Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Agrociencia

versión On-line ISSN 2521-9766versión impresa ISSN 1405-3195

Agrociencia vol.48 no.8 Texcoco nov./dic. 2014

Ciencia de los alimentos

Physicochemical, functional, thermal and rheological characterization of starch from huauzontle seeds (Chenopodium berlandieri spp. nuttalliae)

Caracterización reológica, térmica, funcional y fisicoquímica del almidón de semillas de huauzontle (Chenopodium berlandieri spp. nuttalliae)

Melissa Assad-Bustillos1,2, Mariana Ramírez-Gilly1, Alberto Tecante1, Leandro Chaires-Martínez3*

1 Departamento de Alimentos y Biotecnología, Facultad de Química, Universidad Nacional Autónoma de México. 04510. Ciudad Universitaria. D.F. México.

2 AgroParis Tech-Centre de Massy, 1 avenue des Olympiades. 91744. Massy, France.

3 Centro de Investigación en Alimentos. Instituto Tecnológico Superior de Álamo Temapache. 92750. Carretera Potrero del Llano-Tuxpan, km 6.5 Álamo, Veracruz, Mexico. *Author for correspondence (leandrochaires@yahoo.com.mx).

Received: May, 2014.

Approved: October, 2014.

Abstract

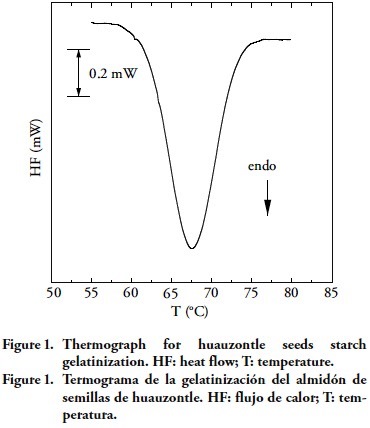

Huauzontle seeds (Chenopodium berlandieri spp. nuttalliae) are produced in the central part of Mexico but their use is limited to seedling process. Thus, in order to diversify their applications it is necessary to study their components such as proteins and starch. Therefore, the objective of this study was to extract and characterize the starch contained in the seeds of huauzontle by means of chemical and physical techniques. Analysis of the results showed 50 % extraction yield, 72.5 % starch purity, 5.32 % moisture, 1.09 % ash, 0.083 % fat, 11.4 % total nitrogen, and 4.13 % crude fiber. The amylose content was 10.5 %, which suggests that huauzontle starch gels could have a low tendency to retrograde. Swelling and solubility were similar to reported values for corn, lower than potato and higher than quinoa starches. The peak temperature of gelatinization was 68 °C. Pastes with 4 and 8 % (w/v) starch exhibited solid-like behavior attributable to amylose gelation with clear differences in dynamic moduli values and dependence with angular frequency when starch concentration increased. Non-Newtonian, shear-thinning behaviors with some degree of thixotropy that disappeared upon continuous shearing were observed. Laser diffraction data and SEM observations revealed association of very small (0.5-1.0 μm) starch granules into larger particles.

Key words: Chenopodium berlandieri, rheology, starch, viscoelasticity, microscopic structure.

Resumen

Las semillas de huauzontle (Chenopodium berlandieri spp. nuttalliae) se producen en la parte central de México pero su uso se limita al proceso de producción de plántulas. Así, con el fin de diversificar sus aplicaciones es necesario estudiar sus componentes, como las proteínas y el almidón. Por lo tanto, el objetivo de este estudio fue extraer y caracterizar el almidón contenido en las semillas de huauzontle mediante técnicas químicas y físicas. El análisis de los resultados mostró 50 % de rendimiento de extracción, 72.5 % de pureza de almidón, 5.32 % de humedad, 1.09 % de cenizas, 0.083 % de grasa, 11.4 % de nitrógeno total y 4.13% de fibra cruda. El contenido de amilosa fue 10.5 %, lo cual sugiere que los geles del almidón de huauzontle podrían tener una tendencia baja a retrogradar. El hinchamiento y solubilidad fueron similares a los valores reportados para el maíz, menores que para papa y mayores que los almidones de quinua. La temperatura máxima de gelatinización fue 68 °C. Las pastas con 4 y 8 % (p/v) de almidón exhibieron un comportamiento semisólido atribuible a la gelificación de la amilosa con claras diferencias en los valores de módulos dinámicos y dependencia con frecuencia angular cuando aumentó la concentración de almidón. Hubo comportamientos pseudoplásticos no Newtonianos con cierto grado de tixotropía que desaparecieron tras continuo cizallamiento. Los datos de difracción laser y observaciones MEB revelaron una asociación de gránulos de almidón muy pequeños (0.5-1.0 μm) en partículas más grandes.

Palabras clave: Chenopodium berlandieri, reología, almidón, viscoelasticidad, estructura microscópica.

INTRODUCTION

The pseudocereal huauzontle (Chenopodium berlandieri spp. nuttalliae) is commercialized as a broccoli-like vegetable in several states of central México, and represents an alternative for profitable purposes (Partap et al., 1998). The main producing zones of huauzontle are in the state of Puebla, with approximately 3100 t year−1 (SAGARPA, 2013). The edible part of the plant is the inflourescence but its seeds, which are used only for seedling process, present functional properties for the food industry due to the presence of antioxidants, proteins and starch, as it is the case of other pseudocereals (Aghamirzaei et al., 2013; Chaires et al., 2013). Therefore, in order to diversify the food applications of all of the huauzontle plant, it is necessary to characterize their components and to encourage their cultivation and use as an alternative to cereals. The fact that huauzontle starch can be extracted makes it available for food applications; however, its industrial potential remains untapped and it is important to understand the structural characteristics of starches in order to suggest further applications.

Starch is organized in discrete granules in most vegetable tissues, but it is particularly abundant in storage organs including roots/tubers, stems, seeds/ grains and fruits (Copeland et al., 2009). The complexity of starch biosynthesis produces variability in amylose and amylopectin molecules, which is reflected in the diversity of granule morphology. Variability in granule size and shape is associated with differences in functional properties such as gelatinization, retrogradation, solubility, swelling power, water-binding capacity, rheological behavior and pasting properties (Wang et al., 2010). For this reason, the tendency is to look for alternative sources to obtain starches exhibiting novel physicochemical and functional characteristics (Nwokocha and Williams, 2009). There are basic investigations on the properties of starch contained in pseudocereals plants like buckwheat (Fagopyrum esculentum) (Steadman et al., 2001), quinoa (Chenopodium quinoa) (Chauhan et al., 1992) and amaranth (Amaranthus spp.) (Calzetta et al., 2000), but none on the Mexican pseudocereal huauzontle. Thus, the objective of the present study was to evaluate swelling and solubility behavior, amylose content, gelatinization, morphology, particle size and rheological behavior of huauzontle seed starch.

MATERIALS AND METHODS

Starch extraction

The raw mature seeds were collected from huauzontle crops from Cholula, Puebla, Mexico. Cholula has a temperate climate with an average temperature between 18-20 °C, and the rainy season from May to October provides 800 to 900 mm of rainfall per year. The soils of the region are predominantly Feozem type (INEGI, 2014).

The seeds were cleaned manually to remove foreign objects. Starch was isolated according to Lindeboom et al. (2005) and air-dried at 38 °C in a convection oven (Thermal Control, Genlab, Widnes, England).

Chemical analysis

The starch moisture, ash, total nitrogen (protein content calculated as nitrogen X 6.25), crude fat, crude fiber and carbohydrates were determined according to AOAC (1990) methods. Reducing sugars were determined by the dinitrosalicylic acid (DNS) method (Bernfeld, 1951).

Starch and amylose

Starch was determined by an enzymatic method using a Starch Assay Kit (Sigma-Aldrich, USA) based on the hydrolysis of starch to glucose catalyzed by α-tamylase and amyloglucosidase (Sigma-Aldrich, 2014). Amylose content was analyzed using an Amylose/Amylopectin Assay Kit (Megazyme, Ireland) based on the concanavalin A method (Yun and Matheson, 1990).

Swelling power and solubility

Starch paste was prepared at 4 % (w/v) by using a thermostatic bath (Polystat mod. 12101-50, Cole Parmer, USA) with a gradual heating program (1.5 °C min-1) from 25 to 90 °C under constant stirring. The paste was kept at 90 °C for 10 min. Determinations were carried out as described by Leach et al. (1959).

Gelatinization and rheological behavior

The gelatinization properties of starch were determined using differential scanning micro-calorimetry (Micro-DSC 7-evo, Setaram Instruments, Caluire, France). Starch dispersions at 4 % (w/v) were placed in the sample cell. The samples were heated from 25 to 90 °C at a rate of 1.2 °C min−1. Once the samples reached 90 °C they were maintained 10 min and then cooled to 25 °C at rate of 1.2 °C min−1. Onset (Tonset) and peak (Tpeak) temperatures, and enthalpy of gelatinization (AH) were determined. The rheological properties were analyzed for 4 and 8 % (w/v) starch pastes. The starch dispersions were heated in sealed tubes immersed in a water bath maintained at 99 °C for 30 min. The samples were agitated 3 min until pasting occurred. The pastes were removed and left at 25 °C and 1 h later the rheological properties were evaluated. Rheological measurements were carried out in a rheometer (Ares® RFS III™, TA Instruments, USA) with serrated parallel plates geometry (25 mm in diameter and 1 mm gap). The storage modulus (G') and loss modulus (G") of the starch pastes were determined by small deformation oscillatory measurements in the zone of linear viscoelasticity, previously determined from strain sweep tests carried out at 25 °C and 6.28 rad s−1. The variation of shear stress with shear rate was examined at 25 °C within a 0-140 s−1 range. Two consecutive up and down shear rate loops, 6 min up and 6 min down, for each loop were carried out.

Particle size and distribution and starch morphology

Particle size and particle size distribution of the starch granules were measured by laser light scattering (Mastersizer 2000, Malvern Instruments®, UK) for 4 and 8 % (w/v) pastes. A polydisperse mode of analysis and a 300 mm lens were used. The starch was evenly dispersed in deionized water with magnetic agitation to attain an obscuration of 20-30 %. The particle size distribution was determined in triplicate, and the results were expressed as volume (%) occupied by starch granules (Tecante and Doublier, 1999). Granule micrographs were obtained with a JSM 35 Genie Scanning Electron Microscope (SEM). The starch was sprinkled onto a double-backed adhesive carbon tab stuck to a circular aluminum stub. The aluminum stub with the starch sample on it was placed in the vacuum chamber of a Polaron PS 3 sputter coater, after attaining a vacuum of 0.1-0.2 Torr and plasma current of 42 mA; the gold coating process was carried out for 140 s. The stub with gold-coated starch was then placed in the SEM chamber which was evacuated before the electron beam was turned on. A 10 kV/2.05 setting was used for the subsequent imaging on starch, and the aperture size was fixed at 3.

Statistical analysis

To verify the statistical significance between three measurements of each variable, means and standard deviation were determined (Fry, 1996).

RESULTS AND DISCUSSION

Chemical analysis and functional characteristics

Partial chemical composition and functional characteristics of starch are shown in Table 1. The starch yield of the huauzontle seeds (50 ±1.4 %) was close to Chenopodium quinoa (Chauhan et al., 1992), amaranth (Souci et al., 2000), and corn (Zea mays) (Ji et al., 2004); but lower than wheat (Triticum spp.) (Aguilar and Eckhoff, 2007) starches. Variability in yield values may have been affected by the structure of the source and the method used for extraction (Nwokocha and Williams, 2009). The moisture content (5.32±0.2 %) was low and within the acceptable range for marketing and storage (Wolfgang et al., 1999). Differences in starch moisture from several samples could be attributed to differences in drying and storage environment (Soni et al., 1993). The ash (1.09±0.1 %) and fat (0.083±0.2 %) content were slightly higher than quinoa and amaranth, but close to corn and wheat samples. The shelf life of flours depends largely on the fat content; thus, the lower the fat content the highest starch shelf life (Skrabanja et al., 2004).

Huauzontle seed starch had higher in protein content (11.4 ±0.4 %) than the values reported by Clerici et al. (2011) for Solanum lycocarpum (6.27 %) and Stevenson et al. (2006) 6.7 % for corn. Besides starch, protein content would be responsible for the textural characteristics of future huauzontle products, as was described for buckwheat and other grains (Skrabanja et al., 2004). Therefore, choosing the appropriate ratio between starch and protein content is important for designing and manufacturing products.

The presence of protein in huauzontle seed starch could be ascribed to non-separating protein from the matrix where the starch is embedded inside the grain (Ruales and Nair, 1994). By definition, starch granule-associated proteins are the proteins naturally positioned in and on starch granules. They are different from storage proteins and are bound tightly on the surface or as integrated constituents within the granule structure, or both (Baldwin, 2001). Some authors have tried to separate the soluble and insoluble fractions of protein from the starch-milk of amaranth and other sources. For example, Middlewood and Carson (2012) reported 32 % protein content from the starch-milk composition, and using microfiltration they obtained a starch-rich concentrate with low protein content.

Total carbohydrates, 82.1± 0.4 %, which include reducing sugars, 1.0±0.1 %, and crude fiber, 4.13 ± 0.1 %, were found in huauzontle seed starch. The isolated starch purity was 72.5 %, which is high as compared to 56-59 % of Pachyrhizus ahipa varieties and to 87 % of red sweet potato (Ipomoea batatas) (Osundahunsi et al., 2003; Torruco-Uco and Betancur-Ancona, 2007). The amylose composition was 10.5 %, which is close to amaranth species (Kong et al. 2009) and quinoa starch (Lorenz 1990), but amylose content of starches from rice (Oryza sativa) cultivars ranges from 18.1 to 31.6 % (Wang et al., 2010). The amylose/amylopectin ratio for huauzontle seed starch (10.5/89.5 ±0.29) was 0.117 and this starch could form gels with a low tendency to retrograde (Beynum and Roels, 1985). This result differs from corn starches (0.394) and red sweet potato (0.519) (Osundahunsi et al., 2003; Charles et al., 2005); besides, the amylose to amylopectin ratio of potatoes (Solanum tuberosum) starches ranges from 1:2.96 (Mayan Gold) to 1:2.44 (Brodick) (Alvani et al., 2001), which reflects the spread in amylose content (Yusuph et al., 2003). Variability between samples and species can be affected by botanical sources, climatic conditions and types of soil during cultivation, as well as by harvest time (Noda et al., 2004).

Swelling and solubility patterns provide information about the nature of the associative bonding within the starch granule. The ratio of amylose and amylopectin in the starch granule and the manner in which they are arranged inside affect swelling and solubility of the starch (Beleia et al., 1980). The solubility of starch is dominated by the amylose content and amylopectin mainly influences the starch swelling power (Tester and Morrison, 1990). Starches such as quinoa, amaranth and huauzontle have reduced proportions of amylose and show low solubility when heated in excess water (Ahamed et al., 1996). For sources such as potato, 100 % solubility (Pomeranz, 1991) is associated with the easy bonding of water molecules to the free hydroxyl groups of amylose and amylopectin by hydrogen bonds, which could increase the absorption capacity and solubility (Singh et al., 1994; Ahamed et al., 1996). According to Kong et al. (2009), there was no correlation between amylose content and swelling power, but the correlation was negative with solubility index, as compared to several amaranth genotypes with 4.7 to 12.5 % amylose. For huauzontle seed starch, the results of amylose content, swelling power and solubility agree with values for K350 and R159 (Amaranthus cruentus L. from US) samples reported by Kong et al. (2009). Huauzontle seed starch swelling values (23.3± 1.37 g g−1) are close to quinoa (Lindeboom et al., 2005) and corn (Sandhu and Singh, 2007), but different from potato starches (36.5-40.5 g g−1) (Singh et al., 2006). Low swelling power of starches as in huauzontle seed starch may be attributed to the presence of a large number of crystal regions formed through the association between long amylopectin chains (Jiang et al., 2012). In pearl millet (Pennisetum glaucum) starches, values obtained for huauzontle seed starch can be considered as highly restricted as swelling power was below 16 g g−1. Starches showing restricted swelling behavior are relatively stable against shearing action during cooking in water (Galvez and Resurreccion, 1992). Solubility of starch is an indicator of the degree of starch granules dispersion after cooking. The solubility could imply the amount of amylose leaching out from starch granule when swelling; therefore, the higher the solubility the higher will be the amylose leaching (Srichuwong et al., 2005).

Gelatinization properties

A typical DSC thermogram for a 4 % (w/v) dispersion of the huauzontle seed starch is shown in Figure 1. The DSC curve shows an endothermic peak which is attributed to the gelatinization process. The Tpeak for huauzontle seed starch was 68.4±0.57 °C. The Tonset was 63.2±0.64 °C. For other pseudocereals, quinoa starch gelatinizes at a relatively low temperature (54.2-61.9 °C), which is similar to the Tpeak of wheat and potato starch, but lower than for corn starch. Kong et al. (2009) found a wide range of variations in thermal parameters among 15 cultivars of amaranth: the highest Tpeak (77.8 °C) was for cultivar K350 and the lowest (68.8 °C) for cultivar NO1 (Amaranthus hypochondriacus). The difference in Tpeak among starches is attributed to the interplay of three factors: starch composition, molecular structure of the amylopectin and granule architecture.

The ΔH of huauzontle seed starch was 10.5 ± 0.54 J g−1. Quinoa starch has a AH of 7.3-10.5 J g−1(Inouchi et al., 1999), amaranth starch 15.0 to 18.4 J g−1(Kong et al, 2009), corn starch 17.2-20.5 J g−1, wheat starch 12.1 J g−1, rice starch 14.2-16.3 J g−1and potato starch 18.8 J g−1(Zobel, 1984). The AH gives an overall measure of crystallinity (quality and quantity), and is regarded as an indicator of the loss of molecular order of the double helices that form the amylopectin crystallites due to hydrogen bond breaking within the granule (Hoover and Vasanthan, 1994; McPherson and Jane, 1999). Amylopectin plays a major role in starch granule crystallinity, the presence of amylose lowers the melting point of crystalline region and the energy for starting gelatinization (Flipse et al., 1996).

Rheological properties

The storage modulus G' was significantly greater than the loss modulus G" (Figure 2), and both moduli exhibited some frequency dependence (Figure 3) indicating solid-like characteristics (Nwokocha et al., 2010; Mandala, 2012). The G' of starch pastes is affected by the rigidity of starch granules (Han et al., 2002); besides, G' is positively correlated with amylose content and molecular mass (Case et al., 1998). The lineal viscoelasticity zone at 4 % concentration was 0.1 to 3.0 % strain, while at 8 % it was 0.1 to 10.0 % (Figure 2).

Figure 3 shows the variation of storage modulus (G') and loss modulus (G") with angular frequency. G' was higher than G" over all the frequency range with the separation between them becoming narrower as angular frequency increased, which is a characteristic of solid-like behavior. There are similar results for other starches from Lablab purpureus (Nwokocha et al., 2010).

Figure 4 shows the flow behavior of 4 and 8 % (w/v) huauzontle seed starch pastes. The shear stress vs. shear rate curve shows the non-Newtonian shear-thinning character of the pastes (Nuñez-Santiago et al., 2004). There are similar shear-thinning characteristics for other polysaccharides (Nurul et al., 1999).

During the first up-down cycle, an hysteresis loop was observed; for a given shear rate, upward shear stresses were greater than downward shear stresses, indicating some degree of thixotropy. However, on a second up-down cycle the hysteresis loop practically disappeared and the thixotropic behavior was no longer present. This behavior, commonly observed in starch pastes, is attributed to orientation of starch granules along the flow field when pastes are continuously sheared, which leads to destruction of the original granule accommodation at the beginning of the first up and down shear rate cycle. An anti-thixotropic loop was observed for chemically modified waxy corn starch, but it disappeared when pastes were continuously sheared (Tecante and Doublier, 1999). According to Izidoro et al. (2007), the knowledge of rheological parameters is important in industrial applications not only to determine the energy consumption to pump a fluid with greater viscosity, but also to solve problems with air incorporation, which causes difficulties in pump operation and with undesired reactions such as oxidation and contamination. Examination of the rheological properties of starches is an important step in the characterization and understanding of their functional properties.

Particle size and scanning electron microscopy

The particle size distribution was monomodal for 4 and 8 % (w/v) pastes, and bimodal for raw starch (Figure 5, left). The median diameter for raw starch, 4 and 8 % starch pastes was 19.1, 14.1 and 15.5 μm, respectively. Microscopic observations (Figure 5, A-B right) of the starch samples confirmed association as clusters such as that reported by Varriano-Marston and DeFransisco (1984), who observed aggregates of 18-20 μm in quinoa starch. Aggregates typical of most starches consist of small granules, such as quinoa, amaranth and cow cockle (Saponaria vaccaria) (Lorenz, 1990). Clusters have different size and morphology according to the processing, drying or milling; thus, Zhao and Whistler (1994) found spherical aggregates produced by spray drying of the sample. In the present study, air drying and an analytical mill of blades were used, resulting in block aggregates. Figure 5 (C-D right) shows the morphology of the huauzontle seed starch granules with a 0.5-1.0 μm size, and irregular and polygonal morphology typical of most small granule starches (Jane et al., 1994). The morphology and size observed were similar to those of quinoa and amaranth cultivars with diameters from 1.05 μm to 1.32 μm (Chauhan et al., 1992; Kong et al., 2009). In the present study, the granule surfaces were smooth and without pores, although the presence of broken and truncated granules is not considered in the quality standard of starches (Sriroth et al., 2000). The morphology of starch granules depends on the biochemistry of the chloroplasts or amyloplasts, as well as plant physiology (Singh et al., 2003). Moreover, several factors can affect the granules' properties, including environmental factors such as temperature, storage and cultural practices, thereby influencing the physicochemical and thermal properties of starch granules (Kaur et al., 2009).

CONCLUSIONS

Starch was extracted from huauzontle seeds with adequate yield and acceptable purity. The amylose content suggests that huauzontle starch gels could have a low tendency to retrograde. Pastes exhibited solid-like behavior due mainly to amylose gelation, but amylopectin-rich ghost remnants could act as suspended particle reinforcing the solid-like behavior of gels formed in the continuous phase, with clear differences in dynamic moduli values and dependence with angular frequency when starch concentration was increased. There was non-Newtonian shear-thinning behavior with some degree of thixotropy, as well as an association of very small starch granules into larger particles. These results are the first contribution to describing starch from huauzontle seeds.

ACKNOWLEDGEMENTS

The authors appreciate the financial support from the Consejo Nacional de Ciencia y Tecnología (CONACYT) through grant 101498.

LITERATURE CITED

Aghamirzaei, M., A. Heydari-Dalfard, F. Karami, and M. Fathi. 2013. Pseudo-cereals as a functional ingredient: effects on bread nutritional and physiological properties-Review. Int. J. Agric. Crop Sci. 5: 1574-1580. [ Links ]

Aguilar, Z. E., y S. R. Eckhoff. 2007. Proceso de molienda húmeda a nivel laboratorio de 100 g de maíz amarillo dentado. Rev. Ciencia Tecnol. 13: 80-81. [ Links ]

Ahamed, N. T., R. S. Singhal, P. R. Kulkarni, and M. Pal. 1996. Physicochemical and functional properties of Chenopodium quinoa starch. Carbohydr. Polym. 31: 99-103. [ Links ]

Alvani, K., X. Qi, R. Tester, and C. Snape. 2011. Physico-chemical properties of potato starches. Food Chem. 125: 958-965. [ Links ]

Araujo-Farroa, P. C., G. Podadera, J. P. J. A. Sobral, and F. C. Menegalli. 2010. Development of films based on quinoa (Chenopodium quinoa, Willdenow) Starch. Carbohydr. Polym. 81: 839-848. [ Links ]

AOAC. 1990. Official Methods of Analysis (15th ed.). Arlington, VA: AOAC International. 765 p. [ Links ]

Baldwin, P. M. 2001. Starch granule-associated proteins and polypeptides: A review. Starch/Starke 53: 475-503. [ Links ]

Beleia, A., E. Varriano-Marston, and R. C. Hoseney. 1980. Characterization of starch from pearl millets. Cereal Chem. 54: 1096-1107. [ Links ]

Bernfeld, P. 1951. Enzymes of starch degradation and synthesis. Adv. Enzymol. 12: 379-428. [ Links ]

Beynum, G. M. A., and J. A. Roels. 1985. Starch Conversion Technology. New York, USA. Marcel-Dekker. 980 p. [ Links ]

Blaszczak, W., S. Valverde, J. Fornal, R. Amarowicz, G. Lewandowicz, and K. Borkowski. 2003. Changes in the microstructure of wheat, corn and potato starch granules during extraction of non-starch compounds with sodium dodecyl sulfate and mercaptoethanol. Carbohydr. Polym. 53: 63-73. [ Links ]

Calzetta-Resio, T. N., M. P. Tolaba, and C. Suarez. 2000. Some physical and thermal characteristics of amaranth starch. Food Sci. Technol. Int. 6: 371-378. [ Links ]

Case, S. E., T. Capitani, J. K. Whaley, and Y. C. Shi. 1998. Physical properties and gelation behavior of a low-amylopectin maize starch and other high-amylose maize starches. J. Cereal Sci. 27: 301-314. [ Links ]

Chaires, L., M. Pérez, H. A. Jiménez, A. I. Cantor, and F. Cruz. 2013. Total phenolic content and antioxidant capacity of germinated, popped and cooked Huauzontle (Chenopodium berlandieri spp. nuttalliae) seeds. Cereal Chem. 90: 263-268. [ Links ]

Charles, L. A., H. Y. Chang, C. W. Ko, K. Shiroth, and C. T. Huang. 2005. Influence of amylopectin structure and amylose content on the gelling properties of five cultivars of cassava starches. J. Agric. Food Chem. 53: 2717-2725. [ Links ]

Chauhan, G. S., A. A. M. Eskin, and R. Tkachuk. 1992. Nutrients and antinutrients in quinoa seed. Cereal Chem. 69: 85-88. [ Links ]

Clerici, M., C. Kallmann, F. Gaspi, M. Morgano, F. Martinez-Bustos, and Y. Chang. 2011. Physical, chemical and technological characteristics of Solanum lycocarpum A. St.-Hill (Solanaceae) fruit flour and starch. Food Res. Int. 44: 2143-2150. [ Links ]

Copeland, L., J. Blazek, H. Salman, and M. C. Tang. 2009. Form and function of starch granules. Food Hydrocolloid, 23: 1527-1534. [ Links ]

FAO. Food and Agricultural Organization. 1998. Carbohydrates in human nutrition. Food and Nutrition Papers, Rome, Chap. 1. 129 p. [ Links ]

Flipse, E., C. J. Keetels, E. Jacobson, and R. G. F. Visser. 1996. The dosage effect of the wildtype GBSS allele is linear for GBSS activity, but not for amylose content: absence of amylose has a distinct influence on the physico-chemical properties of starch. Theor. Appl. Genet. 92: 121-125. [ Links ]

Fry, J. 1996. Biological Data Analysis. A Practical Approach. OIRC Press. USA. 418 p. [ Links ]

Galvez, F. C. F., and A. V. A. Resurreccion. 1992. Reliability of the focus group technique in determining the quality characteristics of navy bean noodles. J. Sensory Study. 7: 315. [ Links ]

Gomes, A., P. Da Silva, S. Soares, C. Da Silva, M. Galláo, R. Germani, and R. Nágila. 2009. Isolation and physico-chemical and rheological characterisation of the Brazilian jalap starch (Operculina tuberosa Meisn.). Carbohydr. Polym. 77: 885-890. [ Links ]

Han, X. Z., O. H. Campanella, H. Guan, P. L. Keeling, and B. Hamaker. 2002. Influence of maize starch granule-associated protein on the rheological properties of starch pastes. Part I. Large deformation measurements of paste properties. Carbohydr. Polym. 49: 315-321. [ Links ]

Hoover, R., and T. Vasanthan. 1994. Effect of heat-moisture treatment on the structure and physicochemical properties of cereal, legume and tuber starches. Carbohydr. Res. 252: 33-53. [ Links ]

INEGI. Instituto Nacional de Estadística y Geografía. Septiembre del 2014. www.inegi.org.mx.

Inouchi, N., K. Nishi, S. Tanaka, M. Asai, Y. Kawase, Y. Hata, Y. Konishi, Y. Shaoxian, and H. Fuwa. 1999. Characterization of amaranth and quinoa starches. J. App. Glycosci. 46: 233-240. [ Links ]

Izidoro, D. R., B. D. Junior, C. W. Isidoro, M. R. Sierakowski, R. J. Sossela de Freitas, and A. De Paula. 2007. Granules Morphology and rheological behavior of green banana (Musa cavendishii) and corn (Zea mays) starch gels. Cien. Agrotec. Lavras. 31: 1443-1448. [ Links ]

Jane, L., T. Kasemsuwan, S. Leas, H. Zobel, and J. F. Robyt. 1994. Anthology of starch granule morphology by scanning electron microscopy. Starch/Starke. 46: 121-129. [ Links ]

Jiang, Q., W. Gao, X. Li, Y. Xia, H. Wang, S. Wu, L. Huang, C. Liu, and P. Xiao. 2012. Characterizations of starches isolated from five different Dioscorea L. species. Food Hydrocolloids 29: 35-41. [ Links ]

Ji, Y., K. Seetharaman, and P. J. White. 2004. Optimizing a small-scale corn-starch extraction method for use in the laboratory. Cereal Chem. 81: 55-58. [ Links ]

Kaur, A., N. Singh, R. Ezekiel, and N. S. Sodhi. Properties of starches separated from potatoes stored under different conditions. Food Chem. 114: 1396-1404. [ Links ]

Kong, X., J. Bao, and H. Corke. 2009. Physical properties of Amaranthus starch. Food Chem. 113: 371-376. [ Links ]

Leach, H. W., L. D. McCowen, and T. J. Schoch. 1959. Swelling power and solubility of granular starches. Cereal Chem. 36: 534-544. [ Links ]

Lindeboom, N., P. R. Chang, K. C. Falk, and R. T. Tyler. 2005. Characteristics of starch from eight quinoa lines. Cereal Chem. 82: 216-222. [ Links ]

Lorenz, K. 1990. Quinoa (Chenopodium quinoa) starch: physico-chemical properties and functional characteristics. Starch/ Starke 42: 81-86. [ Links ]

Mandala, I. G. 2012. Viscoelastic properties of starch and non-starch thickeners in simple mixtures or model food. In: de Vicente, J. (ed). Viscoelasticity: From Theory to Biological Applications. InTech. England. pp: 217-236. [ Links ]

McPherson, A. E., and J. Jane. 1999. Comparison of waxy potato with other root and tuber starches. Carbohydr. Polym. 40: 57-70. [ Links ]

Middlewood, P. G., J. K. Carson. 2012. Extraction of amaranth starch from an aqueous medium using microfiltration: Membrane characterisation. J. Membr. Sci. 405-406: 284-290. [ Links ]

Noda, T., S. Tsuda, M. Mori, S. Takigawa, C. Matsuura-Endo, and K. Saito. 2004. The effect of harvest dates on the starch properties of various potato cultivars. Food Chem. 86: 119-125. [ Links ]

Nuñez-Santiago, M., L. Bello-Pérez, and A. Tecante. 2004. Swelling-solubility characteristics, granule size distribution and rheological behavior of banana (Musa paradisiaca) starch. Carbohydr. Polym. 56: 65-75. [ Links ]

Nurul, I. M., B. M. N. Mohd-Azemi, and D. M. A. Manan. 1999. Rheological behavior of sago (Metroxylon sagu) starch paste. Food Chem. 64: 501-505. [ Links ]

Nwokocha, L., and P. Williams. 2009. Some properties of white and yellow plantain (Musa paradisiaca, Normalis) starches. Carbohydrate Polym. 76: 133-138. [ Links ]

Nwokocha, L., K. Soetan, and P. Williams. 2010. A study of the properties of starch isolated from three varieties of Lablab purpureus seeds. Carbohydrate Polym. 79: 685-693. [ Links ]

Osundahunsi, F. O., N. T. Fagbemi, E. Kesselman, and E. Simón. 2003. Comparison of the physicochemical properties and pasting characteristics of flour and starch from red and white sweet potato. J. Agric. Food Chem. 51: 2232-2236. [ Links ]

Partap, T., B. D. Joshi, and N. W. Galwey. 1998. Chenopods. Chenopodium spp. Promoting the conservation and use of underutilized and neglected crops. 22. Institute of Plant Genetics and Crop Plant Research, Gatersleben/International Plant Genetic Resources Institute, Rome, Italy. 67 p. [ Links ]

Pomeranz, Y. 1991. Functional Properties of Food Components. 2a ed. Academic Press. USA. pp: 24-78. [ Links ]

Ruales, J., and B. M. Nair. 1994. Effect of processing on in vitro digestibility of protein and starch in quinoa seeds. Int. J. Food Sci. Technol. 29:449-456. [ Links ]

SAGARPA. Secretaria de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación. www.siap.gob.mx/aagricola_siap/icultivo/index.jsp. (Consulta: diciembre 2013). [ Links ]

Sandhu, K.S.,and N. Singh.2007.Someproperties ofcornstarches II: Physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem. 101: 1499-1507. [ Links ]

Sigma-Aldrich. 2014. http://www.sigmaaldrich.com/content/dam/sigma-aldrich/docs/Sigma/Bulletin/sa20bul.pdf. (Consulta: marzo 2014).

Singh, J., O. McCarthy, and H. Singh. 2006. Physico-chemical and morphological characteristics of New Zealand Taewa (Maori potato) starches. Carbohydr. Polym. 64: 569-581. [ Links ]

Singh, Y. C., P. A. Seib, and J. E. Bernardin. 1994. Effects of temperature during grainfilling on starches from six wheat cultivars. Cereal Chem. 71: 369-383. [ Links ]

Singh, N., J. Singh, L. Kaur, N. S. Sodhi, and B. S. GILL. 2003. Review: morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 81: 219-231. [ Links ]

Skrabanja, V., I. Kreft, T. Golob, M. Modic, S. Ikeda, K. Ikeda, S. Kreft, G. Bonafaccia, M. Knapp, and K. Kosmelj. 2004. Nutrient content in buckwheat milling fractions. Cereal Chem. 81: 172-176. [ Links ]

Soni, P. L., H. Sharma, D. Dun, and M. M. Gharia. 1993. Physicochemical properties of Quercus leucotrichophora (Oak) starch. Starch/Starke. 45: 127-130. [ Links ]

Souci, S. W., W. Fachmann, and H. Kraut. 2000. Food Composition and Nutrition Tables. Stuttgart: Wissenschaft Verlags. 1300 p. [ Links ]

Srichuwong, S., C. Suharti, T. Mishima, M. Isono, and M. Hisamatsu. 2005. Starches from different botanical sources: Contribution of starch structure to swelling and pasting properties. Carbohydr. Polym. 62: 25-34. [ Links ]

Sriroth, K., K. Piyachomkwan, S. Wanlapatit, and C. G. Oates. 2000. Cassava starch technology: the Thai experience. Starch/Starke. 52: 439-449. [ Links ]

Steadman, K. J., M. S. Burgoon, B. A. Lewis, S. E. Edwardson, and R. L. Obendorf. 2001. Buckwheat seed milling fractions: description, macronutrient composition and dietary fibre. J. Cereal Sci. 33: 271-278. [ Links ]

Stevenson, D. G., J. Jane, and G. E. Inglett. 2006. Physicochemical properties of pin oak (Quercus palustris Muenchh.) acorn starch. Starch/Starke. 58: 553-560. [ Links ]

Tecante, A., and J. L. Doublier. 1999. Steady flow and viscoelastic behavior of crosslinked waxy corn starch-k-carrageenan pastes and gels. Carbohydr. Polym. 40: 221-231. [ Links ]

Tester, R. F., and W. R. Morrison. 1990. Swelling and gelatinization of cereal starches. Effect of amylopectin, amylose and lipid. Cereal Chem. 67: 551-557. [ Links ]

Torruco-Uco, J., and D. Betancur-Ancona. 2007. Physicochemical and functional properties of makal (Xanthosoma yucatenensis) starch. Food Chem. 101: 1319-1326. [ Links ]

Varriano-Marston, E., and A. DeFrancisco. 1984. Ultrastructure of quinoa fruit (Chenopodium quinoa Willd.). Food Microstruct. 3: 165-173. [ Links ]

Wang, L., B. J. Xie, J. Shi, S. Xue, Q. C. Deng, and Y. Wei. 2010. Physicochemical properties and structure of starches from Chinese rice cultivars. Food Hydrocolloid. 24: 208-216. [ Links ]

Wolfgang, B., W. Detmold, and G. Hans-Peter. 1999. Potato starch technology. Starch/Starke 51: 235-242. [ Links ]

Yun, S. H., and N. K. Matheson. 1990. Estimation of amylose content of starches after precipitation of amylopectin by concavalin A. Starch/Starke 42: 302-305. [ Links ]

Yusuph, M., R. F. Tester, R. Ansell, and C. E. Snape. 2003. Composition and properties of starches extracted from tubers of different potato varieties grown under the same environmental conditions. Food Chem. 82: 283-289. [ Links ]

Zhao, J., and R. L. Whistler. 1994. Spherical aggregates of starch granules as flavor carriers. Food Technol. 48: 104-105. [ Links ]

Zobel, H. F. 1984. Starch gelatinization and mechanical properties. In: Whistler, R. L., J. N. BeMiller, and E. F. Paschall (eds). Starch Chemistry and Technology. Academic Press, London, UK. 291 p. [ Links ]