Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Madera y bosques

versão On-line ISSN 2448-7597versão impressa ISSN 1405-0471

Madera bosques vol.21 no.spe Xalapa Dez. 2015

Scientific papers

Evaluation of chemical compositions, air-dry, preservation and workability of eight fastgrowing plantation species in Costa Rica

Evaluación de la composición química, secado al aire, preservación y trabajabilidad de ocho especies de rápido crecimiento en plantación de Costa Rica

Róger Moya1,*, Cynthia Salas1, Alexander Berrocal1 y Juan Carlos Valverde1

1 Escuela de Ingeniería Forestal, Instituto Tecnológico de Costa Rica, Cartago, Costa Rica. * Corresponding author: rmoya@itcr.ac.cr

Manuscrito recibido el 12 de enero de 2014.

Aceptado el 14 de septiembre de 2015.

Abstract

Costa Rica has successfully planted various forestry species for wood production. However, the use of their wood is limited, due to poor knowledge about their chemical properties, air-dry, preserved and workability performance. The present study details information of these properties for the species: Alnus acuminata (Aa), Acacia mangium (Am), Bombacopsis quinata (Bq), Cupressus lusitanica (Cl), Swietenia macrophylla (Sm), Terminalia amazonia (Ta), Terminalia oblonga (To) and Vochysia guatemalensis (Vg). Among the results obtained, it was found that the wood of these species is in general slightly acidic, except Bq, which presented tendency to be basic. Different species show considerable variability in the content of holocellulose, lignin and extractable micronutrients. Regarding micronutrients, and in relation to other species it was found a high percentage in Vg. The use of boron as a preservative, may be applied in the 8 plantation species. The presence of heartwood in some species made it not possible to be preserved by the vacuum-pressure method, but the sapwood was possible to preserve in all species. The drying rate increased with increasing board thickness and drying time was different among species. The fastest drying rate was found in Ta and Am, followed by Sm, To, Aa and Cl with intermediate values and Vg with the slowest air-drying rate. Am, Bq, Cl, Sm and To present from excellent to good planing, sanding , drilling and molding, but Ta, Bq, Aa and Vg, especially Aa and Vg, in the workability operations were catalogued as poor or very poor quality.

Keywords: Central America, commercial wood, tropical species, wood variation.

Resumen

En Costa Rica se han plantado con éxito varias especies forestales para la producción de madera. No obstante, el uso de la madera es limitado debido al poco conocimiento acerca de sus propiedades químicas, secado al aire, preservado y trabajabilidad. En el presente estudio se detalla información de esas propiedades para las especies: Alnus acuminata (Aa), Acacia mangium (Am), Bombacopsis quinata (Bq), Cupressus lusitanica (Cl), Swietenia macrophylla (Sm), Terminalia amazonia (Ta), Terminalia oblonga (To) and Vochysia guatemalensis (Vg). Dentro de los resultados obtenidos, se encontró que la madera presenta un pH ligeramente ácido, a excepción de Bq, con tendencia a ser básica. Las diferentes especies muestran una considerable variabilidad en el contenido de holocelulosa, lignina, extraíbles y micronutrientes; con respecto a los micronutrientes, y en relación con las otras especies se encontró un alto porcentaje en Vg. El uso de boro como preservador, puede ser aplicado en las 8 especies de plantación. Las especies con presencia de duramen no fue posible preservarlas con el método vacío-presión; sin embargo, la albura sí es posible de preservar en todas las especies. El tiempo de secado incrementa con el incremento de espesor de la tabla y presenta variación entre especies. El menor tiempo de secado se encontró para Ta y Am, seguido por Sm, To, Aa y Cl, con valores intermedios y Vg con el secado al aire más lento. Am, Bq, Cl, Sm y To presentan de excelentes a buenas propiedades de cepillado, lijado, taladrado y moldurado, pero el resto de las especies (Ta, Bq, Aa and Vg), en especial para Aa y Vg, en las operaciones de trabajabilidad son catalogadas como de mala o muy pobre calidad.

Palabras clave: América central, madera comercial, especies tropicales, variación de propiedades.

Introduction

The environmental conditions in the tropical region, allows that countries like Costa Rica develop a variety of wood trees species (Petit and Montagnini, 2004). Some of these species have been successfully used in reforestation programs for commercial purposes (Nichols and Vanclay, 2012). It is estimated that by the year 2011 Costa Rica has successfully planted about 20 tree species including exotic species (Acacia mangium, Cupressus lusitanica, Gmelina arborea and Tectona grandis) and native species (Terminalia amazonia, Terminalia oblonga, Vochysia guatemalensis, Bombacopsis quinata, Swietenia macrophylla and Alnus acuminata). The exotic species are characterized by having high yield (m3/ha) and rotation periods of less than 30 years (Baraloto et al., 2010) either in pure plantation or mixed plantation (Petit and Montagnini 2004). Also, these species have been used in agroforestry, plantations for carbon sequestration, soil conservation and recovery, among others (González and Fisher 1998). However, the limiting factor found with the use and exploitation of many species, is the lack knowledge of their chemical properties, air-drying properties, preserveation treatmen response and workability performance of wood (Moya and Muñoz, 2010). Nevertheless, recently studies has been developed on the physical and mechanical properties (Moya and Muñoz 2010), their behavior in kiln dry (Moya et al., 2013) and energetic properties (Tenorio and Moya, 2013). Studies carried out by Butterfield et al. (1993), Gonzalez and Fisher (1998) and Moya et al. (2009) have evaluated some of these species in aspects of physical properties and not in industrial aspects.

The importance of knowing about aspects such as chemical properties, air-drying, preserved, durability and workability performance of the species, growing in conditions of fast growing plantations, is important because it determines the quality of wood and the potential uses and markets that they may provide. The fact that native species have different properties to the wood from the logs of trees growing in natural forests has been proved before (Butterfield et al., 1993). It is also important to know the characteristics and behavior of wood, because these should be criteria for acceptance to continue planting a particular species. Therefore, considering the growing demand for wood of new species and especially from forest plantations of fast growth condition and the need to know the properties of wood, it was carried out this study with theobjective of evaluating the chemical properties, air-drying, preservation, durability and workability performance of wood of Alnus acuminata, Acacia mangium, Bombacopsis quinata, Cupressus lusitanica, Swietenia macrophylla, Terminalia amazonia, Terminalia oblonga and Vochysia guatemalensis of fast growth plantations in Costa Rica.

Materials and methods

Site, plantation description, and tree sampling

Eight different pure plantations located in several parts of Costa Rica were studied. The initial planting density was 1 111 trees/ha (3 m x 3 m spacing). At the time of sampling, the average age was 9-18 years old and the density was at 495 trees/ha -575 trees/ha (Table 1). Nine trees per species were randomly selected for harvesting, including suppressed, intermediate, and dominant trees, in accordance with the methodology developed by Moya and Muñoz (2010). Selected trees, with straight trunks, normal branching, and no disease or pest symptoms were felled. Two stem sections from the base of the tree to 2.5 m high were obtained from each tree (with 1.25 m in length). Among these logs, a cross-sectional sample of 3.0 cm wide was taken at 1.3 m in height, the diameter at breast height (DBH). Afterwards, stem log with 2.5 m-length were cut from at DBH to commercial height (stem diameter of 13.0 cm over bark is considered the minimum diameter for these species in Costa Rica). Finally a log with 30 cm-length was cut after commercial height with a 10 cm in diameter in each sampled trees. The North-South direction was marked on each stem cross-section and logged for later identification in the laboratory.

Determination of chemical properties and extractives in different solvents

Ash, silice, lignin and holocellulose content, pH, and inorganic ash compo were determined. Ash content determination was done through the ASTM D-1102-84 standard (ASTM, 2012a); to quantify lignin the TAPPI T222 om-02 method was used (TAPPI, 2002), and for holocellulose determination was followed Erickson’s methods (1962). Twelve aqueous solutions of 1 g sawdust in 5 ml of water were used for measuring the pH of the tissues, using an Accumet AP61 pH meter. For inorganic ash compositions analysis, the methods of Sparks (1996) were used, and included determination of mass of nitrogen (N), phosphorus (P), calcium (Ca), magnesium (Mg), potassium (K) and sulfur (S), whose concentrations were reported as percentages, and iron (Fe), manganese (Mn), cupper (Cu), zinc (Zn) and boron (B), whose concentrations were reported as milligrams of inorganic element per gram of ash. From cross-section at DHB in each trees and species, were milled 30 g to a particle size of less than 0.6 mm and then screened through a 40- and a 60-mesh for wood chemical analysis. Particle screened from three trees was grouped, and then three groups from nine trees were obtained. Three samples from each group were used for ash, lignin and holocellulose content, ash analysis, pH measured and different extractives (three groups x three samples = nine total samples for each chemical parameters) Extractives content were determined in water (hot and cool condition) (ASTM, 2012b), in sodium hydroxide (NaOH) (ASTM, 2012c), in an ethanol-toluene solution (ASTM, 2012d) and in dichloromethane (CH2-Cl2) (ASTM, 2012e).

Air-drying properties

Each log (from logs with 2.5 m-length that were cut from at DBH to commercial height) was sawed and piled for drying in boards of different thickness (1.25 cm, 2.50 cm, 3.75 cm, 5.00 cm, 6.25 cm, and 7.50 cm) and a width of 7.5 cm, following a sawing patron used for small-diameter trees in Costa Rica (Moya et al., 2013). A total of 24 air-drying samples (four per each thickness board) per species were weighed every three days until reaching constant values. The drying rate was defined as the time needed to reach 20% of moisture content and was categorized as slow, moderate, and fast according to the Pan-American Committee of Testing Norms for tropical species (Keenan and Tejada, 1988).

Preservation

In the preservation performance two methods were evaluated: (1) dip-diffusion and (2) vacuum-pressure. In the dip-diffusion method, 24 samples from each species of 50 cm length with dimensions of 7.5 cm in width and thickness of 1.25 cm, 2.50 cm, 3.75 cm, 5.00 cm, 6.25 cm and 7.50 cm were obtained. These samples in green and freshly cut condition were immersed for one minute in a preservative solution of boric acid, sodium borate decahydrate dissolved in water with a concentration of 12%. Then the samples were covered with plastic to prevent the drying. The evaluation of the penetration and retention used the methodology proposed by Williams and Mauldin (1996), in which every four days three samples were taken which were selected and cut in half, to measure the penetration and retention of the preservative by the turmeric rhizome curcuma indicator. In vacuum–pressure preservation methods, a total of nine log samples per species, with 30 cm-length was cut after commercial height, were treated with CCA (chrome, cooper, and arsenic) preservatives at 2.8% vv/vv concentration. All samples were placed into an experimental preservation tank under a pressure of 690 kPa (approximately 100 psi). The preservation process consisted of 30 minutes of vacuum, 2 hours of pressure and 15 minutes of vacuum. A colorimetric evaluation was performed for identifying the areas conducting the preservatives in cross sections. The samples were weighed before and after the preservation process, for pressure preservation the absorption capacity was calculated as the absorption of preservatives (liters) by timber volume (m3), while preservative retention was determinate considering the absorption per species given by the difference in weight and concentration of preservative solution.

Workability

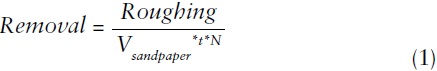

Boards of 2.5 cm thick were used, which were previously oven dried to a moisture content of 12% of the study developed by Moya et al. (2013). From the drying bath, 30 boards were selected considering three types of grain patterns (10 cross-sectional samples, 10 samples of radial cutting and 10 oblique cutting samples). Subsequently, a sample of each board was obtained for each type of workability test (three types of cutting x 10 samples = 30 samples). The tests performed were planing, mortising, shaping, boring, sanding, and turning. They were performed following the specifications in ASTM D-1666-93 (ASTM, 2012f), with amendments proposed to test effects of tropical timber" Workability Standards of the Cartagena Agreement" (PADT.RTF, 1976). Quality and classification criteria for each test are detailed in table 2. For the test of turning, mortising, shaping, boring , planing and sanding the type of quality and classification have been detailed in ASTM D-1666-93 standard (ASTM, 2012f ) and "Standards of the Cartagena Agreement" (PADT.RTF, 1976). Planing specimens were evaluated using two angles of blades (15° and 30°) in two feet rate (6 m/min and 30 m/min). In the sanding test, in the standard is not considered the aspect of temperature measurement and sawdust removal, but this measurements, were included using the criteria developed by Serrano (1983). The temperature was measured by a laser type temperature gauge (Raytec Brand, model Raynger ST) immediately after sanding. The temperature was measured at 3 different points. The removal in the sanding process was calculated using equation 1. In the boring test, the chip thickness calculation was included (Equation 2) and this test basically uses two types of drill bits used for wood and metal, both with two speeds. The classification for different workability performance are detailed in table 2. More information can be found in Serrano (1983).

Where:

Roughing: mm removed based on an average of 0.5 mm,

Vsandpaper: sanding speed m/min

t: duration of sanding

N: number of passes to achieve a roughing of approximately 0.5 mm

Where:

CT: chip thickness

D: Depth of hole in mm

T: drilling time in min

n: speed of test in min-1 (rpm)

N: number of propellers

Statistical analyses

Normality and the presence of anomalous data or outliers were examined for each variable. A general statistical overview was performed for the different variables. An analysis of variance (ANOVA) was used for evaluating differences between species in different wood properties evaluated. Where statistical differences occurred, the means were compared using Tukey’s test at 1.0% significance.

Results

Chemical properties

In table 3, shows the chemical composition of the 8 species tested. It is evident that: (I) the pH varied from 3.79 to 9.72, where Bq presented the pH significantly more basic (9.72), in contrast Ta obtained the more acidic pH (3.72) and Am and Vg were the only species that showed no difference in pH. (II) Holocellulose content (Table 3) varied from 69.04% to 52.54%, the Cl and Sm species showed holocellulose values significantly lower compared to the other 6 species, which showed no differences between them. (III) in the lignin content, four group are formed: one group consisting of Cl with the highest value, followed by two groups with an intermediate value of the amount of lignin, one formed by Bq, To and Vg, the third group consisted solely for Sm and finally the group Am, Aa and Ta, which showed lignin values significantly lower.

Regarding macroelements in ash (Table 3), it was determined that (IV) for the proportion of N, three groups were formed: a first group with significantly higher values consisting of 4 species (Aa, Bq, Cl and To) and the second group was formed by Am , Sm and Ta, and finally Vg showed the lowest value of N. (V) For P, this element was not detected in Am and Cl. Bq had the highest amount of P, while Ta showed the lowest presence and, the remaining four species showed no significant differences between them. (VI) In relation to Ca, Bq showed the highest value of Ca, Ta and Vg showed lower concentrations of this element and the remaining five species showed no statistical differences between them. (VII) For the Mg element, three groups were formed, one group with the highest concentration , which is composed solely of Vg , followed by the group of Aa, Am, Bq and a third group consisting of Cl, Sm and Ta with the least presence of Mg. (VIII) For the K element, Bq obtained the highest value, followed by Vg and subsequently Aa , Sm, Ta and To species showed no differences between them and finally Am and Cl reported the lowest percentages of K. (IX) Two groups were formed in the S element (Table 3): the first group with the lowest values of S consisting of Cl and Am and a second group formed with the remaining 6 species, which showed no significant difference between each other.

Regarding microelements in ash (Table 3) it revealed that: (I) to the Fe element, there were only differences in Vg which showed a significantly smaller presence of Fe to the remaining seven species, which showed no difference between each other. (II) In the elements of Cu, Zn, Mn and B statistical analyzes showed that these micronutrients were significantly higher Vg in relation to the remaining seven species, which have no statistical difference between them.

Amount of extractives

Different percentages of extractives obtained with various solvents are presented in table 4. Extractives in cool water were significantly higher Vg, contrary, Aa and Am showed lower values, while Ta and Sm show differences between them and Bq, Cl and To show a proportion of between 2.9% and 5.3% and showed no differences between them. (II) The hot water extractives present three groups of species: a first group consisting of Ta, with significantly higher value, a second group consisting of Am and Aa and finally the third group consisting of the remaining 5 species, which showed no significant differences between them. (III) The extractives dissolved in NaOH present two groups: the first is composed of Ta, To, Vg and Sm, which showed no variations between them and the second group was formed of Am, Aa, Bq and Cl. (IV) For the ethanol - toluene extractives, it was only found significant difference in Aa and Am, which showed significantly lower values to the remaining six species that showed no significant differences between them. (V) Finally for extractives in Dichloromethane three groups formed: the first, with significantly higher percentages, which is formed by Cl and Am, the second group consisting of Bq and Vg and the third group contemplated the remaining four species.

Dip-diffusion Preservation

Boron penetration increased with storage time in all species and this time varies from 4 days to 40 days depending on the species and the thickness of the wood (Fig. 1). It is remarkable to note that: (I) Ta and Vg showed a period of less widely to 6 days for any thickness of wood (Fig. 1) and (II) for heartwood of Cl boron dip-diffusion was not achieved and only got a penetration of 2 mm at all thicknesses (Fig. 1). For the rest of the five species, the diffusion time varied with the thickness of the wood. In the thickness of 12.7 mm (Fig. 1a), 100% of the diffusion is accomplished in 15 days to 16 days in Aa, Am and Sm. Meanwhile To achieve full penetration in 32 days (Fig. 1a). For the case of Bq it was not evaluated in this thickness. In the thickness of 25.4 mm (Fig. 1b), Aa, Am and Bq have similar diffusion time (20 days to 24 days), whereas the time for To has wider diffusion, 40 days. In thicknesses of 38.1 mm and 63.5 mm (Fig. 1c and 1f), Am and Aa showed similar period of diffusion in two thicknesses, followed by Sm, while for To, after 40 days, full penetration was not achieved. In thickness of 50.8 mm (Fig. 1c) again Aa and Am have a similar diffusion time, followed Sm and Ta and Bq no penetration was achieved beyond 80% of the thickness at 40 days. Finally for the thickness of 76.2 mm (Fig. 1f) Aa, Am and Sm showed a similar period of diffusion. In case of Bq, for this thickness was not studied.

Vacuum-Pressure Preservation

The introduction of preservatives, using vacuum pressure method was not possible in the heartwood of the four reforestation species studied with presence of heartwood, while the sapwood succeeded in introducing the preservative (Table 5). The kind of penetration is different and therefore, 6 types of impregnation were listed: regular total penetration (in Vg), regular partial (in Am), irregular vascular partial (in Aa, Ta and Ta), regular vascular partial (in Bq), irregular (Cl) and irregular partial (in Sm). The absorption obtained for sapwood of species varied from 103.3 l/m3 to 476.0 l/m3, and retention ranged between 2.1 kg/m3 and 8.9 kg/m3. The ANOVA for these two parameters showed that Vg has the highest absorption and retention, followed by Ta, To and Sm. The remaining four species showed no significant differences between them.

Air drying

As expected in all species and for different thicknesses, the time to reach 20% moisture content increased with lumber thickness (Fig. 2a). However, the drying time was different and different groups were formed: the first consisting of Ta and Am, which showed the shorter drying periods at all thicknesses. Then Aa species has slightly more time than the previous two species drying. Subsequently the species Cl, Sm and To with a longer drying time. Finally the species Vg presents the longest drying times in almost all thicknesses (Fig. 2a).

The drying rate obtained is smaller than 2% day-1 in the thicknesses of lumber about 50 mm, while for the wood thickness of 12 mm presents the highest drying rates compared to the rest of the thickness (Fig. 2b). Also, the drying ratio confirms species grouping for the air drying process, especially if it considers thickness over 37 mm (Fig. 2b). The drying ratios in Sm and To are the lowest, then with a drying rate slightly larger is presented in Ta and Aa, then with slightly higher values are Am and Cl Finally, Vg presents the highest ratios for moisture loss.

Workability

The behavior of wood in planing test varied between species, cutting angles and feeding rates. Regarding the species, four species groups were established: a first group formed by Am, Bq, Cl, Sm and To, with the highest percentage of area free of defects and planing quality from excellent to good (Table 6). However Bq wood, for speed 20 m/min, would not be included in this group. The second group is only composed by Ta with lower area free of defects than the previous group and presents a surface quality from fair to good. Aa has a lower value compared to the previous species and a planing quality from very poor to poor. Finally Vg is the species with the smallest area free of defects and the lowest brushing quality, from very poor to poor.

Regarding cutting angles, again there is no clear trend in which angle is the most appropriate for all species. For example, in Aa and Bq the angle of 15° has higher area free of defects than the angle of 30°, but in Cl, Sm and To, the greatest percentage of area free of defects occur when planing is performed with a blade with a cutting angle of 30°. As for the other species no definite trend is observed. As for the feet rate in most species was found that a feet rate of 6 m/min produces the best area percentage except Aa and Cl in the cutting angle of 15° and To and Vg in the angle of 30° (Table 6).

In the sanding test, the highest temperature was obtained in Ta, followed by Vg and then followed by a group of species (Aa, Cl and To) with average and low temperatures. Finally, Am, Bq and Sm presented the lowest statistically temperatures. The dust removal parameter, that indicates the ease of sanding, again classifies the species into five groups: one group (easily sanded) formed only by Sm with the highest removing, followed by second group compound alone by Bq, thereafter, a third group (median easiness to sanding) composed of Am, Aa and Vg, then a group consisting of Cl and To and finally the group, of harder sanding consisting by Ta. It is important to note that in this test the presence of fluffy grain was found in the sanded surface (Table 6).

For the boring test, when this operation is performed with a wood drill bit, the quality of excellent is presented in Cl and Vg, but if these species are bored with a metal drill bit, the hole quality is poor quality. Likewise, the quality of the holes is excellent with metal drill bit in Sm, Ta, To and Am to a 500 min-1 rotation, but these species with the wood drill bit show a poor quality. Moreover, a deficient quality was recorded when Am used a wood drill bit in the two-speed turns and with a metal drill bit with a rotation of 1000 min-1. For Aa and Bq, with two types of drill bits, there is poor or deficient qualities of hole (Table 6).

Regarding the chip thickness, the highest values are presented in Cl with a wood drill bit, followed by Bq and Vg, then a group consisting of Aa, Sm, and the two species of Terminalia. Finally the smallest chip thickness with wood drill bit was reported for Am. The chip thickness, when a metal drill bit is used, is varied. At the speed of 500 min-1 the greatest thickness is presented in Am, followed by Sm and To, then a group consisting of Ta and Vg and last Aa and Cl. In the speed of 1000 min-1 the order is different: first Sm and Am, then an intermediate group composed of the two species of Terminalia, and the lowest chip thickness is a group composed of Aa, Bq and Vg (Table 6).

The behavior of the species is similar in mortising and shaping test, showing excellent surface quality in Cl and Bq. In Sm, the species of Terminalia and Vg, the quality of the surface is classified as good. The Am and Aa species shown fair quality in mortising and poor to good quality in shaping (Table 6). In the test for turning, the best performance is obtained in Bq and Sm with few defects and slight presence of ripped grain. Am is another species with good turning, because it presented good surface quality and when there is presence of any defect is a fluffy grain. Species To and Vg show a surface quality in turning from fair to good, with the presence of fluffy grain and the presence of a rough surface. The lowest conditions of surface quality were obtained in Aa, Cl and Ta (Table 6).

Discussion

The wood has, generally, a slightly acidic pH (below 7) (Johns and Niazi, 1980; Abe and Ono, 1982) this is fulfilled for most of the species in this study. When there is a very low pH, like the case of the two species of Terminalia, leads to problems of corrosion of metals (Zelinka and Stone, 2011), or decrease in curing of the adhesive (Johns and Niazi, 1980). Meanwhile, Bq wood showed a tendency to be basic (Table 3), a situation that is not common in the wood (Abe and Ono, 1982). Regarding holocelullose and lignin content, again reflects the difference between softwood and hardwood species. The hardwood species have a greater content of holocellulose and lower lignin content relative to softwood species (Schroeder, 1972; Bárcenas-Pazos y Dávalos Sotelo, 1999; Pereira et al., 2003). In this study, the only softwood specie (Cl) showed the lowest value in the content holocelullose and was the species with the lowest amount of lignin (Table 3). Moreover, within the hardwood species analyzed the variability that occurs in tropical woods is shown, which have a wide range of variation, which is related to the amount of polysaccharides present in the cellulose and hemicellulose, amounts that are variables between species (Pereira et al., 2003).

The micro and macro elements in ash, although it does not have great importance from the point of use of wood (Bougnom et al., 2011) are considered by some authors as important aspects related to ash production. This because they represent a waste necessary to handle and also because they are an indicator of the quantity of nutrients removed by the tree during growth (Demeyer et al., 2001). As expected, the amount of microelements varies among the different species (Bougnom et al., 2011), as occurred in this study (Table 3). But the differences obtained should be taken with great care since these variations occur between species, tree age, tree section, soil type and climate, combustion type, type of sampling and wood storage (Demeyer et al., 2001). Importantly, to point out the differences in the five micro-elementes analyzed (Fe, Cu, Zn, Mn and B) of Vg in relation to the other seven species studied (Table 3). This result agrees with studies by Kukachka and Miller (1980), which had noted the high concentration of microelements in the genre Vochysia, feature that can be used to identify the species of this genus.

The percentage of extractives, that were extracted in the studied species (Table 4), again reflects the variation in the chemical composition of extractives found in the species, this because each solvent reflects the chemical nature of these compounds (Pereira et al., 2003). For example, the high values obtained in the extractives in hot and cold water, reflect the amount of tannins, gums, sugars, and coloring matters and starches (ASTM, 2012b), so that the highest values found in Vg and Ta, indicate that these components are present in the wood. Likewise, high levels of soluble extractives in NaOH, found Sm, Ta, To and Vg indicate the high presence of low molecular weight extractives such as carbohydrates consisting mainly of hemicellulose and degraded cellulose in wood (ASTM, 2012c). The high value of soluble extractives in dichloromethane, found in Cl, indicates the high presence of waxes, fats, resins, phytosterols, and nonvolatile hydrocarbons in the wood of this species (ASTM, 2012e). Tropical wood extractives have several effects on the properties of the wood, specifically by the values of swelling and shrinking, the equilibrium moisture content that wood can reach, the dimensional stability and the physical and mechanical properties of wood (Kilic and Niemz, 2012). Thereby, indicating that the differences found between species (Table 4), affect the properties of the plantation species studied.

The preservation of wood aims to increase its resistance to attack by insects and fungi (Lloyd, 1998). The use of boron salts caters mainly for insect protection and has its advantage over other types of preservatives, since it does not dependent on the presence of sapwood/heartwood and has a low cost (Ra et al., 2001). The protective effect and application can be used in the eight plantation species analyzed in this work, since all species achieved full penetration of the preservative. However, this penetration is related to two aspects: the thickness of the wood to be preserve and the species (Fig. 1). The differences in thickness were to be expected, since the boron diffusion arises from the surface to the inner part of wood, chemically explained by a difference in boron concentration between the outside part and the inside part (Ra et al, 2001). So in a smaller thickness, the preservative reaches the center of the piece of wood (Fig. 1) more quickly.

The species factor is the most influential in the types of boron diffusion. Two species (Ta and Vg) showed a very rapid diffusion period, less than six days in any of the thicknesses evaluated (Fig 1). The rapid diffusion in Vg can be explained because it presents the initial moisture content (close to 145%) higher relative to the other species (Moya and Munoz, 2010) and a high moisture accelerates the diffusion of boron into the wood (Morrell et al., 1990) while the rapid diffusion of Ta can be attributed to the low pH present in the wood of this species (Table 3), since a low pH (3-4) in the wood favors boron diffusion (Lloyd, 1998). In other species the variations that occur can be attributed to differences in moisture conditions. For example, Aa has low moisture content and pH within the range of timber species, justifying why this species presented a slow diffusion time in some thicknesses. Likewise, the slightly basic pH found in Bq, would not allow the adequate diffusion of boron, which explains the high treatment times in certain thicknesses.

Regarding Cl, it was observed that the boron is diffused only in the sapwood. Although the determination of moisture content was not performed in this study, Nakada (2006) reports a marked difference in moisture content between the portion of sapwood and part of heartwood in the wood of Cl, 152% and 47% respectively. Jrabbnhoft et al. (2004) agrees with this result, an appropriate moisture content for the diffusion of boron is 100%, but when it has low moisture content, the diffusion of boron is little effective. For this reason, it is expected that the low humidity in the heartwood of Cl would limit the diffusion of boron.

Regarding the preservation of wood with the vacuum-pressure method is important to note that it was not possible to preserve, with this method, species with presence of heartwood. It is mentioned that the heartwood of most species would refract preservative impregnation by the pressure method (Stan, 2010), however, some wood species, both temperate and tropical climates, may have preservative penetration with this method (Keenan and Tejada, 1988). This ability to absorb or no the preservative, is related to the anatomical structure and the abundance and amount of extractives (Stan, 2010).

Moreover, the preservation by the vacuum pressure method showed that, for all species, it is possible to preserve the sapwood (Table 5), however, two major differences between species are presented: first the type of penetration and second the absorption (l/m3) of the preservative. Both parameters are related to the variety of the anatomical structure of the species (Keenan and Tejada, 1988). A total and regular penetration, as recorded in Vg, occurs when the anatomical structure of the wood has pathways (pit) suitable for fluid flow between the different anatomical features such as punctuations and perforation plates of the vessels. The partial, irregular and vascular penetration the most common among the species analyzed, occurs when the vessels have almost no obstructions to the passage of preservative lengthwise, but in the transverse direction (radial or tangential) there is greater blockage of the vessels. When the flow of the preservative crosswise is not prevented, the penetration is regular, as happened in Bq and Aa. Finally, the irregular penetration occurs when areas of the cross section of the wood, the flow of the preservative is not uniform (Keenan and Tejada, 1988).

The other aspect that shows the differences between the species studied is the absorption of the preservative (Table 5). Keenan and Tejada (1988) found that the absorption of preservative is related to the density of the wood in different tropical species of natural forest in the Andean Region of Colombia, Peru, Bolivia and Venezuela. However, this behavior was not fully complied with these plantation species (Table 5). For example, Bq, Aa and Vg, similarly specific weight, showed large differences in absorption (approximately 331 l/m3 to 367 l/m3). The lack of correlation between specific weight and absorption, in this case, it is related to the penetration type. Species with partial and irregular penetration would present a proportionality between the specific gravity and absorption of preservative, but in the other species what happens is a combined influence between specific weight and the penetration type of the preservative.

The drying rate increased with increasing board thickness in air-dry conditions (Fig. 2), following the common rule of proportionality (Moya et al., 2009). The water in lumber moves from high to low moisture content zones, aiming at a moisture equilibrium through-out the board. This means that the drying within a board occurs from its interior, moving the moisture to drier surfaces more rapidly in thinner boards (Moya et al., 2009). The difference in drying time among species with different board thicknesses can be attributed to initial moisture content. The initial or green moisture content showed a positive correlation with air-drying time. The fastest drying rate was found in Ta and Am (with 45% and 47% in moisture content), followed by Sm, To, Aa and Cl, with intermediate values (with 52%, 53%, 80% and 94% in moisture content) and Vg (initial moisture content of 137%) with the slowest air-drying rate. However, others inherent wood characteristics can affect the relationships between initial moisture content and drying time, such as vessels and parenchyma rays compositions (Pereira et al., 2003), but they not considered in this research.

On the others hand, studies by Serrano (1983) in Costa Rica and Torelli and Cufar (1996) with 43 Mexican woods, showed that species of low density and high density (especially of interlocked grain) present problems in different operations of workability as happens in this study with species Aa and Vg (both low density), which showed the greatest problems in workability. Am, Bq, Cl, Sm and To (medium density species) generally have from excellent to good properties in planing, sanding, boring, and shaping, which makes them potential species to use in the manufacture of furniture since in this type of use, these operations are applied most frequently. For all other species (Ta, Bq, Aa and Vg), especially for Aa and Vg, much more care must be taken in these operations, since the quality of the surface that can be obtained is low, scored as poor or very poor. However, to reduce this intrinsic effect of wood, it is possible to apply some treatments to wood. Recent research has shown that workability properties in plantation species can be improved. For example thermal rectification en Eucalyptus grandis and Pinus caribaea var. hondurensis (De Mauro et al., 2011) or Hevea brasiliensis (Ratnasingam and Ioras, 2012) improves workability problems of these species. This type of treatment, for example, could be applied on wood from plantations of Ta, Bq, Aa and Vg in Costa Rica to increase quality in the operations of workability.

Conclusions

1. Wood from the plantation species analyzed, presents a slightly acidic pH (less than 7), however Bq wood tended to be basic. Also, the only softwood specie (Cl) showed the lowest value in the content holocelullose and it was the species with the lowest amount of lignin, reflecting the difference in chemical composition between softwood and hardwood species. The species studied show considerable variability in the content of holocelullose, lignin, and amount of extractable and micronutrients, which is common in tropical woods. In connection with the micronutrients, a high percentage was found in Vg, compared with the seven species studied.

2. The preservatives based on boron salts can be applied in the 8 plantation species analyzed, however two aspects must be considered: the thickness of the wood and the species to be preserved. In the wood with lower thickness, the preservative reaches the center of the treated piece more quickly and conversely in the wood with greater thickness, the boron diffuses more slowly. Regarding the species Ta and Vg showed a faster diffusion period, compared with the other species, where the time is longer.

3. It was not possible to preserve the species with presence of heartwood with vacuum-pressure method, but it was possible to preserve the sapwood in all species. Two major differences were observed between the species studied: first the type of penetration (partial, irregular and vascular) and second the preservative absorption which varied from 103 l/m3 to 476 l/m3.

4. The drying rate increased with increasing board thickness in air-dry conditions and the difference in drying time among species. The fastest drying rate was found in Ta and Am (species with 45% and 47% in initial moisture content), followed by Sm, To, Aa and Cl, with intermediate values in moisture content (52%, 53%, 80% and 94%) and Vg (initial moisture content of 137%) with the slowest air-drying rate.

5. The Am, Bq, Cl, Sm and To species have excellent to good properties of planing, sanding, turning and shaping , but the rest of the species (Ta, Bq, Aa and Vg) and especially Aa and Vg are catalogued in the operations of workability, as poor or very poor quality.

Acknowledgements

The authors wish to thank the Vicerrectoría de Investigación y Extensión at the Instituto Tecnológico de Costa Rica (ITCR), and Precious Woods of Central America (MACORI), Maderas Cultivadas de Costa Rica and Escuela de Agricultura de Trópico Húmedo (EARTH) for the raw materials and facilities for the study.

References

Abe, I. and K. Ono.1982. The acidity of wood and the extractives of some tropical species. Journal of the Japan Wood Research Society 28(6):535-540. [ Links ]

PADT.RFT. 1976. Acuerdo de Cartagena. Normas y metodología para las actividades tecnológicas. Proyecto Andino de Desarrollo Tecnológico en el área de recursos tropicales. Documento PADT.RFT/di 2. Lima, Perú. 25 p. [ Links ]

ASTM. 2012a. D1102-84 Standard test method for ash in wood. Annual Book of ASTM Standards. Vol. 11.06. Philadelphia, US. 2 p. [ Links ]

ASTM. 2012b. D1110-84 (1995) Standard test methods for water solubility of wood. Annual Book of ASTM Standards. Vol. 11.06. Philadelphia, US. 2p. [ Links ]

ASTM. 2012c. D1109-84 Standard test method for 1% sodium hydroxide solubility of wood. Annual Book of ASTM Standards. Vol. 11.06. Philadelphia, US. 2p. [ Links ]

ASTM. 2012d. Standard test method for ethanol-toluene solubility of wood. Annual Book of ASTM Standards. Vol. 11.06. Philadelphia, US. 2p. [ Links ]

ASTM. 2012e. D1108-96 Standard test method for dichloromethane solubles in wood. Annual Book of ASTM Standards. Vol. 11.06. Philadelphia, US. 2p. [ Links ]

ASTM. 2012f. D-1666-2003. Standard test methods for conducting machining tests of wood and wood-base materials. Annual Book of ASTM Standards. Vol. 11.06. Philadelphia, US. 16p. [ Links ]

Baraloto, C., C Paine, L. Poorte, J. Beauchene, D. Bonal and A. Domenach. 2010. Decoupled leaf and stem economics in rain forest trees. Ecology Letters 13(11):1338-1347. [ Links ]

Bárcenas Pazos, G.M. y R. Dávalos Sotelo. 1999. Importancia de la lignina en las contracciones de la madera: revisión bibliográfica. Madera y Bosques 5(1):13-26 [ Links ]

Bougnom, B.P., B.A. Knapp, F. Etoa and H. Insam. 2011. Possible use of wood ash and compost for improving acid tropical soils. In: H. Insam, and B.A. Knapp, eds. Recycling of biomass ashes. Springer Verlag. New York. p:87-105. [ Links ]

Butterfield, R., R. Crook, R. Adams and R, Morris. 1993. Radial variation in wood specific gravity, fiber length and vessel area for two Central American hardwoods; Hyeronima alchorneoides and Vochysia guatemalensis: natural and plantation-grown trees. IAWA Journal 14(2): 153-161. [ Links ]

Demeyer, A., J.C. Voundi and M.G. Verloo, 2001. Characteristics of wood ash and influence on soil properties and nutrient uptake: an overview. Bioresource Technology 77(3): 287-295 [ Links ]

De Mauro, L.F., J. Brito, A.M. Nolasco and L. Rodrigues. 2011. Effect of thermal rectification on machinability of Eucalyptus grandis and Pinus caribaea var. hondurensis woods. European Journal of Wood Products 69(4):641–648. [ Links ]

Erickson, H.D. 1962. Some aspects of method in determining cellulose in wood. TAPPI Journal 45(9):710-719. [ Links ]

Jrabbnhoft, K., P. Hoffmeyer, C.G. Bechgaards and L. Damkilde. 2004. Finite element analysis of boron diffusion in wooden pole. Wood Fiber and Science 36(4): 573-584. [ Links ]

González, E. and R. Fisher. 1998. Variation in selected wood properties of Vochysia guatemalensis from four sites in Costa Rica. Forest Science 44(2):185-191. [ Links ]

Johns, W. and N. Niazi. 1980. Effect of pH and buffering capacity of wood on the gelation time of urea-formaldehyde resin. Wood fiber and Science 12(4):255-263 [ Links ]

Kukachka, B.F. and R.B. Miller. 1980. Chemical spot-test for aluminum and its value in wood identification. IAWA Bulletin n.s. I(3): 104-109. [ Links ]

Kilic, A. and P. Niemz, 2012. Extractives in some tropical woods. European Journal of Wood Products 70(1-3):79–83 [ Links ]

Keenan, F.J. and M. Tejada. 1988. Maderas tropicales como material de construcción en los países del grupo andino de América del Sur. Ottawa, Canada. 147 p. [ Links ]

Lloyd, J.D. 1998. Borates and their biological applications. Inteernational Research Group on Wood Preservation. IRG/WP 98-30178. IRG Secretariat, Stockholm Sweden. 17 p. [ Links ]

Monique, T., I. Bosman, K. ven Genderen and P. Baas. 1994. Radial variation in wood properties of naturally and plantationvariation in wood properties of naturally and plantation. IAWA Journal 15(2): 111-120. [ Links ]

Moya, R. and F. Muñoz. 2010. Physical and mechanical properties of eight species from fast-growth plantation in Costa Rica. Journal of Tropical Forest Science 22(4):317-328. [ Links ]

Moya, R., L. Leandro and O. Murillo. 2009. Wood characteristics of Terminalia amazonia, Vochysia guatemalensis and Hyeronima alchorneoides planted in Costa Rica. Revista Bosque 30(2):78-87. [ Links ]

Moya, R. and C. Tenorio. 2013. Fuelwood characteristics and its relation with extractives and chemical properties of ten fast-growth species in Costa Rica. Biomass and Bioenergy 56(1): 14-21 [ Links ]

Moya, R., E. Ureña, C. Salas, F. Muñoz and O. Espinosa. 2013. Kiln drying behavior of lumber from ten fast-growth plantation species in Costa Rica. Wood Material Science and Engineering 8(1):37-45. [ Links ]

Morrell, J.J., C.M. Sexton and A.E. Preston. 1990. Effect of moisture content of douglas-fir heartwood on longitudinal diffusion of boron from fused borate rods. Forest Products Journal 40(4):37-40. [ Links ]

Nakada, R. 2006. Within-stem water distribution in living trees of some conifers. IAWA Journal. 27(3):313–327 [ Links ]

Nichols J.D. and J.K. Vanclay. 2012. Domestication of native tree species for timber plantations: key insights for tropical island nations. International Forestry Review 14(4):402-413. [ Links ]

Pereira, H., J. Graca and J.C. Rodrigues. 2003. Wood chemistry in relation to quality. In: Barnett, J., G. JeEronimidis, eds. Wood quality and its biological basis. Blackwell Publishing Ltd, London, 3-40 p. [ Links ]

Petit, B. and F. Montagnini. 2004. Growth equations and rotation ages of ten native tree species in mixed and pure plantations in the humid neotropics. Forests Ecology and Management 199(2):243-257. [ Links ]

Ra, J.B., H.M. Barnes and T.E. Conners. 2003. Determination of boron diffusion coefficients in wood. Wood Fiber and Science 31(1): 90-103. [ Links ]

Ratnasingam, J. and F. Ioras. 2012. Effect of thermal rectification on machinability of Eucalyptus grandis and Pinus caribaea var. hondurensis woods. European Journal Wood Products 70(4):759-761. [ Links ]

Schroeder, H.A. 1972. Shrinking and swelling differences between hardwoods and softwoods. Wood and Fiber 4(1):20-25. [ Links ]

Sparks, D.L., 1996. Methods of soil analysis. Part 3, Chemical methods. Soil Science Society of America. Madison, WI, USA. 356 p. [ Links ]

Stan, L., 2010. Wood Preservation. In: USDA (United States Department of Agriculture). Wood Handbook. General Technical Report FPL-GTR-190. Forest Service. Forest Products Laboratory. Madison, WI: USA. 15 p. [ Links ]

Serrano R., 1983. Características de cepillado, taladrado, lijado y torneado de 16 especies. III Parte. In: Serrano R, Tuk, J. Informe Final del proyecto: Propiedades físicas, mecánicas, preservación, durabilidad, cepillado, taladrado, lijado, torneado de 18 especies maderables de Costa Rica. Centro de Investigación en Ingeniería en Maderas. Instituto Tecnológico de Costa Rica. 72 p. [ Links ]

TAPPI. 2002. Standard test for acid–insoluble lignin in wood and pulp. Parkway South Norcross, USA. 4 p. [ Links ]

Torelli, N. and K. Čufar. 1996. Mexican tropical hardwoods: machinability, nailing and screwing. Holz als Roh-und Werkstoff 54(1): 69-71. [ Links ]

Williams, L. and J. Mauldin. 1996. Integrated protection against lyctid beetle infestations. III. Implementing boron treatment of Virola lumber in Brazil. Forest Products Journal 36 (11-12):24-28. [ Links ]

Zelinka, S. L. and D.S. Stone. 2011. The effect of tannins and pH on the corrosion of steel in wood extracts. Materials and Corrosion 62(3):739-744. [ Links ]

Nota

Este documento se debe citar como: Moya, R., C. Salas, A. Berrocal y J.C. Valverde. 2015. Evaluation of chemical compositions, air-dry, preservation and workability of eight fast-growing plantation species in Costa Rica. Madera y Bosques 21 (Núm. esp.):31-47.