Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista mexicana de ingeniería química

Print version ISSN 1665-2738

Rev. Mex. Ing. Quím vol.11 n.2 Ciudad de México Aug. 2012

Biotecnología

Effect of aeration on the fermentative activity of Saccharomyces cerevisiae cultured in apple juice

Efecto de la aireación en la actividad fermentativa de Saccharomyces cerevisiae cultivado en jugo de manzana

W. Estela-Escalante1,3*, M. Rychtera1, K. Melzoch1 and B. Hatta-Sakoda2

1 Department of Fermentation Chemistry and Bioengineering, Faculty of Food and Biochemical Engineering. Institute of Chemical Technology Prague. Technická 5, 166 28. Praha 6, Dejvice. Czech Republic.*Corresponding author. E-mail: Waldir.Desiderio.Estela.Escalante@vscht.cz, waldire@post.cz

2 Facultad de Ingeniería de Industrias Alimentarias, Universidad Nacional Agraria La Molina. La Molina, Lima, Perú.

3 Laboratorio de Biotecnología Agroindustrial, Escuela de Ingeniería Agroindustrial, Universidad Nacional Micaela Bastidas de Apurímac. Av. Arenas 121, Abancay-Apurimac, Perú.

Received October 30, 2011;

Accepted December 27, 2011

Abstract

The influence of aeration on the fermentative activity of Saccharomyces cerevisiaeRTVE V 15-1-416 was studied in order to evaluate the synthesis of fermentation by-products. To achieve this, the strain was cultured in Erlenmeyer flasks and bioreactor containing sterilized and aroma removed apple juice. The chemical compounds produced during fermentations in shaken (200 min-1) and static (without agitation) flasks and bioreactor, all in batch mode, were determined by GC and HPLC. The results showed that agitation of the culture médium dimishes production of total higher alcohols (316.0±27.5mg/L) compared to static cultivation (557.8±28.1mg/L) and enhances slightly ethyl acétate production (75.0±6.5mg/L), whereas on the contrary, the production of acetic acid and glycerol (266.0±8.0mg/L and 2.9±0.2g/L) were higher compared to shaken cultivation (51.0±4.5mg/L and 0.11±0.05g/L) respectively. Batch cultivations carried out in bioreactor with constant air flow of 0.28vvm reported a specific growth rate (μ) of 0.13h-1 and maximum concentration of ethanol of 42.3g/L during aerobic fermentation. Aeration promotes cell growth, diminishes ethanol yield and, provokes acetic acid uptake and succinic acid synthesis whereas malic acid and ethanol were consumed after sugar depletion. The best results in terms of sensory acceptability of the fermented beverage were obtained when cultivated statically. Aeration control during fermentation with this strain can be used to control the synthesis of chemical compounds of sensory importance.

Keywords: Saccharomyces cerevisiae, alcoholic fermentation, higher alcohols, ethyl acétate, batch cultivation.

Resumen

Se ha estudiado la influencia de la aireación en la actividad fermentativa de Saccharomyces cerevisiae RIVE V 15-1-416 con la finalidad de evaluar la síntesis de sub productos de la fermentación. Para lograr esto, la cepa se cultivó en frascos Erlenmeyer y en biorreactor conteniendo jugo de manzana estéril y sin aroma. Los compuestos químicos producidos durante la fermentación en cultivo agitado (200 min-1), estático (sin agitación) y en cultivo batch fueron determinados por GC y HPLC. Los resultados mostraron que la agitación del medio de cultivo disminuye la producción total de alcoholes superiores (316.0±27.5mg/L) comparado al cultivo estático (557.8±28.1mg/L) y mejora ligeramente la producción de etil acetato (75.0±6.5mg/L), mientras que por el contrario, la producción de ácido acético y glicerol (266.0±8.0mg/L y 2.9±0.2g/L) fueron mayores comparado al cultivo agitado (51.0±4.5mg/L y 0.11±0.05g/L) respectivamente. Cultivos batch realizados en biorreactor con flujo constante de aire de 0.28vvm reportaron una tasa específica de crecimiento (μ) de 0.13h-1 y una máxima concentración de etanol de 42.3g/L durante la fermentación aerobia. La aireación promueve el crecimiento celular, disminuye el rendimiento de etanol y provoca la toma de ácido acético y la síntesis de ácido succínico, mientras que el ácido málico y etanol fueron consumidos después del agotamiento de los azúcares. Los mejores resultados en términos de aceptabilidad sensorial de la bebida fermentada fueron obtenidos cuando se cultivo estáticamente. El control de la aireación durante la fermentación puede ser usado para controlar la síntesis de compuestos químicos de importancia sensorial.

Palabras clave: Saccharomyces cerevisiae, fermentación alcohólica, alcoholes superiores, etil acetato, cultivo por lote.

1 Introduction

The capability of Saccharomyces cerevisiae to ferment rapidly sugars is used in different technological applications, such as beer, bread, wine and, industrial ethanol productions. S. cerevisiae is facultatively fermenting yeast. Depending on the oxygen and glucose concentration in the médium this yeast shows different metabolic behaviour. Thus, under anaerobic or oxygen-limited conditions it exhibits alcoholic fermentation (Van Dijken and Scheffers, 1986). Moreover, S. cerevisiae is one of the few yeasts with capacity to grow rapidly under anaerobic conditions (Visser et al., 1990). Under fully aerobic conditions a mixed respiro-fermentative metabolism is observed (Crabtree-positive effect) when the sugar concentration exceeds a certain threshold valué (approx. 1 mM) (Verduyn et al., 1984; Kappeli, 1986; Verduyn, 1991). Conditions leading to sugar fermentation results in the formation of ethanol, acetic acid, glycerol and other compounds and consequently it reduces the biomass yield (Beudeker et al, 1990). A fully respiratory sugar metabolism can only be achieved aerobically in fed batch cultivation or cultures grown under sugar limitation in chemostat at specific growth rates lower than two-thirds of the máximum specific growth rate on glucose, i.e. 0.44 h-1 Petrik et al., 1983; Sonnleitner and Kappeli, 1986; Postma et al, 1989; van Dijken et al, 1993; Paalme et al., 1997). Molecular oxygen serves mainfy as final electrón acceptor during respiration of glucose but also it is necessary in several biosynthetic pathways, such as those for heme (prosthetic group), sterols, unsatured fatty acids, pyrimidines and deoxyribonucleotides synthesis (Andreasen and Stier, 1953; Nagy et al., 1992; Rosenfeld and Beauvoit, 2003; Snoek and Steensma, 2006). The respiratory metabolism of S. cerevisiae yields approximately 16 ATP per mol of glucose consumed (Verduyn et al., 1991; Pronk et al., 1994). This results in a yield of 0.50 g biomass per g glucose (Verduyn et al, 1991; Pronk et al, 1994). Under fermentative conditions the yield is only two ATP per mol of glucose and consequently, the biomass yield of purely fermentatively growing cells is only 0.10 g biomass per g glucose (Verduyn et al., 1990).

When S. cerevisiae is grown under anaerobic conditions, all metabolites of the glycolysis except 2-phosphoglycerate, 3-phosphoglycerate and phosphoenolpyruvate and those of the tricarboxylic acid cycle are in high concentrations as compared with aerobic conditions. Presence of only 0.5-1% vol. O2 in the inlet gas reduces the concentrations of these metabolites (Wiebe et al, 2008). In addition, regarding to the activity of the pentose phosphate pathway, if the amount of oxygen available for cellular metabolism is reduced, the relative flux through this pathway diminishes and the flux through glycolysis increases (Gombert et al., 2001; Fiaux et al., 2003; Franzen, 2003; van Winden et al, 2005). Additionally, when S. cerevisiae is grown on glucose in batch culture under aerobic conditions, a certain part of the glucose is initially fermented to ethanol, which, in a sepárate second growth phase, serves as a carbon and energy source (Fiechter et al., 1981). Ethanol uptake rate and respiration decrease as the concentration of oxygen in the médium diminishes (Wiebe et al., 2008). During glucose metabolism reduced coenzymes (NADH) are produced and in order to maintain the redox balance inside the yeast cell, it must be reoxidized (NAD+).

Anaerobically, the only means by which S. cerevisiae can reoxidize surplus production of NADH is by glycerol production (Nordstrom, 1968; van Dijken and Scheffers, 1986; Albers et al., 1998). Under aerobic conditions, several systems for transporting excess of cytosolic NADH to the mitochondrial electrón transpon chain exist in S. cerevisiae (Luttik et al, 1998; Small and McAlister-Henn, 1998; Larsson et al, 1998). Moreover, glycerol may be also utilized as a carbon source under aerobic conditions by many yeasts. Acetic acid is normally produced during alcoholic fermentation; its accumulation would be a consequence of the insufficient activity of acetyl-CoA synthase required to completely oxidize acétate produced from acetaldehyde (van Urk et al, 1990).

2 Production of sensory important compounds by Saccharomyces cerevisiae

During alcoholic fermentation many chemical compounds of sensory importance are synthesized by S. cerevisiae. These compounds include esters, higher alcohols, organic acids, aldehydes, etc. Esters are the most important flavour compounds in many alcoholic beverages including beer and wine (Suomalainen, 1981). In order to produce esters, ethanol or higher alcohols, fatty acids, co-enzyme A (CoASH) and ester synthesizing enzyme are necessary (Nordstrom, 1962). Esters are formed intracellularly (Nykanen et al., 1977) and, depending on their chain length, they diffuse outside the yeast cell (Nykanen et al., 1977; Suomalainen, 1981). Several types of alcohol acetyltransferase (AATase) are responsible for ester synthesis (Yoshioka and Hashimoto, 1983; Fujii et al, 1996). During the synthesis of acétate esters, the acetyltransferases react with acetyl coenzyme A (acetyl-CoA) and, depending on the degree of affinity, with ethanol or higher alcohols (Nordstrom, 1962; Peddie, 1990; Yoshioka and Hashimoto, 1981; 1983). The synthesis of acétate esters such as isoamyl acétate and ethyl acétate by Saccharomyces cerevisiae during fermentation is ascribed to at least three acetyltransferase activities, namely alcohol acetyltransferase (AAT), ethanol acetyltransferase and iso-amyl AAT (Malcorps and Dufour, 1987; Minetoki et al, 1993; Lilly et al, 2000). It is believed that these enzymes may be involved in very different functions, including cellular fatty acid homeostasis and detoxication mechanisms. It was also reported that AATase activity is strongly inhibited by trace amounts of oxygen or by addition of unsaturated fatty acids to the médium (Yoshioka and Hashimoto, 1981, 1983).

Higher alcohols are quantitatively the largest group of aroma compounds in many alcoholic beverages (Amerine et al, 1980). They are identified by a strong, pungent smell and taste and can have a significant effect on the sensorial quality and character of wines (Rapp and Mandery, 1986; Pretorius and Hoj, 2005; Swiegers and Pretorius, 2005; Swiegers et al, 2005). Higher alcohols are produced either catabolically from the degradation of imported amino acids or anabolically via the biosynthetic route from the carbon source (Hammond, 1993). The amino acids are converted to their corresponding α-keto acids by transamination (leucine to α-oxoisocaproic acid, valine to aα-oxoisovaleric acid, and isoleucine to α-oxo-β-methylvaleric acid) (Dickinson and Norte, 1993; Dickinson et al., 1997). Alternatively, these α-oxo acids can be generated through the breakdown of glucose (Dickinson et al., 1997). Higher alcohols are then synthesized from the corresponding α-oxo acids by decarboxylation and reduction (Dickinson et al, 1997, 2000). The supplement of oxygen and the increase of temperature during fermentation enhance the production of higher alcohols since it increases the metabolism and as consequence it promotes the cellular growth (Barker et al, 1992).

The present manuscript reports on the effect of aeration on the fermentative metabolism and production of compounds of sensory importance by Saccharomyces cerevisiae RIVE V 15-1-416 cultivated in apple juice. In our experiments we considered basically three conditions of cultivation taking into account their technological importance; first when fermentation is carried out under very poor oxygen conditions (oxygen limited static cultivation), then under oxygen limited condition (agitated cultivation in shaker), depending on the speed of agitation and third when air is supplied to the médium (in bioreactor) with a constant flow rate (aerobic culture).

3 Material and methods

3.1 Microorganism and maintenance

Yeast strain Saccharomyces cerevisiae RIVE V 15-1-416 acquired from the collection of yeasts of the former Research Institute of Viticulture and Enology of Bratislava, Slovak Republic was used in the experiments. The strain was maintained on malt extract agar at 7 oC and reinoculated each three months.

3.2 Synthesis of compounds of sensory importance

In the experiments there was used concentrated, sterile and aroma free apple juice acquired from Severofrukt a.s, Terezin, Czech Republic. It was reconstituted with sterilized water until obtaining a total sugar concentration of 12.8%(w/v) and a corresponding pH 3.8 (Downing, 1988). Fermentations were carried out in agitated and in static (without agitation) modes at 28oC in 500 mi Erlenmeyer flasks containing 250 mi of médium. Fermentations carried out in shaken flasks on an orbital shaking machine (200min-1) during 8 days and those cultivated statically were left running for 15 days. All experiments were realized at 28oC. Inoculum propagation was carried out in 100 mi of sterile apple juice at 28 oC during 24 hours. The flasks were shaken at 200 min-1 in an orbital shaker. Cells were separated by centrifugation (3000 min-1 during 10 minutes) and then washed three times with sterile physiological solution. Fermentation media were inoculated with cells (approx. 1.0±0.1 grams based on wet weight) obtained immediatelly after centrifugation.

3.3 Batch cultivation in bioreactor

Apple juice of Rubin variety containing 13% (w/v) of total sugars and pH 3.8 was utilized in the experiments.

The apples were acquired from CZ-fruit, Prague-CR. The juice was extracted by pressing and then placed in 10 L glass containers. Pasteurization of the juice was done in order to eliminate the microflora and volatile compunds (El-Nemra et al., 1988; Su and Wiley, 1998). Subsequently, the juice was supplied with 1.2 g/L KH2PO4 and 1.2 g/L (NH4)2SO4 as phosphorus and ammonium sources in order to promote the growth of the yeast cells.

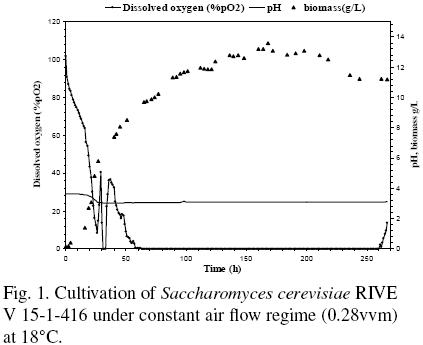

Cultivations were carried out in 1.5 L apple juice contained in a 2 L bioreactor (BIOSTAT-B.Braun International, Germany). The bioreactor was equipped with a pH-meter, thermometer and dissolved oxygen monitor. The bioreactor was connected to a control micro-DCU-300. The parameters which were kept constant during the whole process were: temperature 18oC, stirring frequency 300 min-1 and, air flow rate 0.28vvm (for oxygen 0.053vvm). Cultivation time was determined by the increase of the dissolved oxygen valué to its initial saturation valué then the cultivation was stopped.

The inoculum was propagated in 80 mi synthetic médium of the following composition: glucose 8.0 g/L; peptone 10.0 g/L; KH2PO4 1.2 g/L; (NH4)2SO4 1.2 g/L and yeast extract 10.0 g/L. The pH was adjusted to 3.8. Cell propagation was carried out in an orbital shaker at 150 min-1 during 48 hours at 28oC. Subsequently, the cells were separated by centrifugation (3000 min-1 during 10 minutes), washed with sterile physiological solution and finally inoculated into the bioreactor.

3.4 Analytical methods

Volatile compounds (higher alcohols and esters) produced during fermentation were analyzed by GC (Hewlett-Packard 5890II), equipped with a HP5 column (30m x 0.32mm) and FID detector. The samples were centrifuged and then filtered through 0.45 /im micro-membranes. Analyses of volatile compounds were performed using the method of dichloromethane micro extraction (Ortega et al., 2001). Finally 1 μl of each extract was injected into the column of the equipment.

Acetic, succinic and malic acid, ethanol, glycerol, fructose and glucose were analyzed by HPLC (Pump LCP 4000), equipped with a repacking Watrex 250 x 8mm column (Ostión LGKS 0800 H+ form) and a RID detector. The conditions of analysis were: column temperature 80°C, mobile phase 5mM H2SO4, flow rate 1ml/min. The samples after centrifugation (at the rotational frequency of 10000min-1) and filtration were diluted with demineralized water (1:3) before injecting to the equipment.

Cellular biomass was determined by gravimetry. Cells were separated by centrifugation (3000 min-1 during 10 minutes), then washed three times with distilled water, dried at 110°C during 2 hours and finally weighed. Additionally, the yield of biomass and ethanol (YX/s and YE/S) and, the specific growth rate (μ) were determined (van Hoek et al., 1998).

5.5 Sensory and statistical analyses

Sensory assessment of samples of fermented apple juice was performed using descriptive and preference tests. Attributes such as tas te, aroma and odor were evaluated using a Hedonic scale of 5 points (1=dislike extremely and, 5=like extremely). Samples were evaluated by a trained panel of 10 judges. The sensory evaluation was done according to Meilgaard et al. (1999). The sensory evaluation data were presented as means of the judge's score. A standard t-test was used to test for the statistical significance (P < 0.01) of the differences observed between the scores of the two fermented beverages (cultivated in agitation and statically). Statistical analysis was done using Statistica v.8.0 software.

4 Results and discussion

4.1 Cultivation under static and agitated conditions

When cultivating yeast Saccharomyces cerevisiae in fruit juices, in media with high sugar content the fermentation always occurred even when oxygen is present in sufficient concentration in the médium. Oxygen is necessary to improve the metabolism of Crabtree positive yeast and so to successfully complete the fermentation. Results showing formation of chemical compounds during fermentation by S. cerevisiae RIVE V 15-1-416 in static and agitated cultivations are shown in Table 1. Additionally, there are also shown compounds analyzed in ciders produced with different strains of Saccharomyces cerevisiae. Marked difference was observed in production of glycerol in static (2.9+0.2g/L) and agitated (0.11±0.05g/L) cultivations. Aerobic conditions would promote cellular respiration and so diminishing the glycerol production. It was reported that, its production would be a response to the osmotic stress as yeasts are cultured in presence of high sugar concentration. From the technological point of view a higher production of glycerol is required since it influences positively the sensory quality of alcoholic beverages; so it imparts a slightly sweet taste (Nieuwoudt et al, 2002).

Higher alcohols are important because of their detrimental impact on the sensory quality of fermented beverages, however a few exceptions exist. But at low concentrations they would contribute positively to the flavor and taste of eider, wine and beer for instance. In this study, it has been observed lower production of total higher alcohols in agitated cultivation (316.0+27.5mg/L) in comparison with static one (557.8+28. lmg/L). In this case, very low amount of oxygen (static cultivation) seemed to enhance the production of higher alcohols. Several authors reported that oxygen promotes the respiratory metabolism and as consequence a higher flux of glucose and amino acids whose break down produces intermediary compounds (α-cetoacids) for the higher alcohol synthesis (Ribereau-Gayon etal., 1975; Valero et al, 2002). In results of these experiments, production of higher alcohols would also depend on the yeast strain itself. From the sensory point of view, concentrations of higher alcohols higher than 400mg/L would contribute negatively to the organoleptic quality of wines (Rapp and Mandery, 1986). With exception of 2-phenylethanol which imparts a floral aroma (Ribereau-Gayon et al, 2006), whose perception threshold is lOmg/L (Rous et al., 1983), the rest of higher alcohols imparts unpleasant sensory characteristics (Rapp and Mandery, 1986; Ribereau-Gayon et al, 2006). The physiological function of higher-alcohol production by yeast is unclear. It has been suggested that, physiologically, oxidative deamination of amino acids provides the yeast with a mechanism for obtaining nitrogen when its pool has become depleted (Vollbrecht and Radler, 1973). It was also suggested that higher-alcohol synthesis contributes to the maintenance of the redox balance in the cell because the final reduction step in higher-alcohol production involves the reoxidation of NADH+H+ to NAD+ (van Dijken and Scheffers, 1986; Quain, 1988; Zoecklein et al, 1995). However, it has also been stated that there appears to be enough acetaldehyde to maintain the redox balance and that the formation of higher alcohols is not considered to be an important means for the reoxidation of NADH (Boulton et al, 1995). Finally, it has been also suggested that higher alcohol production might act as a detoxification process for the intracellular médium of α-keto acids and aldehydes, or as ameans of regulating the metabolism of amino acids (Ribereau-Gayon et al, 2000). Riberau-Gayon et al. (1975) reported that 10% of total higher alcohols is synthesised from corresponding amino acids, 65% from other amino acids and 25% from sugars. Sacchawmyces cerevisiae yeasts produce active amyl alcohol, isoamyl alcohol and isobutyl alcohol from isoleucine, leucine and valine respectively (Dickinson et al, 1997, 1998, 2000). On the other hand, it was reported that a major conversión of sugars during fermentation provides a higher concentration of higher alcohols in eider (Mangas et al., 1994).

Esters are undoubtedly the most important aroma compounds in alcoholic beverages; their presence determines the sensory quality. Ethyl acétate is probably the most important due to its high concentration compared to the rest of acétate esters. It imparts a light-fruity or solvent-like aroma depending on its concentration. Ethyl acétate is mainly produced using acetyl-CoA as a substrate instead of acétate in Sacchawmyces cerevisiae cells (Yoshioka and Hashimoto, 1981). Results of this study showed that agitation enhanced slightly production of ethyl acétate (75.0±6.5mg/L) compared to static fashion (51.0±6.0mg/L). Ethyl acétate formation is related to the availability of acetyl-CoA, ethanol and alcohol acetyltransferases necessary for its synthesis (Yoshioka and Hashimoto, 1981; Rojas et al., 2002). Swiegers and Pretorius (2005) reported that the rate of ester formation depends on the concentration of precursors and on the activity of the enzymes involved in the synthesis and hydrolysis. Nevertheless, others factors should also be involved in the synthesis such as for example the type of strain and the initial oxygen concentration in the médium. Additionally, acétate esters are produced in high concentrations during the early stage of fermentation (Henschke and Jiranek, 1993). From the sensory point of view, ethyl acétate concentrations lower than 80 mg/L would contribute positively to the flavour and taste of wines (Ribereau-Gayon, 1978). On the contrary, concentrations over 200 mg/L would impart a vinager taste (Dequin et al., 2003). In addition, fatty acid ethyl esters such as ethyl decanoate (floral odor) are also important for the overall bouquet. The role of ester production in yeast metabolism is also unclear. It is believed that esters might be formed to remove toxic fatty acids from the yeast cell (Nordstrom, 1962, 1964), whereas it has been also proposed that esters could simply be overspill producís from the sugar melabolism of yeasl during fermenlalion and mighl be of no advanlage lo íhe yeasl cell (Peddie, 1990).

Acetic acid is a very important compound; it contributes to the total volatile acidity in wines and ciders. In this study, its production was higher in static cultivation (266.0±8.0mg/L) compared to agitated one (51.0±4.5mg/L). Cultivation conditions leading to alcoholic fermentation promote its synthesis and then it is exported outside the yeast cell. From the technological point of view, the use of yeast strains with low capability of synthesizing acetic acid is advantageous. Temperature is one of the most important parameter for the development of alcoholic fermentation since it can affect both the kinetics of the process in terms of duration and rate of fermentation and the final quality of the fermented beverage, Le., production of secondary metabolites (Lafon-Lafourcade, 1983; Fleet and Heard, 1993). The use of low fermentation temperatures (10-15°C) are currently increasing since it enhances the production and retention of flavour volátiles for example in winemaking (Killian and Ough, 1979; Kunkee, 1984).

Shake-flask cultures exhibit oxygen limitation (van Dijken van den Bosch et al, 1986; Gupta and Rao, 2003; Tolosa et al, 2002), which likely affects fermentative metabolism of yeasts. Factors that influence the oxygen transference to the surface of the liquid include flask volume/liquid volume ratio, diameter and length of the neck of the flask and even the type of plug or closure (Nikakhtari and Hill, 2006).

Statistical analysis of the results of flavour, taste and odour showed significant difference (P < 0.01) between the two types of fermented beverages. Results of panelists have ascribed to the beverage fermented statically with slightly taste to solvent-like, little acidic and unbalanced sensory profile, but not unpleasant. On the other hand, they ascribed to the beverage fermented in agitation as "bodiless" referring to sensory character, lack of aroma and taste compounds. The beverage fermented statically had an overall sensory acceptability based on the attributes evaluated.

4.2 Batch cultivation in bioreactor under constant air flow

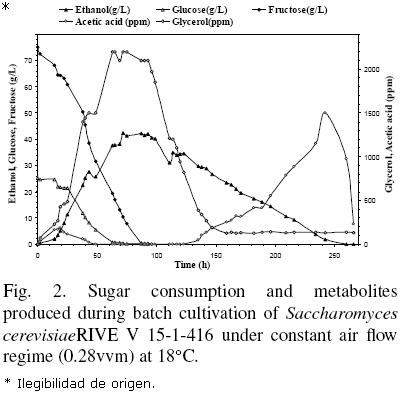

Batch cultivation with constant air flow regime allows keeping a constant supply of oxygen into the médium. Transfer of oxygen into the liquid phase depends on many parameters such as the geometry of the bioreactor, viscosity of the médium, agitation speed, number of baffles, temperature, etc. Only oxygen dissolved in the liquid phase is totally available for the yeast cells. In experiments carried out in this study, air flow rate of 0.28vvm was kept constant during the whole fermentation time. In figures 1, 2 and 3 there are shown the courses of oxygen consumption, cellular growth, change of pH and synthesis and utilisation of by-products. The oxygen is the most important parameter which determines the balance between the fermentative and respiratory activity in many yeasts. At oxygen concentration lower than the critical valué, the rate of respiration depends on the concentration of oxygen in the médium (Johnson, 1976). In presence of oxygen as a limiting substrate, the relationship between the growth rate and the concentration of oxygen in the médium follows the Michaelis Menten kinetics (Johnson, 1976). Critical concentration of oxygen for yeasts normally is very low ranging about 0.12 mg/L at 20 oC (Furukawa et al., 1983; Burke et al., 1997). In Fig. 1 is shown that, after 60th hour the concentration of dissolved oxygen in the médium dropped to zero and, it remained at this valué towards the 260th hour of cultivation. During this time the oxygen transferred to the liquid phase was totally consumed. Nevertheless, this valué does not give information about the rate of oxygen consumption. In this case, measurement of the oxygen concentration in the oulet gas is required. The oxygen has low solubility in pure water (9.1mg/L, 20oC) and depends on the temperature and physico-chemical properties of the liquid médium (e.g. viscosity). The oxygen consumed is utilized mostly in respiration process (glucose oxidation), but also in non-respiratory pathways such as synthesis of sterols and unsaturated fatty acids, which are essential components of the cellular membrane (Rosenfeld and Beauvoit, 2003).

Under this condition sugars were early depleted, glucose was first consumed (towards 60th hour) and then fructose (towards 80th hour). Studies reported that glucose is preferentially metabolised when fermentations are conducted in media containing an equal concentration of glucose and fructose. In this case, glucose is utilized approximately two times faster than fructose (D'Amore et al, 1989), oxygen would enhance their rapid utilisation. During the first stage (aerobic fermentation), production of ethanol, glycerol and acetic acid took place (figure 2). Acetic acid was produced from the first hours of fermentation and then it was totally consumed. Saccharomyces cerevisiae is a Crabtree positive yeast so in presence of high sugar concentration fermentation takes place even when oxygen is available in the médium. Glucose and fructose were consumed from the beginning and, as soon as they were totally depleted the microbial population showed the first diauxia (80th hour), probably due to the consumption and hydrolysis of sucrose and, soon afterwards a second diauxia was observed when ethanol started being consumed (98th hour). In Sacharomyces cerevisiae glucose is utilised first and invertase secretion is repressed when the glucose concentration is higher than 20 g/L (Mwesigye and Barford, 1996). Sucrose utilisation involves its hydrolysis outside the yeast cell since localisation of invertase is outer membrane. The occurrence of diauxic growth and catabolite inactivation of enzymes involved in ethanol metabolism suggest that simultaneous utilization of ethanol and glucose occur in S. cerevisiae RIVE V 15-1-416 only when the concentration of sugar (glucose or fructose) in the médium is very low (Fig. 2).

Consumption of sugars during the aerobic fermentation resulted in high production of ethanol (max. 42.3 g/L) and glycerol (max. 2.2 g/L) before being aerobically consumed, indicating higher biomass production (Fig. 2). Barford (1981) observed that in the aerobic ethanol formation from glucose in batch cultures with Saccharomyces cerevisiae, all sugar was first consumed with simultaneous ethanol production, followed by a short lag phase and resumed growth on ethanol. This phenomenon is often called the diauxic growth. The lag phase is characterised by the induction of enzymes of the glyoxylate cycle and gluconeogenesis, which are needed for synthesis of C3 - C6 compounds from ethanol and other C2 substrates (Haarasilta and Oura, 1975). The aerobic batch fermentation process can be described by low cell concentration (its máximum dropped tol3.02 g/L dried cells) due to ethanol inhibition and a low biomass yield (0.11 g of biomass/g sugar) (see Table 2). The first stage of an aerobic fermentation is a consequence of a phenomenon called Crabtree effect (De Deken, 1966). In the presence of relatively low concentrations of glucose the expression of genes involved in the tricarboxylic acid cycle, oxidative phosphorylation, glyoxylate cycle, gluconeogenesis and metabolism of sugars other than glucose are repressed (Carlson, 1999; Gancedo, 1998). During aerobic growth of Sacchawmyces cerevisiae on fermentable carbon sources, the fermentation/respiration is controlled as a response to the glucose level. Thus, this yeasts switch to a mixed respiro-fermentative metabolism, resulting in ethanol production, as soon as the external glucose concentration exceeds approx. lmM (Verduyn et al, 1984). Higher ATP yield from the respiratory sugar dissimilation is reflected in the higher biomass yields of glucose limited cultures. Typical biomass yield obtained on glucose médium under respiration conditions is 0.5 g dry biomass per g consumed glucose; whereas the biomass yield of anaerobic, fermentative cultures is typically 5-fold lower (Verduyn, 1991). After sugar depletion, the ethanol and glycerol produced served as a carbon source for maintaining the cellular growth. From this stage of sugar depletion, concentration of dissolved oxygen dropped to zero and it remained almost constant towards the end of the cultivation. Acetic acid was produced again in higher concentration in a second stage during ethanol assimilation.

Glycerol under this condition was mostly assimilated. Assimilation of acetic acid produced in the second stage started almost immediately after ethanol was totally consumed. Transpon of ethanol and acétate may occur by passive diffusion; however, evidence for the existence of at least an acétate carrier has been obtained (Casal et al., 1996). Increase of dissolved oxygen concentration in the liquid phase at the end of cultivation would be a result of carbon source depletion.

Production of glycerol by yeast cell would be mostly a response to increased osmolarity of the environment (osmoregulation) (Hohmann, 2002). Apple juice normally contains high sugar concentrations and it can provoke this phenomenon in S. cerevisiae RIVE V 15-1-416. Glycerol is a compatible solute produced in order to maintain the osmolarity inside the cells otherwise they would lose water and gradually it would slow down metabolic reactions inside the yeast cell. It was reported that, production of glycerol is controlled at the level of gene expression in yeasts (Hohmann, 1997; Gustin et al., 1998). To control properly gene expression, the cell has to detect (sense) osmotic changes and to transmit the signal to the nucleus. Then, a high osmolarity glycerol pathway is activated in S. cerevisiae (Gustin et al, 1998; Posas et al, 1998). Under aerobic conditions glycerol can be utilized as a carbon source. Thus, glycerol is converted into dihydroxyacetone phosphate, which subsequently enters the glycolytic or gluconeogenic pathway.

It was also observed that, the specific growth rate (0.13b1) obtained during the first stage is typically noticed in fermentations carried out in media with high sugar concentrations (see table 2). Under glucose limitation and fully aerobic conditions the energy generated from the metabolism of glucose would be mostly used in cellular growth but, in cultivation conditions used in this study, part of the energy would be used in processes such as maintenance (Beeftink et al, 1990).

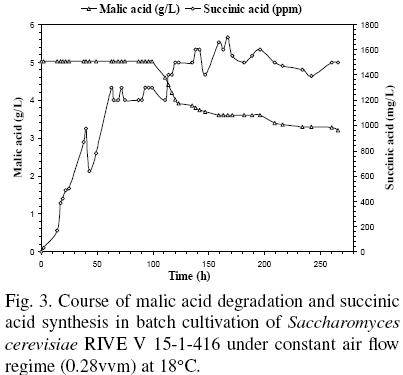

Malic acid is the most important organic acid present in the apple juice; it contributes to the total acidity in ciders. The decrease of its content gives ciders better sensory quality. Wine yeasts in general cannot effectively degrade malic acid during alcoholic fermentation. Comercial wine yeasts of Sacchawmyces cerevisiae are able to degrade only 18% of the malic acid (Redzepovic et al., 2003). Results obtained in this study showed that, S. cerevisiae RIVE V 15-1-416 was able to utilise 36.0 % of the total malic acid present in apple juice. Nevertheless, degradation of malic acid by S. cerevisiae would depend on the strain. Presence of oxygen probably would enhance its utilisation as well. It was reported that some strains of S. cerevisiae could degrade significant quantities (up to 48%) of malic acid (Rainieri et al, 1998). It was also observed that degradation of malic acid started after sugar depletion (aerobic fermentation) and, simultaneously with ethanol assimilation (figure 3). Previous studies reported that, in S. cerevisiae, expression of the malic enzyme gene increases towards the end of fermentation as soon as glucose is depleted (Redzepovic et al., 2003). According to Salmon (1987), in S. cerevisiae yeasts malic and other dicarboxylic acids can be transponed only via simple diffusion. Therefore due to at least transpon limitations the yeasts are unable to degrade or utilise effectively extracellular malic acid. Succinic acid is the main organic acid produced by S. cerevisiae during metabolism of carbon source. It contributes to the taste of many alcoholic beverages such as for example in sake. Production of succinic acid during cultivation of S. cerevisiae RIVE V 15-1-416 in apple juice has attained valúes about 1.6 g/L (Fig. 3). In presence of oxygen, succinate is mainly synthesized through the tricarboxylic acid cycle (oxidative direction) even in presence of glucose at a concentration as high as 15% (Arikawa et al, 1999).

The variability of its synthesis observed during the course of the aerobic fermentation (Fig. 3) could be due to the fact that succinic acid is continuously excreted and imponed in and out of the yeast cells. In presence of oxygen, succinic acid is an intermediary compound of the tricarboxylic acid cycle (TCA) during the complete oxidation of glucose. It was stated that, succinic acid could be synthesized through two pathways, namely, α-ketoglutarate oxidation via the TCA cycle under aerobic conditions (oxidative direction) (Magarifuchi et al, 1995; Arikawa et al, 1999) and, fumarate reduction under anaerobic conditions (reductive direction) (Rossi et al., 1964; Wakai et al, 1980; Arikawa et al, 1999). Under slightly aerobic and glucose-depleted conditions, the glyoxylate cycle is a theoretically possible pathway for supplying succinate (Fernandez et al, 1992).

During aerobic fermentation, production of by-products such as higher alcohols and acétate esters occurs. In experiments carried out in this study, residual concentrations of acetic acid, ethyl acétate and some higher alcohols at the end of cultivation (see Table 2) confirm that the sugar metabolism in the first part of the cultivation was predominantly fermentative. In the second stage (aerobic assimilation of ethanol) probably these higher alcohols served as carbon source in order to keep the growth of the cellular population. The low concentrations of higher alcohols found at the end of cultivation would support this suggestion (Table 2). From the technological point of view, fermentations should be stopped when the sugar is depleted or when the concentration of ethanol attains the inhibitory valué. Excessive aeration during fermentation would lead to an increase in the cellular biomass concentration and as consequence of a decrease in ethanol production.

Conclusions

Concentrations of sugar and dissolved oxygen are the most important factors that affect the metabolism of Sacchawmyces cerevisiae. At high concentration of sugar (glucose), alcoholic fermentation takes place even when oxygen is present in sufficient amount. In agitated cultivations carried out in Erlenmeyer flasks, transfer of oxygen is a limiting factor since concentration of dissolved oxygen in the liquid phase is very low. Under this condition, presence of very low amount of oxygen affect the synthesis of fermentation by-products of Sacchawmyces cerevisiae RIVE V 15-1-416. Oxygen has influenced the synthesis of glycerol, diminishes the synthesis of higher alcohols and on the contrary slightly increases the production of acétate esters such as ethyl acétate. These observations are controversial to those observed in cultivations carried out in similar conditions with some non-Sacchawmyces yeast. The capability of synthesis of higher alcohols and esters under these conditions would also depend on the strain.

Additionally, production of acetic acid diminished in agitated cultivation; it would be advantageous since alcoholic beverages with low volatile acidity are desirable. Temperature is an important factor that influences the metabolism of yeasts. It is known that high temperature of fermentation promotes a major production of higher alcohols. From this point of view, fermentations at temperatures lower than 28°C would be suitable in order to diminish production of higher alcohols. From the sensory point of view, static cultivation resulted in fermented beverages of better sensory acceptability and the best alternative to carry out fermentation of apple juice.

In batch cultivations carried out at constant air flow (0.28vvm), sugars are depleted towards the first three days of cultivation. Consumption of oxygen during this stage enhances the yeast growth and as a consequence the speed of fermentation but, on the contrary affects the yield of ethanol. In this case, excessive aeration should be avoided in order to improve the ethanol yield. On the other hand, a diauxic growth is observed when S. cerevisiae RIVE V 15-1-16 is grown in médium containing different carbon sources such as glucose, sucrose and ethanol. This phenomenom is a result of the short adaptation to a new carbon source.

Sacchawmyces cerevisiae RIVE V 15-1-416 normally produces acetic acid and glycerol during aerobic fermentation, moreover, acetic acid is then consumed under this condition.

From the technological point of view, control of aeration rate would be a useful tool to reduce the concentration of acetic acid in ciders or other fermented beverages but, on the other hand, oxygen would increase synthesis of succinic acid. In consequence, reduction of volatile acidity and increase of non-volatile acids is somehow still beneficial. The aerobic fermentation process must be carefully controlled since after depletion of sugars, ethanol serves as carbon source. In this case, the process should be stopped once the máximum ethanol concentration has been attained. S. cerevisiae RIVE V 15-1-416 is not able to use malic acid during aerobic fermentation when fermentable sugars are still present in the médium. The continuous air flow to the médium once the aerobic fermentation has finished would not be suitable since it leads to the ethanol consumption. Finally, oxygen plays a very important role in the metabolism of S. cerevisiae RIVE V 15-1-416 and from the technological point of view only small amounts would be suitable in order to control the synthesis of fermentation by-products if production of alcoholic beverages is the purpose.

Acknowledgment

The authors thank the Collection of Yeast of the Institute of Research of Viticulture and Enology, Bratislava, Slovak Republic for supplying the yeast strains used in our study.

References

Albers, E., Liden, G., Larsson, C. and Gustafsson, L. (1998). Anaerobic redox balance and nitrogen metabolism in Saccharomyces cerevisiae. Recent Research Development in Microbiol 2, 253-279. [ Links ]

Amerine, A.M., Berg, H.V., Kunkee, R.E., Ough, C.S., Singleton, V.L. and Webb, A.D. (1980). The Technology of Winemaking, (4th edn). AVI Technical Books Inc, Westport, Connecticut, USA. [ Links ]

Andreasen, A.A., Stier, T.J.B. (1953). Anaerobic nutrition of Saccharomyces cerevisiae. I. Ergosterol requirement for growth in a defined médium. Journal of Cellular and Comparative Physiology 41,23-6. [ Links ]

Arikawa, Y., Kuroyanagi, T., Shimofqaka, M., Muratsubaki, H., Enomot, K., Kodaira, R. and Okazak, M. (1999). Effect of gene disruptions of the TCA cycle on production of succinic acid in Saccharomyces cerevisiae. Journal of Bioscience and Bioengineering 87, 28-36. [ Links ]

Barford, J.P. (1981). A mathematical model for the aerobic growth of Saccharomyces cerevisiae with a saturated respiratory capacity. Biotechnology and Bioengineering 23, 1735-1762. [ Links ]

Barker, R.L., Irwin, A.J. and Murray, C.R. (1992). The relationship bewteen fermentation variables and flavour volatiles by direct gas chromatographic injection of beer. Master Brewers Association of the Americas Technical Quarterly 29, 11-17. [ Links ]

Beeftink, H.H., van der Heijden R.T.J.M. and Heijnen, J.J. (1990). Maintenance requirements: Energy supply from simultaneous endogenous respiration and substrate consumption. FEMS Microbiology Letters 73, 203-209. [ Links ]

Beudeker, R.F., van Dam, H.W., van der Plaat, J.B. and Vellenga, K. (1990). Developments in bakers' yeast production. In: Yeast Biotechnology and Biocatalysis, (H. Verachtert and R. De Mot, eds.), Pp. 103-46. Marcel Dekker, New York, USA. [ Links ]

Boulton, R.B., Singleton, V.L., Bisson, L.F. and Kunkee, R.E. (1995). Principies and Practices of Winemaking. Chapman and Hall, New York, USA. [ Links ]

Burke, P.V., Raitt, D.C., Alien, L.A., Kellogg, E.A. and Poyton, R.O. (1997). Effects of oxygen concentration on the expression of cytochrome c and cytochrome c oxidase genes in yeast. Journal of Biological Chemistry 272, 14705-14712. [ Links ]

Cabranes, C, Moreno, J. and Mangas, JJ. (1998). Cider production with immobilized Leuconostoc oenos. Journal of the Institute of Brewing 4, 127-130. [ Links ]

Carlson, M. (1999). Glucose repression in yeast. Current Opinión in Microbiology 2, 202-207. [ Links ]

Casal, M., Cardoso, H. and Leao, C. (1996). Mechanisms regulating the transport of acetic acid in Saccharomyces cerevisiae. Microbiology 142, 1385-1390. [ Links ]

D'Amore, T., Russell, I. and Stewart, G.G. (1989). Sugar utilization by yeast during fermentation. Journal of Industrial Microbiology 4, 315-324. [ Links ]

De Deken, R.H. (1966). The Crabtree effect: A regulatory system in yeast. Journal of General Microbiology 44, 149-156. [ Links ]

Dequin, S., Salmon, J.M. and Nguyen, H.V. (2003). Wine yeasts. In: Yeasts in Food-Beneficial and Detrimental Aspects, (T. Boekhout and V. Robert, eds.), Pp. 389-412. Behr's Verlag, Hamburg, Germany. [ Links ]

Dickinson, J.R. and Norte, V. (1993). A study of branched-chain amino acids aminotransferase and isolation of mutations affecting the catabolism of branched-chain amino acids in Saccharomyces cerevisiae. FEBS Letters 326, 29-32. [ Links ]

Dickinson, J.R., Lanterman, M.M., Danner, D.J., Pearson, B.M., Sanz, R, Harrison, SJ. and Hewlins, M.J.E. (1997). A 13C Nuclear magnetic resonance investigation of the metabolism of leucine to isoamyl alcohol in Saccharomyces cerevisiae. Journal of Biological Chemistry 272, 26871-26878. [ Links ]

Dickinson, J.R., Harrison, SJ. and Hewlins, M.J.E. (1998). An investigation of the metabolism of valine to isobutyl alcohol in Saccharomyces cerevisiae. Journal of Biological Chemistry 273, 25751-25756. [ Links ]

Dickinson, J.R., Harrison, S.J., Dickinson, J.A. and Hewlins, M.J.E. (2000). An investigation of the metabolism of isoleucine to active amyl alcohol in Saccharomyces cerevisiae. Journal of Biological Chemistry 275, 10937-10942. [ Links ]

Downing, D.L. (1988). Processed Apple Producís, (L.D. Donald, ed.). Van Nostrand Reinhold Pub., New York, USA. [ Links ]

El-Nemra, S.E., Ismaila, LA and Askar, A. (1988). Aroma changes in mango juice during processing and storage. Food Chemistry 30, 269-275. [ Links ]

Fernandez, E., Moreno, F. and Rodicio, R. (1992). The ICL1 gene from Saccharomyces cerevisiae. European Journal of Biochemistry 204, 983-990. [ Links ]

Fiaux, J., Cakar, Z.P., Sonderegger, M., Wuthrich, K., Szyperski, T. and Sauer, U. (2003). Metabolic flux profiling of the yeasts Saccharomyces cerevisiae and Pichia stipitis. Eukaryotic Cell 2, 170-180. [ Links ]

Fiechter, A., Fuhrmann, G.F., Kappeli, O. (1981). Regulation of glucose metabolism in growing yeast cells. Advances in Microbial Physiology 22, 123-183. [ Links ]

Fleet, G.H. and Heard, G.M. (1993). Yeasts-growth during fermentation. In: Wine Microbiology and Biotechnology, (G.H. Fleet, ed.), Pp. 27-54. Harwood Academic Publishers, Switzerland. [ Links ]

Franzen, C.J. (2003). Metabolic flux analysis of RQ-controlled microaerobic ethanol production by Saccharomyces cerevisiae. Yeast 20, 117-132. [ Links ]

Fujii, T., Yoshimoto, H. and Tamai, Y. (1996). Acétate ester production by Saccharomyces cerevisiae lacking the ATF1 gene encoding the alcohol acetyltransferase. Journal of Fermentation and Bioengineering 81, 538-542. [ Links ]

Furukawa, K., Heinzle, E. and Dunn, I.J. (1983). Influence of oxygen on the growth of Saccharomyces cerevisiae in continuous culture. Biotechnology and Bioengineering 25, 2293 -2317. [ Links ]

Gancedo, J.M. (1998). Yeast carbon catabolite repression. Microbiology and Molecular Biology Reviews 62, 334-361. [ Links ]

Gombert, A.K., dos Santos, M.M., Christensen, B., Christensen, B. and Nielsen, J. (2001). Network identification and flux quantification in the central metabolism of Saccharomyces cerevisiae under different conditions of glucose repression. Journal of Bacteriology 183, 1441-1451. [ Links ]

Gupta, A. and Rao, G.A. (2003). Study of oxygen transfer in shake flasks using a non-invasive oxygen sensor. Biotechnology and Bioengineering 84, 351-358. [ Links ]

Gustin, M.C., Albertyn, J., Alexander, M. and Davenport, K. (1998). MAP Kinase pathways in the yeast Saccharomyces cerevisiae. Microbiology and Molecular Biology Review 62, 1264-1300. [ Links ]

Haarasilta, S. and Oura, E. (1975). On the activity and regulation of anaplerotic and gluconengenetic enzymes during the growth process of baker's yeast. European Journal of Biochemistry 52, 1-7. [ Links ]

Hammond, J.R.M. (1993). Brewer's yeasts. In: The Yeast. Yeast Technology, (A.H. Rose and J.S. Harrison, eds.). Academic Press, London, UK. [ Links ]

Henschke, P.A. and Jiranek, V. (1993). Yeasts-metabolism of nitrogen compounds. In: Wine Microbiology and Biotechnology, (G.H. Fleet, eds.), Pp. 77-164. Harwood Academic Publishers, Langhorne, Pensilvania, USA. [ Links ]

Hohmann, S. (1997). Yeast Stress Responses, (S. Hohmann and W.H. Mager, eds.), Pp. 101-145. Landes, R.G., Co., Austin, Texas, USA. [ Links ]

Hohmann, S. (2002). Osmotic stress signaling and osmoadaptation in yeasts. Microbiology and Molecular Biology Review 66, 300-372. [ Links ]

Jarvis, B., Forster, M.J. and Kinsella, W.P. (1995). Factors affecting the development of eider flavour. Journal of Applied Bacteriology 79, 5S-18S. [ Links ]

Johnson, MJ. (1976). Aerobic microbial growth at low oxygen concentrations. Journal of Bacteriology 94, 101-108. [ Links ]

Kappeli, O. (1986). Regulation of carbon metabolism in Saccharomyces cerevisiae and related yeasts. Advances in Microbial Physiology 28, 181-209. [ Links ]

Killian, R.E. and Ough, C.S. (1979). Fermentation esters-formation and retention as affected by fermentation temperature. American Journal of Enology and Viticulture 30, 301-305. [ Links ]

Kunkee, R.E. (1984). Selection and modifieation of yeasts and lactic acid bacteria for wine fermentation. Food Microbiology 1, 315-332. [ Links ]

Lafon-Lafourcade, S. (1983). Wine and brandy. In: Biotechnology. Food and Feed Production with Microorganisms, (H.J. Rehm and G. Reed, eds.), Pp. 81-163. Verlag Chemie, Weinheim, Germany. [ Links ]

Larsson, C, Pahlman, I.L., Ansell, R., Rigoulet, M., Adler, L. and Gustafsson, L. (1998). The importance of the glycerol-3-phosphate shuttle during aerobic growth of Saccharomyces cerevisiae. Yeast 14, 347-357. [ Links ]

Lilly, M., Lambrechts, M.G. and Pretorius, I.S. (2000). Effect of increased yeast alcohol acetyltransferase activity on flavor profiles of wine and distillates. Applied andEnvironmental Microbiology 66, 744-753. [ Links ]

Luttik, M.A.H., Overkamp, K.M., Kotter, P, de Vries, S., van Dijken, J.P and Pronk, J.T. (1998). The Saccharomyces cerevisiae NDE1 and NDE2 genes encode sepárate mitochondrial NADH dehydrogenases catalyzing the oxidation of cytosolic NADH. Journal of Biological Chemistry 273, 24529-24534. [ Links ]

Malcorps, P. and Dufour, J.P. (1987). Ester synthesis by Saccharomyces cerevisiae: localisation of acetyl-CoA: iso-amylalcohol acetyltransferase ("AT"). Procedings of European Brewing Convention 21, 377-384. [ Links ]

Mangas, J.J., Cabranes, C, Moreno, J. and Gomis, D.B. (1994). Influence of eider making technology on eider taste. Lebensmittel und Wissenschaft Technologie 27, 583-586. [ Links ]

Magarifuchi, T., Goto, K., Iimura, Y., Tadenuma, M. and Tamura, G. (1995). Effect of yeast fumarase gene (FUM1) disruption on production of malic, fumaric and succinic acids in sake mash. Journal of Fermentation and Bioengineering 80, 355-361. [ Links ]

Meilgaard, M., Civille, G.V. and Carr, B.T. (1999). Sensory Evaluation Techniques. CRC Press, Boca Ratón, New York, USA. [ Links ]

Minetoki, T., Bogaki, T., Iwamatsu, A., Fujii, T. and Hamachi, M. (1993). The purifleation, properties and internal peptide sequences of alcohol acetyltransferase from Saccharomyces cerevisiae Kyokai no. 7. Bioscience, Biotechnology and Biochemistry 57,2094-2098. [ Links ]

Mwesigye, PK. and Barford, J.P. (1996). Mechanism of sucrose utilisation by Saccharomyces cerevisiae. Journal of General and Applied Microbiology 42, 297-306. [ Links ]

Nagy, M., Lacroute, F. and Thomas, D. (1992). Divergent evolution of pyrimidine biosynthesis between anaerobic and aerobic yeasts. Procedings of the National Academy ofSciences of USA 89, 8966-8970. [ Links ]

Nikakhtari, H. and HUÍ, G. (2006). Closure effeets on oxygen transfer and aerobic growth in shake flasks. Biotechnology and Bioengineering 95, 15-21. [ Links ]

Nieuwoudt, H.H., Prior, B.A., Pretorius, I.S. and Bauer, F.F. (2002). Glycerol in South African table wines: an assessment of its relationship to wine quality. South African Journal of Enology and Viticulture 23, 22-30. [ Links ]

Nordstrom, K. (1962). Formation of ethyl acétate in fermentation with brewer's yeast. III. Participation of coenzyme A. Journal of the Institute of Brewing 68, 398-407. [ Links ]

Nordstrom, K. (1964). Formation of esters from acids by brewer's yeast. IV. Effect of higher fatty acids and toxicity of lower fatty acids. Journal of the Institute of Brewing 70, 233-242. [ Links ]

Nordstrom, K. (1968). Yeast growth and glycerol formation. II. Carbón and redox balance. Journal of the Institute of Brewing 74,429-432. [ Links ]

Nykanen, L. and Nykanen, I. (1977). Production of esters by different yeast strains in sugar fermentations. Journal of the Institute of Brewing 83,30-31. [ Links ]

Ortega, C, López, R., Cacho, J. and Ferreira, V. (2001). Fast analysis of important wine volatile compounds: Development and validation of a new method based on gas chromatography-flame ionization detection analysis of dichloromethane micro extracts. Journal of Chrornato graphy A 923, 205-214. [ Links ]

Paalme, T., Elken, R., Vilu, R. and Korhola, M. (1997). Growth emciency of Saccharomyces cerevisiae on glucose/ethanol media with a smooth change in the dilution rate (A-stat). Enzime andMicrobial Technology 20, 174-181. [ Links ]

Peddie, H.A.B. (1990). Ester formation in brewery fermentations. Journal of the Institute of Brewing 96,321-331. [ Links ]

Picinelli, A., Suarez, B., Moreno, J., Rodríguez, R., Caso-García, L.M. and Mangas, JJ. (2000). Chemical characterization of Asturian eider. Journal of Agricultural and Food Chemistry 48, 3997-4002. [ Links ]

Petrik, M., Kappeli, O. and Fiechter, A. (1983). An expanded concept for glucose effect in the yeast Saccharomyces uvarum: involvement of short-and long-term regulation. Journal of General Microbiology 129, 43-9. [ Links ]

Posas, F., Takekawa, M. and Saito, H. (1998). Signal transduction by MAP kinase cascades in budding yeast. Current Opinión in Microbiology 1, 175-182. [ Links ]

Postma, E., Verduyn, C, Scheffers, W.A. and van Dijken, J.P. (1989). Enzymic analysis of the Crabtree effect in glucose-limited chemostat cultures of Saccharomyces cerevisiae CBS 8066. Applied and Environmental Microbiology 55, 468-477. [ Links ]

Pretorius, I.S. and Hoj, P.B. (2005). Grape and wine biotechnology: Challenges, opportunities and potential benefits. Australian Journal of Grape and Wine Research 11, 83-108. [ Links ]

Pronk, J.T., Wenzel, T.J., Luttik, M.A.H., Klaassen, C.C.M., Scheffers, W.A., Steensma, H.Y. and van Dijken, J.P. (1994). Energetic aspeets of glucose metabolism in a pyruvate-dehydrogenase-negative mutant of Saccharomyces cerevisiae. Microbiology 140, 601-610. [ Links ]

Quain, D.E. (1988). Studies on yeast physiology - impact of fermentation performance and product quality. Journal of the Institute of Brewing 94,315-323. [ Links ]

Rainieri, S., Zambonelli, C, Tini, V., Castellari, L. and Giudici, P. (1998). The enological traits of thermotolerant Saccharomyces strains. American Journal of Enology and Viticulture 49,319-324. [ Links ]

Rapp, A. and Mandery, H. (1986). New progress in wine and wine research. Experientia 42, 873-884. [ Links ]

Redzepovic, S., Orlic, S., Majdak, A., Kozina, B., Volschenk, H. and Viljoen-Bloom, M. (2003). Differential malic acid degradation by selected strains of Saccharomyces during alcoholic fermentation. International Journal of Food Microbiology 83, 49- 61. [ Links ]

Ribereau-Gayon, J., Peynaud, E., Ribereau-Gayon, P. and Sudraud P. (1975). Traite d'oenolgie: Sciences et techniques du vin. Dunod, Paris, France. [ Links ]

Ribereau-Gayon, P. (1978). Wine aroma. In: Flavour ofFoods and Beverages, (G. Charalambous and G.E. Inglett, eds.), Pp. 362-371. Academic Press, New York, USA. [ Links ]

Ribereau-Gayon, P, Dubourdieu, D., Doneche, B. and Lonvaud, A. (2000). Biochemistry of alcoholic fermentation and metabolic pathways of wine yeasts. In: Handbook of Enology. The Microbiology of Wine and Vinifications, (J. Wiley and Sons, eds.), Pp. 51-74. New York, USA. [ Links ]

Ribereau-Gayon, P., Dubourdieu, D. and Doneche, B. (2006). Biochemistry of alcoholic fermentation and metabolic pathways of wine yeasts. In: Handbook of Enology. The Microbiology of Wine and Vinifications, (J. Wiley and Sons, eds.), Pp. 74-77. The Atrium, Southern Gate, Chichester, England. [ Links ]

Rojas, V., Gil, J.V., Manzanares, R, Gavara, R., Pinaga, F. and Flores, A. (2002). Measurement of alcohol acetyltransferase and ester hydrolase activities in yeast extracts. Enzyme and Microbial Technology 30, 224-230. [ Links ]

Rosenfeld, E. and Beauvoit, B. (2003). Role of the non-respiratory pathways in the utilization of molecular oxygen by Saccharomyces cerevisiae. Yeast 20, 1115-1144. [ Links ]

Rossi, C, Hauber, J. and Singer, T.P. (1964). Mitochondrial and cytoplasmic enzymes for the reduction of fumarate to succinate in yeast. Nature 204, 167-170. [ Links ]

Rous, C.V., Snow, R. and Kunkee, R.E. (1983). Reduction of higher alcohols by fermentation with a leucine-auxotrophic mutant of wine yeast. Journal of the Institute of Brewing 89, 274-278. [ Links ]

Salmon, J.M. (1987). L-Malic-acid permeation in resting cells of anaerobically grownSaccharomyces cerevisiae. Biochimica et Biophysica Acta 901, 30- 34. [ Links ]

Small, W.C. and McAlister-Henn, L. (1998). Identification of a cytosolically directed NADH dehydrogenase in mitochondria of Saccharomyces cerevisiae. Journal ofBacteriology 180, 4051-4055. [ Links ]

Snoek, I.S.I. and Steensma, H.Y. (2006). Why does Kluyveromyces lactis not grow under anaerobic conditions? Comparison of essential anaerobic genes of Saccharomyces cerevisiae with the Kluyveromyces lactis genome. FEMS Yeast Research 6, 393-403. [ Links ]

Sonnleitner, B. and Kappeli, O. (1986). Growth of Saccharomyces cerevisiae is controlled by its limited respiratory capacity: Formulation and verification of a hypothesis. Biotechnology and Bioengineering 28, 927-937. [ Links ]

Souci, S.W., Fachmann, W. and Kraut, H. (2000). Juices from fruits and berries: Food composition and nutrition tables (6th edition), Pp. 13-52. Scientific publishers, Stuttgart, Germany. [ Links ]

Su, S.K. and Wiley, R.C. (1998). Changes in apple juice flavor compounds during processing. Journal of Food Science 63, 688-691. [ Links ]

Suarez Valles, B., Pando Bedrinana, R., Fernandez Tascon, N., Gonzales Garcia, A. and Rodríguez Madrera, R. (2005). Analytical differentiation of eider inoeulated with yeast (Saccharomyces cerevisiae) isolated from Asturian (Spain) apple juice. LWT-Food Science and Technology 38, 455-461. [ Links ]

Suomalainen, H. (1981). Yeast esterase and aroma esters in alcoholic beverages. Journal of the Institute of Brewing 87, 296-300. [ Links ]

Swiegers, J.H. and Pretorius, I.S. (2005). Yeast modulation of wine flavour. Advances in Applied Microbiology 57, 131-175. [ Links ]

Swiegers, J.H., Bartowsky, E.J., Henschke, P.A. and Pretorius, I.S. (2005). Yeast and bacterial modulation of wine aroma and flavour. Australian Journal of Grape Wine Research 11, 139-173. [ Links ]

Tolosa, L., Kostov, Y, Harms, P. and Rao, G. (2002). Noninvasive measurement of dis solved oxygen in shake flasks. Biotechnology and Bioengineering 80, 594-597. [ Links ]

Valero, E., Moyano, L., Millan, M.C., Medina, M. and Ortega, J.M. (2002). Higher alcohols and esters production by Saccharomyces cerevisiae. Influence of the initial oxygenation of the grape must. Food Chemistry 78, 57-61. [ Links ]

van Dijken, J.P. and Scheffers, W.A. (1986). Redox balances in the metabolism of sugars by yeasts. FEMS Microbiology Reviews 32, 199-224. [ Links ]

van Dijken van den Bosch, E., Hermans, J.J., de Miranda, L.R. and Scheffers, W.A. (1986). Alcoholic fermentation by 'non-fermenting' yeasts. Yeast 2, 123-127. [ Links ]

van Dijken, J.P., Weusthuis, R.A. and Pronk, J.T. (1993). Kinetics of growth and sugar consumption by yeasts. Antonie van Leeuwenhoek 63, 343-352. [ Links ]

van Hoek, P, van Dijken, J.P. and Pronk, J.T. (1998). Effect of specifie growth rate on fermentative capacity of Baker's yeast. Applied and Environmental Microbiology 64, 4226-4233. [ Links ]

van Urk, H., Voll, W.S.L., Scheffers, W.A. and Van Dijken, J.P. (1990). Transient-state analysis of metabolic fluxes in Crabtree-positive and Crabtree-negative yeasts. Applied and Environmental Microbiology 56, 281-287. [ Links ]

van Winden, W.A., van Dam, J.C., Ras, C, Kleijn, R.J., Vinke, J.L., van Gulik, W.M. and Heijnen, JJ. (2005). Metabolic-flux analysis of Saccharomyces cerevisiae CEN. PK113-7D based on mass isotopomer measurements of 13C-labeled primary metabolites. FEMS Yeast Research 5, 559-568. [ Links ]

Verduyn, C, Zomerdijk, T.P.L., van Dijken, J.P. and Scheffers, W,A. (1984). Continuous measurement of ethanol production by aerobic yeast suspensions with an enzyme electrode. Applied Microbiology and Biotechnology 19, 181-185. [ Links ]

Verduyn, C, Postma, E., Scheffers, W.A. and van Dijken, J.P. (1990). Physiology of Saccharomyces cerevisiae in anaerobic glucose-limited chemostat cultures. Journal of General Microbiology 136, 395- 403. [ Links ]

Verduyn, C. (1991). Physiology of yeasts in relation to biomass yields. Antonie van Leeuwenhoek 60, 325-353. [ Links ]

Verduyn, C, Stouthamer, A.H., Scheffers, W.A. and van Dijken, J.P. (1991). A theoretical evaluation of growth yields of yeasts. Antonie van Leeuwenhoek 59, 49-63. [ Links ]

Visser, W., Batenburg-van der Vegte, W.M., Scheffers, W.A. and van Dijken, J.P. (1990). Oxygen requirements of yeasts. Applied and Environmental Microbiology 56, 3785-3792. [ Links ]

Vollbrecht, D. and Radler, F. (1973). Formation of higher alcohols by amino acid deficient mutants of Saccharomyces cerevisiae. I. The decomposition of amino acids to higher alcohols. Archives of Mikrobiology 94, 351-358. [ Links ]

Wakai, Y., Shimazaki, T. and Hará, S. (1980). Formation of succinate during fermentation of sake mash and grape must. Hakkokogaku 58, 363-368. [ Links ]

Wang, L., Xu, Y., Zhao, G. and Li, J. (2004). Rapid analysis of flavor volátiles in apple wine using Headspace Solid-Phase microextraction. Journal of the Institute of Brewing 110, 57-65. [ Links ]

Wiebel, M.G., Rintala, E., Tamminen, A., Simolin, H., Salusjarvi, L., Toivari, M., Kokkonen, J.T., Kiuru, J., Ketola, R.A., Jouhten, P., Huuskonen, A., Maaheimo, H., Ruohonen, L. and Penttila, M. (2008). Central carbon metabolism of Saccharomyces cerevisiae in anaerobic, oxygen-limited and fully aerobic steady-state conditions and following a shift to anaerobic conditions. FEMS Yeast Research 8, 140-154. [ Links ]

Yoshioka, K. and Hashimoto, N. (1981). Ester formation by alcohol acetyltransferase from brewer's yeast. Agricultural and Biological Chemistry 45, 2183-2190. [ Links ]

Yoshioka, K. and Hashimoto, H. (1983). Cellular fatty acid and ester formation by brewers' yeast. Agricultural and Biological Chemistry 47, 2287-2294. [ Links ]

Zoecklein, B.W, Fugelsang, K.C., Gump, B.H. and Nury, F.S. (1995). Alcohol and extract. In: Wine Analysis and Production, (The Chapman and Hall Enology Library, eds.), Pp. 97-114. New York, USA. [ Links ]