Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Agrociencia

versão On-line ISSN 2521-9766versão impressa ISSN 1405-3195

Agrociencia vol.50 no.4 Texcoco Mai./Jun. 2016

Food Science

Effect of fat, add water, carragennan and phosphates on carp (Cyprinus carpio) meat emulsioned product

1 Instituto de Ciencias Agropecuarias. Universidad Autónoma del Estado de Hidalgo. Avenida Universidad s/n km 1. Tulancingo, Hidalgo. 43600.

2 Departamento de Ciencias Veterinarias y Agronómicas. Instituto Tecnológico de Sonora, Campus Náinari, Antonio Caso s/n y E. Kino, Colonia Villa ITSON. 85130. Ciudad Obregón, Sonora. México.

Carp (Cyprinus carpio) is produced in several countries, although its commercial value may be low, and a way of adding value is to generate meat products based on this type of meat. In the preparation of such products, the ingredients may affect their final thermal and physical properties. The aim of this study was to evaluate the influence of added water, amount of fat, phosphates and carrageenan on the quality and stability of an emulsified sausage produced with carp meat. Two successive experiments were carried out with 12 treatments, each with random designs. With the data, an analysis of variance was carried out, along with a Tukey test (p≤0.05). Sausages were measured for color, texture profile (TPA), firmness when cut with a Warner-Bratzler blade, Kramer shear cell, heat penetration, water activity and losses due to cooking. Results show an increase in firmness, elasticity, and resilience with more fat and phosphates, with a lower inclusion of fat and added water; contrary to cohesiveness. Brightness values (B*) increasing when including phosphates; the use of carrageenan increased the firmness of the product and the values for b*. Thermal diflusivity fluctuated between 7.1 and 9.6X10-4m2 s-1 with the use of carrageenan, fat, and water. This indicates that sausages can be produced with better elasticity, resilience, cohesiveness, firmness, and color when including phosphates, carrageenan, pig fat, and water in their preparation.

Key words: Sausage; thermal diffusivity; carrageenan; phosphates; Cyprinus carpio; meat

La carpa (Cyprinus carpio) es producida en varios países, pero su valor comercial puede ser bajo, y una forma de dar valor agregado es obtener productos cárnicos con base a este tipo de carne. En la elaboración de dichos productos, los ingredientes pueden afectar sus propiedades termo físicas finales. El objetivo del presente estudio fue evaluar la influencia del agua añadida, cantidad de grasa, fosfatos y carragenina sobre la calidad y estabilidad de un producto cárnico emulsionado tipo salchicha, usando carne de carpa. Se realizaron dos experimentos sucesivos con 12 tratamientos, cada uno con un diseño completamente al azar. Con los datos se realizó un análisis de varianza y la prueba de Tukey (p≤0.05). En las salchichas se midió color, perfil de textura (TPA), fuerza al corte con navaja de Warner-Bratzler, celda de Kramer, penetración de calor, actividad de agua y pérdidas por cocción. Los resultados muestran aumento de dureza, elasticidad y resiliencia con mayor cantidad de grasa y fosfatos, con menor inclusión de carne y agua añadida; contrario a la cohesivid3r34ncorporar en su elaboración fosfatos, carragenina, grasa de cerdo y agua.

Palabras clave: Salchicha; difusividad térmica; carragenina; fosfatos; Cyprinus carpio; carne

Introduction

Carp (Cyprinus carpio) is produced due to its high growth rate and easy farming (Guler et al. 2007; Ibañez et al. 2014; Wang and Lu, 2015), yet little is known about the cooked meat products prepared with the flesh of this fish. Cooking conditions are important in the quality of a meat product when boiling them, and therefore, time and temperature are optimized to improve chemical reactions and physical characteristics of the product, including the texture of the meat products, which are desirable for the consumer (Lund, 2003; Abdolghafour and Saghir, 2014). The color of the meat products is produced mainly by the pigment of the meat, which may vary according to myoglobin content; however, if this is kept constant, color will be affected by the amount of fat and added water (Pietrasik and Duda, 2000; Abdolghafour and Saghir, 2104). Color is important in food processing and acceptance (Awuah et al. 2007); therefore, it is the most used sensory attribute or evaluating the quality of fish (Ocaña-Higareda et al. 2009). Kaspar and Buchtova (2014) performed the sensory analysis of sausages prepared with pork and different amounts of carp meat, concluding that the increase in the amount of carp meat reduces the preference of the sausages by the panelists.

Phosphates are used in the meat industry to improve the product's yield, since it increases the water retention capability (Son Long et al. 2011), therefore influencing the reduction of oxidative staleness of the meat products (Fonseca et al. 2012) and shelf life (Lin and Lin, 2002; Son Long et al. 2011).

Thermal and physical properties are important due to their influence on thermal exchange meat and meat emulsions must undergo when being cooked. The cooking-cooling process depends on the heat transfer throughout the product (Marcotte et al. 2008). High temperatures lead proteins to form as series of chemical interactions with the fat and water, which allows the emulsion to stabilize (Carciofi et al. 2002). According to Ayadi et al. (2009a), the variation in the heat penetration is attributed to the characteristics of the raw material and the formulations used in the preparation of emulsified products. The interaction between carbohydrates and proteins is important to conform the structure and stability of the processed products, although such interactions affect the bioavailability of proteins (Ramírez et al. 2011). In cooked meat products, myofibrillar proteins have a key function during the process due to their capacity to produce gels during heating and later cooling down, which have an influence on the properties of the texture of the processed products (Ayadi et al. 2009b). Therefore, the aim of this study was to evaluate the influence of the amount of fat, added water, phosphates and carrageenan on the quality and stability of an emulsified meat product using carp meat.

Materials and Methods

Preparation of the product

This study was carried out between January and June 2010, in the facilities of the Agriculture and Livestock Science Institute of the Autonomous University of the State of Hidalgo. To prepare the product 45 kg of eviscerated carp were used (450 g carp-1), which were transported at a temperature of 4 °C from a commercial farm in Tezontepec de Aldama, Hidalgo, to the meat products workshop of the Agriculture and Livestock Science Institute (ICAp) located in Tulancingo, Hidalgo. The meat was ground, homogenized, and split into two batches: the first was kept for 24 h at 4 °C in a Torrey brand refrigerator (Model R36, Monterrey, Nuevo León, Mexico), and the second was frozen at -18 °C for 15 d in a Torrey brand freezer (Model CHC25, Monterrey, Nuevo León, Mexico). The meat from the first batch underwent 12 sausage emulsion treatments (Guerrero et al., 2000) (Table 1), to evaluate texture (greater, intermediate, and lower), color and firmness, according to the level of inclusion of fat and water. The meat from the second batch also underwent 12 sausage emulsion treatments (Guerrero et al., 2000), but was added phosphates (Emulfos 2000®, Fabpsa, Mexico) and carrageenan (Fabpsagel®, Fabpsa, Mexico) in its formulation (Table 2).

Table 1 Treatments with different amounts of fat and water in a product emulsified with carp meat (g).

Chemical analyses

The proximal chemical analysis was carried out according to the AOAC (1999): moisture (method 934.01), fat (method 948.15) and raw protein (method 981.10).

Determining color

Color was determined with parameters L*, a* and b* (AMSA, 2012), using a Minolta 508d spectrophotometer (Minolta Inc., Tokyo, Japan), with a D65 light and an angle of the observer of 10°, and three color measurements were taken on the surface of each portion of the mass. The values were registered according to recommendations by the Comission Internationale de l'Éclairage (CIE).

Texture profile analysis

For the texture profile analysis, cubed pieces measuring 2.5 cm on each side were cut, enough to cover the surface of the texture analyzer P25/L (cylindrical perspex, 25 mm diameter, Stable MicroSystems, Surrey, UK), which was placed on the base of the texture analyzer (TA-HDi Instruments, Stable MicroSystems, Surrey, UK) and compressed using a 5 kg load cell at 50 %, with a speed of 1 mm s-1. The texture profile analysis (TPA) gave the following parameters: firmness, elasticity, resilience, and cohesiveness. Analyses were carried out in triple.

Resistance to cutting with a Warner-Bratzler blade

A Warner-Bratzler blade (HDP/BSW, Stable MicroSystems, Surrey, UK) was used for this test, adapted to the texture analyzer. Samples were analyzed according to indications by Ruiz de Huidobro et al. (2005), with the following modifications: the 9 cm long sample was placed horizontally between the base of the cell and the blade that made the cut by descending vertically until it cut the sample in two pieces. Resistance to the cut was evaluated using a test speed of 1 mm s-1 and a return speed of 2 mm s-1 with a 5 kg load cell; each sausage was cut in three places, and the maximum firmness and effort for cutting were reported during the test.

Maximum firmness detected with a Kramer shear cell

This test was performed according to Cavestany et al. (1994) with the following modifications: we used a 10 - blade Kramer shear cell (TA-91, Stable MicroSystems, Surrey, UK) adapted to the texture analyzer, with a load cell of 50 kg at a speed of 1 mm s-1. The sample was cut in a piece 8 cm long and was placed horizontally between the mass of the cell where it was cut, and the cell fell vertically until the complete penetration of the blade along the structure of the product. The maximum strength found during the compression-extrusion g-1 of the sample was reported.

Heat penetration

The reading of the internal temperature of the meat was taken every minute for 20 min with a digital Hanna Instruments HI98609 thermometer which was introduced in the center at the middle of the sausage, which rose up to, and remained at, 85 °C.

To determine thermal diffiusivity of the meat, the equation (1) proposed by Markowski et al. (2004) was used.

where α: thermal diffusivity of the meat (m2 s-1), B: gradient of each treatment, R: radius of the sausage (m), L: length of the sausage (m).

To evaluate the changes between the temperature in the center and the surface of the sample against time, equation 2 was used, proposed by Markowski et al. (2004). To calculate the gradient of each treatment it was necessary to graph the values for ln [ Ts-Tc ] min- 1 for which the temperature was monitored.

where Ts: temperature on the surface of the sample (°C); Tc: temperature in the center of the meat (°C); A: intersection; B: gradient of each treatment; t: min time.

The calculation of the theoretical temperatures was obtained with a quadratic function, using the time taken for cooking, in order to obtain the description of the penetration of heat.

where Y: temperature in the center of the product and x: time for cooking.

Experimental design and statistical analysis

The experimental design was completely randomized and treatments are described in Tables 1 and 2. To determine the statistical differences in color and texture of the emulsified carp meat products, an ANDEVA was applied, and the measurements of the treatments were compared with Tukey's test (p≤0.05), for which we used the GLM procedure (SAS, 2002).

Results and Discussion

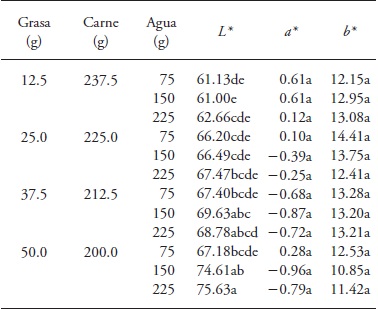

Chemical composition of carp meat

The variation in the chemical composition of carp meat is due to age, sex, environment, season of the year, and feeding (Guler et al. 2007). The carps used in our study were taken from tanks in a farm, under the same feeding and age conditions. The amount of fat in the carp meat in this study was 0.1 % (Table 3), which is lower than that reported by Guler et al. (2007), who found that lipids in fresh muscle are low (0.91 %) during the warm season, and high (1.73 %) in the cold season; Mahmoud et al. (2006) reported 3.90 % fat, and Ganesh et al. (2005) 2.8 %. Regarding moisture, values were similar (Table 3) to those reported by Mahmoud et al. (2006), 76 % for carp fillets, and by Ganesh et al. (2005), 78.3 %. Protein and ash (Table 3) were higher than those found by Ganesh et al. (2005), 17.8 % and 0.95 %, respectively.

Table 3 Chemical composition of the fish (Cyprinus cardio) from a farm, in Tezontepec de Aldama, Hidalgo.

% Carbohydrates= 100 % - % Moisture + % Ashes + % Fat + % Protein (FAO, 1999).

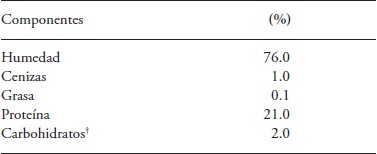

Effect of added fat and water on the texture

The loss in texture during the storage of fish products is related to a low pH in muscles, a hard texture, high loss of water due to dripping and enzyme activity. Fish muscles can be more complex when it constantly loses fluids; water retention capacity is reduced, which is a good quality indicator for fish and this is shown with a loss in texture (Ocaña-Higareda et al. 2009). In our4hy the meat recovers more water in its structure and improves its texture. As more fat and water are used, the product becomes less sensitive to breakages, the product can be more homogenous, elastic, cohesive, and with a firmness that allows a greater use of water in its structure, which improves the performance and economic benefit. These observations are similar to those by Ayadi et al. (2009a), who consider that the differences between the amount of fat/moisture and protein/moisture are factors that influence the elasticity of products made with turkey meat. Huda et al. (2012) point out that there is a relationship between the moisture and firmness of fish sausages, as well as Intrapichet et al. (1995), who show that reducing the fat in sausages with a mixture of goat meat and pig fat increases elasticity.

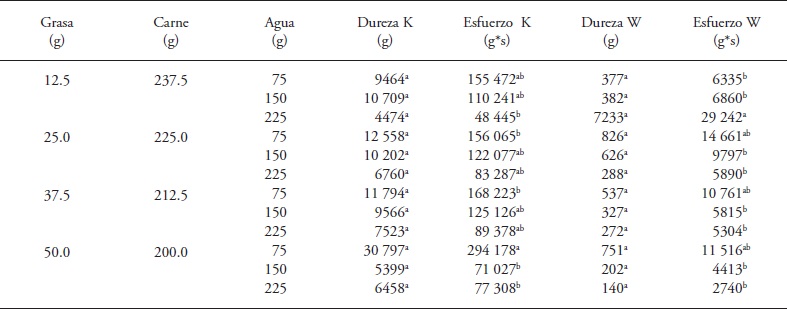

There was no effect of the amount of fat, meat or water on firmness. In the values obtained for the effort for cutting with both analyzers, the increase in the amount of water and fat reduced it, except for the first treatment using the Warner-Bratzler, in which it increases (Table 5).

Table 4 Profile analysis for texture by the effect of added water, fat and carp meat in an emulsified sausage product.

Means with different letters in a column indicate statistical difference (p≤0.05).

Table 5 Averages of the least squares of the maximum strength detected with the Kramer shear cell (K) and strength in the cut using a Warner- Bratzler blade (W) by effect of the added water, fat, and carp meat in an emulsified sausage.

Means with different letters in a column indicate statistical difference (p≤0.05).

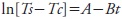

Effect of fat and added water on the color

The highest value in L* was with treatments with a greater amount of far and less meat, whereas in parameters a* and b* there was no difference between treatments (Table 6). This is different to Ocaña-Higareda et al. (2009) who mention that parameters a and b are low in the product when low amounts of fat are added.

Effect of added fat and water on heat penetration

Markowski et al. (2004) determined the effective thermal diffusivity for Lyoner sausages cooked by immersion in hot water with a diameter of 96 mm, and thermocouples were used to measure the increase in temperature during cooking, one thermocouples submerged in hot water, a second one placed in the center of the meat product and a third one on the surface of the product, with a water bath at a constant temperature of 95 °C; once the samples reached 75 °C in the center, the samples were removed from the water and cooled using cold water. Ayadi et al. (2009) determined the thermal diffusivity in formulations for salami and ham made with turkey meat, cooked by immersion in hot water, used a system of thermocouples and took the temperature in the center and surface of the product, as well as the temperature of the constant water bath at 90 °C; once the internal temperature of the sample reached 74 °C, they were removed from the hot water. Like these authors, a scheme was carried out in which the experimental data were taken during the cooking of the meat. The temperatures obtained from the monitoring for 20 min showed that the heat penetration of the sausages are similar in the different treatments and indicate that there is no difference in the time of cooking (Figure 1).

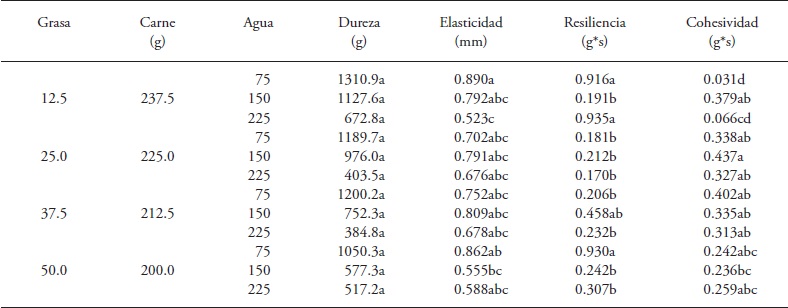

Effect of the addition of phosphates and carrageenan on texture

The use of table salt and phosphates increases the capacity of emulsification of carp meat (Yapar et al. 2006), and improves its texture. The firmness increases with the amount of carrageenan, which correlated positively with the amount of fat, and negatively with the amount of water (Table 7). Ayadi et al. (2009) studied the influence of adding carrageenan on the properties of sausages produced with turkey meat, and mention that the carrageenan reduces the stability of the emulsion and increases the water capacity, it produces more firm and cohesive, and less elastic sausages. Hsu and Chung (2001) also observed an increase in the performance of low-fat meatballs with 2 % de carrageenan. According to Totosaus and Pérez-Chabela (2009), the mix of gellan gum and MgCl2 in low-fat meats improves the texture, producing firmness values of 3365 to 3773 g due to the capacity of carrageenan to catch water in the three-dimensional mesh it forms; water is not released as cooking juice, but it remains inside the product. This is an advantage in the use of carrageenan, which also controls the leakage during storage. Another advantage is that it improves the slicing and performance in emulsified products (Abdolghafour and Saghir, 2014).

Table 7 Texture profile in treatments with different inclusions of phosphate and carrageenan in a sausage-type emulsified product with carp meat.

Means with different letters in a column indicate statistical difference (p≤0.05). F: phosphates, C: carrageenan.

Elasticity increased in the treatments with a greater inclusion of phosphate and a lower amount of water (Table 7), since phosphate helps proteins retain water, and therefore added water (Lin and Lin, 2002; Son Long et al. 2011). This indicates that the product recovers part of its initial form after the first compression, since the added water was not released as cooking juice, but remained in the product, (Abdolghafour and Saghir, 2014).

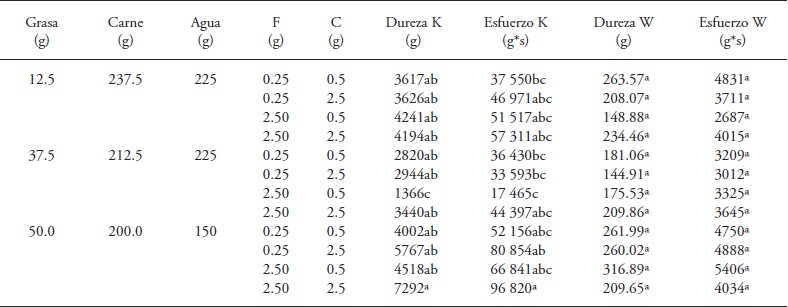

The use of the Kramer shear cell gave a greater firmness and effort (Table 8) in the treatments that contained more carrageenan and water, with less meat and fat since carrageenan is more free, therefore it forms a more firm gel and, with that, the effort. This coincides with Totosaus and Pérez-Chabela (2009), who point out that the use of the Kramer shear cell causes the gellan gum in combination with MgCl2 to produce stronger structures, which is why the maximum firmness values are higher. But with the use of the Warner-Bratzler blade (Table 8), no differences were found between treatments: 144.91-316.89 g for firmness and 3012-5406 g*s for effort when cutting. This is explained according to Totosaus and Pérez-Chabela (2009), since in meats with added gellan gum a solid structure is obtained, which results in larger values of the area under the curve when using the test with a Warner-Bratzler blade.

Table 8 Maximum strength detected with the Kramer shear cell (K) and strength when cutting with the Warner-Bratzler blade (W) in treatments with different inclusions of phosphates and carrageenan in a sausage-type emulsified product with carp meat.

Means with different letters in a column indicate statistical difference (p≤0.05). F: phosphates, C: carrageenan.

Effect of the addition of phosphates and carrageenan on color

L* increased when including a greater amount of phosphates in the treatments with less fat, meat, and water (Table 9). This coincides with Hsu and Chung (2000), who studied the effect of the k-carrageenan, salt, phosphates and fat on the quality of low-fat meatballs, and found that the poliphosphates affected the values of a* and b significantly. Likewise, Pietrasik and Duda (2000) reported no effect in the addition of carrageenan and soy protein concentrate on the values of L* and a* in sausages produced with beef and pork.

Effect of the addition of phosphates and carrageenan on thermal diffusivity

Thermal diffusivity depends on the thermodynamic properties of the raw material, structure, heat transfer mechanisms and mass (Markowski et al. 2004; Marcotte et al. 2008). That property is closely related to the three thermophysical properties: thermal conductivity, specific heat, and density (Marcotte et al. 2008).

Marcotte et al. (2008) studied the thermophysical properties of process products made with poultry, and point out that thermal diffusivity is a property that changes in regard to temperature; as moisture increases, conductivity and diffusivity increase. This is due to the 2 % of salt added in the emulsion. The proportion of proteins does not have a significant influence on these properties; the results of the calculation of the thermal diffusivity were between 8.30X10-8 m2 s-1 and 1.36X10-7 m2 s-1. Ayadi et al. (2009b) used the same equation to calculate diffusivity in salami and turkey ham, and obtained values between 5.11 X10-6 m2 s-1 and 7.02X10-6 m2 s-1 for salami, and for ham, 1.98x10-8 m2 s-1. Markowski et al. (2004) determined the thermal diffusivity in Lyoner sausages during cooking and cooling in a water bath, and obtained results between 3.5X10-7 m2 s-1 and 4.5X10-7 m2 s-1, respectively; besides they point out that the variations in thermal diffusivity are due to the fat and water contents in the product. Both authors determined the thermal diffusivity with the data on the temperature of the center and surface of the sample. The treatment with the highest amount of fat, phosphates and carrageenan with the least amount of meat obtained the highest thermal diffusivity of 9.61X10-4 m2 s-1, since phosphates capture water and carrageenan makes a gel, that in combination with fat causes this thermal incrementdfd. On the other hand, the treatment with the lowest amount of phosphates, water and meat had a lower value of 7.10 X 10-4 m2s-1 (Figure 2).

Conclusions

The commercial value of carp meat can be improved, giving it an added value creating emulsified meat products, keeping this meat type as a base, and: phosphates to improve the elasticity, resilience, and cohesiveness; carrageenan to improve firmness and color. Also, the incorporation of pig fat and water improves the texture of the emulsified product.

Literatura Citada

Abdolghafour, B., and A. Saghir. 2014. Development in sausage production and practices-A review J. Meat Sci. Technol. 2: 40-50. [ Links ]

AMSA. 2012. Meat Color Measurement Guidelines American Meat Science Association, Illinois USA, 124 p. [ Links ]

AOAC. 1999. Official Methods of Analysis. AOAC Association of Official Analytical Chemists, 15 th ed. Washington, DC. [ Links ]

Awuah, G., B., H. S. Ramaswamy, and A. Economides, 2007. Thermal processing and quality; Principles and overview. Chem. Eng. Process. 46: 584-602. [ Links ]

Ayadi M. A., A. Kechaou, I. Makni and H. Attia, 2009a. Influence of carragenan addition on turkey meat sausages properties. J. Food Eng. 93: 278-283. [ Links ]

Ayadi, M.A., I. Makni and H. Attia. 2009b. Thermal diffusivities and influence of cooking time on textural, microbiological and sensory characteristics of turkey meat prepared products. Food Bioprod. Process. 87: 327-333. [ Links ]

Cavestany, M., F. J. Colmenero, M. T. Solas, and J. Carballo, 1994. Incorporation of sardine surimi in bologna sausage containing different fat levels. Meat Sci. 38: 27-37. [ Links ]

Carciofi, B. A. M., J. Faistel, G. M. F. Aragao, and J. B. Laurindo. 2002. Determination of thermal diffusivity of mortadella using actual cooking process data. J. Food Eng. 55: 89-94. [ Links ]

De Huidobro, F. R., E. Miguel, B. Blázquez, and E. Onega. 2005. A comparison between two methods (Warner-Bratzler and texture profile analysis) for testing either raw meat or cooked meat. Meat Sci. 69: 527-536. [ Links ]

Fonseca, J. M. D. A. 2012. Acompanhamento das atividades do Laboratório de controle físico-químico de produtos de origem animal Facultad de Agronomia e Medicina Veterinária. Doctoral dissertation, Universidade de Brasília Brasília. 34 p. [ Links ]

Food & Agriculture Organization. 1999. Los carbohidratos en la nutrición humana. Informe de una consulta mixta. FAO/ OMS. Roma. 14-18 abril 1997. ISSN 1014-2916. 152 p. [ Links ]

Ganesh, A., A. O. Dileep, B. A. Shamasundar, and U. Singh. 2005 Gel-forming ability of Common carp fish (Cyprinus carpio) meat: effect of freezing and frozen storage. J. Food Biochem. 30: 342-361. [ Links ]

Guerrero, L. I., A. E. Ponce, y C. M. L. Pérez. 2002. Curso Práctico de Tecnologías de Carnes y pescado. UAMI, D.F. Méx. [ Links ]

Guler, G. O., B. Kiztanir, A. Aktumsek, O. B. Citil, and H. Ozparlak. 2007. Determination of the seasonal changes on total fatty acid composition and 0)3/0)6 ratios of carp (Cypri-nus carpio L. ) muscle lipids in Beyseir Lake (Turkey). Food Chem. 108: 689-694. [ Links ]

Hsu, S. Y., and H .Y. Chung. 2000. Interactions of konjac, agar, curdlan gum, k-carrageenan and reheating treatment in emulsied meatballs. J. Food Eng. 44:199-204. [ Links ]

Huda, N., T. L. J. Alistair, H. W. Lim and R. Nopianti. 2012. Some Quality Characteristics of Malaysian Commercial Fish Sausage. Pakistan J. Nutr. 11: 700-705. [ Links ]

Ibáñez, A.L., R. M. Pérez, and C. J. L. García. 2014. Institutional development of freshwater fish stocking in Mexico. J. Fish Biol. 85: 2003-2009. [ Links ]

Intarapichet, K., W. Sihaboot, and P. Chungsiriwat, 1995. Chemical and sensory characteristics of emulsion goat meat sausages containing pork fat or shortening. ASEAN Food J. 10: 57-61. [ Links ]

Kašpar, L., and H. Buchtová. 2015. Sensory evaluation of sausages with various proportions of Cyprinus carpio meat. Czech J. Food Sci. 33: 45-51. [ Links ]

Lin, K. W., and S. N. Lin, 2002. Effects of sodium lactate and trisodium phosphate on the physicochemical properties and shelf life of lowfat Chinese-style sausage. Meat Sci. 60:147-154. [ Links ]

Lund, D. 2003. Predicting the impact of food processing on food constituents. J. Food Eng. 56,113-117. [ Links ]

Mahmound, B. S. M., Y. Kawai, K. Yamazaki, K. Miyashita, and T. Susuki. 2006. Effect of treatment with electrilyzed NaCl solutions and essential oil compounds on the proximate composition, amino acid and fatty acids composition or carp fillets. Food Chem.101: 1492-1498. [ Links ]

Marcotte, M., R. A. Taherian, and Y. Karimi. 2008. Thermophy-sical properties of processed meat and poultry products. J. Food Eng. 88: 315-322. [ Links ]

Markowski, M., I. Bialobrzewski, M. Cierach, and A. Paulo. 2004. Determination of thermal diffusivity of Lyoner type sausages during wáter bath cooking and cooling. J. Food Eng. 65: 592-596. [ Links ]

Ocaña, H. V. M., R. E. Márquez, D. M. Canizales, Y. F. J. Castillo, A. R. Pacheco, S. E. M. Lugo, O. K. D. García, and V. A. Z. Graciano. 2009. Postmortem changes in cazon fish muscle stored on ice. Food Chem. 116: 933-938. [ Links ]

Pietrasik, Z., and Z. Duda. 2000. Effect fat content and soy protein carrageenan mix on the quality characteristics of com-minuter, scalder sausages. Meat Sci. 56: 181-188. [ Links ]

Ramírez, J. A., Uresti, R. M., Velazquez, G., and M. Vázquez. 2011. Food hydrocolloids as additives to improve the mechanical and functional properties of fish products: A review. Food Hydrocoll. 25:1842-1852. [ Links ]

SAS Institute Inc. 2002. SAS User's guide: Stat, version 6.03, SAS Institute Inc., Cary, NC, USA. [ Links ]

Son Long N, H. B., R. Gal, and F. Bunka. 2011. Use of phosphates in meat products. Afr. J. Biotechnol. 10: 19874-19882. [ Links ]

Totosaus A., M., and C. M. L. Pérez. 2009. Textural properties and microstructure of low-fat and sodium-reduced meat batters formulated with gellan gum and dicationic salts. LWT - Food Sci. Technol. 42: 563-569. [ Links ]

Yapar, A., S., Atay, A., Kayacier, and H. Yetim. 2006. Effects of different levels of salt and phosphate on some emulsion attributes of the common carp (Cyprinus carpio L., 1758). Food Hydrocoll. 20: 825-830. [ Links ]

Wang, M., and M. Lu. 2015. Tilapia polyculture: a global review Aquac. Res. 1-12. [ Links ]

Received: June 2015; Accepted: February 2016

texto em

texto em