Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Revista mexicana de ingeniería química

versão impressa ISSN 1665-2738

Rev. Mex. Ing. Quím vol.9 no.1 Ciudad de México Abr. 2010

Diseño y optimización

Refractive index modulation of SU-8 polymer optical waveguides by means of hybrid photothermal process

Modulación del índice de refracción de guías de onda ópticas de polímero SU-8 por medio de un proceso hibrido fototérmico

D. Salazar-Miranda1*, F. F. Castillón2, J. J. Sánchez-Sánchez1, J. L. Angel-Valenzuela1 and H. Márquez1

1 Departamento de Óptica, CICESE, Centro de Investigación Científica y de Educación Superior de Ensenada, Km.107 Carretera Tijuana-Ensenada, Ensenada, B.C., México. *Corresponding author. E-mail: davisa@cicese.mx.

2 Centro de Nanociencias y Nanotecnología, CNyN-UNAM, Km. 107 Carretera Tijuana-Ensenada, Ensenada, B.C., México.

Received 2 of June 2009;

Accepted 18 of December 2009

Abstract

This paper describes the fabrication and characterization of multimode polymer optical waveguides obtained using a SU-8-2005 polymer by means of photolithographic process. Critical information about refractive index modulation of polymer waveguides as function of fabrication parameters as pre-baked and ultraviolet exposure times is presented. Physical properties of the waveguides were determined by means prism-coupling technique, optical and SEM microscopy.

Keywords: optical waveguides, polymer, photolithography, modulation, refractive index.

Resumen

Este trabajo describe la fabricación y caracterización de gulas de onda ópticas multimodales obtenidas a partir del polímero SU-8-2005 mediante un proceso de microlitografía. Presentamos información importante acerca de la modulación del índice de refracción en las guías de onda ópticas en función de los tiempos de pre- horneado e irradiación con luz ultravioleta. Las propiedades físicas de las guías de onda son determinadas usando la técnica de acoplamiento de prisma, microscopia óptica y microscopia electrónica de barrido.

Palabras clave: guías de onda, polímeros, fotolitografía, modulación, índice de refracción.

1. Introduction

Optical waveguides and micro-devices using polymer materials are attracting considerable interest because of their potential applications in optical communications, integrated optics, and bio-sensors (Eldada and Shackelette, 2000; Lee et al., 2003). Optical polymers are versatile materials that can be readily formed into planar single-mode, multimode, and microoptical waveguide structures ranging in dimensions from under a micrometer to several hundreds micrometers.

These materials can be photopolymers or thermoplastics, and waveguides can be formed by means of techniques as, direct photolithography, reactive ion etching, laser ablation, molding or embossing (Immonen and Kivilahti, 2002).

Although after several years since the idea arose to use optical polymers for the manufacture of circuits of integrated optics, are few the developed to date (Immonen et al., 2005). Conventional microlithography process is a reliable and affordable technique widely used for different purposes, and considered one of the most suitable waveguide fabrication methods for board level integrated optics.

The starting point for waveguide design or modeling optical propagation in guided-wave devices is knowledge of the waveguide structure, defined by the refractive index and physical dimensions. Refractive index of optical polymers depends of fabrication process, and is considered to be particularly influenced of pre-exposure baked and UV exposure conditions (Henzi et al., 2006, Ong, et al., 2006). Exists some works in polymeric optical waveguides obtained by using some specific polymer of the family SU-8 polymers from MicroChem Corp (del Campo et al., 2007). A few publications are available about modification of the optical properties of polymers such as PMMA polymers (Henzi et al., 2006), and SU-8 (Ong, et al., 2006, Ong, et al., 2006). In particular, the last works showed a new fabrication technique based on UV exposure lithographic process to achieve marginally refractive index modulation of SU-8 photoresist. However, there is a lack of information about the complete range of refractive index modulation of SU-8 photoresist, and for hence their potential in waveguide design.

In this work, an approach to determine the influence of pre-exposure baked and UV exposure on refractive index modulation of SU-8 photoresist is presented.

2. Refractive index modulation

SU-8 is an epoxy-based photoresist with several important properties that make it suitable for optical lithography. First, the material has a low molecular weight enabling it to be dissolved in a variety of organic solvents to form highly concentrated solutions (72 %-85 % solids by weight). Secondly, the absorption for SU-8 in the UV spectrum is low, thus allowing the patterning of thin or thick films. Thirdly, since the resist has high functionality, a high degree of cross-linking can be obtained, permitting a high aspect ratio and straight side-wall to be achieved in lithographic applications (Shamsuddin et al., 2006).

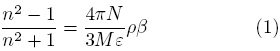

Optical properties are related to the chemical composition and structural features of a polymeric material and described by the Lorentz-Lorentz equation. The increase in refractive index n is attributed to an increase in the density p of the resist after more thermal treatment, as indicated by the Lorentz-Lorentz equation:

where N is the Avogadro number, M is the molecular weight of the polymer repeat unit, ε is the permittivity of free space, and β is the polarizability of the molecules, which increase with density during shrinkage of the resist (β α ρ) (Ong, et al., 2006).

A typical fabrication process consist of the following steps: a) substrate cleaning, b) spin coating, c) pre-exposure baked, d) exposure to UV, e) post-exposure baked, and f) hard baked.

Pre-exposure baked is considered that evaporates the solvent and solidifies the film. However, as the pre-exposure baked temperature is low, a residual amount of solvent is still left in the film. The amount of solvent within the SU-8 film prior to UV exposure will determine the density of the final film. Therefore, the degree of thermal densification prior to UV exposure will affect the refractive index and thickness of the film. The last effect enabled refractive index modulation of SU-8 photoresist films (Ong, et al., 2006). On the other hand, photoreactions are successfully applied to control solubility, polarity, surface energy and mechanical strength of polymers. Optical waveguides were made by using UV-induced refractive index modification in methylmethacrylate polymers (Henzi et al., 2006). Therefore, information about the influence of pre-exposure baked and UV exposure on refractive index modulation is researched.

3. Experimental

A set of planar optical waveguides was fabricated using SU-8-2005 polymer by means of direct ultraviolet photolithography process. First, glass substrates were submitted to a cleaning process that includes polishing abrasives, and standard optical cleaning techniques. Then, substrates were submitted to a baked at 100°C during 30 minutes, in order to eliminate water and solvents residuals. The polymer was spin-coated on glass substrates. A preliminary target was fabricating waveguides with dimensions around 7-10 μm that is close to the core of fiber optics. By using recommendations of SU-8 technical data sheet, the polymer was spin-coated on glass substrates a spin rate of 1400 rpm during 45 seconds. Then, a pre-baked itinerary is used to remove any traces of solvent and solidify the polymer film before ultraviolet exposure of the samples. Therefore, with the purpose of define the influence of pre-baked conditions and ultraviolet irradiation over final refractive index of SU-8 waveguides; a set of 25 samples were prepared under a two step pre-baked process of 2 minutes at 65°C followed by 5, 10, 15, 20, and 25 minutes at 95°C. After, the samples were submitted to direct ultraviolet irradiation of samples with duration of 2, 4, 8, 12, and 16 seconds. Finally, the samples were submitted to a gradual post-baked process of 5 minutes at 65°C, 15 minutes at 95°C, and 45 minutes at 175°C.

Fig. 1 shows the schematic diagram of the fabrication process for polymeric channel waveguides by means of direct ultraviolet photolithography. The optical polymer was spin-coated on glass substrates, and then pre-baked using the same conditions described above. Channel waveguides widths were defined by means ultraviolet exposure in Oriel Model 832210-V mask-aligner equipment operating with vacuum-contact mode, and using a mask with contains sets of lines with widths of 15, 20, 25, 30, 35 and 40 μm. The exposure time was 20 s, and post-exposure baking times of 5 minutes at 65°C, and 15 minutes at 95°C were used to crosslink the polymer. The SU-8-2005 photoresist was developed in a PGMEA (Propylene Glycol Monomethyl Ether Acetate) solution for 15 seconds, in a 6:1 solution of PGMEA- isopropylic alcohol for 30 s, and a last immersion in isopropylic alcohol for 30 s. Finally, samples were submitted to a post-baked of 45 minutes at 175°C to ensure a final dry.

Film thickness, refractive index, effective modal indices TE/TM, and birefringence were measured by the prism coupling technique using a Metricon 2010 prism-coupler system. The morphology and surface topography of the waveguide structures were examined by means scanning electron microscopy (SEM).

4. Results and discussion

The capacity to modulate the refractive index of an optical polymer is a crucial step for design and fabrication of optical waveguides. Therefore, information about variations of refractive index as function of fabrication parameters is relevant for the development of integrated optics circuits, and is described next.

4.1. Planar optical waveguides

Cross-sectional samples were prepared to characterize the core/substrate optical interface and their morphology. SEM micrographs of the waveguides are shown in Fig. 2. Polymer waveguides have amorphous structure and uniform appearance free of defects like bubbles, cracks or impurities; which is advantageous for polarization independence purposes in waveguides. An adequate fabrication processes was reached and enable controlled solvent evaporation, which is critical for film wetting, planarization, and avoidance of bubble generation.

Process guidelines for epoxy based negative photoresist like SU-8 indicates that after the resist has been applied to the substrate, it must be pre-baked to evaporate the solvent and densify the film. For best results, ramping or stepping the pre-bake is recommended (SU-8 2000, 2009). Lower initial bake temperatures allow the solvent to evaporate out of the film at a more controlled rate, which results in better coating quality. In order to determine the influence of pre-baked and UV irradiation in SU-8 refractive index: a) second step of pre-bake conditions were changed from 5 to 25 minutes at 95°C, and b) UV exposure was varied from 2 to 16 seconds of duration.

As SU-8 is an epoxy-based photoresist, we are able to alter its refractive index marginally by varying several processing parameters. Prior to UV exposure, pre-baking of the photoresist is usually performed to evaporate the solvent and den-sify the film. However, as the pre-exposure baking temperature is low ~95° C, a residual amount of solvent is still left in the film. The amount of solvent within the film prior UV exposure will determine the looseness and height of the final film.

Upon exposure, cross-linking proceeds in two steps: 1) formation of a strong acid during the exposure process, followed by 2) acid-initiated, thermally driven epoxy cross-linking during the post-exposure bake step. To minimize stress, wafer bowing and cracking, a two steps process is recommended for post exposure bake and done here for 5 minutes at 65°C, followed by 15 minutes at 95°C. Finally, the samples were submitted to a controlled hard bake, of 45 minutes at 175°C, for further and/or finish cross-linking the photoresist in the final optical waveguide.

We are considering that the degree of thermal densification prior UV exposure and/or UV-exposure effect will affect the refractive index and thickness of the fabricated film. Hence, refractive index measurements of the films are described below.

The waveguides were analyzed by the use of a prism-coupler system; the main components of the equipment are shown in Fig. 3. A laser beam strikes the base of a prism with a high refractive index and is reflected onto a photodetector. The waveguide to be analyzed is brought into contact with the prism base by means of a coupling head. The angle of incidence, θ, of the laser beam can be varied by means of a rotary stage on which the prism, waveguide, coupling head, and photodetector are mounted. At certain values of θ, called mode angles, photons violate the total internal reflection criterion and tunnel from the base of the prism into the waveguide and enter into optical propagation modes, causing a sharp drop in the intensity of the light striking the photodetector. In the prism-coupling method, as shown in Fig. 3, an incident light beam enters the prisms at an angle φ. At the prism base, the light beam forms an angle θ to the normal. This angle, θ, determines the phase velocity in the propagation direction of the incident beam in the prism and in the gap between the prism and the waveguide. Efficient coupling of light into the waveguide occurs only when we choose the angle such that i is equal to the phase velocity, vm, of one of the guided modes of the waveguide (m = 0,1, 2,...) (Salazar et al., 2002).

The effective refractive index, Nm, of the mth mode is related to θm, by

where A and np are the base angle and refractive index of the prism, respectively. The effective refractive index indices of the guided modes, were obtained by the measurement of the coupling mode angles of the prism coupler. The refractive index and thickness of the waveguides were then calculated by the use of an appropriate computer algorithm based on the dispersion curve (Ulrich and Torge, 1973).

Fig. 4 shows refractive indices of the photoresist films measured by means of prism coupling technique. Refractive index of final cross-linked films increase moderately during the first ~15 minutes of pre-baked, and slowly for pre-baked times > 20 minutes with tendency to saturation. This indicates that a moderate amount of solvent is evaporated during the first 20 minutes of pre-baked at 95, and almost all the solvent would have evaporated after 20 minutes. An increase of ultraviolet exposure time at prebaked times, i.e. 5, 10, 15 and 20 minutes, produce a higher refractive index of the polymer. Likewise, increases of prebaked time produce a higher refractive index of the polymer. This refractive index response can be explained by the molecular cross-linking evolution inside the photopolymer, acid-initiated cross-linking by ultraviolet exposure and thermal driving cross-linking during pre-baked and post-baked steps.

4.2. Channel waveguides

Channel waveguides are the building blocks of integrated optical devices. Light is confined and guided through modal propagation in the waveguide structure with cross-section dimensions of few microns. Sets of polymeric channel waveguides with different sizes, with dimensions around 7-10 /tm that is close to the core of fiber optics, were fabricated by means of direct ultraviolet photolithography. Again, samples were submitted to SEM examination and results are shown in Fig. 5. A gold layer was deposited over the samples before being submitted to SEM to ground static charges. As can be observed from Fig. 5, polymeric channel waveguides fabrication process brings us a good yield; the majority of channel waveguides are almost free of imperfections. A preliminary optical propagation evaluation of the waveguides was obtained using the experimental set-up shown in Fig. 6. Intensity distributions of the output face of waveguides at 632nm are presented in Fig. 7. Modal-profile characterization and propagation losses of planar and channel waveguides are under evaluation.

Conclusions

Multimode planar and channel polymer optical waveguides were obtained, with very good yield, using a microlithography process. SEM images of the waveguides indicate amorphous structure and uniform appearance free of defects. SU-8 is an epoxy-based photoresist with potential to modulate its refractive index by varying processing parameters, like ultraviolet exposure time, and pre-baked conditions. Refractive index of final cross-linked films increase moderately during the first ~15 minutes of pre-baked, and slowly for pre-baked times > 20 minutes with tendency to saturation. An increase of ultraviolet exposure and pre-baked times produce a higher increase in refractive index of the polymer, reaching ~ Δn = 0,017. This refractive index response can be explained by the molecular cross-linking evolution inside the photopolymer, acid-initiated cross-linking by ultraviolet exposure and thermal driving cross-linking during pre-baked and post-baked steps.

References

Del Campo A., Greiner C., (2007). SU-8: a photoresist for high-aspect-ratio and 3D submicron lithography, Journal of Micromechanics and Micro Engineering 17, R81-R95. [ Links ]

Eldada, L., Shacklette L.W. (2000). Advances in polymer integrated optics. IEEE Journal of Selected Topics in Quantum Electronics 6(1), 54-68. [ Links ]

Henzi, P., Rabus, D.G., Ichihashi Y., Bruendel M., Mohr J., (2006). Photonic Integrated Polymer Components and Circuits by UV-Induced Refractive Index Modification. Proceedings of the SPIE 6185, 618-502. [ Links ]

Immonen, M., Kivilahti, J.K. (2002). Optics and PWB Technology. OHIDA Technical Report Chap.7, Helsinki University of Technology. [ Links ]

Immonen, M., Karppinen, M., Kivilahti, J.K. (2005) Fabrication and characterization of polymer optical waveguides with integrated micromirrors for three-dimensional board-level optical interconnectors. IEEE Transactions on Electronics Packing Manufacturing 28(4), 304-311. [ Links ]

Lee, G.B., Lin,C.H., Chang,G.L. (2003). Micro flow cytometers with buried SU-8/SOG optical waveguides. Sensors and Actuators A 103, 165-170. [ Links ]

Lin, H.C., Huang, H.C., Tsao, S.L. (2005). Tolerance analysis of 4x4 SU-8 polymer array waveguide grating. Optics Communications 250, 69-76. [ Links ]

Ong, B.H., Yuan, X., Tjin, S.C. (2006) Adjustable refractive index modulation for a waveguide with SU-8 photoresist by dual-UV exposure lithography. Applied Optics 45(31), 8036-8039. [ Links ]

Ong, B.H., Yuan, X., Tao, S., and Tjin, S.C. (2006) , Photothermally enabled lithography for refractive-index modulation in SU-8 photoresist, Optics Letters 31(10),1367-1369. [ Links ]

Tung, K.K., Wong, W.H., Pun, E.Y.B. Polymeric optical waveguides using direct ultraviolet photolithography process. (2005). Applied Physics A Materials Science & Processing 80, 621-626. [ Links ]

Salazar, D., Villegas, L.J., Valles, N., Angel, J.L., Cardoso, R., Marquez, H. (2002) Copper ion-exchanged optical waveguides: a review. Research Signpost. Recent Res. Developtment Optics 2, 343-374. [ Links ]

Shamsuddin A., Hyeung J., Jo T., Sool H., (2006). Thick SU-8 Mask for Micro Channeling of Glass by using Micro Abrasive Jet Machining. Towards Synthesis of Micro-Nano-systems, Springer London, 187-190. [ Links ]

SU-8 2000 Permanent epoxy negative photoresist. www.microchem.com/products/pdf/SU-82000DataSheet2000_5thru2015Ver4.pdf. Accesed in april, 2009. [ Links ]

Ulrich, R. and Torge, R. (1973) Measurement of thin film parameters with a prism coupler. Applied Optics 12(12), 2901-2908. [ Links ]