Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Agrociencia

versión On-line ISSN 2521-9766versión impresa ISSN 1405-3195

Agrociencia vol.49 no.8 Texcoco nov./dic. 2015

Ciencia de los alimentos

Drying kinetics of slices of nopal (Opuntia ficus indica) cladodes in a convective transversal flow dryer

Cinética de secado de tiras de cladodios de nopal (Opuntia ficus indica) en un secador convectivo de flujo transversal

Felipe Díaz-Ayala, G. del Socorro Álvarez-García*, Efraín Simá-Moo

Centro Nacional de Investigación y Desarrollo Tecnológico, CENIDET-TecNM-SEP, Prolongación Avenida Palmira S/N, Colonia Palmira, 62490. Cuernavaca, Morelos, México.

Received: January 2015.

Approved: July, 2015.

Abstract

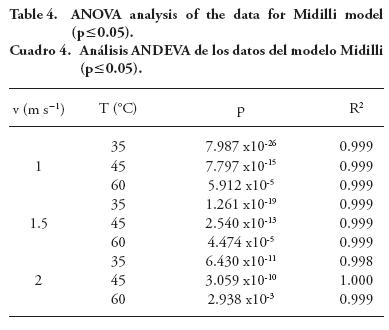

Opuntia ficus-indica, also known as nopal, is a cactus which grows on arid and semiarid lands of America. Dehydrated nopal is an alternative for food preservation, but drying times of cladodes are very long. The objective of this study was to evaluate dry kinetics of nopal thin slices, of 4 mm thick, 140 mm long and 17 mm wide. We conducted the drying process in a convective cross flow tray dryer at 35 °C, 45 °C and 60 °C and air velocities of 1 m s-1, 1.5 m s-1 and 2 m s-1, under laboratory conditions. Results indicated that the effect of air temperature on the drying time of nopal slices was higher than the air velocity (p≤0.05). The drying time for nopal in thin slices was remarkably lower (99 %) compared to that for whole cladode (p≤0.05 and 50 % lower for cylindrical 25 mm nopal pieces previously reported. Further, the experimental data of drying curve of nopal slices were fitted to different thin layer models and the Midilli model with empirical constants was the best describing the of nopal slices drying. ANOVA analysis indicated that all the tests were significant (p≤0.05) for all drying temperatures and velocities evaluated.

Keywords: Food drying, nopal cladode drying, drying kinetics of cactus, thin layer drying, drying time.

Resumen

Opuntia ficus-indica, también conocido como nopal, es un cactus que crece en zonas áridas y semiáridas de América. La deshidratación del nopal es una alternativa para su conservación como alimento pero el tiempo para secar los cladodios es muy largo. El objetivo de este estudio fue evaluar la cinética de secado de tiras delgadas, de 4 mm de grosor, 140 mm de longitud y 17 mm de anchura de nopal. El secado se realizó en un secador de charola con flujo convectivo cruzado a 35 °C, 45 °C y 60 °C y velocidades de aire de 1 m s-1, 1.5 m s- 1 y 2 m s- 1, en condiciones de laboratorio. Los resultados mostraron que el efecto de la temperatura del aire en el tiempo de secado de las tiras de nopal fue mayor que la velocidad del aire (p≤ 0.05). El tiempo de secado de las tiras delgadas fue notablemente menor (99 %) en comparación con el del cladodio entero (p≤ 0.05) y 50 % menor que para piezas cilíndricas de nopal de 25 mm reportado previamente. Además, los datos experimentales de la curva de secado de las tiras de nopal se ajustaron a diferentes modelos de capa fina, y el modelo Midilli con constantes empíricas describió mejor el secado de nopal en rebanadas. El análisis estadístico ANDEVA indicó que todas las pruebas fueron significativas (p≤ 0.05) para todas las temperaturas de secado y velocidades evaluadas.

Palabras clave: Secado de alimentos, secado de cladodio de nopal, cinética de secado de cactus, secado de capa delgada, tiempo de secado.

INTRODUCTION

Cacti belong to the genus Opuntia and they are native of northern desert zones of Mexico and south of USA. In Mexico, there are approximately 100 species among the 258 documented species (Guzmán et al., 2007). For human consumption, only 10 to 12 species are used to produce fruit (pears) and vegetables (cactus). The Opuntia ficus-indica is also called nopal; the nopal cladode is well known for nutritional and healing qualities, it is rich in fiber, minerals, and vitamins (Maki-Díaz et al., 2015). It is exported (85 % fresh) from Mexico. But the overabundance of fresh nopal in the market causes a price decrease and economic loss to producers FND, (2011).

Drying and grinding nopal cladodes are part of a preservation method used as an alternative to increase marketing opportunities, because cladodes shelf life can be extended and the high cost of transport and storage can be reduced (Erechukwu 1999; Midilli et al. 2002). A variety of dry fruits and vegetables with forced convection hot air were reported by Hossain and Bala (2002), Midilli et al. (2002), Kashaninejad and Tabil (2004), Doymaz (2006) and Waewsak et al. (2006), but few studies were found in the literature reviewed about cladode drying. Medina-Torrez et al. (2008) studied the effects of three drying methods (convective, osmotic and osmotic-convection) on the mechanical properties of the nopal. Higher elasticity was observed in the dried tissue using osmotic method showed than by convective hot air and it was harder than that osmotically dried; textural properties of nopal were strongly affected by combining drying processes this increasing brittle, and reducing cohesiveness and springiness. Authors recommended using convective drying to preserve the best mechanical characteristics of the nopal. They reported for a convective area of 0.0578 m2 dry times of 11 to 18 h, at 65 and 45 °C for 3 and 5 m s-1, to reach 2 % humidity, but they did not specify if the cactus cladode had been cut or if the cuticle was eliminated. Vasconcelos et al. (2012) studied osmotic dehydration of whole cladode considering binary and ternary solutions and found that temperature had a greater influence on water loss, the concentration of the osmotic solution (sucrose/NaCl/water) had a greater effect on nopal and the best conditions for osmotic dehydration were in a glucose solution at 40 °C. They did not account for the nopal drying time only for the study of effects of independent variables such as temperature and velocity on the drying process. López et al. (2009) used a convective dryer tunnel to study the kinetics of drying whole nopal cladodes with and without thorns at 35 °C, 45 °C and 60 °C and 1.5 m s-1 and 3 m s-1 air speed. They found that time to dry cladodes was very large; it ranged from 80 to 360 h for those with thorns and from 50 to 260 h for those without thorns. However they did not investigate the slices of cladode drying kinetics. Touil et al. (2010) investigated the effect of three infrared dry temperatures (40, 50, 60 °C, not airflow) on O. ficus indica fruits and cladodes. Drying times of cladode, cut in small cylinders of 25 mm in diameter and 5 mm thick, ranged between 2.5 to 5.5 h. Therefore, the drying time is related to temperature, airflow, nopal geometry and the type of process used. Thus cutting the nopal cladode in small thin strips may diminish significantly the drying time, saving energy for drying.

The objective of this study was to evaluate: the drying kinetics of nopal cladode cut in thin slices of 17 mm width, 4 mm thick and 140 mm long, using a convective drier; the influence of the combined effects of varying air temperatures and velocities on the drying process; and ten kinetic models considering the combining effects of drying time, temperature, speed and relative humidity.

MATERIALS AND METHODS

Fresh nopal cladodes harvested during September-October 2008 in Tepoztlán, Morelos, Mexico, were used. They were selected according to maturity and geometric dimensions. The cladodes without thorns of 17 mm thick, 140 mm wide and 200 mm long were washed and cut in 10 thin slices of 4 mm thick, 17 mm width, and 140 mm long, approximately. The sample weight was 120 g. The initial moisture content (92.8 %) was determined in a laboratory oven (Imperial Laboratory Lab Oven Model 3478 M-line Instruments) according to AOAC (2000).

The experiments were carried out in a cross flow tray dryer designed and built at the Mechanical Engineering Department of Cenidet in Cuernavaca, Mexico (Figure 1). The dryer provided air at 35 °C, 45 °C and 60 °C and speed between 1.0, 1.5 and 2 m s-1. Air was conducted by a centrifugal fan AXC 315B (Elicent) of 300 W and heated by five electric heaters of 600 W. Air temperature was controlled by a heating control unit (0.25 m wide, 0.25 m high and 0.9 m length) located at the entrance of the duct dryer. The test chamber was a transparent box (0.55 m and 0.60 m high) containing a stainless steel grid (0.25 m long and 0.25 m wide). Eleven LM-35 (±0.5 °C accuracy) sensors measured the ambient, interior, inlet and outlet air temperatures of the drying test chamber. Five HIH-4000-004 (Honeywell ± 3.5 % accuracy) sensors measure exterior, interior, inlet and outlet air humidity of the test chamber.

A hot wire digital anemometer (Model 731A; BK Precision; ± 3 % accuracy) measured the air velocity. A USB-6008 (National Instruments) acquisition system was used to gather and process the data. A J-100 (Reyo) digital scale (± 0.01 g accuracy) monitored the weight of nopal slices.

After the experimental data were obtained a suitable theoretical model that describes the drying curve of thin nopal slices was selected. Thus the experimental drying curves were fitted by 10 different thin layer models (Table 1).

Experimental procedure

Nopal sample of 10 thin slices, 4 mm thick, 140 mm long and 17 mm wide, was extended on the grid tray (Figure 2). Air temperature and speed were set on the convective dryer. The drying temperature and relative humidity of air at the duct entrance, upper and lower tray and exit were measured and recorded. The samples were weighted manually every 10 min throughout the experiment. The ambient temperature and air relative humidity in the room ranged from 24.9 to 27.5 °C and from 39.9 to 59.6 %. The initial moisture content of the nopal slices ranged from 0.943 to 0.953 kgH2O/kgdry-matter and the final nopal moisture content needed to grind the slices should be kgH2O/kgdry.

RESULTS AND DISCUSSION

In order to determine the variability among the experiments, three experiments were performed for every condition of velocity and temperature. The data of the three experiments were analyzed by computing the average standard deviation. The average standard deviation of these experiments, for all the conditions of velocity and temperature, was 0.024. The maximum standard deviation was 0.032, which happen when the humidity of the product was higher than 60 % and the minimum standard deviation of 0.007 was when the humidity of the product was 4%.

Drying times of 4.78, 3.00, 1.68 h, for 1 m s-1; 3.8, 2.91, 1.53 h for 1.5 m s-1 and 2.99, 2.31 and 1.25 h for 2 m s-1, respectively (Figure 3). For the highest temperature and velocity the drying time was 1.25 h, which was 40 % lower than the drying time for high velocity and lower temperature (2.99 h). Besides the drying constant period was absent, which means that the drying process was carried out only in the falling rate period, indicating that diffusion is the mechanism governing the motion of the moisture migration in nopal slices. This result agrees with that reported by Touil et al. (2010).

A comparison (Figure 4) between the convective drying times of cladode slices, of the present work, and the whole nopal cladode with and without thorns at 45 °C and speed of 1.5 m s-1 reported by Lopez et al. (2009) indicated that time to dry slices was substantially lower, 1.25 h against 50 h of Lopez et al. (2009), even when nopal cuticle was reduced by 30 %. Comparing the drying time of cylinders of nopal, reported by Touil et al. (2010), against the drying time of thin strips of 4 mm thick, 140 mm long and 17 mm width was also very low; 1.25 h against 2.5 h. The difference is that they considered 25 mm diameter cylinder and we considered strips of 4 mm thick. It is worth to mention, that drying cladode in thin strips remarkably decreased the drying time compared to the drying time of whole cladodes with or without thorn and cylinders of 25 mm diameter (99 % and 50 %). It seems that geometry and thickness are important to reduce the drying time of nopal.

The drying rate continuously decreased as the moisture ratio drop (Figure 5). Some overlapping drying rate curves seems that air velocity for these conditions has no effect on the drying kinetics.

The drying time at 60 °C decreased significantly (1.75 h) compared to 35 °C (3.5 h) (Figure 6). The drying time was almost the same (3 h) at 1 m s-1 than 1.5 m s- 1 and decreases slightly (2.75 h) at 2 m s-1 (Figure 7). As it can be seen, the effect of air temperature was a more significant parameter compared with air velocity.

Thin layer model

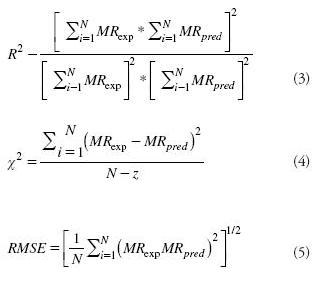

The most suitable theoretical model selected among the 10 thin layer models (Table 1) was found fitting the drying curves of experimental data (Figure 3). In order to determine the best model that describes the experimental data of sliced nopal cladode, statistical parameters (Panchariya et al., 2002; Ghazanfari et al., 2006) such as correlation coefficient (equation 3), reduced chi-square (equation 4) and root mean square error (equation 5) were calculated by:

where R2 is the correlation coefficient, MRexp is the experimental humidity relationship, MRpred is the moisture content calculated, δ2 is the Chi-square, N is the data number, z is the number of constants of the model, and RMSE is the root mean square error. The calculated empirical constants for different conditions of air velocities and temperatures of the 10 equation models are shown in Table 2. The coefficient of determination (R2), coefficient chi-square (x2) and root mean square error (RMSE) were calculated. R2 was in the range of 0.983-0.999, x2 was in the range of 4.694x10-5-6.691x10-3 and RMSE was between 6.378x10-3-4.417x10-2 (Table 3).

From the Arrhenius equation (equation 2), the four empirical constants for the fitted model equation for nopal cladode slices were:

where HR is the air relative humidity, v is the air velocity and Tabs is the air drying temperature.

A good agreement between experimental data and drying model curves for air at 35 °C, 45 °C y 60 °C and air speeds of (a) 2 m s-1, (b) 1.5 m s-1 and (c) 1 m s-1 were obtained (Figure 8).

The p-values obtained with the ANOVA analysis were lower than 0.05 for all drying temperatures and velocities used (Table 4).

CONCLUSIONS

The drying time for 4 mm thick nopal slices is remarkably lower than the drying time of the complete cladode (99 %) reported by Lopez et al. (2009). The drying time of cylinder of cladodes reported by Touil et al. (2010) is also high (50 %) than those in rectangular slices of 4mm thick. The difference is the cylindrical geometry, 25 mm diameter in that study and 4 mm thick slices, of cross sectional area of 23.8 cm2, in the present study. Also the drying curve showed that the constant rate period of drying is absent, so only the falling drying rate period is present. The combined effects of different temperatures and velocities on the drying time showed that air temperature was more important than the drying air velocity. The variability of experiments showed an average of standard deviation of 0.025. The fitted equation showed that the Midilly model was the best model for the thin layer of 4 mm thick nopal slices with empirical constants presented here.

ACKNOWLEDGMENTS

The authors are grateful to Consejo Nacional de Ciencia y Tecnología for the support given to this project and to Dr. R. Díaz-Acosta (National Institute of Public Health, Biostatistical Department, Mexico) for sharing his experience for the regression analysis of the experimental data.

LITERATURE CITED

AOAC, Association of Official Analytical Chemists. 2000. Official Methods of Analysis. No. 934.06 (17th ed.). International, Maryland. [ Links ]

Diamante, L. M., and P. A. Munro. 1991. Mathematical modeling of hot air drying of sweet potato slices. Int. J. Food Sci. Technol. 26: 99-109. [ Links ]

Doymaz, I. 2006. Thin-layer drying behavior of mint leaves. J. Food Eng. 74: 370-375. [ Links ]

Erechukwu, O. V. 1999. Review of solar-energy drying systems I: an overview of drying principles and theory. Energ. Convers. Manage. 40: 593-613. [ Links ]

FND. 2011. Financiera Nacional de Desarrollo Agropecuario, Rural, Forestal y Pesquero. Monografía del Nopal y la Tuna. http://www.financierarural.gob.mx/informacionsectorrural/Documents/Monografias/MonografiaNopal-Tuna%28jul11%29.pdf (Accessed: May 2015). [ Links ]

Ghazanfari, A. S., L. G. Emami, S. Tabil, and Panigrahi. 2006. Thin-layer drying of flax fiber: II. modeling drying process using semi-theoretical and empirical models. Dry. Technol. 24: 1637-1642. [ Links ]

Guzmán, U., S. Arias, and P. Dávila. 2007. Catálogo de Cactáceas Mexicanas. Editorial: UNAM. Ciudad Universitaria México D. F. 320 p. [ Links ]

Hossain, M. A., and B. K. Bala. 2002. Thin-layer drying characteristics for green chilli. Dry. Technol. 20: 489-505. [ Links ]

Karathanos, V. T., and V. G. Belessiotis. 1999. Application of a thin layer equation to drying data fresh and semi-dried fruits. J. Agr. Eng. Res. 74: 355-361. [ Links ]

Kashaninejad, M., and L. G. Tabil. 2004. Drying characteristics of purslane (portulaca oleraceae L.). Dry. Technol. 22: 2183-2200. [ Links ]

López, R., A. de Ita and M. Vaca. 2009. Drying of prickly pear cactus cladodes (Opuntia ficus-indica) in a forced tunnel. Ener. Convers. Manage. 50: 2119-2126. [ Links ]

Maki-Díaz, G., C. B. Peña-Valdivia, R. García-Nava, M. L. Aré- valo-Galarza, G. Calderón-Zavala, y S. Anaya-Rosales. 2015. Características físicas y químicas de nopal verdura (Opuntia ficus-indica) para exportación y consumo nacional. Agrociencia 49: 31-51. [ Links ]

Medina-Torrez, L., J. A. Gallegos-Infante, R. F. Gonzalez-Laredo, and N. E. Rocha-Guzman. 2008. Drying kinetics of nopal (opuntia ficus-indica) using three different methods and their effect on their mechanical properties. Food Sci. Technol-Leb. 41: 1183-1188. [ Links ]

Midilli, A. H., Z. Kucuk, and Yapar. 2002. A new model for single-layer drying. Dry. Technol. 20: 1503-1513. [ Links ]

Panchariya, P. C., D. Popovic, and A. L. Sharma. 2002. Thin-layer modeling of black tea drying process. J. Food Eng. 52: 349-357. [ Links ]

Rahman, M. S., C. O. Perera, and C. Thebaud. 1997. Desorption isotherm and heat pump drying kinetics of peas. Food Res. Int. 30: 485-491. [ Links ]

Touil, A., S. Chemkhi, and F. Zagrouba. 2010. Modelling of the drying kinetics of Opuntia ficus-indica fruits and cladodes. Int. J. Food Eng. 6: 11-21. [ Links ]

Vasconcelos, J. L. A., A. S. C. Andrade, M. I. S. Maciel, N. B. Guerra, and M. A. S. Vasconcelos. 2012. Osmotic dehydration of the indian fig (Opuntia ficus-indica) with binary and ternary solutions. Int. J. Food Sci. Tech. 47: 2359-2365. [ Links ]

Waewsak, J., S. Chindaruksa, and C. Punlek. 2006. A mathematical modeling study of hot air drying for some agricultural products. Thammasat Int. J. Sci. Tech. 11: 1420. [ Links ]

Westerman, P., G. White, and I. Ross. 1973 Trans. ASAE 16: 1136-1139. [ Links ]

White, G. M., I. J. Ross, and R. Ponelert. 1981. Fully exposed drying of popcorn. Trans. ASAE 24: 466-468. [ Links ]

Yagcioglu, A., A. Degirmencioglu, and F. Cagatay. 1999. Drying characteristic of laurel leaves under different conditions. In: Bascetincelik, A. (ed). Proc. 7th Int. Congress on Agricultural Mechanization and Energy: 565-569. [ Links ]

Yaldiz, O., and C. Ertekin. Thin layer solar drying of some vegetables. 2001. Dry. Technol. 19: 583-597. [ Links ]

Yaldiz, O., C. Ertekin, and H. I. Uzun. 2001. Mathematical modeling of thin layer solar drying of Sultana grapes. Energy 26: 457-465. [ Links ]