Introduction

The genus Carpinus, from Betulaceae, comprises approximately 35 woody species around the world. It is widely found in Europe, eastern Asia, northern and Central America and China (Alden, 1997). In Iran, hornbeam (Carpinus betulus) covers about 33% of commercial volume of Hyrcaniyan forest and is a native, diffuse-porous hardwood species (Abdi et al., 2009). It is classified as a medium density hardwood, high in volumetric shrinkage and low in cleavage strength. Hornbeam, with its superior technological properties and high usage potential, is an important species in the lumber industry. Mostly, it is used for tool handles, levers, fuel wood, furniture and paper-making. Hornbeam has the maximum fiber length among Iranian hardwood species (Kiaei, 2012).

Surface roughness strongly and directly affects the usages of wood products. The surface roughness is vital in production processes related to adhesive bonding and gluing of wood elements and final processing of finished products (Tan et al., 2012).

Roughness characterizes the fine irregularities on a machined surface of the wood. These irregularities can be determined by measuring the height, width and shape of the peaks and valleys produced by woodworking operations or by anatomical structural properties. The surface quality is a complex definition and it is characterized today by different parameters such as the more common Ra, Rz and Rmax parameters. Further details can be established using the Abbottcurve and its related parameters Rpk, Rk and Rvk (Fujiwara et al., 2003; Fujiwara et al., 2005).

The surface quality depends on wood properties and machining conditions. For the wood properties, the wood species, wood density, moisture content and the structural properties are more important. The structural properties are the annual ring width, latewood/earlywood ratio, specific number and distribution of inside diameter of tracheids and vessels (Theoma et al., 2015; Gurau, 2014).

The machining process has also a significant influence on the surface roughness. The most effective factors are the cutting velocity and the dullness of knives, the knife cutting angle to the grains and the vibration amplitude of machine table and workpiece (Kilic et al., 2006; Gurau, 2004; Gurau et al., 2005).

This study aimed to examine the surface roughness of hornbeam wood taken from various altitudes to investigate the relationship between wood density and surface roughness parameters.

Materials and Methods

Six hornbeam trees with no obvious defects were selected from Mazandaran province, North of Iran. The trees were taken at three different elevations, namely 400 m above sea level (low elevation), 800 m (medium elevation) and 1200 m (high elevation). In January 2014, all six trees (two trees at each elevation) were randomly cut and transferred to the laboratory. All trees were at the same age range (45-50 years old), close range of height (18 m - 20 m) and same class diameter at breast height (30 cm - 35 cm). The annual temperature and annual rainfall in all of altitude classes were varied between 8 ºC - 14 ºC and 1300 mm/year - 1350 mm/year, respectively.

The boards were taken from mature wood (near to bark). The age demarcation point between juvenile and mature wood was estimated at round 25 years (Clark and Saucier, 1989). The boards was first air dried to 30% - 35% moisture content before drying in a laboratory type kiln to 12% of target moisture content. Dried board was cut to specimens with dimensions of 300 mm × 300 mm × 30 mm (radial, tangential, transverse) with tangential orientations for the surface roughness measurements. Surface of test pieces were sanded with sandpaper P80. Totally, 21 specimens (seven specimens × three altitudes) were selected to examine roughness parameters.

Measurements of surface roughness were done with a Contact stylus profilmeter PGK (Mehr Company, Germany) according to ISO-4287 (International Organization for Standardization [ISO], 1998b) and IS0-13565-2 (ISO, 1998a). The measured parameters were: average roughness (Ra), mean peak-to-valley height (Rz), root-mean square deviation of the profile (Rq), core roughness depth (Rk), reduced peak height (Rpk) and reduced valley depth (Rvk). The Ra, Rz and Rq are the most commonly used parameters in stylus method. In addition to these two parameters, Rk family parameters were also used to achieve more detailed information about the surfaces of machined specimens. The Ra, Rz and Rq parameters are discussed in the previous studies (Hiziroglu, 1996; Mummery, 1993). However, description of Rk, Rvk, and Rpk are illustrated in Figure 2 (Kilic et al., 2006; Mummery, 1993; Tan et al., 2012).

To determine wood oven-dried density (WD), a total of 60 specimens were selected (at breast height and specimens of mature wood), 20 from each different altitude. The measurement was based on ISO 3131 (ISO, 1975) standard. The wood density was measured based on the air-dry weight on the corresponding volumes. The air-dry volumes were calculated according the displacement method.

Statistical analyses

Duncan’s post hoc test (Duncan multiple range test) at the probability level of 95% (p > 0.05) was used to detect differences between the variables at different altitudes. The skewness and Shapiro-Wilk tests were performed for normality of collective data. Pearson’s correlation coefficients between altitude-roughness features were also determined to show their relationships. Linear regression equations were formulated to predict the relationship between surface roughness and wood density.

Results

The results of analysis of variance (ANOVA) of roughness parameters are shown in Table 1. The results of the measurements of the roughness parameters are shown in Table 2. The values in the Table 2 are average values of the surface roughness parameters and their standard deviation measured for hornbeam wood in three different altitude classes. Several measurements were done at different points of the wood surface and averaged.

Table 1 ANOVA results of roughness parameter and WD in three different altitudes.

| Properties | Sum of squares | df | Mean square | F | Sig |

|---|---|---|---|---|---|

| WD | 0.030 | 2 | 0.015 | 23.405 | 0.001 |

| Ra | 0.809 | 2 | 0.405 | 0.593 | 0.563 |

| Rz | 2.532 | 2 | 1.266 | 0.087 | 0.977 |

| Rq | 2.622 | 2 | 1.311 | 1.878 | 0.182 |

| Rk | 26.264 | 2 | 13.132 | 0.865 | 0.438 |

| Rpk | 9.420 | 2 | 4.710 | 1.669 | 0.216 |

| Rvk | 98.423 | 2 | 49.211 | 4.008 | 0.036 |

Wood density (WD); average roughness (Ra), mean peak-to-valley height (Rz), root-mean square deviation of the profile (Rq), core roughness depth (Rk), reduced peak height (Rpk), and reduced valley depth (Rvk).

Table 2 The mean and standard deviation of surface roughness parameters in three different altitude classes for hornbeam wood.

| Altitude classes (m) | Features | |||

|---|---|---|---|---|

| Average | 1200 | 800 | 400 | |

| 676 | 681 (18) b | 628 (30) a | 721 (26) c | WD (kg/m3 ) |

| 4.896 | 4.906(0.903) | 4.651 (0.971) | 5.132 (0.536) | Ra (µm) |

| 27.431 | 26.940(3.663) | 27.673 (4.542) | 27.680 (3.138) | Rz (µm) |

| 6.572 | 6.368 (0.940) | 6.279 (0.866) | 7.069 (0.677) | Rq (µm) |

| 13.608 | 14.380 (4.426) | 14.417 (3.041) | 12.026 (4.087) | Rk (µm) |

| 6.233 | 5.802 (1.793) | 5.718 (1.826) | 7.179 (1.382) | Rpk (µm) |

| 10.779 | 9.225 (2.899)a | 9.271 (1.902)a | 13.840 (4.980) b | Rvk (µm) |

The ANOVA results indicated that significant differences among all types of altitude indices were found for WD. The highest and lowest WD found in low and intermediate altitudes.

The results showed that the altitude index had no significant difference by the Ra parameter (p > 0.05). The highest and lowest means of Ra were found in low (400 m) and intermediate altitudes (800 m), respectively. At the same sanding conditions, intermediate altitude had smoother surface roughness than others. There was a weak positive relationship between Ra and WD (R2 = 0.140) in hornbeam wood (Fig. 1).

The results showed no significant difference between the altitude index and the Rq parameter at a 95% confidence level. The highest and lowest means for Rq were found in low (400 m) and intermediate altitude (800 m), respectively. At the same sanding conditions, intermediate altitude had smoother surface roughness than other altitudes. A weak positive relationship between Rq parameter and WD (R2 = 0.199) in hornbeam wood was determined (Fig. 1).

Related to Rz parameter, no significant difference was observed by the altitude index (P > 0.05). The Rz value was decreased by increasing the altitude indices. At the same treatment conditions, the specimens in high altitude were smoother than others. There was a weakly positive relationship between Rz parameter and WD (R2 = 0.038) in hornbeam wood (Fig. 2).

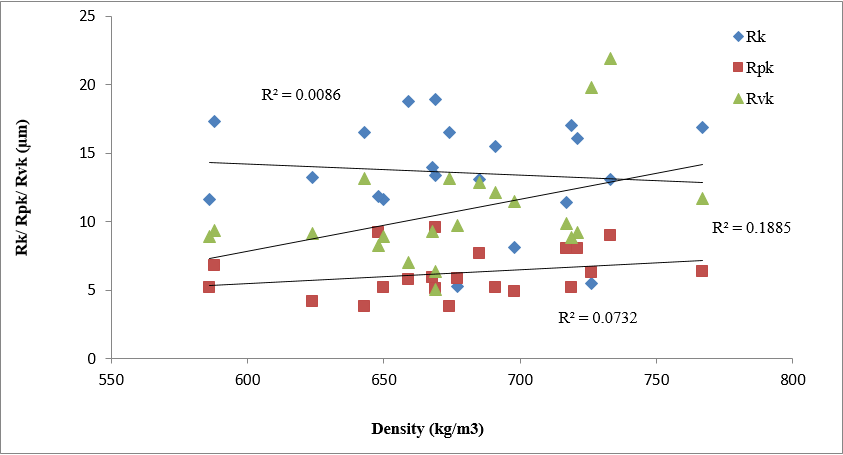

Concerning to Rk parameter, there were no significant differences between them on different levels of altitudes at 95% confidence level. At the same sanding conditions, low altitude had smoother surface roughness than other altitudes. There was a weak and negative relationship between Rk parameter and WD (R2 = -0.009) in hornbeam wood (Fig. 3).

The statistical analysis revealed no significant difference on the Rpk parameter at different levels of altitudes (p > 0.05). At the same sanding conditions, intermediate altitude had smoother surface roughness than other altitudes. There was a weak (positive) relationship between Rpk parameter and WD (R2 = 0.073) in hornbeam wood (Fig. 3).

The ANOVA results indicated that significant differences were found among all classes of altitude indices for Rvk at a 95% confidence level. The Duncan's mean separation test showed that a significant difference in the Rvk between low and high and between low and intermediate altitudes. Rvk value was decreased by increasing the altitude indices. At the same sanding conditions, high altitude had smoother surface roughness than other altitudes. There was weakly (positive) relationship between Rvk parameter and WD (R2 = 0.189) for hornbeam wood (Fig. 3).

Discussion

Some of researchers have stated that the surface roughness improved (low surface roughness) with increasing WD value (Lavery et al., 1995; Theoma et al., 2015). This statement is in disagreement with our results. There was no relationship between WD and surface roughness according to the linear regression coefficients in this study. Overall, the WD of hornbeam trees growing in low altitude (721 kg/m3) is higher than other altitudes (628 kg/m3 in intermediate altitude and 681 kg/m3 in high altitude) and it has a higher surface roughness parameter (rougher surface) than other altitude.

The mean Ra parameter of hornbeam wood growing in three different altitudes was 4.896 µm. This value is higher than five Turkish species (beech, oak, walnut, Aleppo pine, white fir) and Albanian beech wood (Table 3). The mean Ra parameter for mentioned species was respectively determined 2.89 µm, 4.62 µm, 3.97 µm, 4.25 µm, 3.32 µm and 4.63 µm (Thoma et al., 2015; Kilic et al., 2006). Thoma et al. (2015) founded that beech species has a smoother surface roughness than oak. The same can be said for the white fir, which has a smoother surface roughness than the Aleppo pine.

Table 3 Roughness parameters of various hardwood and softwood species.

| Species | Hornbeam | beech | oak | walnut | Aleppo pine | White fir | beech |

| Ra (µm) | 4.896 | 2.89 | 4.62 | 3.97 | 4.25 | 3.32 | 4.63 |

| Rz (µm) | 27.431 | 20.55 | 37.84 | 31.39 | 36.20 | 29.54 | - |

| Rq (µm) | 6.572 | 3.88 | 6.03 | 5.38 | 5.51 | 4.10 | - |

| Rk (µm) | 13.608 | - | - | - | - | - | 13.96 |

| Rvk (µm) | 6.233 | - | - | - | - | - | 4.69 |

| Rpk (µm) | 10.779 | - | - | - | - | - | 7.34 |

| Sample site | Iran | Turkey | Turkey | Turkey | Turkey | Turkey | Albania |

| Grit size | 80 | 120 | 120 | 120 | 120 | 120 | 80 |

| Load surface | Tangential | Tangential | Tangential | Tangential | Tangential | Tangential | Tangential |

| Classification | HW-DP | HW-DP | HW-RP | HW-SP | SW-AT | SW-GT | HW-DP |

| Reference | Present study | Thoma et al. (2015) | Thoma et al. (2015) | Thoma et al. (2015) | Thoma et al. (2015) | Thoma et al. (2015) | Kilic et al. (2006) |

HW: hardwood; SW: softwood; DP: diffuse porous; RP: ring porous; SP: semi-ring porous; AT: abrupt transition; GT: gradual transition.

These differences of roughness parameters among species can to relate to both factors include structural characteristics and grit size of tested species (Table 3). The softwood tested species are classified in gradual transition earlywood/latewood (white fir) and abrupt transition (Aleppo pine), while the hardwood tested species are classified according wood porosity: diffuse porous (beech, hornbeam), semi-ring porous (walnut) and ring porous (oak). Also, the surface of beech, oak, walnut, fir and pine species were sanded by 120 grit size, while we used from 80 grit size for hornbeam species in the present study. Therefore, grit size of sandpaper can to effect on the surface roughness. We know that the roughness of the specimens significantly improved with increasing grit size of sandpaper (Carrano et al., 2002; Fujiwara et al., 2005; Gurau et al., 2007; Hendarto et al., 2006; Taylor et al., 1999).

The mean Rz parameter of hornbeam wood growing in three different altitudes was 27.341 µm. This value is higher than beech species and is lower than the oak, walnut, Aleppo pine and white fir (Table 3). It can be said the hornbeam wood has a smoother Rz parameter than semi-ring porous (walnut), ring porous (oak) and softwood species (white fir and Aleppo pine).

The mean Rq parameter of hornbeam wood growing in three different altitudes was 6.572 µm. This value in hornbeam wood is higher than all of the mentioned species. In other hand, the beech wood has a smoother surface (according to the results of Rq) than other species (Table 3).

The average Rk of hornbeam wood growing in three different altitudes was 13.608 µm, which is in the expected range of beech species. According to results of Rpk and Rvk, the Iranian hornbeam wood (Rvk = 6.223 µm; Rpk = 10.779 µm) has a rougher surface than Albanian beech wood (Rvk = 4.69 µm; Rpk = 7.34 µm).

Conclusions

In this study, the surface roughness of hornbeam wood in three different altitudes were determined, and these results were compared other wood species in different regions in world. The following conclusions were obtained from this research:

1. There is a significant difference among all of altitude indexes in WD. The value of wood density was decreased by increasing altitude classes from 400 m to 1200 m. This difference can to attribute the variation of site (region), climate condition (rainfall, temperature, humidity) and region ecological condition.

2. Altitude index did not present a significant difference on Ra, Rz, Rq, Rpk and Rk parameters, while it had a significant effect on the Rvk parameter. There is not significant difference between intermediate altitude and high altitude is Rvk according to the results of Duncan's table.

3. Increasing the altitude classes from 400 m to 1200 m decreased the values of Ra, Rz, Rq, Rpk and Rvk surface roughness parameters by 4.40%, 2.67%, 9.92%, 19.18% and 33.34%, respectively; the Rk parameter increased by 19.57%. There was no relationship between WD and surface roughness parameters according to the linear regression models in this study.

4. Hornbeam wood growing at intermediate (800 m) and high altitude (1200 m) has smoother surface roughness than low altitude (400 m) for wood production. Beech and hornbeam species are classified in hardwood species (diffuse porous), but beech wood has a smoother surface roughness than the studied species.

nueva página del texto (beta)

nueva página del texto (beta)