Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Madera y bosques

versión On-line ISSN 2448-7597versión impresa ISSN 1405-0471

Madera bosques vol.21 no.1 Xalapa mar./jun. 2015

Artículos de investigación

Resistance of thermally treated woods to Nasutitermes corniger in a food preference test

Resistencia de maderas tratadas térmicamente al ataque de Nasutitermes corniger en ensayos de preferencia de alimento

Juarez Benigno Paes1, Pedro Gutemberg de Alcântara Segundinho1,*, Allan Ewerton Rezende Euflosino1, Marcio Rogério da Silva2, Carlito Calil Junior2, José Geraldo Lima de Oliveira1

1 Department of Forestry and Wood Sciences, Center of Agricultural Sciences, Federal University of Espírito Santo. Jerônimo Monteiro, Espírito Santo, Brazil. * Corresponding author: p_gutemberg2001@yahoo.com.br

2 Laboratory of Timber and Timber Structures, Department of Structural Engineering, School of Engineering. São Paulo University. São Carlos, São Paulo, Brazil.

Manuscript received on December 2nd 2013.

Accepted on July 2nd 2014.

ABSTRACT

The objective of this study was to evaluate the effects of thermal treatment on the resistance of Corymbia citriodora and Pinus taeda woods to the xylophagous termite Nasutitermes corniger, in a food preference test. We used temperatures of 100 °C (control), 160 °C, 180 °C, 200 °C, 220 °C, 240 °C for both wood species, and 260 °C only for Pinus taeda. Three wood planks measuring 6 cm x 16 cm x 56 cm (thickness x width x length) were thermally treated and manufactured in specimens of 10.0 cm x 2.54 cm x 0.64 cm (longitudinal x radial x tangential). Specimens were distributed in randomized blocks, with six treatments (Corymbia citriodora) and seven treatments (Pinus taeda) with 10 repetitions in a 250 liters box with 10 cm of sand; specimens were inserted in the sand, up to 1/3 of their height. The test was maintained for 45 days under laboratory conditions (25 °C ± 2 °C and 65% ± 5% relative humidity). Temperatures of 220 °C and 240 °C slightly improved the resistance of Corymbia citriodora wood to the termite. Improvements on Pinus taeda wood happened at temperatures of 240 °C and 260 °C. The temperatures of 160 °C for the eucalyptus wood and 200 °C for pinus decreased their resistance to the tested termite.

Key words: bioassay, Corymbia citriodora, Nasutitermes corniger, Pinus taeda, xylophagous termites.

RESUMEN

El objetivo del trabajo fue evaluar el efecto del proceso de modificación térmica en la resistencia de las maderas Corymbia citriodora y Pinus taeda a ser ingerida por la termita xilófaga Nasutitermes corniger, en ensayos de preferencia de alimento. Se probaron temperaturas de 100 °C (testigo), 160 °C, 180 °C, 200 °C, 220 °C, 240 °C, además de 260 °C para el Pinus taeda. Se sometieron al proceso de modificación térmica tres tablones de madera de 6 cm x 16 cm x 56 cm (grosor x ancho x largo), y después fueron transformados en especímenes de 10,0 cm x 2,54 cm x 0,64 cm (longitudinal x radial x tangencial). Los especímenes fueron distribuidos en bloques aleatorios, y sometidos a seis tratamientos (Corymbia citriodora) y siete tratamientos (Pinus taeda) con 10 repeticiones por tratamiento, en cajas de 250 litros con una cama de 10 cm de arena. Los especímenes de prueba se hincaron en la arena hasta 1/3 de su longitud y fueron expuestos al ataque de las termitas. El ensayo fue mantenido durante 45 días bajo condiciones del laboratorio (25 ºC ± 2 ºC y 65 % ± 5% de humedad relativa). Para la madera de Corymbia citriodora, las temperaturas de 220 °C y 240 °C mejoraron sensiblemente la resistencia a la termita. Para el Pinus taeda la mejoría ocurrió con las temperaturas de 240 °C y 260 °C. La temperatura de 160 °C para la madera de C. citriodora y la de 200 °C para el P. taeda causaron disminución en la resistencia a la termita estudiada.

Palabras clave: Ensayo biológico, Corymbia citriodora, Nasutitermes corniger, Pinus taeda, termitas xilófagas.

INTRODUCTION

Wood has some undesirable features, such as dimensional movement and susceptibility to deterioration, therefore having limited suitability for use, when good stability and high natural resistance to xylophagous organisms are required. Thus, knowing the natural resistance of wood beforehand is important to recommend the most appropriate employment of the material, avoiding unnecessary expenses with maintenance or deteriorated parts replacement, reducing impacts on remaining natural forests (Paes et al., 2004). Since the wood of most fast growing species show low biological resistance, it is necessary to use chemical treatments to improve its durability. Although active ingredients emission of such products is low, after its fixation on the wood, the technique is generally seen as environmentally unfriendly (Homan et al., 2000). This way, thermal modification (or thermal treatment) has been used to give greater resistance to fungal degradation and greater dimensional stability to wood. It is considered an environmentally correct technique, since the thermal modification of wood produces a new material that, in the end of the product’s lifecycle, is less environmentally hazardous than untreated wood (Borges and Quirino, 2004).

Quirino and Vale (2002) recorded that higher dimensional stability comes from the hygroscopicity decrease, by degradation of the most hygroscopic component, which is hemicellulose. Thus, reducing the capacity of wood to exchange water with the environment, shrinkage and swelling problems are minimized (Borges and Quirino, 2004). Most authors usually relate the biological resistance of wood to the degradation caused by decay fungi the number of studies involving xylophagous insects is small. Fungi attack wood in contact with the soil or in humid environments. The wood, when exposed in places far from the soil or humidity, is free from attacks of these organisms; however, it is susceptible to insect attacks, especially termites (subterranean or dry wood). Subterranean termites are responsible for the greatest amounts of wood loss (Paes et al., 2003). In Brazil, little is known about the behavior of woods from the genus Eucalyptus (Corymbia) concerning their resistance to termite attacks, because few studies have been developed so far. The results revealed that some species are more susceptible than others to the insects, but, in general, all of them show natural resistance (which range from low to moderate) to Nasutitermes sp. termites (Paes and Vital, 2000).

There are methods to evaluate natural resistance of wood to termite attack. These methods are standardized by the American Society for Testing and Materials - ASTM D - 3345 and the Association Française de Normalisation - AFNOR - NFX - 41-539. Supriana (1985) criticized these methods, considering that, when wood specimens are offered together to insects, results are more realistic, compared to the results that would occur in realistic field conditions. Researchers and research institutions started to perform the food preference test. In Brazil, Abreu and Silva (2000) and Paes et al. (2007; 2010; 2011; 2013) have developed and applied food preference tests with wood and its derivatives, for the genus Nasutitermes sp xylophagous termites.

OBJECTIVE

This research aimed at evaluating the efficiency of thermal treatment for improving the resistance of Corymbia citriodora and Pinus taeda woods to subterraneous termites, in a food preference test.

MATERIALS AND METHODS

Origin and thermal treatment of Eucalyptus and Pinus woods

Pinus taeda trees came from Jaguariaíva region, in the state of Paraná, Brazil; the Corymbia citriodora trees came from the region of Brotas, São Paulo, Brazil. The trees used for the test, from both species, were 18 to 20 years old. Older trees were selected in order to reduce problems related to internal tensions, which happen in younger specimens, thus avoiding excessive cracks during the thermal treatment process. The thermal treatment was conducted at the Chemistry, Cellulose and Energy Laboratory of the College of Agriculture “Luiz de Queiroz”, at the University of São Paulo, in Piracicaba, São Paulo. The heating rate used in this study was 0.033 °C min-1, based on studies performed by Pincelli et al. (2002), with conifers and hardwoods. This heating rate was adopted in order to avoid fissures and cracks on the studied specimens. The thermal treatment was initiated at room temperature (30 °C), and the time used for the temperature raise until the heating ramp was 40 minutes. Different temperatures were needed to start the heating ramp, because of the studied species and the adopted different temperature ranges (Table 1) and 100 °C (control).

Initial humidity of specimens for thermal treatment was 12% ± 2%. The time specimens remained in the heater after reaching the final temperature of the heating ramp was called Final Level with a variation of ± 2 °C min-1. After the heat treatment process, only the heater’s air circulation system was kept on, until it reached the temperature of 30 ºC. The thermal treatment process was carried out in five or six temperature ranges (Table 1). Three repetitions were performed for each temperature range.

Seven wood planks were used for the thermal treatment process, measuring 6 cm x 16 cm x 56 cm (thickness x width x length), placed in a covered metal box, separated by two iron bars of 1 cm in diameter. This procedure was performed in order for gases to move through all sides of the wood (Figure 1). Besides that, nitrogen gas was inserted in the box, in order to prevent wood oxidation. The temperature inside the wood planks was monitored to ensure the homogeneity of heat treatment in the thermal treatment box. This was done by arranging five thermocouples on the first and the sixth planks (of the existing seven planks), from top to bottom, which were named “top plank” and “bottom plank”. Thermocouples type K were connected to the “Agilent” data acquisition system. The thermocouples were installed 3 cm deep; two of them were positioned 3 cm far from the plank’s edge, one in the center, all of them 8 cm far from the side width of the plank (Fig. 1).

Three thermocouples were used on the top plank and two were used on the bottom plank. The thermocouples positions were defined as: “front top plank”, when positioned next to the access lid; “upper middle plank”, when positioned at the center of the plank; “upper bottom plank”, when close to the bottom of the box; “lower front plank”, when placed close to the access lid; and “lower center plank”, when placed at the center of the plank.

Laboratory tests with subterranean xylophagous termites

The assay was performed at the Laboratory of Wood Biodeterioration, Department of Forest and Wood Sciences, Center for Agricultural Sciences, at the Federal University of Espírito Santo, in the city of Jerônimo Monteiro, Espírito Santo, Brazil. The food preference test was developed to analyze the biological resistance of thermally rectified woods against Nasutitermes corniger termites, with the use of specimens sized 2.54 cm x 0.64 cm x 10.16 cm (radial x tangential x longitudinal). The specimens were superficially sanded (to eliminate any defects and to have flat and parallel faces) in order to facilitate the visual analysis of the xylophagous termites attack. Recommendations of Paes et al. (2007; 2010; 2011; 2013) were followed: specimens were placed in a 250 liters box, which contained a layer of ± 10 cm of moist sand. The box was supported by four ceramic blocks (eight-hole baking-bricks), arranged in aluminum trays with water, to avoid the escape of termites (Fig. 2).

All the specimens were placed in the box, on randomized blocks (Fig. 2a) with six treatments (Corymbia citriodora) and seven treatments (Pinus taeda) with and 10 repetitions for each wooden species in a 250 liters box with 10 cm of sand (Fig. 2b). There was a 5.6 cm space among blocks and a 4.5 cm space among treatments; specimens were fixed in the sand up to 1/3 of their height. The termite colony was collected at the city of Jerônimo Monteiro, in the State of Espírito Santo, Brazil. It was arranged on plastic crates and supported on termite-resistant wood blocks, then placed on the sand layer in the box, where the experiment was set. Specimens were exposed to the action of the Nasutitermes corniger termite during 45 days, in a temperature-controlled room (25 °C ± 2 °C and 65% ± 5% relative humidity). After finishing the assay, the specimens were dried and again weighed to assess the percentage of weight loss of specimens, caused by the attack of termites. To analyze the efficiency of thermal treatment in the biological resistance of wood, we calculated the mass loss (%) and waste caused by termites on the specimens (Table 2). The mass loss was corrected by subjecting specimens to the same test conditions, but without the termites.

Results evaluation

Because of the thermal treatment temperatures, we adopted a specific placement for the blocks, in order to compare the resistance of Corymbia citriodora and Pinus taeda woods: 10 blocks were randomly paired with six treatments (Corymbia citriodora) and seven treatments (Pinus taeda) temperatures, so we were able to evaluate the effects of blocks and temperatures on the biological resistance of specific wood species. For variance analyses, mass loss percentage values were transformed into arcsin [square root (mass loss/100)] according to what is recommended by Steel and Torrie (1980), and the values of waste (score) were transformed into root [(score) + 0.5]. Tukey test was used for the evaluation of assays, at 5% significance for the significant factors for the F test.

RESULTS

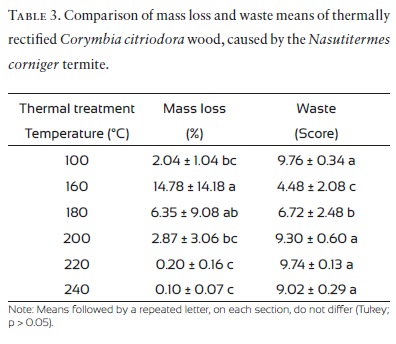

The variance analyses of mass loss and waste for Corymbia citriodora and Pinus taeda woods under food preference tests with Nasutitermes corniger termites showed that Corymbia citriodora and Pinus taeda woods had a 1% significance mass loss and waste at the F test. The treatment means were compared through the Tukey test at 5% significance and are shown in tables 3 and 4, respectively.

It is possible to observe on table 3 that Corymbia citriodora wood had no large amounts of mass loss caused by termites. At the temperature of 160 °C, the mass loss was 7.25 times greater than at 100 °C (control) (consequently, the lowest score) which shows the highest wood waste. This was considered the worst temperature to be used; it is not statistically different from the temperature of 180°C, at which the mass loss was 3.11 times greater than at the control temperature. The best temperature level was at 240 °C, because it produced the smallest mass loss not statistically different from temperatures of 220 °C, 200 °C and 100 °C (control).

The analyses of Pinus taeda wood (Table 4) allow us to state that the worst temperature was at 200 °C, which provided a mass loss that was 8.56 times greater than the control temperature (100 °C), but it does not statistically differ from 180 °C and 220 °C temperatures, which showed values 3.21 and 1.57 times the control mass loss, respectively. For this wood species, the best temperature was at 160 °C, with mass loss 4.79 times smaller than the control temperature but not statistically different from 240 °C and 260 °C temperatures, which showed greater waste scores, with no scarification caused by the termites. Variance analyses of species comparison between Corymbia citriodora and Pinus taeda for thermal treatment temperatures showed that the interaction between species and temperatures was significant. This interaction was unfolded and analyzed at the Tukey test at 5% significance (Table 5).

In table 5 it is seen that Pinus taeda wood showed better resistance than Corymbia citriodora, after they were thermally rectified at 160 °C. However, Corymbia citriodora wood was more resistant than Pinus taeda, after they were thermally rectified at 200 °C, because these were the only treatments in which the mass loss means statistically differed from 5% significance.

The waste scores at 100 °C (control) were the only means that did not statistically differ. The other thermal treatment temperature level means differed statistically: the highest ones were at 160 °C and 240 °C, for Pinus taeda, and at 180 °C, 200 °C and 220 °C for Corymbia citriodora.

DISCUSSION

In table 3, it was observed that Corymbia citriodora wood at the temperature of 100 °C had no major mass loss. This may be related to the species used, which shows high natural resistance, when compared to other fast growing species. The wood resistance is related to the class and content of extractives (Findlay, 1985), and this allows us to conclude that the higher the content of extractives (and mainly ashes), the more reduced will be the waste caused by termites on the wood (Paes et al., 2013).

It is possible to observe that the 240 °C temperature resulted in greater waste than control temperature (100 °C), since the lower the score, the higher the waste caused on the wood by the termite. However, the mass loss at control temperature level was greater than at 240 °C. This may have occurred because of the thermal treatment process, in which the wood loses mass, becoming less dense; the termite may have consumed more wood material, but the consumed material was slightly less dense.

In addition to that, the subjectivity of waste data (score), evaluated according the indications of ASTM D - 3345 (2005), may have caused evaluation difficulties, due to internal cracks (honeycomb cracks), which happened during the thermal treatment process, as stated by Poncsák et al. (2006). Because of the fact that termites attack the borders of these cracks, there is an impression of greater waste. The same situation was found when comparing the control sample to the 160 °C temperature.

For Pinus taeda wood (Table 4), it is possible to notice that higher mass losses and, consequently, smaller waste scores were observed in thermally rectified specimens starting at 180 °C, up to 200 °C. This may happen due to the evaporation of wood’s resin, which shows some resistance to the employed termites, once the control specimens (100 °C) showed little mass loss to the termites.

As Pinus taeda wood shows low natural resistance to various xylophagous organisms, it was hoped that it would show low natural resistance to the tested termite. Paes et al. (2007; 2010; 2011; 2013) had also observed that Nasutitermes genus termites do not attack much Pinus sp woods. Supriana (1985) cited that this may be related to the habits of termites, which do not attack wood with which they have frequent contact. Or else, as observed in this research, the wood’s resin may have hindered the attack of these insects on the Pinus sp wood.

The effects of thermal treatment on the improvement of Pinus taeda wood resistance were observed at the temperatures of 240 °C and 260 °C. For these temperatures, although the resin had evaporated, chemical transformations (caused by thermal treatment) improved the wood resistance to termites. It is possible to notice, on table 5, that specimens of Corymbia citriodora wood treated at 160 °C were the most consumed, whilst the least consumed by the termites were the specimens treated at 220 °C and 240 °C; the other specimens showed intermediate behavior, similar to each other. The specimens of Pinus taeda wood at 200 °C were the most consumed, and the specimens treated at 160 °C and 240 °C were the least consumed; the other specimens showed similar behavior to each other. The results of waste were similar to mass loss results, for both of the analyzed species. Thus, it is possible to observe that the temperature of 240 °C led to better resistance of both wood types to the tested termites.

Gunduz et al. (2009) mentioned that desirable changes in the wood start at 150 °C; this was not seen in the research, regarding the attack of Nasutitermes genus termites. The temperature of 160 °C is therefore not recommended for the thermal treatment of Corymbia citriodora wood to increase its biological resistance to termites. However, Hill (2006) cited that the benefits of thermal treatment occur between 180 °C and 260 °C, once temperatures lower than 140 °C do not significantly affect the wood structure. Temperatures above 260 °C, however, may cause undesired degradation on the wood, reducing its mechanical strength.

CONCLUSIONS

The thermal treatment of Corymbia citriodora wood under 220 °C and 240 °C temperatures improved its resistance to Nasutitermes corniger termites, whilst the temperature of 160 °C decreased the wood resistance. The temperatures of 160 °C and 240 °C increased the resistance of Pinus taeda woods to the termite, and the temperature level of 200 °C decreased the wood resistance. Honeycomb cracks may have occurred inside the specimens, on thermally rectified woods at higher temperatures. The termites corroded the edges of cracks, which caused the impression that these specimens were more consumed, because of the increase of the edges of cracks.

REFERENCES

Abreu, R.L.S. and K.E.S. Silva. 2000. Resistência natural de dez espécies madeireiras da Amazônia ao ataque de Nasutitermes macrocephalus (Silvestri) e N. surinamensis (Halmgrem) (Isoptera: Termitidae). Revista Árvore 24 (2):229-234. [ Links ]

American Society for Testing and Materials. ASTM D - 3345. 2005. Standard method for laboratory evaluation of wood and other cellulosic materials for resistance to termite. Philadelphia. 3p. [ Links ]

Borges, L.M. and W. F. Quirino. 2004. Higroscopicidade da madeira de Pinus caribea var. hondurensis tratada termicamente. Biomassa & Energia 1(2):173-182. [ Links ]

Findlay, W.P.K. 1985. The nature and durability of wood. In: W.P.K. Findlay, ed. Preservation of timber in the tropics. M. Nijhoff; Dr. W. Junk. Dordrecht. p: 1-13. [ Links ]

Gunduz, G., S. Korkut, D. Aydemir and I. Bekar. 2009. The density, compression strength and surface hardness of heat treated hornbeam (Carpinus betulus) wood. Maderas. Ciencia y Tecnologia 11 (1):61-70. [ Links ]

Homan, W., B. Tjeerdsma, E. Beckers and A. Jorissen. 2000. Structural and other properties of modified wood. In: Proceedings of the Fifth World Conference on Timber Engineering. CIB-W18. Bern. CD-ROM. [ Links ]

Hill, C.A.S. 2006. Wood modification: chemical, thermal and others processes. John Wiley & Sons. Chichester. 239p. [ Links ]

Paes, J.B., C.M.B. Fonsêca, C.R. Lima and A.D. Souza. 2010. Eficiência do óleo de candeia na melhoria da resistência da madeira de sumaúma a cupins. Cerne 16 (2):217-225. [ Links ]

Paes, J.B., A.D. Souza, C.R. Lima and P.N. Medeiros Neto. 2011. Eficiência dos óleos de nim (Azadirachta indica) e de mamona (Ricinus communis) na proteção da madeira de sumaúma (Ceiba pentandra) contra cupins xilófagos em ensaio de preferência alimentar. Revista Árvore 35 (3):751-758. [ Links ]

Paes, J.B., R.R. Melo, C.R. Lima and E. Oliveira. 2007. Resistência natural de sete madeiras ao cupim subterrâneo (Nasutitermes corniger Motsch.) em ensaio de preferência alimentar. Revista Brasileira de Ciências Agrárias (2)1:57-62. [ Links ]

Paes, J.B., V.M. Morais, D.W. Farias Sobrinho and O.A. Bakke. 2003. Resistência natural de nove madeiras do semi-árido brasileiro a cupins subterrâneos. Cerne (9)1:136-47. [ Links ]

Paes, J.B., P.N. Medeiros Neto, C.R. Lima, M.F. Freitas and C.E.F. Diniz. 2013. Efeitos dos extrativos e cinzas na resistência natural de quatro madeiras a cupins xilófagos. Cerne 19(3):399-405. [ Links ]

Paes, J.B., V.M. Morais and C.R. Lima. 2004. Resistência natural de nove madeiras do semi-árido brasileiro a fungos xilófagos em condições de laboratório. Revista Árvore 28 (2): 275-282. [ Links ]

Paes, J.B. and B.R. Vital. 2000. Resistência natural da madeira de cinco espécies de eucalipto a cupins subterrâneos, em testes de laboratório. Revista Árvore 24 (1): 97-104. [ Links ]

Pincelli, A.L.P.S.M., J.O. Brito and J.E. Corrente. 2002. Avaliação da termorretificação sobre a colagem da madeira de Eucalyptus saligna e Pinus caribaea var. hondurensis. Scientia Forestalis 1(61):122-132. [ Links ]

Poncsák, S., D. Kocaefe, M. Bouazara and A. Pichette. 2006. Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Science and Technology 1(40):647-663. [ Links ]

Quirino, W.F. and A.T. Vale. 2002. Retificação térmica de Eucalyptus grandis. Floresta (Edição Especial):60-66. [ Links ]

Silva, M.R. 2012. Efeito do tratamento térmico nas propriedades químicas, físicas e mecânicas em elementos estruturais de Eucalipto citriodora e Pinus taeda. Tese (Doutorado em Ciência e Engenharia de Materiais). Universidade de São Paulo. São Carlos. 223p. [ Links ]

Steel, R.G.D. and J.H. Torrie. 1980. Principles and procedures of statistic: a biometrical approach. 2nd ed. McGraw Hill. New York. 633 p. [ Links ]

Supriana, N. 1985. Notes the resistance of tropical wood against termites. Doc. IRG/WP/1249. The International Research Group on Wood Preservation. Stockholm. 9 p. [ Links ]

Note

This paper most be cited as: Paes, J.B., P.G.A. Segundinho, A.E.R. Euflosino, M.R. da Silva, C. Calil Jr. and J.G.L. de Oliveira. 2015. Resistance of thermally treated woods to Nasutitermes corniger in a food preference test. Madera y Bosques 21(1):157-164.