Introduction

The ability for easy reproduction and low cost of maintenance of the Nile tilapia (Oreochromis niloticus) have made this species of white meal an important choice for aquaculture production (El-Sayed, 2006; Food and Agriculture Organization of the United Nations [FAO], 2016). Consequently, the exact cover of dietary nutrients, as proteins, lipids, carbohydrates, vitamins, and minerals, is critical to gain the right weigh in any growth stage. In this way, if the requirement is uncovered, the effect will be observed in the diminution of growth rates and chemical composition of fish meat (Ayisi, Zhao & Rupia, 2017). The nutritional requirement of Nile tilapia for growth, at all stages, has been distinguished and divided into four (larvae, fingerlings, juveniles, and adults) (FAO, 2017; Thongrod, 2007). The specificity of the nutritional requirements makes two stages critical, the larvae and adult stage due to the necessary amount and quality of proteins and carbohydrates (Silva-Soares, Nogueira-Alves, Beldade & Mirth, 2017).

The current commercial foods diets are based on the requirements of protein on the use of fishmeal so that it can be an economic source. This ingredient maintains a fluctuating and rising cost year after year because of its increasing request (FAO, 2016); additionally, fishmeal protein does not have a digestibility coefficient of 100% (El-Sayed, 2006), becoming the primary contaminant of discharge waters in the aquaculture industry (Draganovic, van der Goot, Boom & Jonkers, 2011; Schwitzguébel & Wang, 2007), where it is poorly assimilated by the fish. Moreover, the tilapia eats only on the surface of the bodies of water or at a medium altitude, this compromises the efficient utilization of the feed and leads to a need of well-designed feeds that float at the middle bottom or surface for more than two minutes (El-Sayed, 2006). Feeds that do not float is not consumed and becomes pollution and a waste of money (Schwitzguébel & Wang, 2007; Thongrod, 2007). Recently, the research and development of products have sought to satisfy the nutrition requirements, with a controlled and selective use of fishmeal and efficient designs of products (i.e. extruded pellets), because the nutrition in the intensive aquaculture industry is the most expensive component; it represents between 50%-80% of operating cost (El-Sayed, 2006).

Some nutritional designs have focused on the substitution of fishmeal, by fishery by-products, terrestrial animal by-products, single-cell proteins or vegetable protein sources. With greater sustainability, the utilization of vegetable flour is proposed, it is also more difficult to standardize due to the presence of several antinutrients (Ayisi et al., 2017; El-Sayed, 2006). These substitutions have been documented in the diet of O. niloticus, O. mossambicus, T. guineensis, T. rendalli, and O. aureus, with promising results in the use of seaweed (Pereira, Valente, Sousa-Pinto & Rema, 2012), a mixture like soybean with corn (Hassaan, Soltan & Abdel-Moez, 2015; Herath, Haga & Satoh, 2016), beans (Azaza et al., 2009), and also, recently, jojoba has been tested (Labib, Zaki, & Mabrouk, 2012). However, these studies propose substitutions that result deficient in the content of essential amino acids, needing a step up in the content of lysine, methionine, and tryptophan. Even if the content of vegetable protein is in little amounts, during the substitution, it naturally contains anti-nutrients and is related to adverse effects on growth. Whether they are reinforcing a new diet or supplementing a commercial food or starting from a fermented mixture, a proper heat treatment is indispensable (Carter & Hauler, 2000; Davis, 2015).

Under this idea, the processing of the feed has to be ideal for nutrition and pollution control (feed well consumed and well assimilated), this lead two manufacture possibilities: the formation of submersible pellets or floating pellets. The best alternative is the preparation of floating extruded pellets, because among its advantages is to improve a better digestibility and stability of its components, a complete gelatinization of starches. Besides, many anti-nutrient factors are eliminated with the heat treatment. Also, the feed does not disintegrate nor diffuse, allowing the water of the pond to remain transparent, and the fish can be observed feeding, despite the operating cost that this could represent (Davis, 2015; De Cruz, Kamarudin, Saad & Ramesani-Fard, 2015). However, the presence of vegetable flours, such as leaves, fruits or vegetables in mixtures for extrusion, can hinder the process, due to the presence of sugar, fiber or protein can complicate the transformation to the extrusion (Liu, Alavi & Abughoush, 2011).

The aim of this study is the generation of an extruded pellet to feed the Nile tilapia with the partial replacement of fishmeal through the utilization of vegetable flours as corn and moringa leaves, flours previously described in their amino acid content (Richter, Siddhuraju & Becker, 2003). Also, corn is the best source of starch in the extrusion process (Liu et al., 2011; Richter et al., 2003). Moringa leaves and corn, together, present an amino acid content that can cover the requirements of the Tilapia, even more than other vegetable flours reported.

Materials and methods

Preparation of samples

Proximate chemical composition

The official methods (Association of Official Analytical Chemists [AOAC], 1990) were used to determine the proximate composition of all ingredients (Yellow corn grown in Sinaloa-México, sardine fish meal provided by a fishmeal merchant, moringa grown in Sinaloa-México, starch and unflavored gelatin): moisture (method 925.09) and in the extruded product, ashes (method 923.03), lipids (method 923.05), protein (method 979.09) and fiber (method 962.09). Carbohydrate content was obtained by subtraction, 100 % (crude protein% + crude fat% + crude fiber% + ash %). All measurements were performed in triplicate, and the results were expressed in percentage (%) on dry weight. The chemical analysis of ingredients as moringa, corn, fish meal, starch, and unflavored gelatin is presented in %, with means of three repetitions in Table 1.

Table 1 Chemical composition of the ingredients. Data on mean values with their standard deviation with 95% of confidence.

| Component (%) | Ingredient | ||||

|

Moringa oleifera Lam. (Leaves) |

Fish meal | Corn | Starch | Unflavored gelatin | |

| Moisture | 8.12±0.02 | 8.66±0.17 | 12.43±0.01 | 0.66±0.00 | 0.85±0.12 |

| Crude protein (Nx6.25) | 26.55±0.15 | 44.54±0.24 | 5.11±0.09 | 1.17±0.00 | 2.62±0.29 |

| Crude lipid | 8.57±0.03 | 12.60±0.29 | 0.16±0.01 | 2.12±0.53 | 1.85±0.03 |

| Ash | 10.53±0.02 | 20.50±0.15 | 0.51±0.02 | 0.35±0.15 | 1.35±0.19 |

| Fiber | 1.54±0.00 | 1.26±0.17 | 0.03±0.00 | 0.00±0.00 | 0.00±0.00 |

| Nitrogen-free extract | 60.93±0.01 | 29.76±0.07 | 94.19±0.07 | 96.36±0.37 | 94.18±0.63 |

Source: Author’s own elaboration.

The mineral and vitamin premix composition were formulated by Aqua Florida Farms Inc. and are presented in Table 2. The mineral and vitamin premix represent the necessary requirements for the development of Oreochromis niloticus at any stage. The premix dose is only adjusted according to the stage of development.

Table 2 Concentration of the minerals and vitamins present in the premix.

| Mineral | Amount (ppm kg-1) | Vitamin | Amount (g kg-1) |

| Manganese | 13.25 | Vitamin A | 0.2152 |

| Zinc | 11.04 | Vitamin D3 | 0.0036 |

| Iron | 8.83 | Vitamin E | 64.5695 |

| Copper | 0.88 | Vitamin K | 1.752 |

| Cobalt | 0.11 | Vitamin B12 | 0.0223 |

| Iodine | 8.83 | Riboflavin | 0.0072 |

| Selenium | 0.09 | p-Pantothenic acid | 34.4371 |

| Niacin | 0.043 | ||

| Choline | 5.7395 | ||

| Thiamine | 5.7395 | ||

| Pyridoxine | 5.7395 | ||

| Folic acid | 1.7219 | ||

| Ascorbic acid | 192.2737 | ||

| Biotin | 0.0883 |

Source: Author’s own elaboration.

Elaboration of feed by extrusion cooking

Blends were prepared by mixing yellow corn, fishmeal, and moringa leaf powder in the ratio of a dry-to-dry weight basis. The blends rations were chosen according to the preliminary test without clogging the extruder and for acceptable product characteristics like expansion, continuity of the extruded pellet, and structural stability after drying. From the preliminary extrusion tests, eight diets were generated in which the presence of fishmeal was sought to be reduced and to cover the nutritional requirements of Oreochromis niloticus, which is present in Table 3 (where D diets with unflavored gelatin and Ds represent the diets that are not contained unflavored gelatin). The moisture content of the blended samples for extruder feed was adjusted at 30% (w.b) by mixing it continuously at medium speed with a calculated amount of water sprayed onto each blend. After that, the sample was put in a plastic bag and stored at 4 ºC all night to reach homogeneous moisture distribution. Before extrusion, the blends were allowed to come up to an ambient temperature of 25 ºC and was mixed again.

Table 3 Formulation of dietary diets for O. niloticus during the adult stage (g 100 g-1).

| Ingredient | D1 | D2 | D3 | D4 | Ds1 | Ds2 | Ds3 | Ds4 |

| Fishmeal | 3.5 | 10.5 | 11.5 | 42.5 | 5 | 12 | 12 | 42 |

| Moringa leaf meal | 30.5 | 22.5 | 11.5 | 1.5 | 30 | 22 | 12 | 3 |

| Corn | 50 | 60 | 70 | 40 | 50 | 60 | 70 | 40 |

| Starch | 9 | - | - | 9 | 9 | - | - | 9 |

| Unflavored gelatin | 1 | 1 | 1 | 1 | - | - | - | - |

| Vitamin Premix | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Mineral Premix | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Source: Author’s own elaboration (D, Diet with unflavored gelatin; Ds, Diet without unflavored gelatin).

Extrusion conditions

Feeds were obtained by extrusion, cooking using a single-screw laboratory extruder model 20DN/8-235-00C (CW Brabender Instrument, Inc., Nj, USA), under the following conditions:

Physicochemical characterization

Expansion Index (EI) and Bulk density (BD)

The EI was calculated according to Gujska & Khan (1990) by dividing extrudate diameter by exit die opening diameter. Bulk density was calculated according to Wang, Klopfenstein & Ponte (1993). Each determination was done ten times using randomly 10 samples of each product. Each extrudate was weighed (Pm), density was calculated using the following equation, where d = diameter and l = longitude. The results were expressed in g/cm3.

Water absorption index (WAI) and water solubility index (WSI)

WAI and WSI of extrudates were determined using the technique developed (Anderson, Conway & Peplinski, 1970). One gram of ground product was sieved at 0.420 mm and dispersed in 10 ml of distilled water at 25 °C ± 1 °C. The resulting suspension was gently stirred for 30 min and then centrifuged at 3000x g for 15 minutes (Hermle Z 323K, Labnet, Woodbring, USA). The supernatant was decanted into a tared evaporating dish. The WAI is the weight of gel obtained after removing the supernatant per unit weight of original dry solids. WAI was calculated using:

The WSI was the weight of dry solids in the supernatant expressed as a percentage of original sample weight on a dry basis. All the determination was made in triplicate.

Sinking Velocity (SV)

Sinking velocity was measured according to (Himadri, Hattula, Myllymäki & Mälkki, 1993). It was measured by recording the time required for an extruded pellet to sink from water surface to the bottom of 425 mm in a test tube of 2000 ml.

Hardness (H)

Texture characteristics of selected extrudates were measured using a texture analyzer (Model TA-XTplus, Stable Micro Systems, Ltd., Surrey, UK). Hardness was determined by measuring the maximum force required to the rupture of the extrudate. Twenty randomly selected samples from each treatment were measured, and the values averaged. The results were expressed in Newton (N).

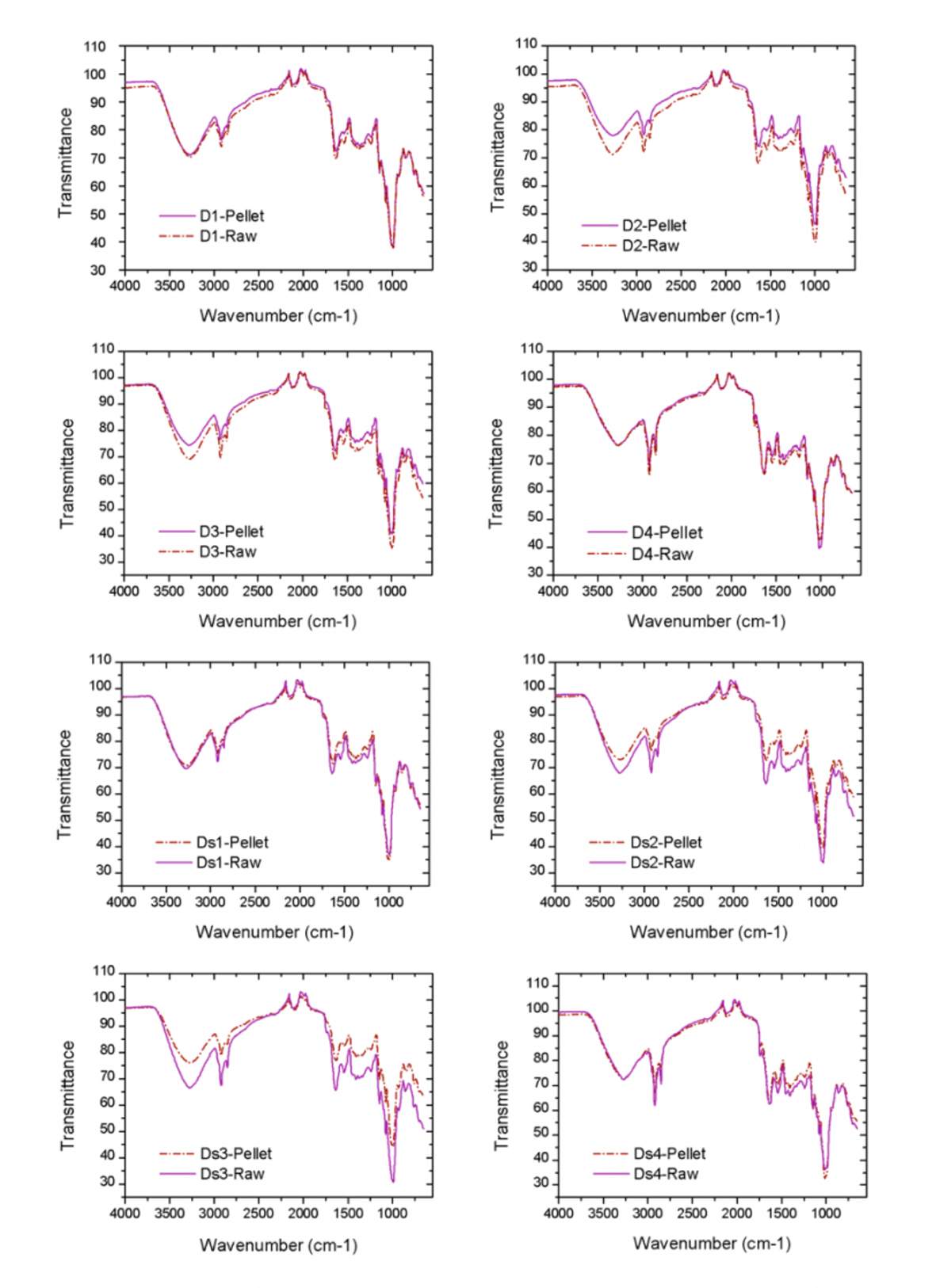

Fourier transform infrared spectroscopy (FTIR) analysis

The FTIR spectroscopy analyses were performed in all the raw blends and extruded products to qualitatively characterize the organic compounds of the solids by this technique transmission. The samples were prepared by grinding the diets and sieved at 0.420 mm. The FTIR spectrum of the powder complexes was measured at room temperature with 32 scans in the FTIR spectrometer (Agilent, Carry 630), in a spectral range of 4000 cm-1 to 650 cm-1. The transmittance results of each diet in its raw state and processed as pellets were plotted with respect to the sweep wavelength.

Structural characterization

Viscosity analysis

The viscosity properties were measured in the Rapid Visco Analyser (RVA 4500, Perten Instruments, Australia). Samples were prepared with 3.24 g of powder and 25.26 g of distilled water; the measurements were performed with three repetitions each. The speed of the paddle was set at 160 rpm, then heated for five minutes from 50 ºC to 90 °C, for four minutes at 90 °C, and cooled at 50 °C in five minutes.

Results

Proximate composition

The chemical-proximal analysis of raw materials allows to balance each component of the diets which is presented in table 1. The protein content of moringa leaf flour with 26% and fishmeal with 44% being relevant as well as the values in the ash content, being 10% moringa leaf flour and flour of fish of 20%. The nitrogen-free extract allowed to balance the amount of carbohydrates in each diet.

The proximal chemical analysis of the raw components and the processed diets is shown in Table 4 to observe that the diets indicate a protein content of 14% to 25% for the feed of Nile tilapia in an adult stage, as an alternative for its composition, having substitutions of fishmeal for vegetable flour of up to 96.5%.

Table 4 Proximal chemical analysis of all the diets. Data on mean values with their standard deviation with 95% of confidence.

| Diet | Component (%) | |||||

| Moisture | Crude protein (Nx6.25) | Crude lipid | Ash | Fiber | Nitrogen-free extract | |

| D1 | 5.33±0.00 | 14.37±0.00 | 5.48±0.01 | 7.67±0.11 | 0.57±0.01 | 71.91±0.09 |

| D2 | 6.55±0.05 | 24.59±0.03 | 5.11±0.03 | 8.38±0.14 | 0.55±0.01 | 61.37±0.05 |

| D3 | 6.99±0.01 | 25.69±0.04 | 4.57±0.01 | 7.58±0.05 | 0.39±0.03 | 61.77±0.07 |

| D4 | 5.12±0.03 | 20.30±0.07 | 6.76±0.04 | 9.64±0.07 | 0.60±0.04 | 62.70±0.02 |

| Ds1 | 5.56±0.01 | 14.69±0.04 | 4.57±0.01 | 7.10±0.05 | 0.61±0.03 | 73.03±0.07 |

| Ds2 | 6.77±0.03 | 17.50±0.03 | 7.96±0.04 | 7.81±0.03 | 0.59±0.04 | 66.14±0.04 |

| Ds3 | 7.21±0.03 | 20.30±0.07 | 4.29±0.02 | 7.01±0.04 | 0.44±0.04 | 67.96±0.02 |

| Ds4 | 5.35±0.07 | 21.10±0.07 | 3.80±0.04 | 10.18±0.06 | 0.65±0.05 | 64.27±0.03 |

Source: Author’s own elaboration (D, Diet with unflavored gelatin; Ds, Diet without unflavored gelatin).

Physicochemical characterization of extruded products

Expansion index (EI) and bulk density (BD)

The expansion index (EI) is related to the bulk density (BD) and the sinking velocity of the products obtained. It was observed that the processing variables and the formulation of the diets had a statistically significant effect (p < 0.05) on EI, obtaining higher expansion rates in the diets without unflavored gelatin (treatments Ds1, Ds2, Ds3, and Ds4) (Table 5). It was observed that the IE values were higher in the diets whose concentration of fishmeal was 5% or lower.

Table 5 Data on mean values of all characteristics of extrudates along with their standard deviation with 95% of confidence.

| Diet | EI (mm/mm) | Bulk density (g/ml) | WAI (g H2O/g) | WSI (%) | Hardness (N) | SV (cm/s) |

| D1 | 0.82 ± 0.01 | 0.91 ± 0.02 | 4.64 ± 0.30 | 12.78 ± 0.11 | 16.40 ± 5.47 | 0.0029 ± 0.00 |

| D2 | 0.66 ± 0.00 | 1.20 ± 0.01 | 4.48 ± 0.03 | 13.17 ± 0.09 | 13.72 ± 6.19 | 4.1821 ± 0.05 |

| D3 | 0.71 ± 0.01 | 0.98 ± 0.02 | 4.45 ± 0.04 | 12.06 ± 0.12 | 13.69 ± 7.16 | 0.0088 ± 0.00 |

| D4 | 0.56 ± 0.00 | 1.24 ± 0.02 | 3.96 ± 0.03 | 14.49 ± 0.10 | 9.53 ± 3.56 | 6.7398 ± 0.08 |

| Ds1 | 0.83 ± 0.01 | 0.85 ± 0.01 | 4.79 ± 0.01 | 12.17 ± 0.12 | 15.17 ± 5.56 | 0.0016 ± 0.00 |

| Ds2 | 0.74 ± 0.01 | 0.97 ± 0.02 | 4.84 ± 0.01 | 13.07 ± 0.10 | 15.70 ± 4.39 | 0.0109 ± 0.00 |

| Ds3 | 0.72 ± 0.00 | 1.12 ± 0.01 | 4.67 ± 0.07 | 10.49 ± 0.10 | 15.58 ± 6.00 | 0.0270 ± 0.00 |

| Ds4 | 0.59 ± 0.01 | 1.17 ± 0.28 | 3.36 ± 0.10 | 14.53 ± 0.05 | 10.18 ± 2.66 | 5.9016 ± 0.08 |

Source: Author’s own elaboration (EI: Expansion Index; WAI: Water Absorption Index; WSI: Water Solubility Index; SV: Sinking velocity).

In general, the BD values are related to the degree of expansion, as well as the possible effect on the buoyancy of the food. The proposed diets have statistically significant differences (p < 0.05). The lowest BD was obtained in the diets with lower fishmeal content; these diets were D1 and with 3.5% and 5%, respectively. The highest BD was obtained in D4 (1.24 g/cm3 ± 0.018 g/cm3), the diet with the lowest content of moringa leaf meal (Table 5).

Water absorption index (WAI) and water solubility index (WSI)

Water absorption and water solubility indexes are shown in table 5. The lowest WAI values were found in the D4 and Ds4 diets, with values of 3.96 g H2O/g and 3.37 g H2O/ g per sample, respectively, because the WAI is related to the amount of water absorbed by the starch and proteins. The latter influenced by the hydrophilic balance of the proteins present in each diet, which is related to the fact that the lower the WAI values, the more compact the food will be.

The water solubility index (WSI) is related to the degree of gelatinization of the starches and the degree of denaturation of the proteins, produced by the extrusion process. The highest values of WSI were found in the D4 and Ds4 diets, with values of 14.49% ± 0.10% and 14.53% ± 0.05%, respectively, which correspond to the diets with the lowest concentration of corn flour and the highest concentration of fishmeal, which can be explained by the fact that both the starch and the proteins of the fishmeal had a greater degradation during the extrusion process. WAI and WSI reflect the interaction between different protein sources and starch, and the results show that the differences between the observed interactions were statistically significant (p < 0.05), being the D4 and Ds4 diets the ones with the greatest interaction.

Sinking velocity (SV)

The lowest SV values were found in the D3 diet, which showed a minimum sinking velocity of 0.0088 cm/s, while the maximum SV was obtained in the D4 diet with 6.7398 cm/s (table 5). The matrix generated by the ingredients presented a statistically significant effect (p < 0.05). One of the objectives in the design of a diet for Tilapia is to obtain a food with low sink rates; this was obtained in all the proposed diets; however, they were selected as the best diets, according to this parameter, the lowest VH values (D1, D3, Ds1, Ds2, and Ds3).

Hardness (H)

The hardness values obtained in the diets allow inferring the possible interactions between the components of the diets, which are influenced by the starch and the different proteins (Table 5). There are statistically significant differences (p < 0.05) among hardness of the diets. The differences are a consequence of the cutting effort applied, which is directly proportional to the degree of degradation of the starch and the level of denaturation of the proteins. The applied forces allow the components of the diet to interact in the extruded matrix. The lowest values were found in the diets D4 and Ds4 (9.248 N and 10.180 N, respectively), and the highest were found in the remaining diets (between 15.584 N and 16.406 N), being necessary to apply a greater cutting effort in the D1 diet, whose content of moringa leaf meal was the highest among the proposed diets.

Fourier transform infrared spectroscopy (FTIR) analysis

The FTIR spectra of the blends and the pellets verify the presence of many functional groups, which indicates the complex nature of the material. The band centered at 3311 cm-1 correspond to the stretching of -OH bonds present in proteins, fatty acids, carbohydrates, and lignin. Due to the high content of protein contained in the diets, there is also a contribution in this region from the N-H stretching of the amide bond. The band observed at 2998 cm-1 corresponds to the stretching vibration of the hydrogen with respect to the bonds (C-H) associated with the glucopyranose ring; the peaks present at 2923 cm-1 and 2852 cm-1, respectively, correspond to asymmetric and symmetric stretching of the C-H bonds. Due to the high intensity of these bands, it is possible to assign them to the lipid component of the moringa leaf, which is present in a portion similar to that of the protein. The peak observed at 1485 cm-1 can be attributed to the stretching connecting C-N and also to the deformation of the N-H bond present in the proteins. In the region known as the fingerprint, characteristic peaks of starch of 1200 cm-1 to 800 cm-1 are observed, corresponding to the vibrations of glucose C-O-C bonds, and peaks at 1131 cm-1, 1090 cm-1, 881 cm-1, and 818 cm-1 can be attributed to a pyranose ring (Figure 1).

Structural characterization

Viscosity analysis

In the viscosity results shown in Figure 2, the characterization of the raw materials (Figure 2a), the mixtures (Figure 2b), and the pellets of the diets is presented (Figure 2c). In the case of raw materials, starch showed the maximum viscosity at 8900 cp, followed by yellow corn flour, with a peak of 1980 cp, and moringa flour, with a peak of 108 cp. The result of fishmeal and unflavored gelatin was close to 0 cp. With respect to the pellets, the highest peak was found in the Ds1 and D1 diets, with values of 399.5 cp and 387.5 cp, respectively, and the lowest values were found in the D4 and Ds4 diets. Similarly, in the mixtures, the highest peaks were found in the Ds1 and D1 diets, with values of 1315.50 cp and 1271.50 cp, respectively, and the lowest peaks were found in the D4 and Ds4 diets.

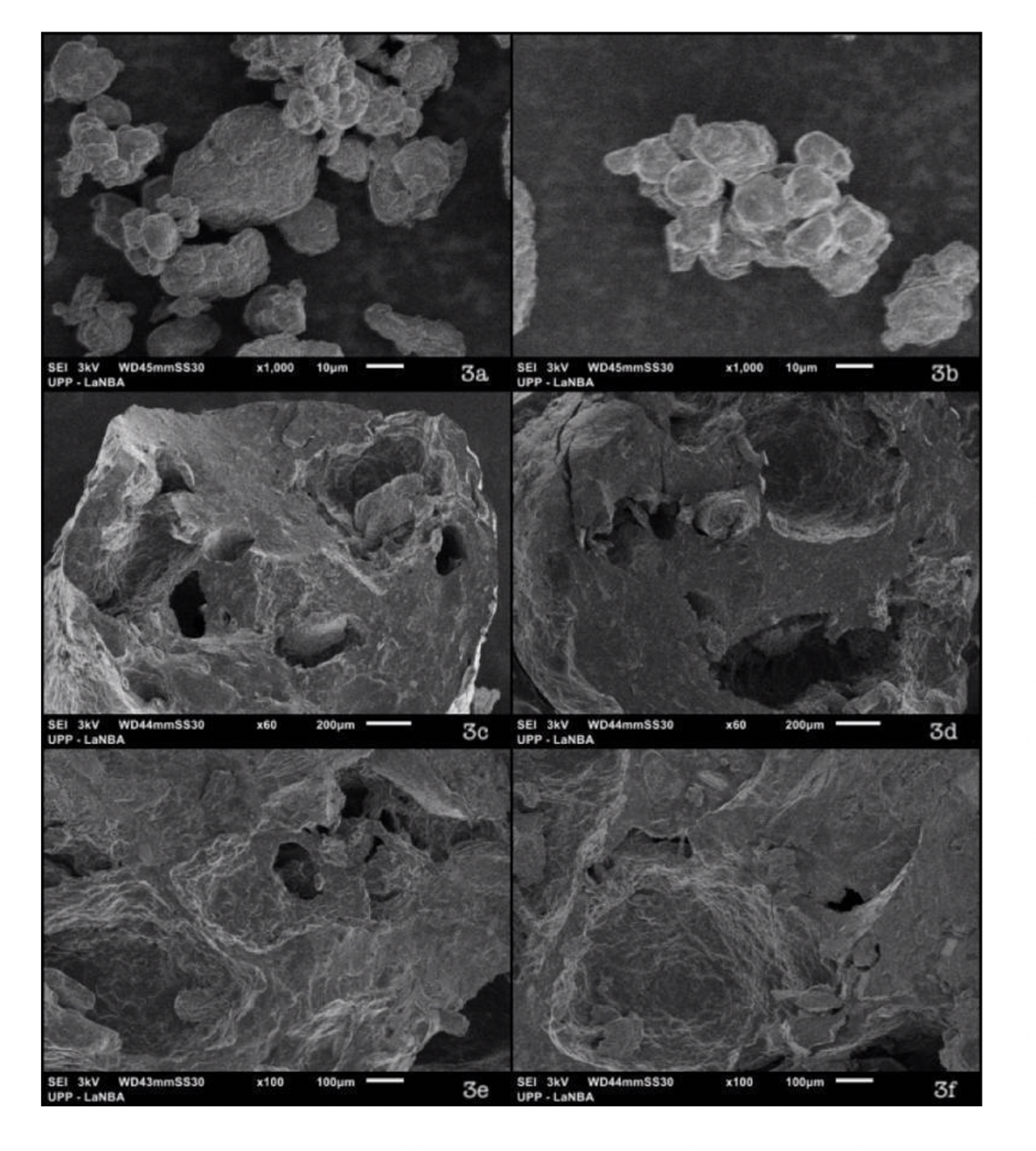

Scanning electron microscopy (SEM)

Figure 3 showed the micrographs taken from the blends and the extrudates of the D2 and D3 diets, because these diets have the best chemical composition and the best sinking characteristics. In Figures 3a and 3b, intact starch granules can be observed, a polyhedral shape and approximately 15 μm in size; some starch granules are coated with protein, while the leaf meal particles of M. oleifera had a variable size and an irregular shape. There is interaction between leaf particles of M. oleifera and starch granules. Figures 3c and 3d show the cross-section of the extrudates, and Figures 3e and 3f show the longitudinal. These figures show a complete gelatinization of the starch granules and a plasticization of the proteins. The cross-section of the pellets corresponding to the D2 and D3 diets show a compact structure with some holes; the holes are the product of water evaporation.

Discussion

Proximate composition

Proximate chemical composition of the blends

Different sources of vegetable protein have been tested to obtain balanced feed for the fattening of fish, such as seaweed and mixtures such as soybeans with corn and jojoba (Azaza et al., 2009; Hassaan et al., 2015; Herath et al., 2016; Labib et al., 2012; Pereira et al., 2012).

Proximate chemical composition of the pellet extruded

The case of Moringa has been proposed (Richter et al., 2003) due to its composition of amino acids, which is special because it meets the requirements of Tilapia in a specific way, coupled with the advantages of the use of proteins of vegetable origin compared to fishmeal, by not possessing biogenic amines. The results indicate that the diets D2 and D3 present the best options, with partial substitutions of 89.5% and 88.5% of fishmeal, apart from meeting the protein requirements of the Tilapia in adult stage, as well as the specific demand of amino acids in the adult stage (Sá, Sabry-Neto, Cordeiro-Júnior & Nunes, 2013; Thongrod, 2007).

Physicochemical characterization of extruded products

Expansion index (EI) and bulk density (BD)

The result of EI may be related to the protein composition of the materials used in the formulation of the diets and their solubility profiles, since the composition and type of protein present in fishmeal and moringa are completely different. However, due to the lack of a characterization of the solubility profiles of commercial fishmeal proteins, the EI values of the diets elaborated in this investigation ranged from 0.56 to 0.83, while the BD values varied from 0.85 g/cm3 to 1.24 g/cm3, which were lower than those reported (Kanmani et al.,2018), who used tapioca corn starches, pregelatinized or not, and reported EI values of 9.14 to 20.43 and BD values of 522.12 g/cm3 to 633.75 g/cm3. Similarly, in this study, the highest EI values were presented by the diets with the highest moringa content, despite the presence of higher starch content in other formulations, which may be related to possible interactions between this source of protein with the starch used.

However, it was impossible to correlate the content of moringa flour with BD of all diets, mainly due to the complexity of the different formulations tested, coinciding as reported (Ramirez-Ascheri, Ciacco, Riaz & Lusas 1995). The characteristics of the starch granules can be improved, since the dietary starch is pregelatinized, generating positive effects on the growth and physiology in the Tilapia as described (Case, Hamman & Schwartz 1992; Kanmani et al., 2018). Additionally, if the degree of gelatinization is increased, better integration of air in the pellet matrix is generated, which allows a greater expansion and decreases the speed of sinking (De Cruz et al., 2015). The behavior of the pellet is influenced by the extrusion conditions, i.e. parameters like temperature, shear, and moisture content, as well as their previous management and during the process (Davis, 2015; Krueger, Thommes & Kleinebudde, 2014). Another important factor to consider is the nature of the blends, that is to say, that the components proposed for the formulation of the diets are not only rich in starch but also in proteins, whose inclusion in an extrusion process is difficult, because of its origin (Ayisi et al., 2017; Davis, 2015; Liu et al., 2011). Taking into account that the reports on obtaining directly expanded foods produced by extrusion, explain the expansion index and the values obtained, by BD based in the characteristics of the starches used. From this perspective, it would have to consider the components rich in proteins that can act as diluents and reducers of the expansion index, affecting the distribution of water in the formulated matrices and the macrostructure of the extruded pellet. However, proteins can contribute to the formation of extensive networks through covalent bonds and electrostatic interactions that can be propitiated during the extrusion process.

Water absorption index (WAI) and water solubility index (WSI)

The water absorption index (WAI) represents the hydrophilic aspect of the mixture formulation, while the WSI is considered to be a measure of hydrophobic behavior (Ayadi, Fallahi, Rosentrater & Muthukumarappan, 2013). Typically, the WAI is related to the starch content present in the diets, because it has the ability to absorb water when the starch granules are damaged. This means that the swelling in the excess water can be used as an index of the degree of gelatinization of it (Alcázar-Alay & Almeida Meireles, 2015; Chevanan, Muthukumarappan & Rosentrater, 2009; De Cruz et al., 2015). However, the proposed formulations were not only enriched with starch but also based on proteins, with the hydrophilic balance present in the formulation. This result depends of the protein denaturation degree on the extrusion process, which induces changes on solubility profiles of proteins (Ayadi et al., 2013; Ojokoh, Yimin, & Eromosele, 2014). The mixtures used in these studies were reflected in the WAI values, which range between 3.37% and 4.84%. Higher values of WAI could be associated with the use of high temperatures and the destruction of the crystalline structure of starch, which allows it to absorb more water (Chevanan et al., 2009). Besides, it is essential to consider whether the compression is higher than the friction forces, since the granules are forced to generate more significant starch destruction. Obtained materials with low WAI values may be associated with restricted availability of water for the starch granule, due to a more compact structure (Anderson et al., 1970).

WSI is related to the macromolecular degradation of starch and the different proteins present in the formulations. This represents a measure of the number of soluble polysaccharides and polypeptides that were produced by the degradation of the starch components (Camire, Camire & Krumhar, 1990; Case et al., 1992, Wang et al., 1993) and the different proteins due to the high shear stresses to which they were subjected inside the extruder.

The values of the solubility index in water ranged between 10.49% and 14.53%. The diets with the inclusion of 40% of yellow corn generated the increase in the value of WSI. Similar results for WSI with increases in the level of starch were observed in previous studies. Generally, extrusion cooking denatures proteins and releases hydrophobic amino acids that reduce water solubility (Camire et al., 1990; Kannadhason, Muthukumarappan & Rosentrater, 2009) and depolymerize starch as well as other macromolecules present in the mixture, which lead to the dextrinization of amylose and amylopectin (Anderson et al., 1970), allowing proteins to interact with starch through the formation of cross-links (Davis, 2015; Fernández-Gutiérrez, San Martín-Martínez, Martínez-Bustos & Cruz-Orea, 2004).

Sinking velocity (SV)

The pellet must float for a limited period of time before it sinks slowly to provide the fish a more reasonable chance to consume the pellet before it reaches the bottom (Himadri et al., 1993). Therefore, sinking rate represents a critical characteristic for the preparation of food in aquaculture. It tends to sink quickly, and the species does not eat at the bottom of the tank; it will be lost food. Therefore, the stability of the food may be related to the absorption of water during the flotation of the food on the surface (Chevanan et al., 2009).

In five of the eight diets formulated, SV values were obtained below the reported, range of 2 cm/s by other authors (Chevanan et al., 2009, Davis, 2015, Kannadhason et al., 2009). Typically, the SV depends on the magnitude of the expansion and the physicochemical changes that occur within the barrel of the extruder, and so this has an effect. The expansion affects the density of the extrudates. In this sense, the magnitude of the physicochemical changes impacts the water absorption capacity and the structural integrity of the extrudates, which equally affect the SV (Chevanan et al., 2009, Davis, 2015).

Hardness (H)

Cut resistance is related to the degree of gelatinization and degradation of starch, as well as to changes in the conformation of proteins (Case et al., 1992). A very compact pellet causes the rise to in shear strength, perhaps by the amylose released from gelatinization, and the crystallinity of the extrudates; reaffirming the texture of the product (Ojokoh et al., 2014). A relationship between the expansion rate and the shear force applied in extruded corn products has been reported; this indicates that the products with the highest expansion rates also had the lowest cut resistance values (Chang & El-Dash, 2003). The hardness of products manufactured by extrusion represents a crucial factor for the industry. It is an important trait for nutrition and commercialization; if the product obtain a low hardness, it will imply that it could break easily on packing and distribution operations.

Fourier transform infrared spectroscopy (FTIR) analysis

The structures found in the FTIR show the heterogeneity of the proposed mixtures; having a variability of intensity between the blends and the pellets because of the thermal process used; being visible in the characteristic spectral peaks of the raw ingredients, like fishmeal and yellow corn which have been reported. In the case of Moringa, the literature presents spectra of seeds and flowers with few differences between them, which corroborates the fact that the composition between the different parts of the tree is similar and is some what variable (Anand et al., 2016; Arias et al., 2016; Pineda-Gómez et al., 2012; Tavengwa, Cukrowska & Chimuka, 2016).

Structural characterization

Viscosity analysis

The extrusion process decreases the viscosity of the different formulations. This decrease can be directly related to the gelatinization process of the starches present in yellow corn flour; however, the remaining viscosity can be directly related to the amount and type of protein present in each formulation, since it depends on whether the protein is from fishmeal or moringa leaf (Becker, Hill & Mitchell, 2001).

Scanning electron microscopy (SEM)

In the micrographs can be see the interactions of the amorphous moringa structures with the rest of the ingredients, which it is observed in the cross-sectional and longitudinal sections. A surface with little porosity are ideal for feeding Tilapia, sometimes the use of the extruder it generates the integration of air in the walls of the food, compromising its physicochemical characteristics according to the reported (Davis, 2015; Kanmani et al., 2018).

Conclusions

The addition of Moringa leaf flour modified the proximal chemical composition, as well as the physical properties of the extrudate, being the D3 diet the one that presented an ideal protein content for the adult stage, apart from having physicochemical characteristics that shape it as the best formulation, capable of efficient feeding in Oreochromis niloticus. The low sink rate of the proposed foods will allow the food to float so that the fish can eat and reduce over-breeding. Adequate changes in the particular content of ingredients had in the extrusion process, significant effects on certain processing conditions and physical properties of the extrudate (Adequate nutrimental balance, palatability, buoyancy, density, and hardness), so they can be modified using various combinations of the same. The heterogeneity of the mixtures only allowed to observe some of the effects.

nueva página del texto (beta)

nueva página del texto (beta)