result of interactions between the functional groups such as C-O and OH, present in starch, glycerol, and water and in some degree of miscibility or compatibility [26]. It can be seen, that for the same proportion 25/25 of glycerol/water in the films the Young's modulus is higher and the elongation at break is lower compared for the 35/15 glycerol/water proportion. It seems, that the plasticizing effect of glycerol is stronger than water. It has been found in the literature that starch and glycerol are partially miscible [27].

For the 50/25/25 composition, the film with the highest Young's modulus was for Faraón triticale starch (1.90 ± 1.09 MPa), followed by Aguacero (1.54 ± 1.12 MPa) and Peteroa (1.16 ± 0.38 MPa). Also, for the 50/35/15 composition, with values of 0.67 ± 0.36 MPa, 0.54 ± 0.42 MPa and 0.37 ± 0.31 MPa, for Faraón, Aguacero and Peteroa, respectively.

Additionally, the moisture content could generate a stiffening effect. From the chemical analysis, it was found, that the starch with the highest moisture content was the Faraón and from Table 1, it can be seen that the composition based on Faraón starch (50/25/25) had the highest Young's modulus. Then, the water associated to the starch molecules has a significant effect in the starch films mechanical properties [28].

On the other hand, for the most flexible film was for Peteroa composition 50/35/15 with 64.77 ± 14.14 % of elongation at break, followed by Aguacero (41.21 ± 8.84 %) and finally by Faraón (37.94 ± 8.64 %). Same behavior was observed for the 50/25/25 composition (see Table 1). These results are in agreement with the behavior of mechanical properties in which the samples with lower Young's modulus had the higher elongation at break and vice-versa [25].

Related to particle size, it was observed that for the starch having the smaller granule size which corresponds to Faraón, had a higher Young's modulus and lowest elongation at break. This is because for a smaller size, there is an increase in the surface-to-area contact having a more stiffening effect [29].

Conclusions

A complete physico-chemical and thermo-rheological characterization of three varieties of triticale starch was achieved by using chemical analysis and Mixolab®. In accordance to SEM observations, a more homogeneous grain size distribution was observed for Peteroa and Aguacero varieties compared to Faraón. Differences in gelatinization temperature were found for the starches. From the mechanical tests, the film with the highest Young's modulus was for Faraón 50/25/25 composition and the highest elongation at break was observed for Peteroa 50/35/15 composition. Triticale could be considered as a new source for thermoplastic biodegradable polymeric films with potential applications in packaging. However, TPS alone, does not have enough mechanical properties. Therefore, it should be used in compounds-based biodegradable polymer matrices.

nova página do texto(beta)

nova página do texto(beta)