Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Madera y bosques

versión On-line ISSN 2448-7597versión impresa ISSN 1405-0471

Madera bosques vol.17 no.2 Xalapa jun. 2011

Artículos de investigación

Properties of laminated curves manufactured with steamed veneers from fast-growth tropical wood in Costa Rica

Propiedades de curvas laminadas construidas con chapas vaporizadas con maderas de árboles de plantaciones de rápido crecimiento

Mahyar Shirazinia1, Róger Moya1 y Freddy Muñoz1

1Escuela de Ingeniería Forestal, Instituto Tecnológico de Costa Rica, Apartado 159-7050, Cártago, Costa Rica. c.e.: osemun@hotmail.com, rmoya@itcr.ac.cr, fmunoz@itcr.ac.cr.

Recibido el: 11 de agosto de 2009

Aceptado el: 09 de mayo de 2010

Abstract

The laminated curves (LC) made with steamed veneers make possible to obtain smaller curvature radius (RC) than when this process is not applied. This research shows the behavior of Alnus acuminata, Tectona grandis, Gmelina arborea, Terminalia oblonga and Swietenia macrophylla -all originated from fast growth plantations- in the manufacture of laminated curves with radios of (4, 6, 8, 10, 12 and 14) cm. The results show that it was possible to reach RC of 4 cm in all species except for T. grandis in which it was only possible to reach RC of 6 cm. The steam process increased the moisture content of the veneer in a range from 3,3% to 10,2%. The adhesive makes possible that bondline for RC smaller than 10 cm do not open, while for RC of 12 and 14 cm the bondline tends to get open (1% as maximum) for all the species. Nevertheless, the bondline opening gets stabilized 4 days after it is fabricated. The veneer deliminations occurred mainly in the interval of RC from 4 to 8 cm. The highest delaminations values take place in the T. grandis and T. oblonga. The shear stress values varied from 7,5 MPa to 11,2 MPa in all tested species. The aging test of adhesive did not alter significantly the shear stress, but delaminating due to the failure of the bondline increased in all species.

Keywords: Laminated curves, delamination, steamed veneers, shear stress, curvature radius.

Resumen

Las curvas laminadas fabricadas con chapas vaporizadas permiten obtener radios de curvatura más pequeños que cuando no se aplica este proceso. En este estudio, se presentan el comportamiento de madera de Alnus acuminata, Tectona grandis, Gmelina arborea, Terminalia oblonga, Alnus acuminata y Swietenia macrophylla provenientes de plantaciones de rápido crecimiento en la fabricación de curvaturas con radios de (4, 6, 8, 10, 12 y 14) cm. Fue posible obtener radios de curvaturas de 4 cm, a excepción de T. grandis de donde solo fue posible obtener radio de 6 cm. El proceso de vaporizado aumentó el contenido de humedad de la chapa en un rango de 3.3% a 10.2%. El adhesivo permite que el radio de la curva fabricada se mantenga en radios menores a 10 cm y en radios de 12 cm y 14 cm la curva tiende a abrirse (máximo 1%), para todas las especies, no obstante, la abertura se estabiliza al día 4 luego de fabricada. Las delaminaciones de las chapas se producen principalmente en los radios de 4 cm a 8 cm y se presentan con mayor incidente en la T. grandis y T. oblonga. La resistencia en cizallamiento de 7,5 MPa-11,2 MPa y no se alteró al someter a pruebas de envejecimiento, pero hay una mayor delaminación en todas las especies.

Palabras clave: Curvas laminadas, delaminación, chapas vaporizadas, cizallamiento, radio de curvatura.

Introduction

Laminated curves (LC) are commonly built with veneers of a uniform thickness between 2 mm and 4 mm, which allows a better bending. For this veneer curved technique, each laminate is glued and placed in the mold, then pressure is applied to join the set of laminates until the adhesive hardens. In this way it is obtained smaller RC than the ones that could be got with a solid piece of wood (Stevens and Turner, 1970). The laminated curves are found in diverse uses, especially in the construction of boats or sailboats and furniture (Wu et al., 1999).

Each wood species that is put under the bending will behave in a different way to the RC that is applied (Wagenführ et al., 2006), which depends on many intrinsic properties of the wood, such as its anatomical properties of bending or spiral grain among others. (Stevens and Turner, 1970). The steam application plasticized wood making it flexible in order to get smaller RC during bending (Wu et al., 1998; Lam, 2001). The applied technique to solid wood to obtain curves where wood is firstly steamed, then curved and pressed (Peck, 1955). Wood plasticizing is consequence of its inner temperature increment and its thermal linear coefficient expansion; as a result it allows a greater flexibility in its structure. A widely accepted hypothesis is that the softening of lignin largely dominates the effect of temperature and moisture (Kärenlampi, 2005).

The lignin and the hemi-cellulloses are the polymers more affected by the temperature and humidity produced by the steam during the steaming (Cousins, 1977; Kärenlampi, 2002). The softwood and hardwood of tropical climates have been par excellence the species widely used in the manufacture of curves with solid wood. However, in recent years the wood shortage of high commercial value and natural durability has allowed that species with less commercial value as well as wood from fast growth plantations be preferred in the wood industry (Wu et al., 1998). In Costa Rica, Teak (Tectona grandis), Birchwood (Gmelina arborea), Yellow-wood (Terminalia oblonga), Aliso (Alnus acuminata), and Mahogany (Swietenia macrophylla) are some of the most important species in reforestation and raw material for wood industry.

T. grandis, and G. arborea, were introduced in Costa Rica, are species of great potential due to their adaptation easy to diverse environmental and site conditions (Moya and Tomazello, 2008; Moya and Pérez, 2008; Piotto et al., 2003) and together with S. macrophylla have their importance in the national and international market of tropical woods. The native species like A. acuminata and T. oblonga have the potential for commercial reforestation because of their excellent growth in highlands, besides that, they are well known species in the national market.

On the other hand, the adhesives polyurethane type has been used lately in the construction of structural wood elements (Vick and Okkonen, 1998, 2000; Widsten et al., 2006). However, the application of this type of adhesive in tropical wood steamed veneers for the manufacture of laminated curves is not well known yet.

The present work, under the concept to innovate with new wood products from fast growth species in tropical regions, will evaluate the behavior of 5 species used in the commercial reforestation of Costa Rica (Tectona grandis, Gmelina arborea, Swietenia macrophylla, Alnus acuminata, and Terminalia oblonga) in the development of laminated-steamed curves with adhesive of type one-part polyurethane, establishing the minimum RC, moisture increment of the steamed veneer, opening percentage (OP) and delamination percentage (pd) of the veneers after vacuum and pressure condition. Also shear stress in the bondline and delamination before and after submitting glued samples to aging in every tested species.

Methodology

Wood samples: Five species were used, T. grandis, G. arborea, S. macrophylla, T. oblonga and A. acuminata. Four of them, used in low heights reforestation zones, and Alnus acuminita used in the high zones. The plantations age rank oscillates between 9 to 10 years, and plantation density between 338-575 trees per hectare. The plantation conditions and the forestry management of the plantations are shown in table 1. Initial spatial arrangement was 3 m x 3 m (1110 n/ha) in all species.

Veneers preparation: Nine trees were selected to represent all the diameter range in the plantation: thinner, average and big diameter. From each one of selected trees, logs of the base of the tree were cut, obtaining veneers 3 mm thick by peeling process, then they were dried to 9,5%-13,3% of moisture content (Table 2). The selected veneers were free of knots and fungi presence. Then they were conditioned at 22 °C and 60% relative humidity during several weeks until they reached a moisture content of 11%-12%. Other veneers samples were also cut with the purpose to determine the initial wood moisture content (MC) without steaming process. From each tree a disc at DBH was cut and then, from each disc it was obtained a central radial strip 3 cm wide through pith from north to south direction. Specific gravity and pH were measured on these samples according with ASTM D-2395 (ASTM 2003a) and D-2395 (ASTM, 2003a) respectively. Another log was cut between the DHB and 2,5 m of height. Then, from this log a central block 6 cm thick was obtained. From the block (5 x 5 x 76) cm samples were obtained to determine the modulus of elasticity (MOE) and modulus of rupture (MOR) in static bending at 12% or air-dried, according with D-143-91 (ASTM, 2003b).

Mold construction: Round segments were drawn with radius of (4, 6, 8, 10 and 14) cm on a plywood laminate. A 180° bent angle of curvature was drawn. After that, 4 laminates 1,5 cm-thick were joined with PVA to give the molds the necessary height (Figure 1a). Once the adhesive was hardened both the mold and against-mold were sandpapered in order to get a finished surface and to calibrate their RC. The mold consists of the following parts: mold, against-mold, support and base (Figure 1a).

Veneers Steaming Process: The steam chamber (200 cm x 30 cm x 30 cm) was constructed with wood, complemented with an electrical heater (non ferrous material) with capacity for 19 liters of water which will be boiled to generate the steam inside the chamber (Figure 2b). The temperature within the chamber can reach 95 °C. Before steaming process, the chamber was previously heated for 1 hour, after the veneers were introduced and steamed during 3 hours.

Process of gluing and bending the veneers: It was used as an adhesive of type one-part polyurethane Titebond®, whose main characteristics are: applicable to wood with moisture content between 15%-40%, density of 1,15 g/cm3, solids percentage 100%, ignition point of 93 °C, joint time of 20 minutes at 21 °C and 50% of relative humidity. The thickness and moisture content of veneers were 3 mm and 9.5%-13.3% respectively. Immediately after the veneer steamed process, the adhesive was applied quickly in order to keep wood flexibility. The amount of adhesive applied was 200 g/m2 on one face of the veneer by using a hand roller. A set of 7 veneers were glued to make a curve (23-24) mm thick, then the set of veneers was bended and pressed in the mold. The press time was 4 hours at room temperature (21 °C). A total of 116 curves were fabricated, 4 replicates by each RC and by each specie (5 species x 6 RC x 4 repetitions). For the evaluation of the laminated curves, several parameters were defined to establish bend susceptibility of veneers, such as:

Minimum RC: This parameter was established during the bend and press process. It is defined as the radio where each one of the veneers were properly bended and did not present failures such as check, shear, twist or tensile. Once the press was retired, the excess of adhesive was removed from the laminated curves and sandpapered with the purpose to obtain clean surfaces. Later, the evaluation of the laminated curves was made considering the parameters below:

Increase on the moisture content (MC): Before steaming process, 4 sample veneers were chosen randomly in order to determine the MC of the wood. Right away after removing the laminated curve from the mold, its MC was evaluated. Two samples of (2,5 cm long) were cut from both extremes of the LC. The MC was determined following the standard D4442 (ASTM, 2003c).

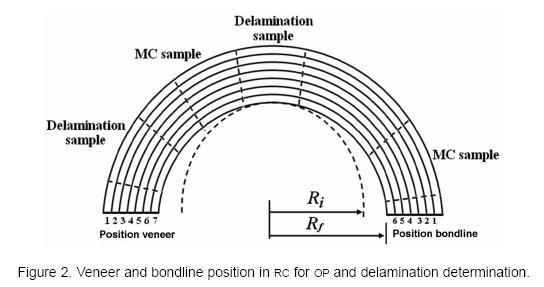

Opening Percentage (OP): It is defined as the difference between initial radius and final radius expressed in percentage of the initial radius (Figure 2) (Equation 1). The opening percentage was daily measured from 0 to 8 days after press process.

Percentage of delamination (DP): It is defined as the separation between veneer and bondline and also adjacent. The total delamination in laminated curves are counted and they are calculated as percentage of total bondline in the laminated curve. 2 samples of 7,5 cm long were extracted, one located in the central part of the laminated curve, and the other one in the lateral side. All of the bondline were numbered from 1 to 6, locating the bondline 1 in the outside of RC, while number 6 at the most internal RC of the laminated curve (Figure 2). When present, the position of delamination was identified with both numbers veneer and bondline; they were classified as in "dry" condition. Afterwards, all the samples were exposed to vacuum-pressure (Va-Pr) according with D2559-76 (ASTM, 2003d), and denominated like emptiness- pressure (VPR). Delamination presence was evaluated and localized again in bondline and veneer position.

Evaluation of adhesive in shear stress and aging test: The adhesive (bondline) was evaluated in shear stress test as in samples with and without aging or accelerated cyclic exposure, with the purpose to evaluate the adhesive behavior toward the species. Additionally for this test 5 samples of 2 cm x 5 cm x 30 cm were prepared according to D-905-03 (ASTM, 2003e). Three 6,3 cm long samples were cut out of the before mentioned specimens. The samples were divided in two groups of equal amount. The first half was used to determine the resistance to shear stress in the bondline number 4 which is located in the central part. This test was denominated shear stress in the dry condition (SH-Dry). The other half of the specimens was used to measure the shear stress after aging. After aging process, the shear stress was measured in bondline number 4 and this test was denominated as shear stress in humidity conditions (SH-Wet).

Results

Bending susceptibility

The table 2 shows some physical and mechanical properties of the species studied and the parameters evaluated in laminated curves. In A. acuminata, G. arborea, S. macrophylla, and T. oblonga it was obtained the proposed minimum RC (4 cm), while with T. grandis, the minimum RC just reached 6 cm. The MC before steaming process was smaller than 13% for all species. MC increased in all species after steaming, however, in T. grandis and S. macrophylla the increment was less than in the others. And also, these species were the ones with the highest specific gravity. Related to the behavior of the different species, it was observed that just A. acuminata was susceptible to produce failures in the veneers after the bending process. A 2,6% of the total veneers (A. acuminata) showed failures in some sections, and the veneers outside RC were the most susceptible to have failures because these are the ones exposed to higher tension efforts. For the other species, it was not observed failure problems in veneers.

Opening percentage of laminated curves

The RC (4, 6, 8 and 10) cm treated in this study did not show any opening of RC after 8 days of having been made the laminated curve. While in RC 12 cm and 14 cm there were found opening problems, with the exception of A. acuminata and G. arborea for their OP was constant (0,3%) in the case of RC 12 cm. On the other hand, for the same species but in RC 14 cm the OP for A. acuminata was constant during the period of 8 days (Figure 3a) and in the case of G. arborea the OP value stabilized on the second day reaching approximately 0,08% (Figure 3b). For the rest of the species, it was observed that the OP in both RC (12 cm and 14 cm) started stabilizing in a maximum period of 4 days (Figure 3a and 3b). According to these results we might say that the adhesive one part polyurethane hardens completely after 96 hours, from that moment on the OP variation pattern keeps constant for all the species. It is important to notice that in RC smaller than 10 cm and RC of 14 cm for A. acuminata and G. arborea, the laminated curves do not lose their RC that is to say their OP is equal to 0%. In the case of RC 12 cm for T. oblonga, S. macrophylla and T. grandis, after removing the molding pressure, the curvature presented small openings (Figure 3a).

Although openings of the curvature appear with time, the measured OP value was always less than 1%, being a little significant percentage. The highest OP value reached was 0,79% in RC of 12 cm for T. grandis; which means that the increment in the radius was 0,75 mm. Then, in RC 14 cm for T. grandis and T. oblonga the highest values were measured again being 0,17% for both species. Variance analysis (ANOVA) showed that in spite these species displayed the highest OP values; they were not statistically different from those obtained for G. arborea, S. macrophylla or A. acuminata in the same RC. In relation to the OP vs. time, the ANOVA also showed that there is no significant difference between OP values in measurement days 0, 2, 4, 6 and 8 for the 5 species in the RC 12 cm or 14 cm.

Veneer Delamination

The highest DP value obtained was in G. arborea laminated curves, that is to say 1,9%, T. oblonga was the second highest with 1,5 %, and subsequently followed by A. acuminata, S. macrophylla, and T. grandis, with values of 0,9%, 0,6% and 0,45% respectively (Figure 4a). DP increased with vacuum-pressure (Va-Pr) treatment (Figure 4a). Although T. grandis presented the lowest values of DP after curving veneers in dry condition, it was the species with the highest DP values after applying vacuum pressure treatment (Figure 4a). It was determined that 17,2% (336 veneers analyzed) of T. grandis presented delamination problems, followed in descendant sequence by T. oblonga, which presented similar values to T. grandis. On the other hand, G.arborea, S. macrophylla and A. acuminata obtained lower delamination values, in Va-Pr condition (Figure 4a).

The lowest values of DP were found in A. acuminata in dry condition in different RC and veneer position of the laminated curve, finding delaminations in RC 4 cm and 6 cm (Figure 5a). These delaminations were located at veneers 1, 2, 4 and 5 of laminated curve for Va-Pr condition. The DP for A. acuminata varied from 12,5% to 37,5% (Table 3). Another species with low DP was S. macrophylla. Although, the delamination were found in all RC for this species (Figure 5b), the highest value was found in RC 4 cm and located in the tension zone of the laminated curve, specifically in the veneer positions 5, 6 and 7 (Table 3). The DP for S. macrophylla varied from 12,5 to 50,0%. The species with higher DP values, compared with A. acuminata and S. macrophylla, was G. arborea, however it obtained lower values than T. oblonga and T. grandis. RC 12 cm and 14 cm were the radius with fewer problems of delamination for most of the species except for T. grandis, while the highest DP values appeared in RC 4 cm and 10 cm, mainly in Va-Pr condition (Figure 5c) and located in the veneer positions 1, 2, 4, 5, and 7 of the laminated curve (Table 3). On the other hand, T. oblonga and T. grandis were the species with highest values in delamination. These values were measured in RC 4 cm and 6 cm respectively. After that, DP in RC 12 cm varied from 5,4% to 23,2% (Figure 5d and 5e). In the case of T. grandis the highest delamination values were found in RC 6 cm specifically in veneers position 3 and 6 for laminated curved in Va-Pr condition (Table 3).

Shear stress in bondline

The figure 4b shows the laminated curves shear stress in bondline before (SH-dry) and after aging process (SH-wet). In the case for samples SH-dry the shear stress varied from 7,6 MPa to 9,7 MPa in for all wood species. S. macrophylla and T. grandis were the species of greater resistance and A. acuminata had the lowest value. Shear stress values in T. oblonga and G. arborea were intermediate values. Although, there were differences in resistance values among the species, ANOVA analysis showed that statistical difference (P- valor < 0,05) was only found between S. macrophylla and A. acuminata and between T. grandis and A. acuminata (Figure 4b). In SH-wet condition data varied from 4,8 MPa to 11,9 MPa and it was determined that the maximum sharp force increased in relation to the SH-dry condition for all species (P-valor < 0,05), with the exception of the A. acuminata (Figure 4b). However, these values were not statistically significant (P-valor<0,05).

The only exception was A. acuminata that displayed inferior statistical values in SH-wet condition than in SH-dry condition (Figure 4b). Shear stress values for T. grandis, S. macrophylla, T. oblonga and G. arborea were not significantly different in SH-wet condition (P-valor<0.05). The A. acuminata was the species that statistically showed inferior resistance compared to the rest of the species (Figure 4b).

Discussion

Using steamed veneer obtained from the 5 studied species the results obtained in RC in most of the cases were even inferior to 6 cm (Table 2). According to the reports from Forest Products Research Laboratory of USA for these species or others with the same genus using veneer 2 mm-3 mm thick they got superior values to those obtained in this study (Peck, 1955). For example, for T. grandis, the FPRL reports minimum RC of 14.7 cm while our minimum RC was 6 cm using the same species. In T. ivorensis (the same genus that T. oblonga and T. amazonia but with a lower density) the FPRL reports minimum RC of 19,1 cm in comparison with RC of 4 cm obtained in this study. On the other hand, in Alnus glutinosa, same genus as Alnus acuminata, FPRL reports 18.8 cm as the minimum RC, which is bigger than minimum RC of 4 cm obtained in this study. Finally for the Swietenia genus, it is reported there are different ranges of radius from 14,7 to 23,6 cm, which are higher than the minimum RC 4 cm got in this study for S. macrophylla. According to a study carried out in Mexico with 34 tropical species with specific gravity between 0,19 and 0,90, using not-steamed (just upgraded to 12% MC) 3 mm thick veneers, they found that only 3 tropical species (Ceiba pentandra, Pseudo-bobmbax ellipticum and Quercus sartorio) presented minimum RC from 6 cm to 4 cm (Martínez and Martínez, 2008), being these values similar to the ones obtained with the 5 species studied in this research. This demonstrates that the steam effect on the veneer allows more flexibility which results on smaller RC compared to veneer in natural condition that has not been plasticized with steam (Stevens and Turner, 1970). The steaming process, among other advantages in the manufacture process, allows using wood of lesser quality or with bad bending properties to be used as internal parts of laminated wood products with curved profiles (Peck, 1957).

The bending behavior in five species was very similar, since all species managed to reach the proposed minimum RC, the only exception was T. grandis which did not reach the minimum RC (Table 2), and this suggests that the degree of flexibility of steamed veneer obtained from the studied species is very similar. However, when analyzing the parameters DP, OP, Shear stress in bondline and MC, there are differences among these tropical species (Figures 3, 4a, 5 and Table 2). These differences could be explained as follow:

(i) Each species of wood is a complex matrix of polymers mainly composed by cellulose, hemicelluloses and lignin (Pereira et al., 2003), the proportion and morphological arrangement of these polymers differences occur between species of wood (Karenlampi, 2005). Other opinions, Cousins (1978) and Salem (1984) mention that when there is a higher moisture presence in hemicelluloses, the wood tends to plasticize and when there is higher presence of lignin and cellulose, the wood fibers tend to stiffen. Our view is that wood is a composite material which consists of cellulose that is the reinforcing fiber that gives it structure. Lignin is a matrix or natural adhesive that supports these reinforcing fibers and hemicelluloses are additives that improve links between cellulose and lignin, when this complex matrix of polymers is not only subjected to the steaming process for a increase the MC, but also it is exposed to a combination of time and temperature causing the wood to reach its glass transition temperature (Tg) and its structure begins the thermo-plasticization. The moisture decreases the energy of breaking bonds between hemicellulose, lignin and cellulose by modifying the value of wood elastic modulus (especially into radial and tangential direction), making it more flexible. The Tg is the point at which the elastic modulus (MOE) of viscoelastic materials, such as wood, is very low which means that fibers wood are more flexible or elastic.

Under the concept of viscoelasticity and rheology of the materials, crystalline or semi-crystalline polymers such as cellulose (Tg 60 °C - 70 °C) do not plasticize. The thermoplasticization occurs only in amorphous polymers such as lignin (Tg 65 °C at Fiber Saturation Point) and hemicellulose (Tg 50 °C - 55 °C at Fiber Saturation Point). According to Rice and Lucas (2003) there is still considerable controversy about the glass transition temperature of these polymers, due to the different testing procedures, pretreatments and methods of isolating the wood components and finally that the Tg depends on wood MC, for example the Tg for the lignin, hemi-celluloses and cellulose isolated from dry wood is (127-235) °C, (150-220) °C and (220-255) °C respectively, at 20% wood MC the Tg range for lignin is (72-128) oC, for hemicelluloses is (54-142) oC and for cellulose is (190-230) oC (Cornejo and Baettig, 2009). Therefore, it could be speculated that variations in the amount of these polymers within wood and the steam exposition, time and temperature affect the behavior of veneer bending. However, a chemical analysis and steaming to different times and temperatures ranges for the studied species was not made to correlate the Tg with elastic modulus.

(ii) Differences in anatomical structure could produce differences among wood species in bending properties. Hepworth et al. (2002) established that the variations in the resistance of the wood in hardwood species could be explained in the amount and frequency of the vessels and the fiber presence. They mentioned that a bigger diameter vessel has less capacity to absorb energy. Also, studies in Fagus sylvatica, Acer pseudo-platanus and Juglans nigra agreed with these and our own results. It was shown that the LC properties were related with anisotropy produced by the orientation of the cellular elements in the bending of those species (Wagenfuhr et al., 2006). Davies (1962) reviewed wood bending experiments carried out by the USDA Forest Products Laboratory, twenty-five hardwood species were tested and rated by the percentage of successful bends and it concluded, that in general, the ring porous woods yielded better results than the diffuse porous woods.

One important aspect to consider when steamed laminated curves are finally made is to stabilize its final MC to acquire dimensional stability, because that steaming process increased the veneers MC (Table 1).

The values obtained in static bending test and specific gravity showed the relationship between MOR and MOE with the bending properties of wood. T. grandis, for instance presented the highest values of MOE, MOR and specific gravity, followed by S. macrophylla and T. oblonga. It is important to note that this tendency was found properties of LC. The produced efforts in flexion and tension are associated with the flexibility of the wood (Wagenfuhr et al. 2006) and that these at the same time are associated to specific gravity values (Wu et al., 1998).

The highest values in MOE and MOR of T. grandis, indicate that this wood is quite rigid (Table 2), therefore it was not possible to achieve the proposed minimum RC with this specie, additionally T. grandis also had severe problems in OP and DP in RC 12 and 14 cm (Figure 3, Figure 4a). G. arborea and A. acuminata with the smallest values of MOE and MOR confirm that species with low values in the flexion parameters display better performance in the curved veneer. In the case of A. acuminata, the number of veneer failures in the laminated curves was higher, which could be linked to the inclined grain in wood, influenced by the mismanagement of prunings applied to the sampled plantations (Table 1).

The delaminations present in the LC were caused by loss of adhesiveness between the adhesive and the adherent in the bondline zone, which can be associated to anatomical factors or chemical incompatibility of some extractives with the adhesive or the pressing process (Wagenfuhr et al., 2006; Gardner, 2006). Besides the chemical incompatibility between wood and adhesives, other factors like the manufacture and shaped curves could also cause variation among species (Wu et al., 1999). Also, the fact that the bondline was submitted to two different type of stress, one located in the external part of the LC (tension stress) and the other in the internal zone under compression stress (Wu and Furuno, 1999), making the bonline susceptible to delamination.

The LC manufactured with Costa Rican fast growth tropical wood was not susceptible to delamination, considering that DP was less than 2% in the bondline (Figure 4a). However, the LC delaminations in SH-wet condition increased significantly in all species (Figure 4a). But shear stress values were not affected, with the exception of A. acuminata (Figure 4b), suggesting that the delaminations are related to the compatibility between wood and adhesive. The delaminations in T. grandis and T. oblonga, were around 17%, being this value higher than the rest of the other species (Figure 4a).

Probably, the physico-chemical affinity between wood-adhesive -in the case of these species- was not the best. T. grandis is considered a species with wettability problem (Chen and Wangaard, 1968; Custodio et al., 2008), problem that could be the cause for a high DP in the T. grandis LC. Recently, it has been demonstrated that lipophenolic and phenolic extractives produce lower wettability between adhesives like the one-part-polyurethane and wood (Widsten et al., 2006). T. oblonga has the most acid pH of all species in this study (pH=4,13). A low value of pH inhibits the polymerization of the adhesives, resulting in resistance problems in the bondline (Mantanis and Young 1997; Serneck et al., 2008).

Even though the A. acuminata, DP was low, this was species with the lowest shear stress after againg process. The power adherence of the adhesive is influenced by other factors related to wood (Stevens and Turner, 1970), such as extractives content and low wood density (Vick and Okkonen, 1998, 2000; Kishino and Nakano, 2004), and it may favor delamination in the LC A. acuminata wood.

Conclusions

The steaming process favored the wood veneer flexibility allowing to reach smaller curvature radius. Only these species A. acuminata, S. macrophylla, G. arborea, T. oblonga reached the minimun curvature radius. T. grandis did not reach the minimum radius, due to both the high specific gravity and stiffness.

The laminated curves with curvature radius less than10 cm did not lose their shape after removing the molding pressure. However, the laminated curves manufactured with wood veneers of S. macrophylla, T. oblonga and T. grandis stabilized their shape 4 days after removing the molding pressure.The laminated curves manufactured with veneers of G. arborea and A. acuminata, with curvature radius of 12 cm and 14 cm did not present openings.

The region of the laminated curve under tension stress (external veneers) is the most susceptible to produce delamination compared to compression stress zone (internal veneers).

The steamed veneer glued with one-part polyurethane adhesive allows to obtain laminated curves with few delaminations and quite stable resistance for the species S. macrophylla and G. arborea. Meanwhile some openings or failure veneer and low shear stress values were obtained after the Va-Pr process, in A. acuminata.

Considering the results obtained, we can conclude that using steamed veneers from fast growth tropical wood and one-part polyurethane adhesive the result is high quality laminated curves and excellent performance. Applicable to manufacturing of other composite materials with curved profiles and laminated curves with radius small enough like the ones used frequently by furniture industry.

Acknowledgements

The authors wish to thank the Vicerrectoría de Investigación y Extensión (VIE) del Instituto Tecnológico de Costa Rica (ITCR) for financial support.

References

ASTM Standard. 2003a. D 2395-02, Standard test methods for specific gravity of wood and wood-base materials. [ Links ]

ASTM Standard. 2003b. D 143-94,Test methods for small clear specimens of timber. [ Links ]

ASTM Standard. 2003c. D4442, Standard test methods for direct moisture content measurement of wood and wood-base materials. [ Links ]

ASTM Standard. 2003d. D 2559 Standard specification for adhesives for structural laminated wood products for use under exterior (Wet Use) exposure conditions. [ Links ]

ASTM Standard. 2003e. D-905-03, Standard test method for strength properties of adhesive bonds in shear by compression loading. [ Links ]

Cornejo, J. and R. Baettig. 2009. Evolución del modulo de elasticidad longitudinal entre 10 y 100 oC en piezas de Pinus radiata usando una técnica no destructiva. Maderas Ciencia & Tecnología 11(2):153-160. [ Links ]

Cousins, W.J. 1978. Young's modulus of hemicellulose as related to moisture content. Wood Science Technology 12:161-167. [ Links ]

Custódio, J., J. Broughton, H. Cruz and A. Hutchinson. 2008. A review of adhesion promotion techniques for solid timber substrates. The Journal of Adhesion 84:502-529. [ Links ]

Chen, C. and F.F. Wangaard. 1968. Wettability and the hysteresis effect in the sorption of water vapor by wood. Wood Science Technology 2:177-187. [ Links ]

Davis, E.M. 1962. Machining and related characteristics of United States hardwoods. Tech. Bull. 1267. USDA Forest Serv., U.S. Gov. Printing Office, Washington DC. 68 p [ Links ]

Gardner, D.J. 2006. Adhesion mechanisms of durable wood adhesive-bonbs. In Stokke, D.D., Groon, L.H. Cellolosic cell wall. Blackwell Publishing CRC Press, USA, 2006 [ Links ]

Hepworth, D.G, J.F. Vincent, G. Stringer and G. Jeronimidis. 2002. Variations in the morphology of wood structure can explain why hardwood species of similar sensity have very different resistances to impact and compressive loading. Philosophical Transactions of Royal Society A 360 (1791):255-272. [ Links ]

Kärenlampi, P.P. 2005. Viscoplasticity of steamed wood. Mechanics of Time-Dependent Materials 9:161-172. [ Links ]

Kishino, M. and T. Nakano. 2004. Artificial weathering of tropical woods. Part 1: Changes in wettability. Holzforschung 58:552-557. [ Links ]

Lam, F. 2001. Modern structural wood products. Progress in Structural Engineering and Materials 3(3):238-245. [ Links ]

Mantanis, G.I. and R.A. Young. 1997. Wetting of wood. Wood Science Technology 31:339-353. [ Links ]

Martínez, J.L. and E. Martínez D. 2008. Laminado de 34 tipos de madera de México: radios mínimos que se pueden obtener con cada una de ellas. GDM 360°. Accesed June 18th, 2008. Available online: http://www.mexicandesign.com/revista/doblado_maderas.htm [ Links ]

Moya, R. and L.D. Pérez. 2008. Effect of physical and chemical soil properties on wood characteristics of Tectona grandis plantations in Costa Rica. Journal of Tropical Forest Science 20:47-155. [ Links ]

Moya, R. and M. Tomazello. 2008. Variation in the wood anatomical structure of Gmelina arborea trees at different ecological conditions in Costa Rica. Revista Biología Tropical 56:689-704. [ Links ]

Peck, E. 1955. Bending solid wood to form. U. S. Department of Agriculture, Forest Service. Agriculture Handbook No. 125 [ Links ]

Pereira, H., J. Graça and J.C. Rodrigues. 2003. Wood chemistry in relation to quality. In: Barnett, J.R., Jeronimidis, G. Wood quality and its biological basis. Blackwell Publishing CRC Press, USA. [ Links ]

Piotto, D., F. Montagnini, L. Ugalde and M. Kanninen. 2003. Performance of forest plantations in small and medium sized farms in the Atlantic lowlands of Costa Rica. Forest Ecology and Management 175: 195-204. [ Links ]

Rice, R.W. and J. Lucas. 2003. The effect of moisture content and bending rate on the work required to bend solid red oak. Forest Products Journal 53(2):71-77. [ Links ]

Salmén, L. 1984. Viscoelastic properties of in situ lignin under water-saturated conditions. Journal Material Science. 19:3090-3096. [ Links ]

Sernek, M., M. Boonstra, A. Pizzi, A. Despres and P. Gérardin. 2008. Bonding performance of heat treated wood with structural adhesives. Holz als Rohund Werkstoff 63:173-180 [ Links ]

Stevens, W. and N. Turner. 1970. Wood bending handbook. Ministry of Technology. London, England [ Links ]

Vick, C.B. and E.A. Okkonen. 1998. Strength and durability of one part polyurethane adhesive bonds to wood. Forest Products Journal 48(11/12):71-76. [ Links ]

Vick, C.B. and E.A. Okkonen. 2000. Durability of one-part polyurethane bonds to wood improved by HMR coupling agent. Forest Products Journal 50(10):69-75. [ Links ]

Wagenführ, A., R. Buchelt and A. Pfriem. 2006. Material behavior of veneer during multidimensional moulding. Journal of Wood Science 64:83-89. [ Links ]

Wu, Z., T. Furuno and B. Zhang. 1998. Properties of curved laminated veneer lumber made from fast-growing species with radiofrequency heating for use in furniture. Journal of Wood Science 44:275-281. [ Links ]

Wu, Z. and T. Furuno. 1999. Stress distributions and failure types of curved laminated veneer lumber for use in furniture under loading. Journal of Wood Science 44:134-142. [ Links ]

Wu, Z., T. Furuno and H. Yoshihara. 1999. Calculation models of pressure and position of laminated veneer lumber on molds during pressing. Journal of Wood Science 45:213-220. [ Links ]

Widsten, P., F. Gutowski, S. Li, T. Cerra, S. Molenaar, M. Spicer. (2006) Factors influencing timber gluability with one-part polyurethanes-studied with nine Australian timber species. Holzforshung 60:423-428. [ Links ]

Nota

Este documento se debe citar como: Shirazinia, M., R. Moya y F. Muñoz. Properties of laminated curves manufactured with steamed veneers from fast-growth tropical wood in Costa Rica. Madera y Bosques 17(2):85-101.