Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista mexicana de ingeniería biomédica

versión On-line ISSN 2395-9126versión impresa ISSN 0188-9532

Rev. mex. ing. bioméd vol.32 no.1 México jul. 2011

Artículo de investigación original

On the mechanical design of cruciate ligaments based on polymeric ropes for knee prosthesis

JM Rodriguez Lelis*, JSA Méndez Aguirre**, JA Arellano Cabrera***, J Navarro Torres***, Marciano Vargas Treviño****, A.A. Pliego*****

* Research-Prof. Centro Nacional de Investigación y Desarrollo Tecnológico, Departamento de Ingeniería Mecánica-Tribología.

** Research-Prof. Universidad Politécnica de Chihuahua, Departamento de Ingeniería Mecánica Automotriz.

*** D. Sc. Student Centro Nacional de Investigación y Desarrollo Tecnológico, Departamento de Ingeniería Mecánica-Tribología.

**** Research-Prof. Universidad Autónoma Benito Juárez de Oaxaca, Escuela de Ciencias, Edificio de Rectoría, Ciudad Universitaria.

***** Research-Prof. Universidad Autónoma de Baja California Norte, Centro de Ingeniería y Tecnología.

Correspondence:

JM Rodríguez Lelis.

Interior Internado Palmira s/n, Col. Palmira

Cuernavaca, Morelos, México. 62490.

Tel.: (+52) 777 362-77-70, Ext. 130 Fax: ( + 52)

777 362-77-70 Ext. 111

E-mail: jmlelis@cenidet.edu.mx

Received article: 08/february/2011.

Accepted article: 27/may/2011.

ABSTRACT

The cruciate ligaments are the ligamentous structure of the knee, which function as a joint stabilizer. It is known that the anterior cruciate ligaments are the most commonly injured ligaments of the knee, and are typically removed during total knee replacement. Also, that exists a limitation of existing grafts which has have motivated the investigation of tissue-engineered anterior cruciate ligament grafts. These investigations include different types of scaffold design. Although these designs have exhibited comparable behavior as natural anterior cruciate ligaments, still there is no commercially available synthetic graft that could achieve fully the mechanical properties of natural ones. In this paper it is attempted to accomplish this goal by introducing the design of cruciate ligaments based on the similarity between the mechanical behavior of the cruciate ligaments and the mechanical behavior of bridge cables, which allows one to apply the theory of the latter to propose an arrangement of braided threads of polyethylene and polypropylene. Mechanical tests on the proposed model show that the mechanical behavior of the designed cables is similar to the cruciate ligaments. The observed differences in stress-strain curves showed an average error of 10.08% for the anterior cruciate ligaments ACL and 9.99% for the posterior cruciate ligaments PCL.

Key Words: Cruciate ligaments, design, knee.

RESUMEN

Los ligamentos cruzados son las estructuras ligamentosas de la rodilla que tienen la función de darle estabilidad a la misma. Se sabe que los ligamentos cruzados anteriores son la estructura de la articulación de la rodilla que más comúnmente se ve afectada por alguna lesión y suelen retirase cuando se realiza una intervención quirúrgica de reemplazo total de rodilla. Por otro lado, existe una limitación en el número de implantes disponibles para las prótesis de rodilla, lo que hai mpulsado el desarrollo de nuevas investigaciones en el área de la ingeniería de tejidos. En estas investigaciones se han creado nuevos tipos de andamios para tejido. A pesar de que estos andamios han demostrado comportarse en cierto modo como los ligamentos cruzados de origen natural, no existe un andamio a nivel comercial que pueda ser utilizado con confianza dado que no reproducen completamente las propiedades mecánicas de los ligamentos. En este artículo, se presenta un desarrollo que trata cumplir este objetivo a partir de las similitudes en el comportamiento mecánico de los ligamentos cruzados y de los cables puentes a base de cables. Esta idea permite usar las ideas de esta última para proponer una serie de hilos trenzados de polietileno y polipropileno. Las pruebas mecánicas realizadas en este tipo de arreglos y en ligamentos cruzados dieron resultados muy similares. Las diferencias observadas en las curvas tensión-estrés mostraron un error promedio de 10.8 % para los ligamentos cruzados anteriores y de 9.99% para los ligamentos cruzados posteriores.

Palabras clave: Ligamentos cruzados, LCA, LCP diseño, injertos, rodilla.

INTRODUCTION

As described by Laskin1, the cruciate ligaments (CL) combined with the quadriceps and patellar tendons provide stability to the knee joint and prevent movement of the tibia on the femur. They also have as a secondary function to prevent hyperextension and excessive internal rotation of the tibia on the femur. Also puts restrictions on the stress experienced during valgus or varus in all flexion angles and allow the movement of the knee to full extension.

Wolfe2, describes that approximately 1% of the population has symptoms of rheumatoid arthritis and 12% had a progressive disabling disease that usually affects multiple joints. For the patients with rheumatoid arthritis, with one and sometimes both knees affected, total knee replacement (TNR) has become the mean to restore normal joint function. The implant survival rates, with a follow up lower than ten years, as described in3, varies from 90 to 97%. It should be mentioned that studies with follow up larger than ten year are difficult to find in the literature4. When a RTR is carried out, it is a common practice to retain the posterior cruciate ligament (PCL) resulting in an improvement of the general performance of the prosthesis5. However as described Paessler and Mastrokalos6, new techniques for reconstruction and replacement of these should be considered.

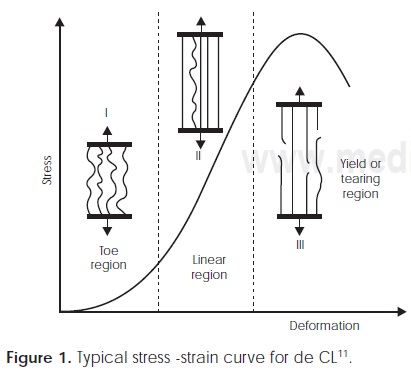

The ligaments are composed of a set of collagen fibers that are oriented in the longitudinal direction and take a wavy form when the ligament is relaxed7. As the tension and deformation increase, the fibers stiffen and begin to bear a load. Figure 1a shows a typical plot of stress-strain of the CL. In region I, at the beginning of loading, most of the collagen fibers are relaxed. When the ligament is stretched, the second zone, the fibers are aligned and straightened along the longitudinal axis of the CL and suffer a lateral contraction. Under this load a linear deformation is presented that varies from 5 to 12% of the total deformation. The third area corresponds to failure of the CL, which begins with the failure of some fibers from the whole set8,9 until the full ligament is tore off.

The cruciate ligaments exhibit viscoelastic mechanical properties as described by Lakes10, i.e. characteristics of creep, relaxation, continuously variable stiffness and hysteresis. This condition was demonstrated by Pioletti11, who introduced a series of stress-strain plots of ligaments at different strain rates. In these graphs, it is shown that the stress-strain curves depend both on the elastic properties as well as the speed with which the tissue is deformed, which implies that the stiffness increases with the speed of deformation.

Traditionally, ACL injuries have been treated with biological grafts. Alternatively, attempts have also beenmadetousesynthetic materials in ligament replacements. There are several commercially available synthetic ACL grafts, including the Gore Tex prosthesis, the Stryker-Dacron ligament, and the Kennedy ligament augmentation device (LAD)5,11-13. Although these synthetic grafts exhibit excellent short-term results, the long-term clinical outcome is poor due to mechanical mismatch, poor abrasion resistance, high incidence of fatigue failures, and limited integration between the graft and host tissue14-17.7

As described by Freeman14, a successful tissue engineered graft must possess mechanical properties similar to the ACL; to date no commercially available synthetic graft has achieved this. He claims to accomplish this goal by having combined the techniques of polymer fiber braiding and twisting to design a novel poly L-lactic acid (PLLA) braid-twist scaffold for ACL tissue engineering. The scaffold was designed to mimic the biomechanical profile and mechanical properties of the ACL. He also says that the ACL is a dense, highly organized, cable-like tissue composed of types I, III, and V collagen, elastin, proteoglycans, water, and cells. In addition, he mentions that ligaments display unique mechanical behavior due in part to the crimp pattern of the collagen fibers in the ligament. The presence of the crimp pattern allows ligaments to increase in length under low strains without straining the collagen molecules and plastically deforming the collagen fibers. This enables the tissue to respond to the presence of maintained stress and still recover (up to a certain amount of strain).

Probably at different times in different parts of the world, but always before recorded history, men and women discovered that they could take fibers or coarser strands found in nature, twist them together to make long, strong yarns, and then twist the yarns together to make thicker ropes Through the centuries, ropes have been used for many purposes: in shipping, in farming and fishing, in bridges, in climbing, as barriers, as hoists, as clothes-lines, to tie people up and to hang them18. A modern engineering definition of rope could be a flexible tension member. Flexibility reflects the ease of handling. Tension member reflects the fact that ropes are only useful in tension.

Together with rope construction, the fibre tensile stress-strain behavior is the controlling factor of the most important properties of ropes. These include not only rope tensile properties, namely extensibility, and its complement, extensional stiffness, recovery from loading, creep and other time-dependent effects, energy absorption on impact loading, energy dissipation (which causes heating) break load, and break elongation, but also bending and torsional stiffness. As shown in18, polymeric fibers exhibit a stress-strain behavior, that can be compared to fractions of the results found in studies such as the one presented by Song19, from where it could be envisage that a combination of materials or rope construction.

The behavior of the ligaments can be represented by the model of Frisen20, which consists of a set of springs in parallel, and where each spring works at different stages of deformation, i.e. spring 1 acts from the moment that begins the deformation, then the spring 2 acts together with the spring 1 when the strain reaches a value of Δ1, after this, the spring 3 acts with the two before reaching the value of strain Δ2 and so on. Since both ropes and ACL works under the action of a tensile force, it can be argued that an arrangement of ropes, similar to the arrangements of Frisen20, can approximate fairly close the common stress-strain behavior of ACL. This assumption sets the foundation of the present work.

MATERIALS AND METHODS

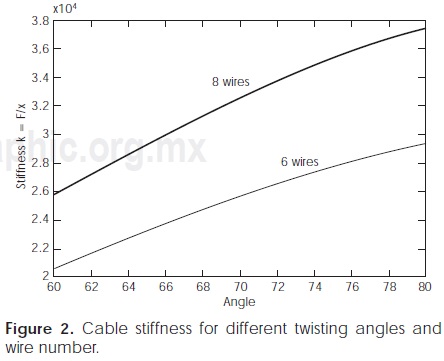

Even when torque is not deliberately applied, the application of tension to a twisted rope structure will generate torque, which, unless fully resisted at the termination, will cause the rope to twist so as to relieve the torque. The twisting, or untwisting, will contribute to rope elongation in addition to the direct effect of tension. Tension, torque, elongation and twist are thus inextricably linked18. General theory of rope design can be found in18,21,22, and will not be repeated here. However, considering that ropes or yarns have a behavior similar to ligaments, when the angle a, at which the threads are twisted, changes, the rope increases its stiffness and requires a increasingly higher load to be deformed. Based on the general theory for rope design, in Figure 2 it is shown the stiffness variation as a function of the angle a. The graph also shows the comparison of stiffness of cables of 6 and 8 threads. It can be seen from this graph that as the angle increases the stiffness increases following a near parabolic behavior. It also increases as the number of threats increases.

ACL design

The characteristics to be met by biomaterials23, on the design of CL are: functionality, stability, compatibility, and sterility. In addition, the demands for the design, requires that materials employed exhibit larger elasticity and tensile strength than the natural ligaments. The most suitable materials according to Brown24 are polyethylene (PE) and polypropylene (PP).

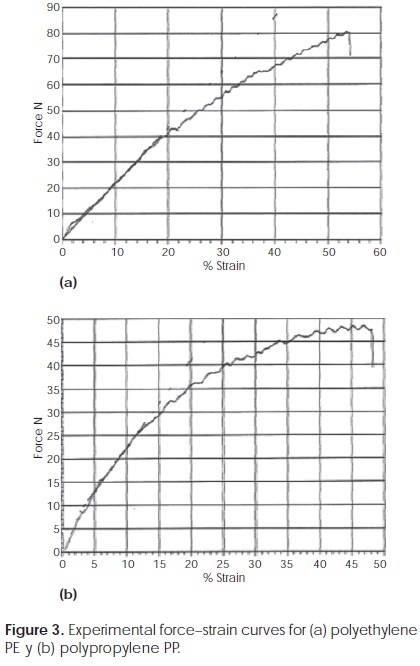

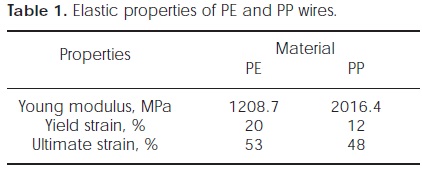

Work on determining the elastic properties of PP and PE yield varying results25,26. Because of this, it is required the mechanical characterization of both materials. Figure 3 shows the force-strain diagrams obtained experimentally for the selected materials. Figure 3a shows the PE curve, where it can be seen that the load on the yield point is 40 N at 20% deformation and the ultimate strength is 80 N at 54% strain. Similarly Figure 3b shows the force-deformation diagram for the PP, whose characteristic point is the load yield strength, which occurs at 28 N and 13 % of deformation. The results of these measurements are shown in Table 1. The properties obtained are the values of the elastic modulus and deformation at yielding and ultimate conditions for the selected materials.

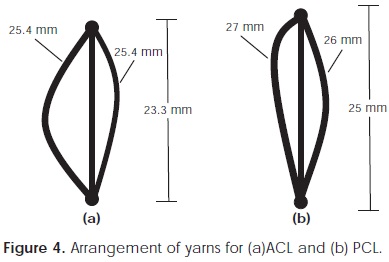

Figure 4 shows the arrangements for the anterior cruciate ligament (a) and posterior cruciate ligament (b) of this work. The arrangements in both cases are composed of three yarns of different lengths. These arrangements are intent to work as described by the model of Frisen20, but here as the yarns start to work together, the stiffness increases steeping its slope as every yarn starts to act with the previous.

RESULTS

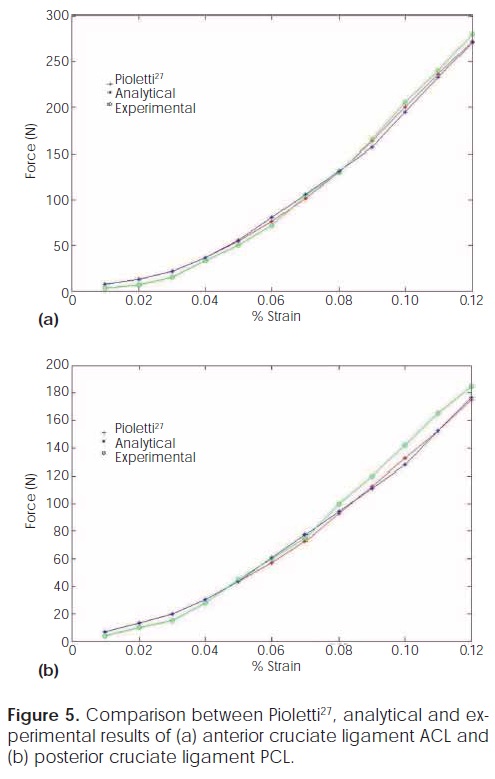

LC were built and evaluated in a universal machine, Testometric® with a capacity of 5 kN. The results obtained are shown in the graphs of Figure 5 and are compared to theoretical results as well as the experimental results obtained from tests Pioletti27. Figure 5a shows the results for the ACL and in 5b are shown the results for the PCL. It can be seen from these graphs that the experimental curve described by the arrangement proposed of three yarns of different length, behave fairly close to the theoretical curve and to the experimental results of the natural ligaments described in Pioletti test27.

The cruciate ligaments are connecting elements between the components of the knee joint. The way in which they work are loading and unloading cycles for each gate cycle at a frequency of 1 cycle per second for normal conditions so that they are exposed to fatigue. Under this circumstances, and as described by Basquin28, the amplitude of fatigue stress, based on the stress for one million cycles per year and a minimum of 10 years, for polyethylene and polypropylene are 45 MPa and 22 MPa. In order to accomplish these conditions, the twisting angle to satisfy them was calculated, these were 63 and 73 degrees which lie below the angle indicated by the criterion of Basquin28.

From the cycling stress tests of strain for the proposed models,thearithmetic meanandmaximum deviation of strength for each percentage of strain was obtained. In Table 2 are shown these values, where  is the arithmetic mean, Dm is the maximum deviation, n is the number of tests, and Xi is the force value of each test. Xmin and Xmax are the maximum and minimum force values respectively.

is the arithmetic mean, Dm is the maximum deviation, n is the number of tests, and Xi is the force value of each test. Xmin and Xmax are the maximum and minimum force values respectively.

DISCUSSION

As described in Freeman12, the anterior cruciate ligament (ACL) is the major intra articular ligament of the knee and the most commonly injured ligament of the knee. There are between 100,000 and over 250,000 (or 1 in 3,000 in the general population) patients per year diagnosed with ACL disruptions with approximately 50,000 ligament reconstructions performed annually. It is also mentioned that there are a number of options available to surgeons for ACL replacement including autografts, allografts, and synthetic devices; the later includes natural and synthetic polymers.

In the past there have been woven or braided ligament replacement structures which performed well in the short term after implantation, but the long-term outcomes of these prostheses have been por. The scaffolds produced using this 3-D braiding technique as described in13, have mechanical properties comparable to the natural ACL. The braiding method provides wear and rupture resistance to the scaffolds. The 3-D braiding technique causes the fibers to be woven throughout the entire thickness of the braid giving it strength and reinforcing the structure, thus preventing total scaffold failure if some of the fibers are damaged. Another recent design is the braid-twist scaffold12,14 combines two techniques, fiber braiding and fiber twisting. According with Freeman12 combining fiber twisting with fiber braiding yields a mechanically stable structure with a larger load capacity and greater degree of extensibility. The degree of braiding or twisting can be altered in order to match the device mechanics with the mechanics of the tissue being replaced. He also mentions that the structure of this scaffold is also similar to the organization of a native ligament and is designed to mimic the biomechanical behavior of the ACL. Unfortunately the final relative stresses (0.873 and 0.829); of his poly α-hydroxyester fibers were higher than those seen in ACL and posterior cruciate ligament (PCL)14.

The twisting of fibers is used in the textile industry to form yarns and then ropes. The twisting direction and degree of twisting affect yarn strength, abrasion resistance, and flexibility. In this work it is attempted to present an arrangement of polymer fibers, based on three yarns of different length that could mechanically exhibit a similar behavior to natural ligament tissue as described by Pioletti27 and have a fatigue resistance mechanically established. A comparison of the experimental results obtained with this model is shown in Figure 5. Here it may be appreciated the fairly agreement between Pioletti27 results and present work. A maximum error difference of 10% can be measured between both experimental results. Fatigue resistance evaluation showed that the one million cycles could be fairly obtained. Although, no clinical test were carried out, it may be envisage the potential of the present arrangement for the application to ACL and PCL substitution.

CONCLUSIONS

The cruciate ligaments CL designproposedinthis paper is based on the mechanical behavior of natural CL, which presents a viscoelastic behavior. This was reproduced with an array of twisted polyethylene and polypropylene fibers. The arrangement of fibers was base don the rope design theory, and with which it was fairly reproduced the viscoelastic behavior of natural CL.

The materials used in this work have a deformation rate of up to four times the natural cruciate ligament, that is, the percentage of deformation at the yield point are 20 and 13% respectively, compared with the natural cruciate ligament, which under physiological conditions normal deformed to 5%. The design of the CL was optimized in accordance to the criterion of failure. This ensures that none of the materials used, reaches the fatigue stress, which corresponds to 44.79 MPa for the PE and 17.7 MPa for the PP This promotes a life expectancy close to 10 years. The maximum error observed for the ACL was 10% and for the LCP 9.9%. Although, no clinical test were carried out, it may be envisage the potential of the present arrangement for the application to ACL and PCL substitution.

REFERENCES

1. Laskin RS. The posterior cruciate ligament and total knee arthroplasty. In: Sculco TP Martucci EA Eds. Knee arthroplasty. Springer New York, 11, 2001. [ Links ]

2. Wolfe F, Zwillich SH. The long-term outcomes of rheumatoid arthritis: a 23-year prospective, longitudinal study of total joint replacement and its predictors in 1,600 patients with rheumatoid arthritis. Arthritis Rheum 1998; 41: 1072-82. [ Links ]

3. Laskin RS, O'Flynn HM. Total knee replacement with posterior cruciate ligament retention in rheumatoid arthritis: problems and complications. Clin Orthop 1997; 345: 24-8. [ Links ]

4. Schai PA, Scott RD, Thornhill TS. Total knee arthroplasty with posterior cruciate retention in patients with rheumatoid arthritis. Clin Orthop 1999; 367: 96-106. [ Links ]

5. Gill GS, Joshi AB. Long-term results of retention of the posterior cruciate ligament in total knee replacement in rheumatoid arthritis. J Bone Joint Surg 2001; 83(B): 510-2. [ Links ]

6. Paessler HH, Mastrokalos DS. Anterior cruciate ligament reconstruction using semitendinosus and gracilis tendons, bone patellar tendon, or quadriceps tendon-graft with press-fit fixation without hardware: A new and innovative procedure. Orthop Clin North Am 2003; 34(1): 49-64. [ Links ]

7. Hurschler C, Provenzano P Vanderby R. Scanning electron microscopic characterization of healing and normal rat ligament microstructure under slack and loaded conditions: Connective Tissue Research 2003; 44: 59-68. [ Links ]

8. De Vita R. Structural constitutive models for the knee ligaments, Ph. D. Thesis , University of Pittsburgh, 2003. [ Links ]

9. Wascher D, Markolf K, Shapiro M, Finnerman G. Direct in vitro measurements of forces in the cruciate ligaments, Part I: the effect of multiplane loading in the intact knee. J Bone Joint Surg 1993; 75(A): 377-386. [ Links ]

10. Lakes RS. Viscoelastic solids, CRC Press, Boca Ratón, 1999. [ Links ]

11. Pioletti D, Rakotomanana L, Leyvraz P Strain rate effect on the O mechanicalbehaviourofthe anterior cruciate ligament-bone complex. Medical Enginnering and Physics 1999; 21: 95-100.

12. Freeman JW, Kwansa AL. Recent advancements in ligament tissue engineering: The use of various techniques and materials for ACL repair. Recent Patents on Biomedical Engineering 2008; 1: 18-23. [ Links ]

13. Freeman JW. Tissue engineered devices for ligament repair, replacement and regeneration. African Journal of Biotechnology 2009; 8(25): 7182-7189. [ Links ]

14. Freeman JW, Woods MD, Laurencin CT. Tissue engineering of the anterior cruciate ligament using a braid-twist scaffold design. Journal of Biomechanics 2007; 40: 2029-2036. [ Links ]

15. Laurencin CT, Freeman JW. Ligament tissue engineering: An evolutionary materials science approach. Biomaterials 2005; 26(36): 7530-7536. [ Links ]

16. Cabaud HE, Rodkey WG, Feagin JA. Experimental studies of acute anterior cruciate ligament injury and repair. Am J Sports Med 1979; 7(1): 18-22. [ Links ]

17. Silver FH. Biomaterials. Medical Devices, and Tissue Engineering: an Integrated Approach. London: Chapman & Hall, 1994. [ Links ]

18. McKenna HA, Hearle JWS, O'Hear N. Handbook of fibre rope technology. CRC Press, 2004. [ Links ]

19. Song Y, Debski RE, Musahl V, Thomas M, Woo SLY. A three-dimensional finite element model of the human anterior cruciate ligament: a computational analysis with experimental validation, Journal of Biomechanics 2004; 37: 383-390. [ Links ]

20. Frisen M, Magi M, Sonnerup L, Viidik A. Rheological analysis of soft collagenous tissues. Part I: Theoretical considerations. Journal of Biomechanics 1969; 2: 13-20. [ Links ]

21. Li D, Miyase A, Williams JG, Wang SS. Damage tolerance of synthetic fiber mooring rope: Small scale experiments and analytical evaluation of damaged subropes and elements. Final Project Report, 2002. [ Links ]

22. Wang RC, Miscoe A, McKewan W. Model for the structure of round strand wire ropes. US Department of Health and Human Services, 1998. [ Links ]

23. Morejón L, Jasso C, Davidenko N, Mendizabal E. Materiales poliméricos para la reconstrucción de partes del cuerpo humano. Revista Universidad de Guadalajara, 1999: 14. [ Links ]

24. Brown M. Suture materials and needles. Dermatologic Surgery Core Curriculum 2003. [ Links ]

25. Raghavendra R, Dahiya A, Kamath M. Nylon fibers, technical report, Department of Materials Science & Engineering. University of Tennessee at Knoxville, 2004.

26. The Plastics Web. http://www.ides.com.

27. Pioletti D, Rakotomanana L, Leyvraz P. Strain rate effect on the mechanical behaviour of the anterior cruciate ligament-bone complex. Medical Enginnering and Physics 1999; 21: 95-100. [ Links ]

28. Basquin OH: The Mechanics of Building Construction. Science 1912; 36: 119-12. [ Links ]

Nota

Este artículo también puede ser consultado en versión completa en: http://www.medigraphic.com/ingenieriabiomedica/