Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Madera y bosques

versión On-line ISSN 2448-7597versión impresa ISSN 1405-0471

Madera bosques vol.20 no.2 Xalapa jun./ago. 2014

Artículos de investigación

Correlation between chemical compounds and mechanical response in culms of two different ages of Guadua angustifolia Kunth

Correlación entre composición química y respuesta mecánica para dos edades de culmos de bambú Guadua angustifolia Kunth

Luz Adriana Sánchez-Echeverri1, Giovanna Aita2, Diana Robert2 and Mario Enrique Rodriguez Garcia3

1 Facultad de Ciencias Naturales y Matemáticas. Universidad de Ibagué. Ibagué Tolima, Colombia. luz.sanchez@unibague.edu.co

2 Audubon Sugar Institute. Louisiana State University Agricultural Center.

3 Centro de Física Aplicada y Tecnología Avanzada, Universidad Nacional Autónoma de México, Campus Juriquilla, Querétaro, México.

Manuscrito recibido el 19 de junio de 2013.

Aceptado el 11 de febrero de 2014.

ABSTRACT

Wet chemical analysis was used to determine carbohydrate structural contents, as well as ash and extractive contents on four Guadua Angustifolia Kunth forms (f. Cebolla, f. Macana, f. Rayada Amarilla and f. Castilla) with two different growth ages (young and mature). Soluble and insoluble fiber content was determined by using AOAC 985.29 method. Bending tests were conducted in a universal testing machine following ASTM D143 standard method in order to determine modulus of rupture (MOR). Finally, a correlation between contents of chemical compounds and bending behavior (MOR modulus) was carried out with SPSS Statistical Package, version 7.0, obtaining Pearson's coefficient correlation and showing the relationship between soluble fibers and bending response for mature Guadua culms.

Key words: bamboo culms, Chemical composition, Fiber Content, Modulus of Rupture, Mechanical properties.

RESUMEN

Mediante un análisis químico, se determinó el contenido de carbohidratos estructurales, contenido de cenizas y el contenido de extractivos de cuatro formas de Guadua Angustifolia Kunth (f. Rayada Amarilla, f. Macana, f. Cebolla y f. Castilla), en dos edades de crecimiento diferente (joven y madura). Se determinó el contenido de fibra soluble e insoluble mediante el método oficial AOAC 985.29. Se realizaron ensayos de flexión, siguiendo el método estándar ASTM D143, para determinar el módulo de ruptura (MOR) en las cuatro variedades de Guadua. Por último, se realizó una correlación mediante el paquete estadístico SPSS versión 7, entre el contenido de compuestos químicos y la respuesta de flexión, obteniendo el coeficiente de correlación de Pearson. Se encontró una correlación entre el contenido de fibra soluble e insoluble y la respuesta de flexión (MOR) en las Guaduas con mayor edad de crecimiento (maduras).

Palabras clave: tallos de bambú, composición química, contenido de fibra, módulo de ruptura, propiedades mecánicas.

INTRODUCTION

Bamboo is a fast growing plant (Porterfield, 1928; Liese and Hamburg, 1987), which grows naturally in all continents except Europe; however, most species are found in Asia Pacific and South America (Liese and Hamburg, 1987; Bystriakova et al., 2003; Chaomao et al., 2004). Some species can tolerate temperatures between 40 °C and 50 °C, whereas others can withstand snow or even temperatures of severe frost. Bamboo plays an essential role in the daily lives of millions of people in subtropical and tropical regions; even in some countries like Japan, bamboo has become an important natural material and it is widely used for many purposes. There are many bamboo species; one of the most important species that grows in Central and South America is called Guadua; this bamboo species is higher and thicker than Asian bamboo species.

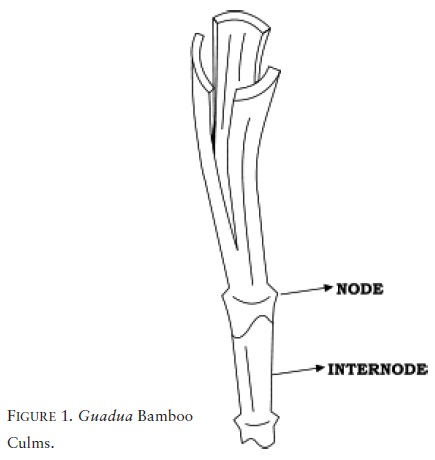

All bamboo species are composite natural materials, whose culms are a vertical consecutive arrangement of nodes and internodes and their properties are mainly determined by their anatomy and chemical composition (Liese and Hamburg, 1987; Ghavami and Marinho, 2005). The total bamboo culm comprises about 50% parenchyma, 40% fibers, and 10% conducting tissue (Liese, 1998), some percentage variations exist according to species, however, all of them have a unique distribution pattern within a culm. The distribution pattern consists of long-fiber aligned cellulose embedded into a lignin and hemicellulose matrix; these fibers do not have a homogenous content within the bamboo culm and it has been recorded that the fibers increase from the inner to the outer wall (Grosser and Liese, 1971), as well as from bottom to top and this distribution affects the mechanical behavior (Mohan and Mohana, 2007; Gyansah et al., 2010). It is well known that the fibers in Asian bamboo culms are grouped into cup shapes of around 1,5 mm to 4,5 mm-long conductive tissue (Porterfield, 1928). This arrangement is quite characteristic of various bamboo species, including Guadua. Knowledge of Asian bamboo fibers has permitted using these fibers mainly in pulp paper and textile industries (Ning y Yang, 2007; Oda, 2003; Hammett et al., 2005); nevertheless, nowadays bamboo fibers have become an important alternative in the research of reinforced composite materials with natural fibers (Ghavami, 2005). That knowledge permits finding in this plant a good material for several necessities like housing, food, furniture, toys, apparel, and paper, among others.

The useful life of bamboo as a plant is around three years and it is possible to find different applications, which are correlated with its age. Young culms are commonly used in food, while the older bamboo culms are used as construction building material (Van der Lugt et al., 2006), but in some applications such as textile, pulp paper, and handicrafts among others, bamboo culm age does not matter. Another important aspect to determine uses for bamboo species is related to their chemical composition. Fiber content and chemical composition has been studied on Asian and Japanese bamboo species and their variation with age and height have also been determined by different authors (Liese and Weiner, 1996; Low et al., 2006; Lybeer and Koch, 2005) and these studies have permitted to consider this type of bamboo as an alternative in biomass research and its application (Scurlock et al., 2000). Despite, all the information about Asian and Japanese bamboo species, Guadua has not been studied in detail and no reports exist of its chemical composition or its mechanical behavior.

OBJETIVE

The objective of this work is to present a complete chemical composition of four Guadua bamboo culms to increase future research areas with this kind of bamboo. Moreover, the present work seeks to provide results from a regression analysis between chemical composition and bending behavior.

MATERIALS AND METHODS

Description of samples

Bamboo samples came from an experimental field located in Armenia, Quindío (Central region of Colombia). All the specimens were oven dried at 40 °C for 8 h to reduce moisture content and decrease microorganism proliferation. The culms of these kinds of bamboo are hollow in the center and the distance between the internal to external wall is on average 1,5 cm; the Guadua bamboo culms are separated by nodes and internodes, as shown in figure 1. In this work, bamboo samples were taken from the bottom culm and were classify as mature for culms with 4 years and young for culms with 2 years.

Wet chemical composition analysis

All bamboo samples were analyzed by using standard biomass analysis by the National Renewable Energy Laboratory (NREL) with laboratory analytical procedures (LAPs) for whole biomass analysis, as listed:

• NREL/TP-510-42620 Preparation of Samples for Composition Analysis

• NREL/TP-510-42619 Determination of Extractives in Biomass

• NREL/TP-510-42622 Determination of Ash in Biomass

• NREL/TP-510-42618 Determination of Structural Carbohydrates and Lignin in Biomass

US National Institute of Standards and Technology (NIST) Bagasse Standard Reference Material # 8491 was analyzed with each batch of bamboo samples, as a quality-assurance reference for determination of extractives, lignin, and carbohydrates. Aqueous and ethanolic extractions were performed in duplicate on the milled, homogenized samples. Each extractive-free sample was analyzed in duplicate for lignin and carbohydrate content, giving a total of four separate determinations for each bamboo sample. Direct measurement of the protein content in these samples was not performed, but the protein content can be estimated from the nitrogen elemental analysis (Phillips,1939) and varies only slightly with age in the range of 1,4% - 3,8%

Soluble and Insoluble Fiber content

Insoluble fiber determination was performed by using the standard Method AOAC 985.29 (AOAC, 2000). All measurements were done in triplicate.

Bending test

The bamboo samples were tested by following the ASTM D143-94 (ASTM, 2007) standard test method, modified accordingly, to accommodate the specific characteristics of the bamboo specimens, in a universal machine (INSTRON 4401). The load was applied on the transverse surface with a crosshead speed of 0,5 mm/min (Fig. 2). The specimens were cut as strips and its size was set at 160-mm length and 10-mm width, and thickness was determined with each culm thickness. The Modulus of Rupture (MOR) was obtained in triplicate for each bamboo sample.

Regression

Statistical analysis was performed with the STATGRAPHICS 5.1 Plus Statistical Package to obtain Pearson's correlation coefficient. Five variables were used and the multiple linear regression analysis was made among Insoluble Fiber, Soluble Fiber, Lignin, Cellulose, and Hemicellulose with the MOR.

RESULTS

Chemical composition

Table 1 shows the complete wet chemical analysis (soluble fiber) of all the Guadua bamboo specimens in mature and young culms. Total mass for all specimens is close to 90% or above, indicating that the analysis was complete and no significant biomass fractions were lost. The direct protein measurement was not performed, but protein content could be obtained by nitrogen element analysis and did not have significant variation (Phillips, 1939). Higuchi (1957) measured chemical composition for different kinds of Asian bamboos and found a similar chemical composition to Guadua bamboo chemical composition. Scurlock et al. (2000) reported a wet chemical composition analysis for a Japanese bamboo; these results are close in value to Guadua bamboo chemical composition analysis.

Lignin content values for Guadua are between 23% and 27%; meanwhile, Scurlock reported a range between 24% and 37% for softwoods (Scurlock et al., 2000), suggesting that Guadua bamboo has similar physical properties and can be used as conventional softwood. On the other hand, a Cellulose content of 37% - 44% and a hemicellulose content of 13% - 20% for Guadua bamboo could be compared to cellulosic biomass feedstock with a content of 35% - 50% for cellulose and 10% - 40% for hemicellulose (McKendry, 2002). It placed Guadua bamboo as natural material comparable to biomass feedstock in which its high cellulose/hemicellulose content could be used for ethanol and paper production.

Soluble and Insoluble fiber

Soluble and Insoluble fiber are the total fiber content and each is made up of complex carbohydrates, including cellulose, hemicellulose, and lignin (Selvendran, 1984). The fiber content was determined for all samples in mature and young culms. Figure 3 shows the insoluble and soluble total fiber content per specimen. It is possible to see that for all samples the main fiber content is insoluble fiber.

From the ANOVA statistical analysis, it is possible to establish that the insoluble and soluble fiber content for some varieties do not have significant differences. It is also possible to see that, in general, the insoluble fiber content exhibit a small decrease in samples with age, while soluble fiber exhibit a high increases with age. Total fiber content is an important test that provides information related to each Guadua bamboo variety and it is possible to establish the potential uses of this kind of bamboo. The results shown in this figure correspond to five measurements per specimen.

Bending test

Failure of test specimens is associated to a common failure mode known as local crushing and this was identified in all specimens tested (Chung and Yu, 2000). Typical load deflection curves were obtained, as shown in figure 4.

Table 2 shows the MOR in each bamboo sample for mature and young culms; from the ANOVA statistical analysis, it is possible to establish that the MOR does not have significant differences in young culms. Decreased MOR with age is noted in most varieties; this decrease is above 50%. These results agree with those reported by Correal and Arbelaez (2010) who found that for Guadua Angustifolia Kunt all mechanical properties including MOR have a correlation with age; they showed that these mechanical properties decrease in old culms. In addition, variations in the chemical components could be correlated to the mechanical behavior (Sánchez-Echeverri et al., 2010). The results shown in Table 2 correspond to three measurements per specimen.

Correlations

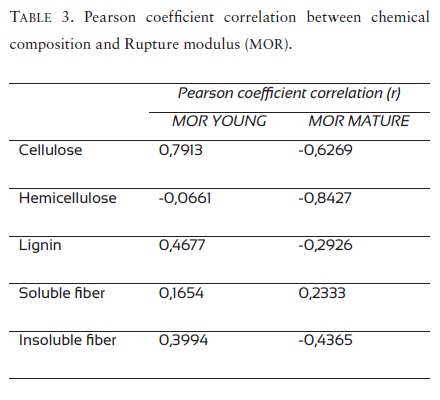

Table 3 shows Pearson's coefficient correlation between MOR and the chemical composition in each Guadua bamboo sample for mature and young culms. The bold number shows a highly significant Pearson's coefficient correlation with p < 0,05. These results indicated that only exists an inverse correlation among MOR and cellulose and hemicellulose content for mature culms, while young culms do not have any correlation. Genet, et al. (2005) related cellulose content with mechanical properties, they found a positive correlation between tensile strength and Cellulose, however; they did not separate Cellulose and Hemicellulose and that positive correlation is influenced by the high stiffness in the longitudinal direction of the cellulose fibers (Persson, 2000), nevertheless; there are no published data about bending behavior and chemical compounds content for transversal direction for those materials or Guadua. It is interesting that results shown here are against others previously published, despite there are not results presented specifically for Guadua, some results for materials composed mainly by cellulose, hemicellulose and lignin (fibrous ligno-cellulosic materials) as leaves and roots increase their mechanical properties with cellulose content (Angeles et al., 2010; Genet et al., 2005).

Figure 5 shows cellulose, hemicellulose content, and MOR for mature Guadua bamboo culms. The MOR is influenced by content of cellulose and hemicellulose as expected in a composite material.

CONCLUSIONS

Wet chemical analysis (soluble fiber) for Guadua bamboo culms can be compared to results found for other kinds of Asian and Japanese bamboos, which currently have important applications. Although there is a variation in both soluble and insoluble fiber content with age, the variation in insoluble fiber is not significant, however; for the two Guadua ages analyzed, the main fiber content is insoluble fiber. The main chemical compounds that have an influence in the mechanical properties are Cellulose, Hemicellulose and Lignin whose elastic properties were described by Davalos-Sotelo (2005); for Guadua these were the main compounds found.

The hemicellulose and cellulose content has inverse proportionality with MOR for mature culms. As is well known, Cellulose fibers has a longitudinal orientation and hence Hemicellulose, which is a polysaccharide linked to cellulose also has the same general orientation; the distribution ratio in these two principal compounds will have an effect in the bending behavior which was tested in transversal direction. The inverse correlation could be explained due the low stiffness strength of cellulose and hemicellulose on radial direction (Persson, 2000), hence a high content of both components results in a low MOR. Knowledge of chemical and mechanical properties and their relationship in Guadua bamboo is a base to develop studies with this plant and generate potential applications.

REFERENCES

AOAC-2000 Official Methods of Analysis of the Association of Official Analytical Chemists, 17th ed. Method 985.29. [ Links ]

Angeles, G., M. Lascurain, R. Davalos-Sotelo, R.P. Zarate-Morales and F. Ortega-Escalona. 2013. Anatomical and physical changes in leaves during the production of tamales. American Journal of Botany 100(8):1509-1521. [ Links ]

ASTM D143-94. 2007. Standard Test Methods for Small Clear Specimens of Timber. ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA, 19428-2959 USA. [ Links ]

Bystriakova, N., V. Kapos, I. Lysenko and C.M.A. Stapleton. 2003. Distribution and conservation status of forest bamboo biodiversity in the Asia-Pacific region. Biodiversity and Conservation 12(9):1833-1841. [ Links ]

Chaomao, H., H. Jizhen, Z.Guoxue and Y. Yuming. 2004. Studies on the present situation and prospects of bamboo diversities and its sustainable development in China. World Forestry Research 2004(1):51-54 [ Links ]

Chung, K.F. and W.K. Yu. 2002. Mechanical properties of structural bamboo for bamboo scaffoldings. Engineering Structures 24(4):429-442. [ Links ]

Correal, J.F. and J. Arbealez. 2010. Influence of age and height position on Colombian Guadua angustifolia bamboo mechanical properties. Maderas. Ciencia y tecnología 12(2):105-113. [ Links ]

Davalos-Sotelo, R. 2005. Determination of elastic properties of clear wood by the homogenization method in two dimensions. Wood Science and Technology 39:385-417. [ Links ]

Genet, M., Stokes, A., Salin, F., Mickovski, S.B., Fourcaud, T., Dumail, J-F. van Beek., R. 2005. The influence of cellulose content on tensile strength in tree roots. Plant and Soil 278(1-2):1-9. [ Links ]

Ghavami, K. 2005. Bamboo as reinforcement in structural concrete elements. Cement and concrete composites 27(6):637-649. [ Links ]

Ghavami, K. and A.B. Marinho. 2005. Propriedades físicas e mecânicas do colmo inteiro do bambu da espécie Guadua angustifolia. Revista Brasileira de Engenharia Agrícola e Ambiental 9(1):107-114. [ Links ]

Grosser, D. and W. Liese. 1971. On the anatomy of Asian bamboos, with special reference to their vascular bundles. Wood Science and Technology 5:290-312. [ Links ]

Gyansah, L., A.S. Akinwonmi and M. Affam. 2010. The fracture behaviour of fresh bamboo under uniaxial compressive loading condition. Research Journal of Applied Sciences, Engineering and Technology 2(8):720-726. [ Links ]

Hammett, A.L., L. Robert, L. Youngs, X. Sun and M. Chandra. 2005. Non- wood fiber as an alternative to wood fiber in China pulp and paper industry. Holzforschung 55(2):219-224. [ Links ]

Higuchi, H. 1957. Biochemical studies of lignin formation, III. Physiologia Plantarum 10(4):633-648. [ Links ]

Liese, W. 1998. The anatomy of bamboo culms, Technical report. International network for bamboo and rattan (INBAR). BRILL. 208 p. [ Links ]

Liese, W. and F.R.G. Hamburg. 1987. Research on bamboo. Wood Science and Technology 21(3):189-207. [ Links ]

Liese, W. and G. Weiner. 1996. Ageing of bamboo culms, A review. Wood Science and Technology 30(2):77-89. [ Links ]

Low, I.M., Z.Y. Che and B.A. Latella,. 2006. Mapping the structure, composition and mechanical properties of bamboo. Journal of Material Research 21:1969-1976. [ Links ]

Lybeer, B. and G. Koch. 2005. A topochemical and semiquantitative study of the lignifications during ageing of bamboo culms (phyllostachysviridiglaucescens). IAWA Journal 26(1):99-109. [ Links ]

McKendry, P. 2002. Energy production from biomass (part 1): overview of biomass. Bioresource Technology 83(1):37-46. [ Links ]

Mohan, K.M. and K. Mohana. 2007. Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Composite Structures 77(3):288-295. [ Links ]

Ning, L. and B. Yang. 2007. Characteristics of bamboo fiber and its application. Progress in Textile Science & Technology 2007(3):15-17. [ Links ]

Oda, T. 2003. Yam and cloths made mainly from bamboo sheaths and methods for manufacturing the same, United States Patent application. Publication number US7060211 B2, Application number US 10/222,839. [ Links ]

Persson, K. 2000. Micromechanical modeling of wood and fiber properties. Ph.D. dissertation, Lund University, Lund-Sweden. [ Links ]

Phillips, M. 1939. Studies on the quantitative estimation of lignin. IV Effect of certain proteins on the determination of lignin by the fuming hydrochloric acid method. Journal of the Association of Official Agricultural Chemists 22: 422-427. [ Links ]

Porterfield, W.M. 1928. A study of the grand period of growth in bamboo. Bulletin of the Torrey Botanical Club 55(7):327-405. [ Links ]

Sánchez-Echeverri, L.A., M. Contreras-Padilla and M.E. Rodriguez-Garcia. 2010. A correlation between soluble and insoluble fiber with the elastic modulus in four varieties of bamboo. Mater. Res. Soc. Symp. Proc. 1277. Materials Research Society Symposium Proceedings 1277 p: 46-51. [ Links ]

Scurlock, J.M.O., D.C. Dayton and B. Hames. 2000. Bamboo: an overlooked biomass resource?. Biomass and Bioenergy 19(4):229-244. [ Links ]

Selvendran, R.R. 1984. The plant cell as a source of dietary fiber: Chemistry and structure. American Journal of Clinical Nutrition 39(2):320-337. [ Links ]

Van der Lugt, P., A.A.J.F. Van de Dobbelsteen and J.J.A. Janssen. 2006. An environmental, economic and practical assessment of bamboo as a building material for supporting structures. Construction and Building Materials 20(9):648-656. [ Links ]

Nota

Este documento se debe citar como: Sánchez-Echeverri, L.A., G. Aita, D. Robert and M.E. Rodríguez-García 2014. Correlation between chemical compounds and mechanical response in culms two different ages of Guadua angustifolia Kunth. Madera y Bosques 20(2):87-94.